Self water-replenishing flat valve plunger type extra-high pressure water pump

A plunger-type, ultra-high pressure technology, applied in the field of volumetric pumps, can solve problems such as high lubricating oil temperature and insufficient self-priming, and achieve the effects of solving wear, good self-priming ability, and reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the drawings and embodiments.

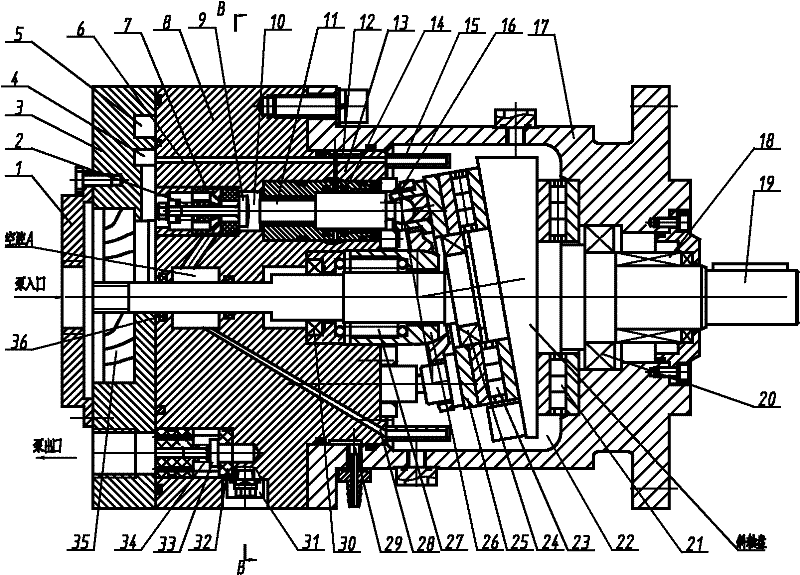

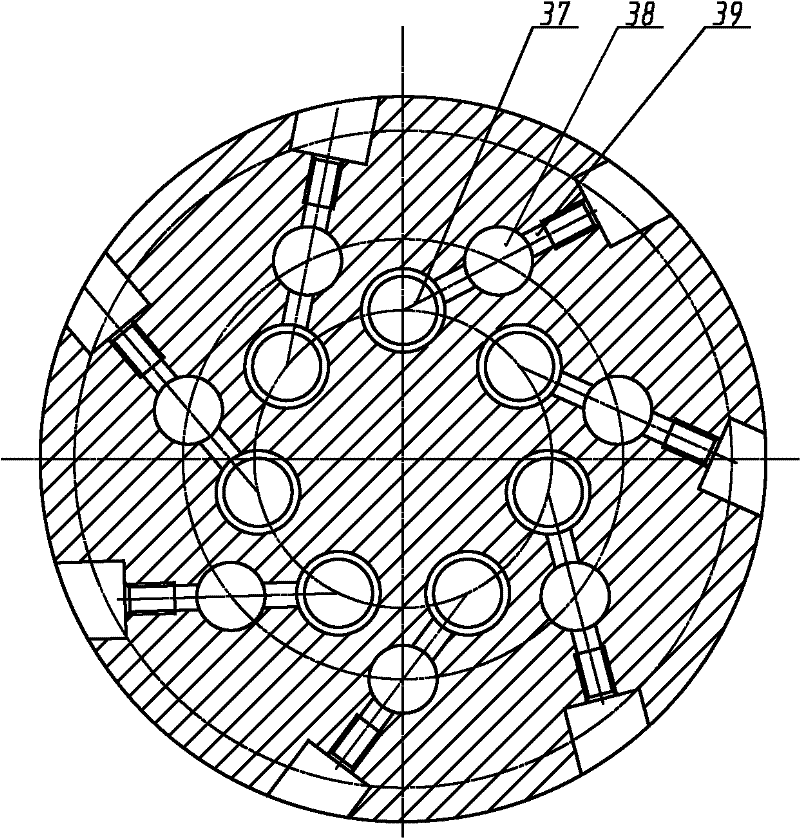

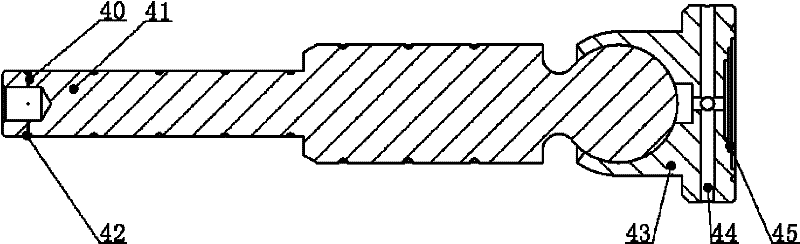

[0030] See figure 1 with 2 One end of the cylinder 8 is connected to the housing 17, and the other end is provided with an end cover 3. The end cover 3 is provided with a water pump inlet and an outlet. The end cover 3 is equipped with a water make-up pump 35 connected to the rotating main shaft 1. A stepped through hole 37 and a stepped hole 38 are opened in the cylinder body 8. The suction valve 7 is installed on the left side of the stepped through hole 37, and the pressure out valve 32 is installed in the stepped hole 38. A stepped plunger sleeve 13 is installed on the right side of the stepped through hole. The two ends of the plunger sleeve 13 are embedded with polymer support rings. The middle part of the plunger sleeve 13 has two annular grooves for installing the grid ring 14. A plunger shoe assembly 11 is installed in the support ring, such as image 3 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com