Water injection auxiliary demolding device for plastic product processing and forming

A technology of processing molding and demoulding device, which is applied in the field of plastic product processing and molding water injection auxiliary demoulding device, which can solve the problems of time-consuming, laborious and complicated operation, and achieve the effect of convenient demoulding work and good demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

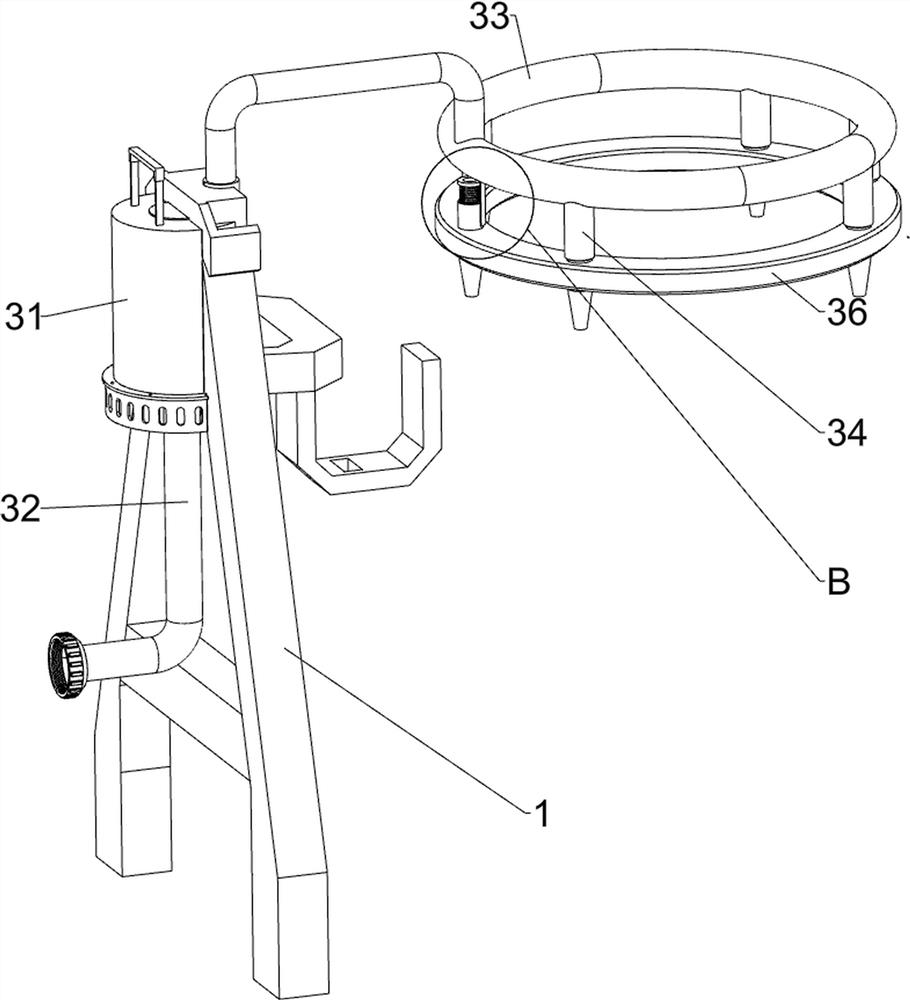

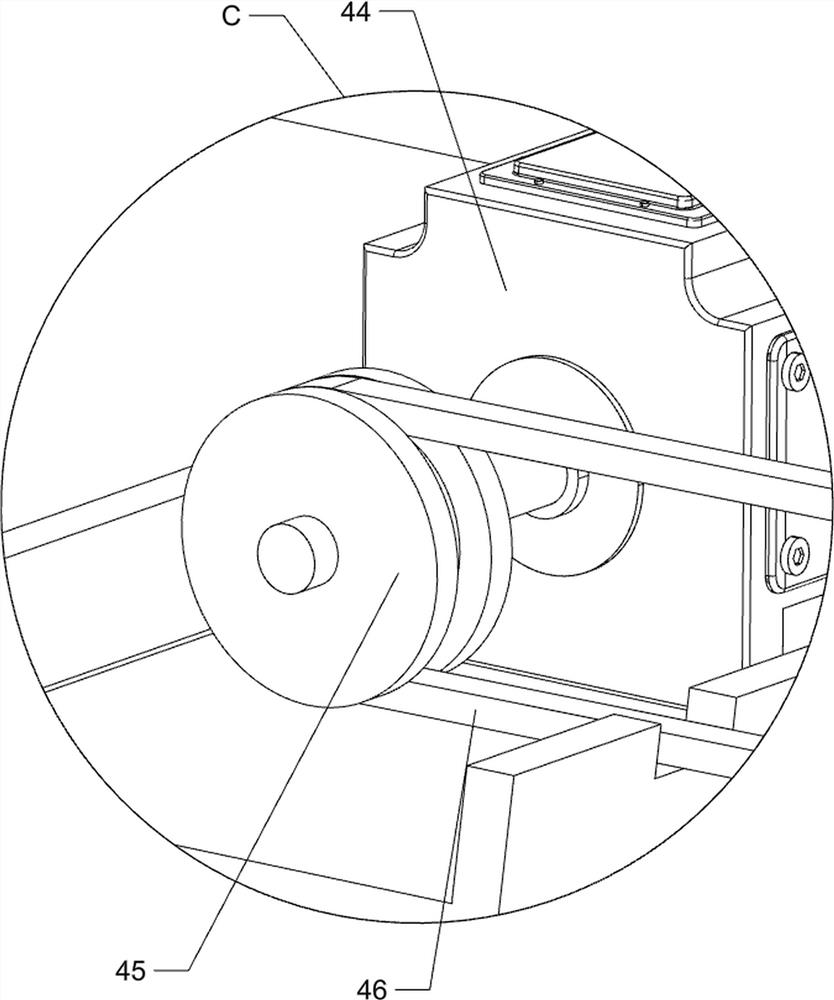

[0070] A plastic product processing and molding water injection auxiliary demoulding device, such as Figure 1-Figure 7 As shown, it includes a mounting frame 1, a water injection pipe 2, a water injection device 3 and a transmission device 4. The upper right side of the mounting frame 1 is provided with a water injection device 3, and the water injection device 3 is provided with a plurality of water injection pipes 2 slidingly at intervals. 1 The lower part is provided with a transmission device 4.

[0071]The water injection device 3 includes a water pump 31, a water inlet pipe 32, a shunt pipe 33, a water outlet pipe 34, a first spring 35 and a connecting ring 36. The right front side of the mounting frame 1 is provided with