Press-fitting support of LED display screen built-in lamp tube press-mounting equipment

A technology of LED display screen and display screen, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of unguaranteed press-fit effect and low press-fit efficiency, and achieve the convenience of press-fit work and the degree of automation High, consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

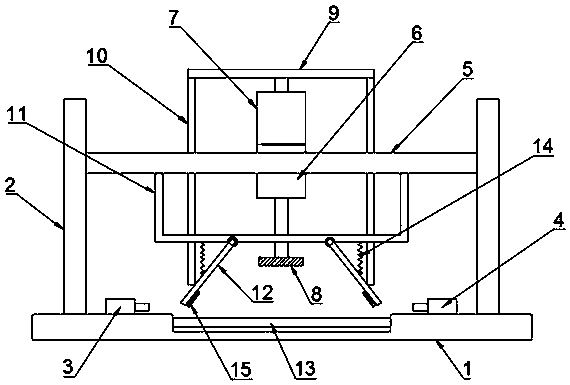

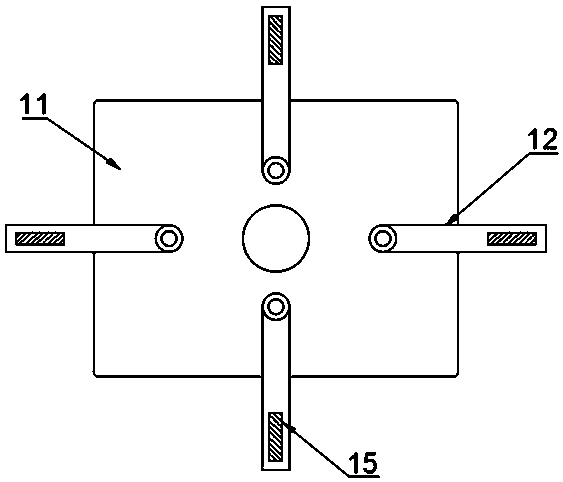

[0020] refer to Figure 1-2 , the press-fit bracket of the LED display built-in lamp press-fitting equipment, including a workbench 1, a groove is opened on the upper side wall of the workbench 1, and a transmission mechanism is arranged in the groove, and the transmission mechanism includes a transmission device installed in the groove. The working principle of the roller 13 and the conveying roller 13 is the prior art. The LED display screen with the lamp tube placed is placed on the conveying roller 13, and the LED display screen is conveyed forward by the work of the conveying roller 13. The upper side of the workbench 1 The wall is fixedly connected with two ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com