Assembling tool for shell and stator of direct drive motor

A direct-drive motor and assembly tooling technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems such as unfavorable press assembly, casing temperature drop, loss, etc., and achieve concentric positioning accuracy Reliable, labor-saving and convenient for press-fitting work, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

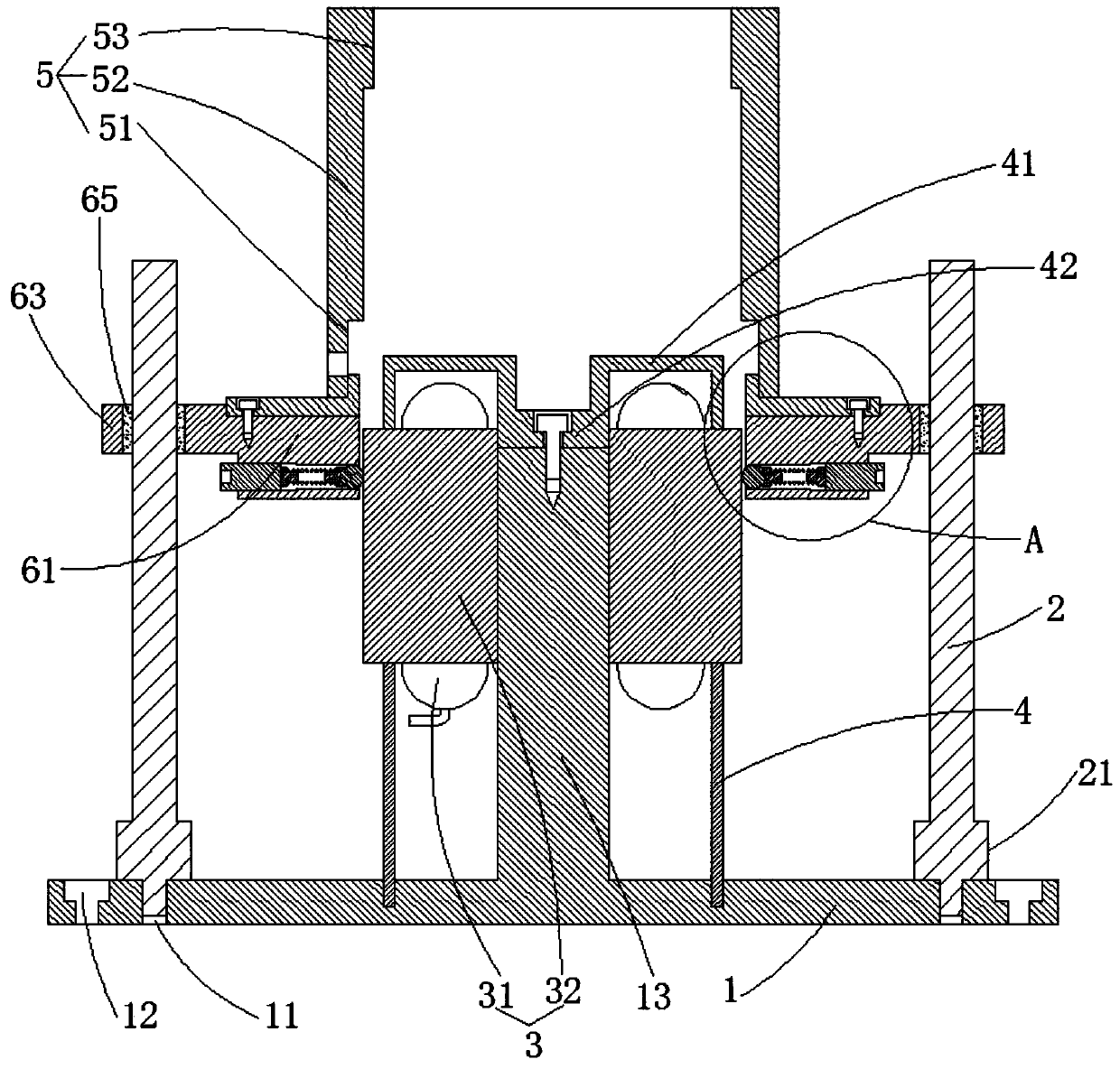

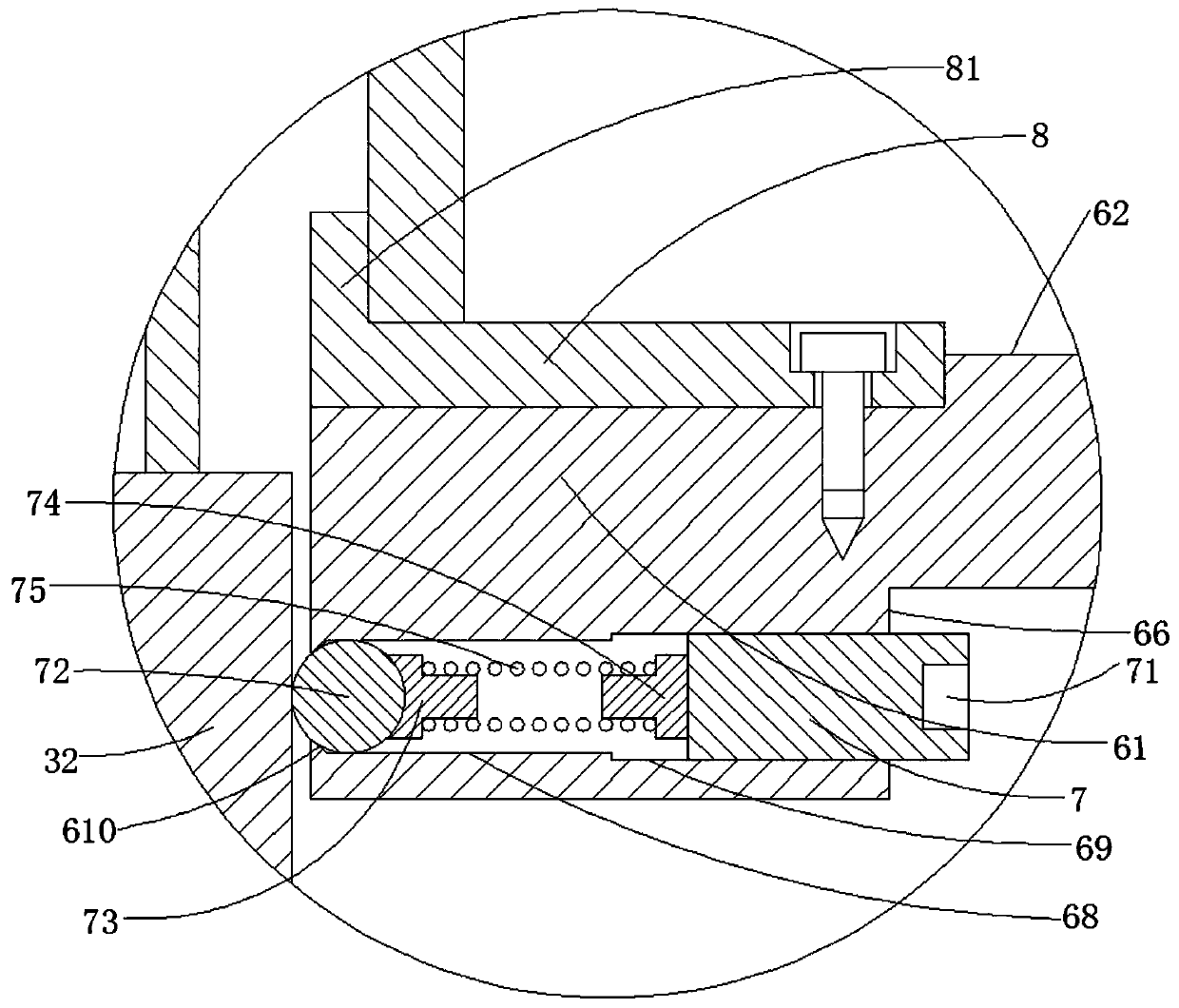

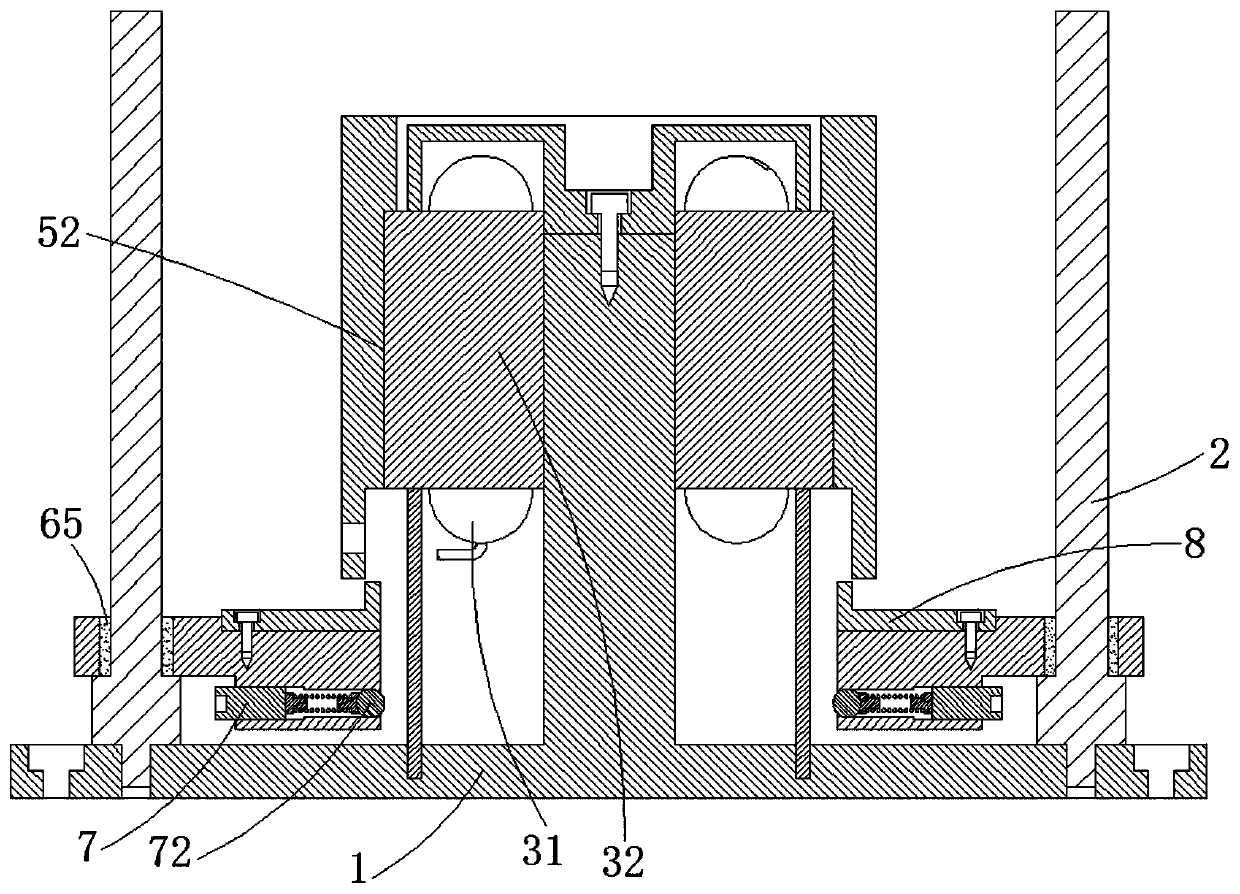

[0020] Such as Figure 1-Figure 5 As shown, a direct drive motor casing and stator assembly tooling includes a base 1, a guide rod 2, a support ring 4 and a guide ring 6, the upper end of the base 1 is symmetrically connected with a guide rod 2, and the base 1 is provided with There is a base screw hole 11, the bottom end of the guide rod 2 is a threaded section, the bottom end of the guide rod 2 is screwed into the base screw hole 11, the lower part of the guide rod 2 is provided with a positioning flange 21 with an enlarged outer diameter, and the guide rod 2 Screw down until the positioning flange 21 abuts against the upper end surface of the base 1 .

[0021] The base 1 is located on the periphery of the base screw hole 11 and is evenly distributed around the base mounting counterbore 12, and the base 1 can be installed and fixed by screwing screws in the base mounting counterbore 12.

[0022] The center of the upper end surface of the base 1 is provided with an upwardly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com