Swing lever press cloth handle

A handle and rod technology, applied in textiles, papermaking, knitting, etc., can solve the problems of high labor intensity and low production efficiency, and achieve the effects of labor-saving operation, high production efficiency and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

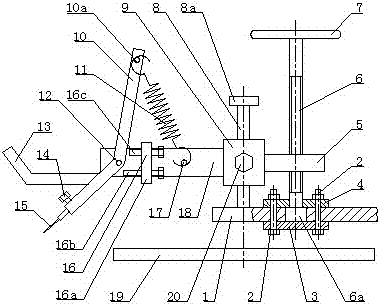

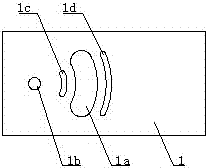

[0008] see Figure 1 to Figure 2 , the present invention includes a cloth pressing handle 15 and a circular dial 19, and also includes a frame 1, two bolts 2, a lower pressing plate 3, an upper pressing plate 4, a connecting plate 5, a screw rod 6, a hand wheel 7, a sliding rod 8, a sliding Seat 9, fork 10, tension spring 11, rotating shaft 12, operating rod 13, pressure cloth handle compression screw 14, limit device 16, seat board pin 17, seat board 18 and sliding seat locking screw 20, described The limit device 16 comprises a limit seat 16a, a lower limit screw 16b and an upper limit screw 16c, the limit seat 16a is welded on the seat plate 18, and the upper limit screw 16c and the lower limit screw 16b are respectively assembled by threaded connections. At the upper and lower parts of the limit seat 16a, the frame 1 is provided with a large waist-shaped hole 1a, a slide rod hole 1b, a short waist-shaped hole 1c and a long waist-shaped hole 1d, and the lower end of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com