Merging equipment for semiconductor graphite production and processing and merging method thereof

A semiconductor and graphite technology, which is applied to the combined equipment and combined fields of semiconductor graphite production and processing, can solve the problems of inability to meet the continuity of subsequent processing, difficult to ensure uniform spacing between graphite sheets, affecting speed and efficiency, etc., so as to improve speed and efficiency. , Improve the speed of pressing and increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

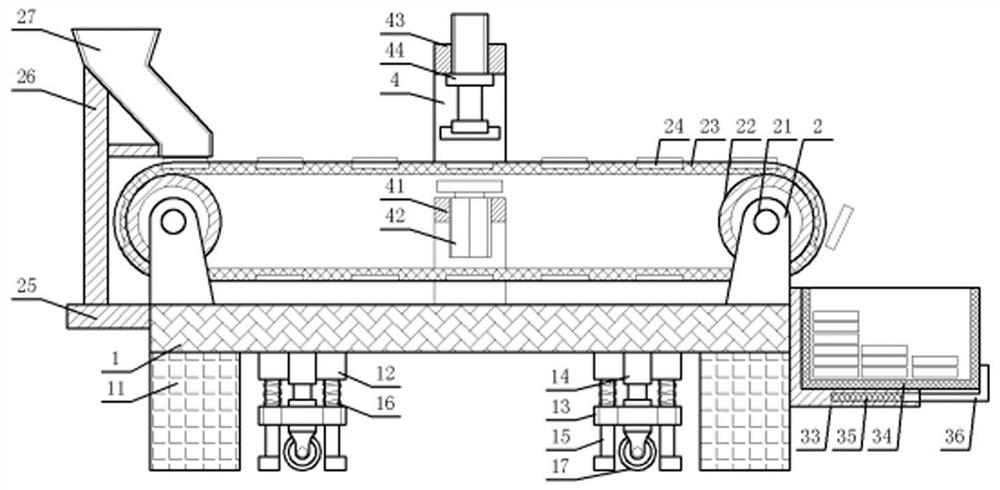

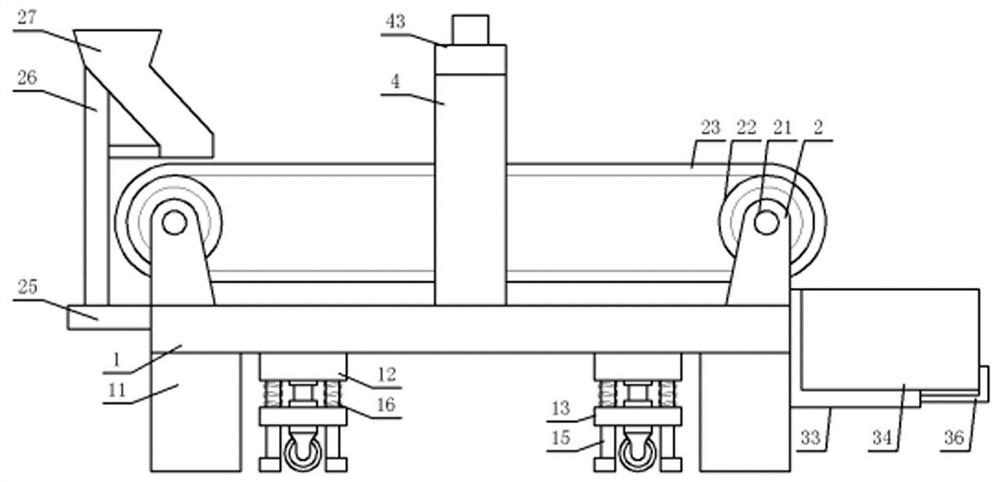

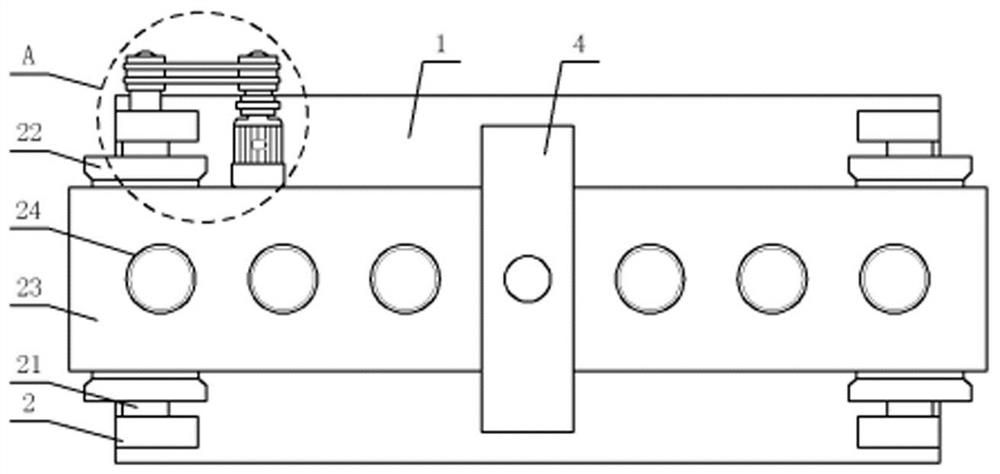

[0032] Embodiment 1: In order to solve the problem that the graphite sheet feeding time interval is not uniform, and improve the speed and efficiency of graphite sheet processing and merging, a merging device for semiconductor graphite production and processing is proposed in this embodiment, see Figure 1-6 , including base plate 1, support assembly, conveyor belt 23, feeding assembly, unloading assembly, and pressing mechanism. The base plate 1 is a rectangular plate placed horizontally and horizontally. Seats 11 are located on the inner side of each support seat 11 and are provided with support components on the bottom surface of the base plate 1. The four corners of the top surface of the base plate 1 are provided with vertically placed fixing plates 2, and the top of each fixing plate 2 is installed There are bearings, a pair of longitudinally placed roller shafts 21 are provided at both ends of the top surface of the bottom plate 1, and the two ends of each roller shaft 2...

Embodiment 2

[0037] Example 2: see Figure 7 , in the present embodiment, the present invention also proposes the merging method of the merging equipment for the production and processing of semiconductor graphite, comprising the following steps:

[0038] Step 1, each electrical component is connected to an external power supply, and the supporting electric push cylinder 14, the first telescopic cylinder 42, the second telescopic cylinder 44, and the motor 3 are respectively electrically connected to the external power supply through the power line;

[0039] Step 2, move the device through the support assembly and fix it, control the extension of the electric push rod supporting the electric push cylinder 14, and drive the support slide plate 13 to slide down along the support slide rod 15 through the electric push connecting block, due to the support spring 16 tension effect, the support spring 16 stretches and becomes longer, and then reversely drives the movable wheel 17 to contact the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com