An environmentally friendly and sustainable recycling wood panel production equipment

A technology for wood panels and production equipment, used in wood processing appliances, pretreatment of molding materials, molding/shaping machines, etc., can solve the problems of waste of resources, environment, pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

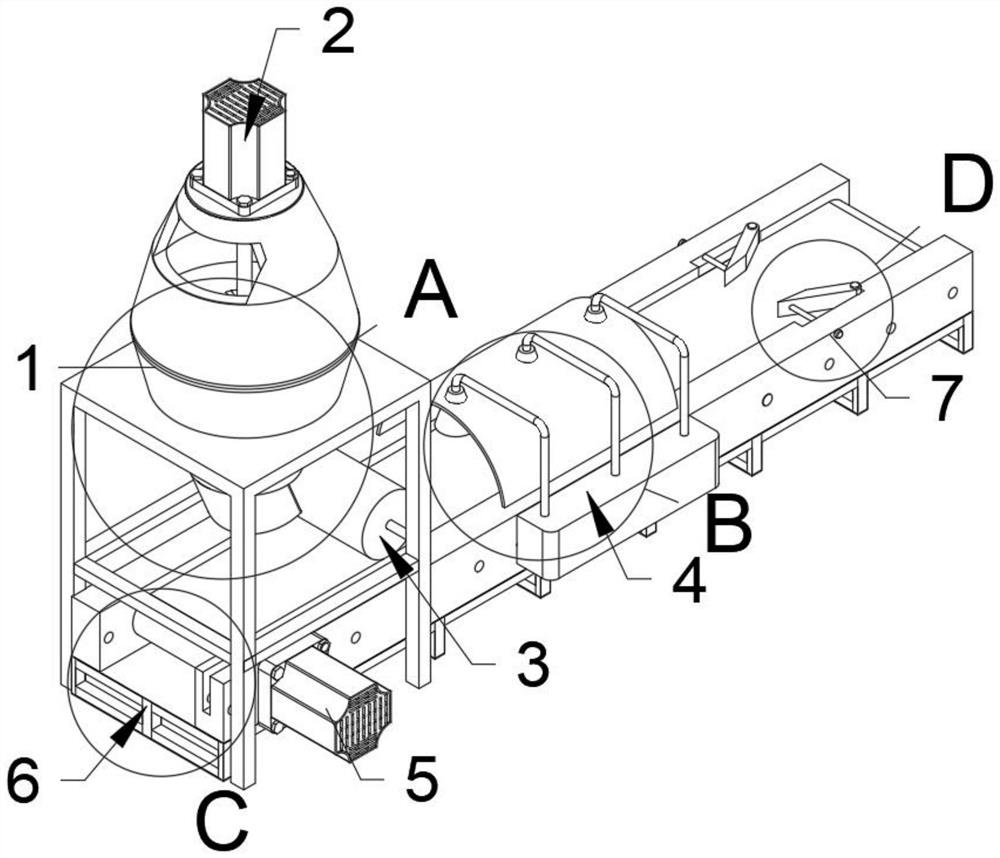

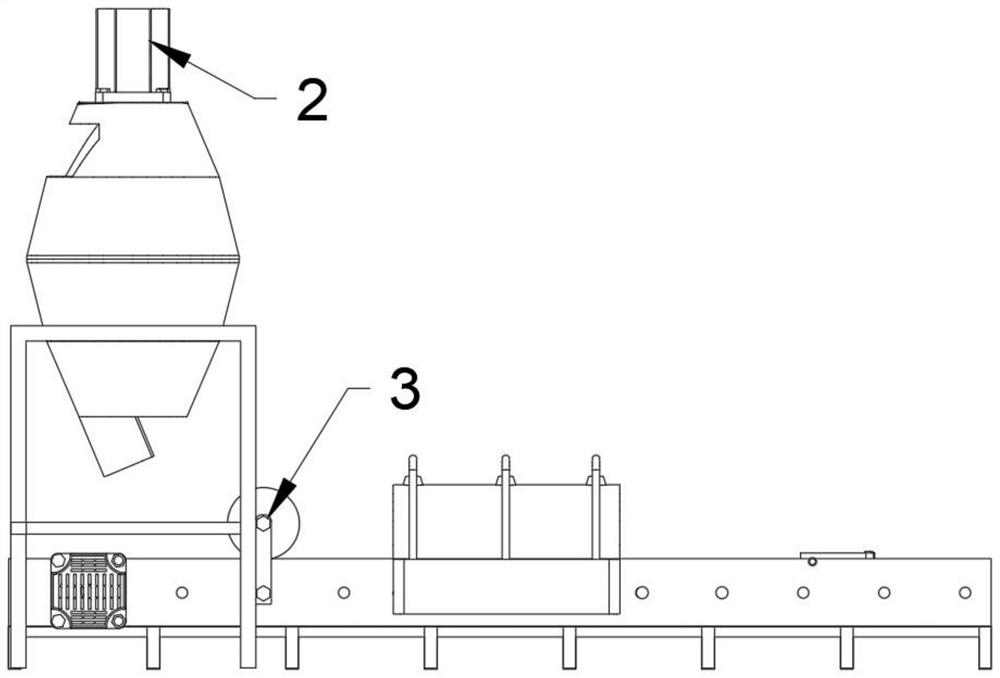

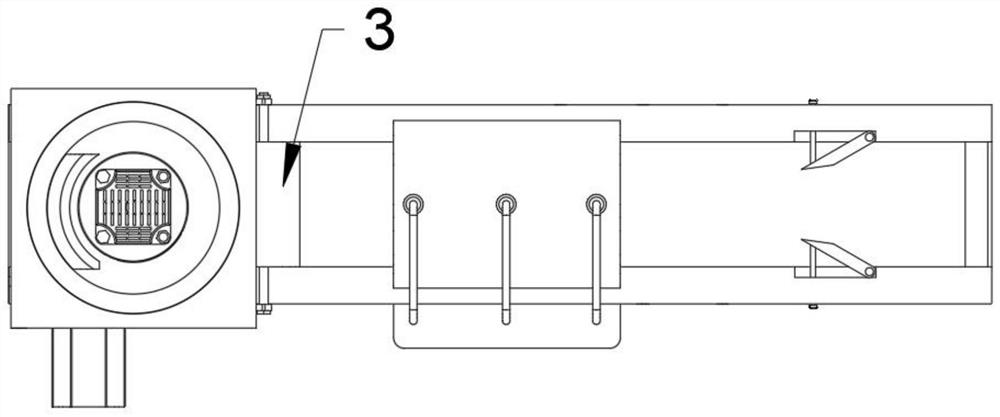

[0034] as attached figure 1 to attach Figure 10 Shown:

[0035]The present invention provides an environment-friendly and sustainable recycling type wooden board production equipment, including: a stirring mechanism 2, a leveling mechanism 3, a glue spraying mechanism 4, a driving mechanism 5, an edge trimming mechanism 7, and the stirring mechanism 2 is fixedly connected to the feeding mechanism 1 The internal position of the leveling mechanism 3 is fixedly connected to the position directly above the support mechanism 6; the leveling mechanism 3 includes a limit plate 301, a limit nut 302, a roller 303 and a roller 304, and the limit plate 301 is provided with two places, and The inner positions of the two limit plates 301 are fixedly connected by the roller 303, and the outer peripheral surface of the roller 303 is fixedly connected with a roller 304; the supporting mechanism 6 is located directly below the feeding mechanism 1; the driving mechanism 5 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com