a water pump 31, and the bottom of the water pump 31 is provided with a water inlet pipe. 32. A shunt pipe 33 is provided in the middle of the upper right side of the installation frame 1. The front end of the shunt pipe 33 communicates with the top of...

Embodiment 2

[0075] On the basis of Example 1, such as figure 1 , figure 2 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, a heating device 5 is also included. The heating device 5 includes a heating furnace 51, a fixed installation block 52, a power module 53 and a heating wire 54. The left side of the upper part of the mounting frame 1 is provided with a heating furnace 51. There are fixed mounting blocks 52 arranged symmetrically, and the number of fixed mounting blocks 52 is 4. A power supply module 53 is arranged between the inner sides of the two fixed mounting blocks 52 on the same side, and a plurality of heating wires 54 are arranged between the power supply modules 53 .

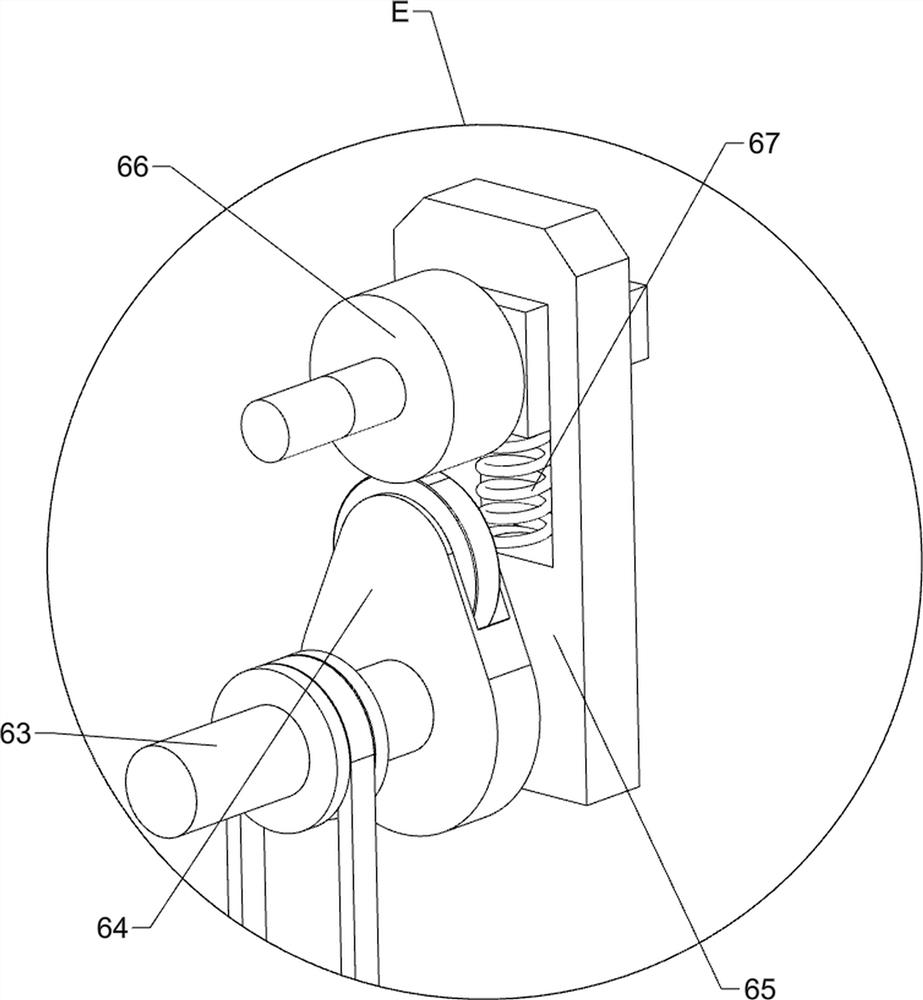

[0076] Also includes starting device 6, and starting device 6 includes second pulley 61, second flat belt 62, second rotating shaft 63, cam 64, fixed block 65, connecting rod 66 and second spring 67, the right side of mounting bracket 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com