Burning stabilizing ring structure of vortex burner

A burner and swirling technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve problems such as short service life, unsafe boilers, falling off, etc., to improve safety and economy, Does not affect the mechanical strength, easy to replace and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

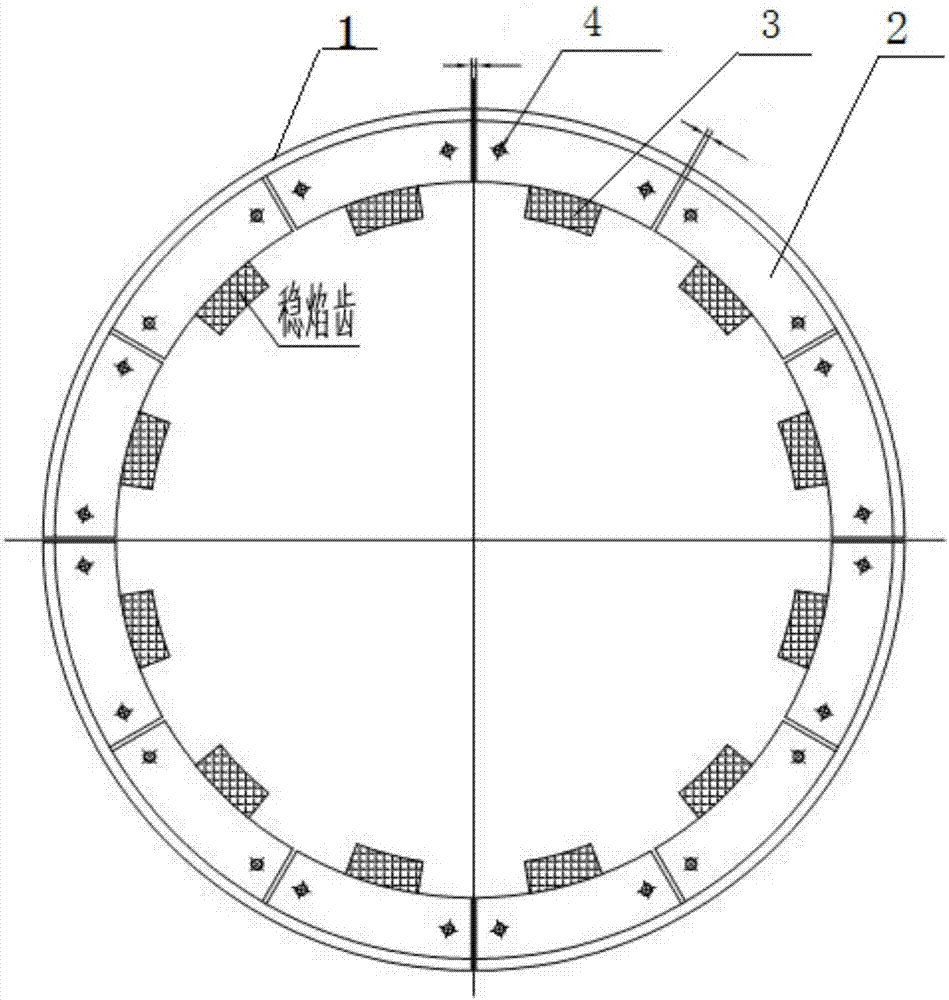

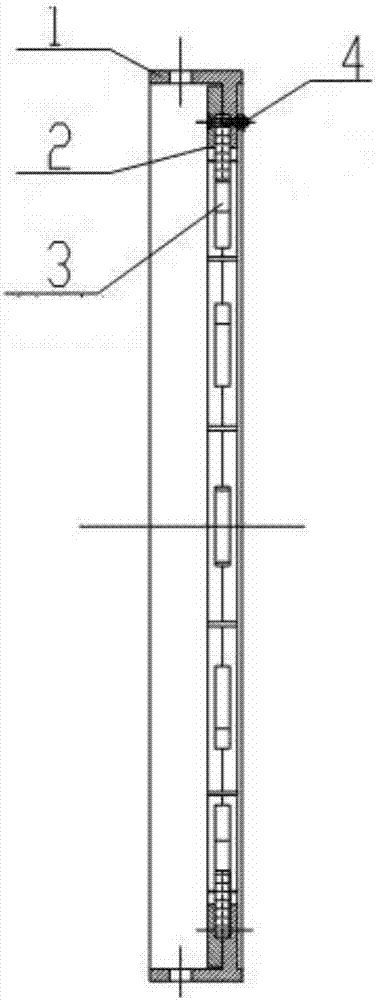

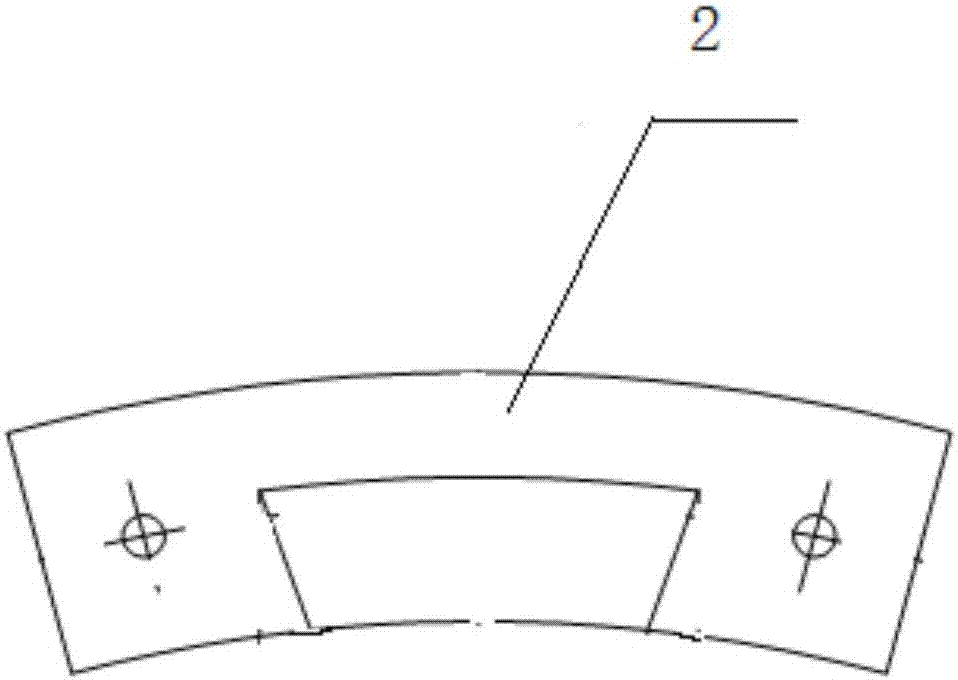

[0023] like figure 1 figure 2 As shown, the flame stabilizing ring structure of the swirl burner of the present invention includes a flame stabilizing ring body 1, a dry flame stabilizing tooth 3, a pressure plate 2, and a bolt assembly 4, and the flame stabilizing tooth 3 is pressed by the pressure plate 2 on the stable flame On the burning ring body, the pressure plate 2 is arranged on the stable burning ring body, and its shape matches the stable burning ring body. The bolt assembly 4 passes through the stable burning ring body 1, the pressing plate 2 and the flame stabilizing tooth 3, so that the flame stabilizing tooth 3 Fixed on the combustion-stabilizing ring body, the flame-stabilizing teeth 3 are evenly spaced on the combustion-stabilizing ring body, and the silicon carbide stabilizing teeth are evenly distributed alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com