Installation device for rotary oil seal

A technology for installing devices and oil seals, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of slow press-fitting speed, tilting of the rotary oil seal, damage of the rotary oil seal, etc., and achieve stable installation effect and stable press-fitting effect , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

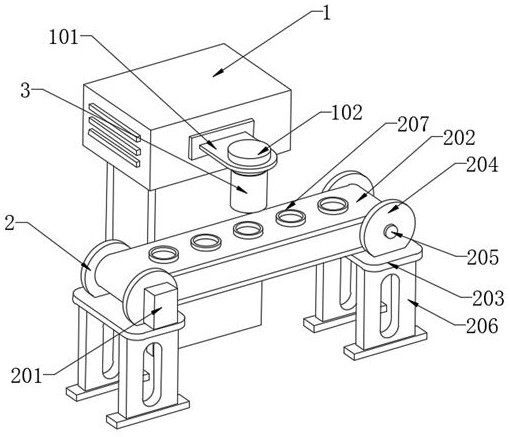

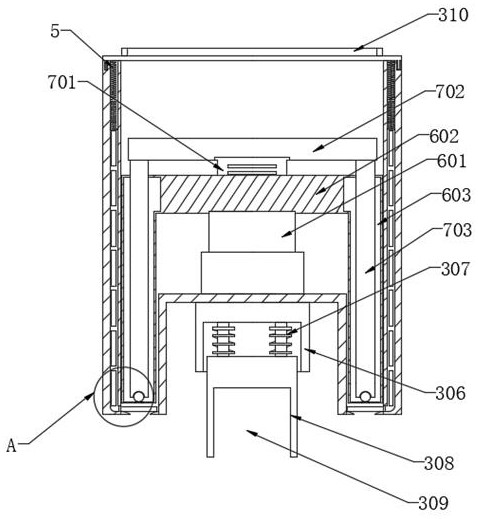

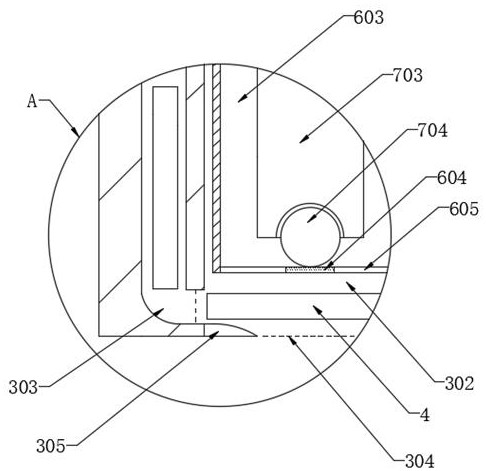

[0042] Combine below Figure 1-Figure 7 As shown, the embodiment of the present invention provides an installation device for a rotary oil seal, including a workbench 1, a transport assembly 2 and a pressure head assembly 3, the transport assembly 2 is located below the pressure head assembly 3, and the worktable 1 is fixedly connected with a plate 101, the first telescopic electric cylinder 102 is connected through the mounting plate 101, the lower part of the first telescopic electric cylinder 102 is fixedly connected with the pressure head assembly 3, the pressure head assembly 3 includes a first housing 301, and the first housing 301 is provided with There is a feeding assembly 5 and an extrusion assembly 6. The first housing 301 is fixed with an annular extrusion chamber 302 and a feeding chamber 303. The feeding assembly 5 is movably arranged on the top of the feeding chamber 303. The feeding chamber 303 is equipped with a plurality of Rotate the oil seal 4, the bottom o...

Embodiment 2

[0060] Please refer to the attached Figure 8 The features of this embodiment that are the same as those of Embodiment 1 will not be repeated here. The difference between this embodiment and Embodiment 1 is that, in this embodiment, the pushing component is the third telescopic electric cylinder 506. Compared with the The first spring group 502 and the third telescopic electric cylinder 506 have enough thrust to push the rotary oil seal 4 to move downward in the feeding chamber 303 , and the pushing effect is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com