Grout feeding device

A technology of cement slurry and discharge device, which is applied in the field of cement slurry mixing, which can solve the problems of physical damage to workers, reduce manpower intensity, and slow feeding speed, and achieve the effects of protecting health, wide application range, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

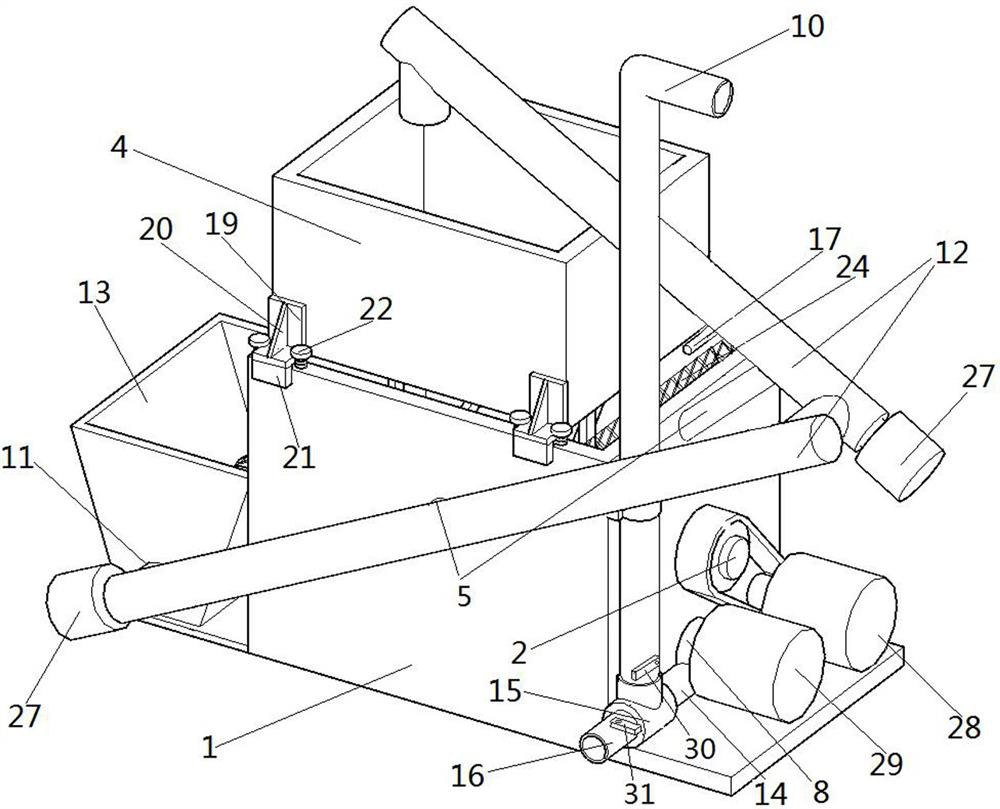

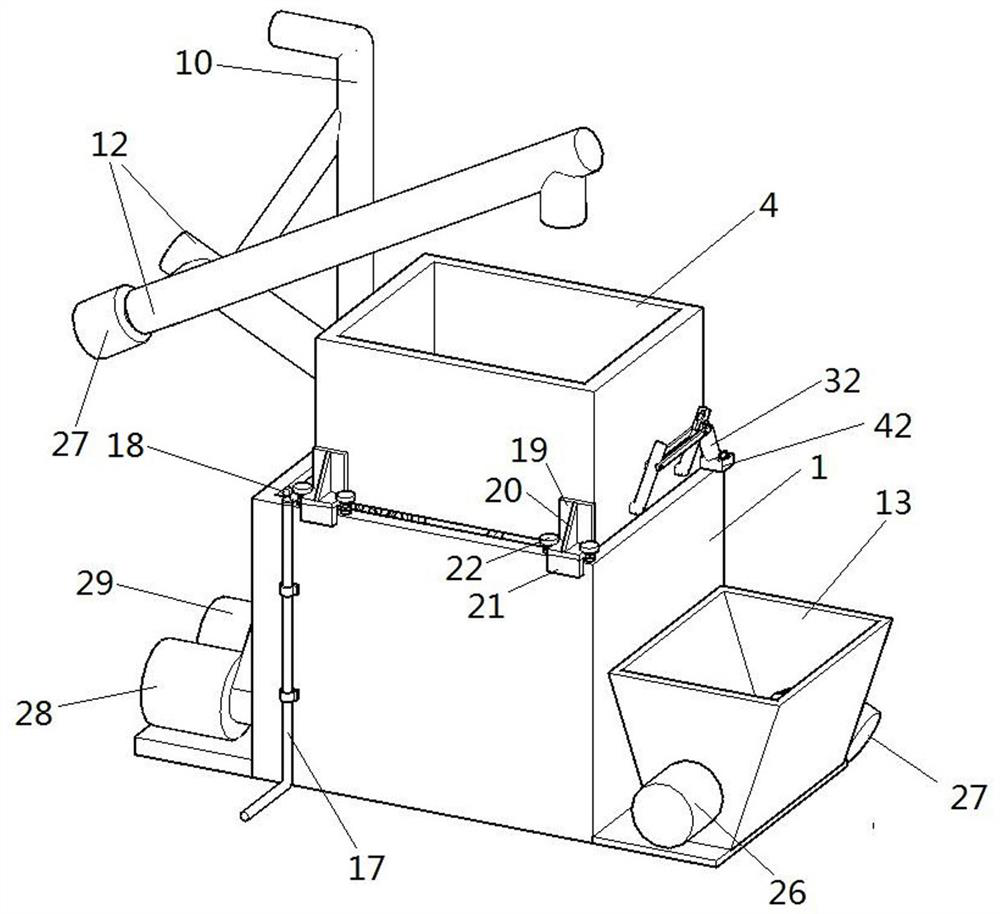

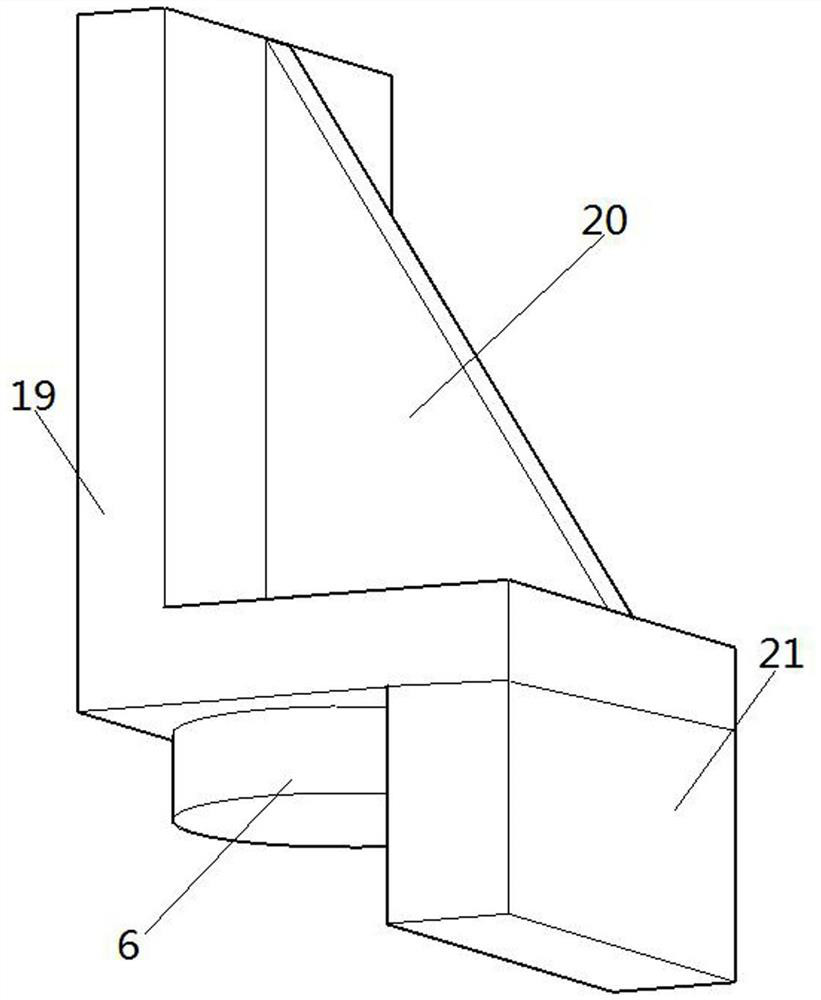

[0044] like Figure 1-8 Shown is the first embodiment of the present invention, a cement slurry feeding device, including a feeding device, a measuring device, a stirring device and a discharging device, and the stirring device is a steel stirring hopper 1 with an open upper end. The structure is shown in Figure 4. It is welded by the front plate, the rear plate, the bottom plate and the left and right side plates. The center of the right plate of the mixing bucket 1 is punched by a punching machine, and the center of the left plate of the mixing bucket 1 is punched by a punching machine. For the blind hole corresponding to the through hole, one end of the steel shaft one 2 is inserted into the blind hole after passing through the through hole. A plurality of stirring rods 3 are uniformly welded at an equal angle on the rotating shaft one 2, and the stirring rods 3 are perpendicular to the rotating shaft one 2.

[0045] The mixing hopper 1 is provided with a measuring device....

Embodiment 3

[0053] like Figure 10 Shown is the third embodiment of the present invention. The difference between this embodiment and the first embodiment is that the end of each stirring rod 3 is welded with a cuboid plate-shaped stirring blade 23 . Stirring blades are arranged at the end of the stirring rod to shorten the stirring time and make the stirring more uniform.

Embodiment 4

[0055] like Figure 11 and Figure 12 Shown is the fourth embodiment of the present invention. The difference between the present embodiment and the first embodiment is that the discharge pipe 10 is composed of an upper pipe 34 and a lower pipe 35, and the bottom end of the lower pipe 35 is vertically installed on the tee joint 15 Inside, the upper flange 36 is press-fitted on the bottom end of the upper tube 34, the lugs in the shape of a cuboid are welded on both sides of the upper flange 36, the top of the lower tube 35 is pressed into the lower flange 37, and the lugs in the shape of a cuboid are welded on both sides of the lower flange 37. Ear 2, the upper and lower correspondence between lug 1 and lug 2, the lug 1 and lug 2 on the same side are hinged through hinges, and the lug 1 and lug 2 on the other side are respectively hinged The hole machine drills the corresponding through holes up and down, inserts the bolts in the through holes, and nuts are arranged at the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com