Plunger type water pump

A plunger type and water pump technology, applied in the field of plunger type water pumps and volumetric hydraulic pumps, can solve the problems of pollution sensitivity, low power-to-weight ratio, oil pollution, etc., achieve reduced use costs, low heat balance temperature, and solve environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

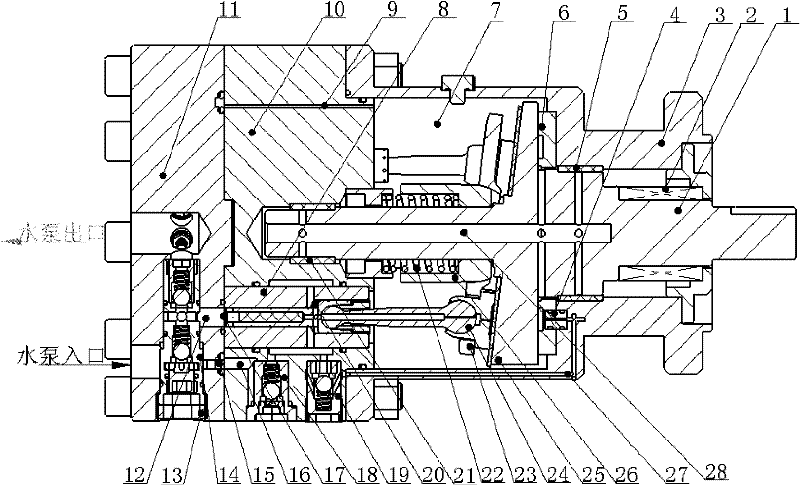

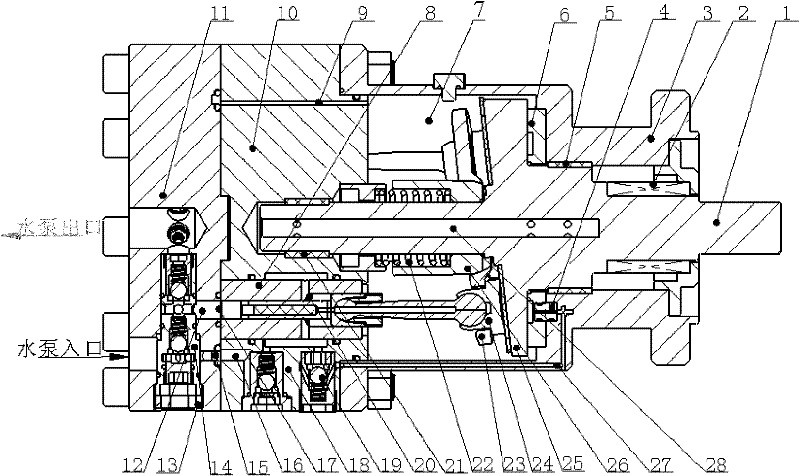

[0037] A schematic structural diagram of a plunger water pump according to an embodiment of the present invention is shown in FIG. 2 . The plunger water pump includes modules such as a pump main body, a rotating unit, and a plunger flow distribution unit. Wherein, the pump main body includes a cavity, a water pump inlet and a water pump outlet. The rotary unit comprises a rotary spindle 1 . The plunger distribution unit mainly includes a plunger shoe assembly 24 , a distribution valve assembly 14 and a supporting valve assembly. Wherein the support valve assembly includes a support suction valve 18 and a support discharge valve 19 . The plunger shoe assembly 24 is arranged in the cavity, and the cavity is divided into a high-pressure chamber 17, a low-pressure chamber 20 and a lubricating chamber 7 which are independent of each other. The supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com