A kind of core-shell structure biofiller and preparation method thereof

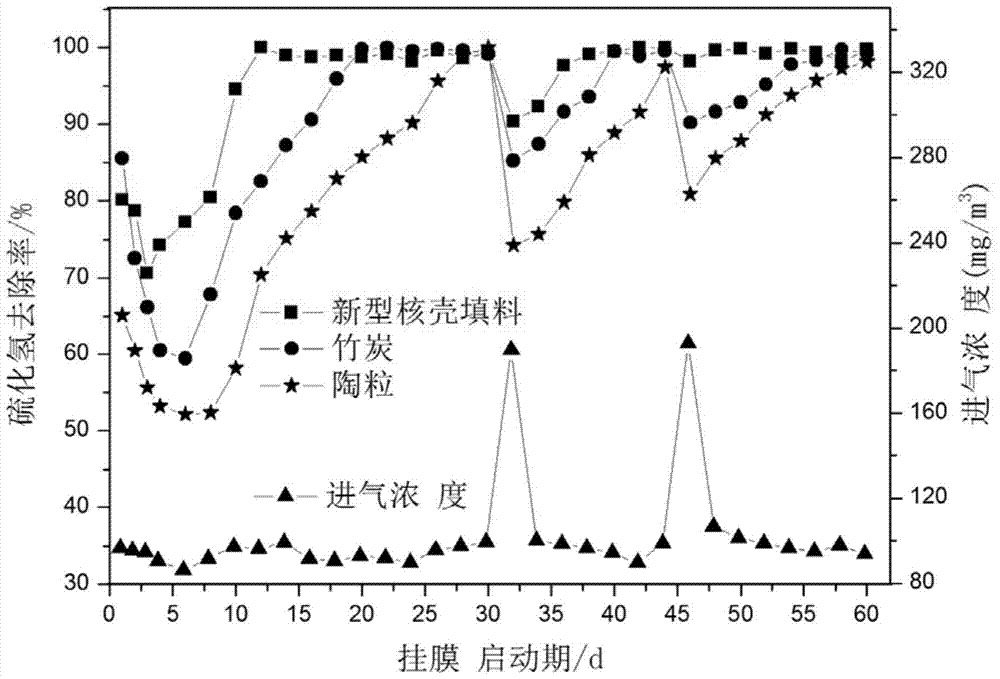

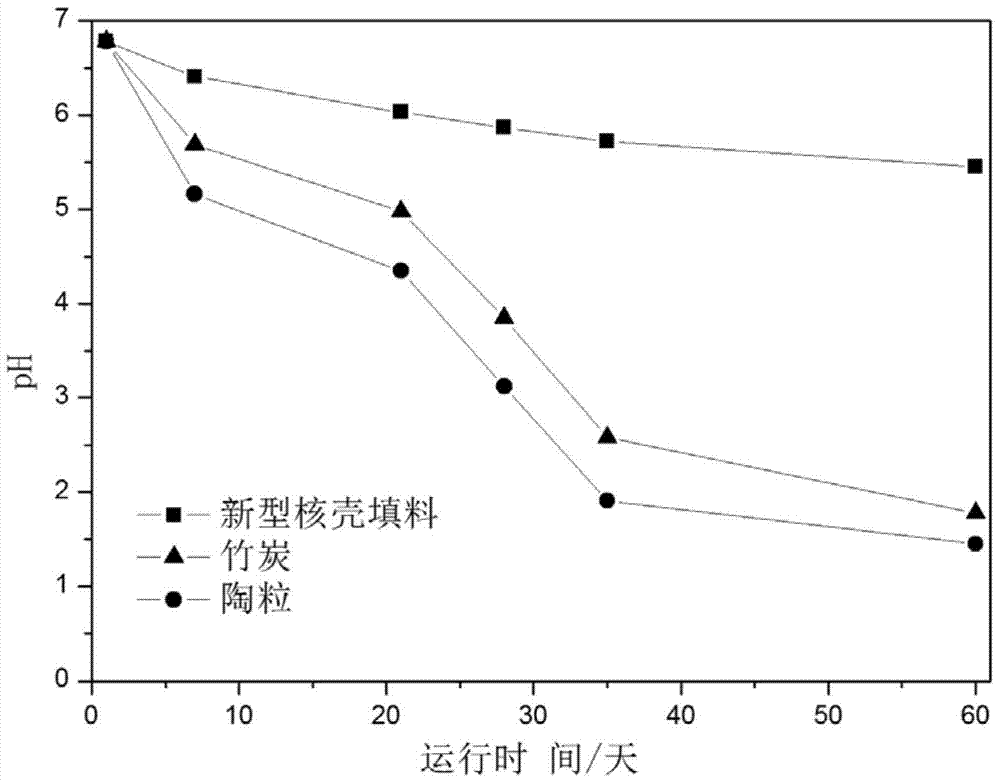

A technology of biofiller and core-shell structure, applied in the field of core-shell structure biofiller and its preparation, can solve the problems such as difficult to control the ratio, difficult to mix uniformly, and increase the complexity of filler loading, etc., to achieve easy material acquisition, delay acidification time, and improve Effect of odor treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

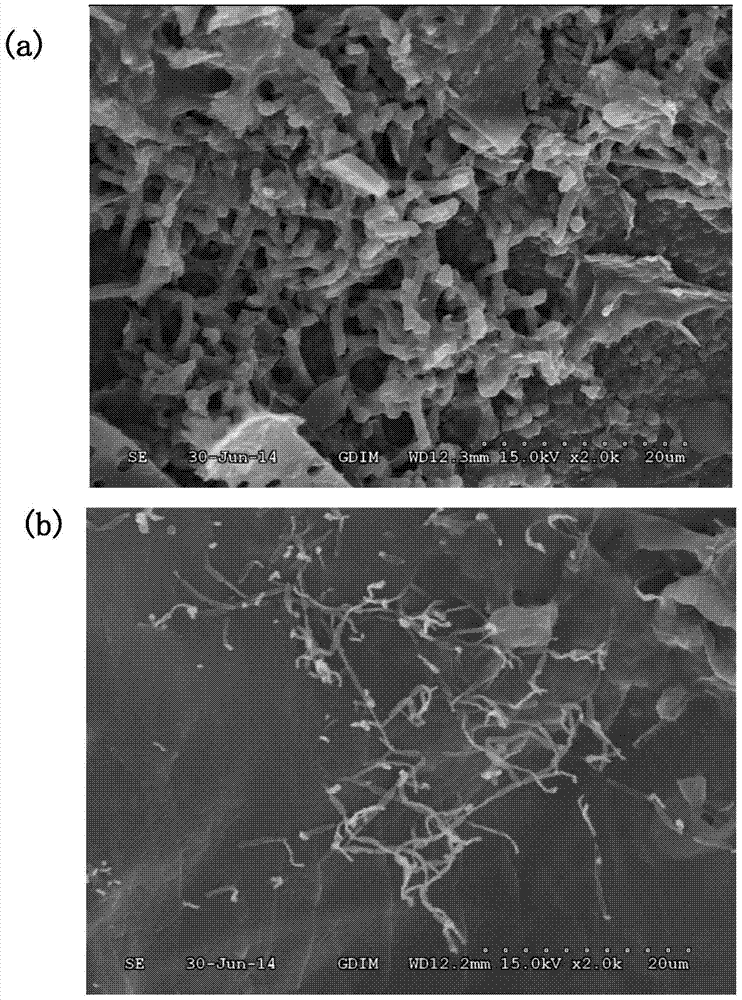

Examples

Embodiment 1

[0029] Raw materials: by mass fraction, including 25% of activated sludge from urban sewage treatment plants with a moisture content of 80%, 1% of deodorant bacteria agent, 20% of bamboo charcoal powder, 4% of iron red, 10% of calcium oxide and silicates Inorganic gel (China Resources Cement, P.Ⅱ52.5R Portland cement) 40%, the deodorizing bacteria agent can be one or more combination bacteria in sulfur oxidizing bacteria, ammonia oxidizing bacteria, VOCs degrading bacteria , what adopted in the present embodiment is the sulfur oxidizing bacteria bacterial agent, becomes powder;

[0030] a. Mix the activated sludge, deodorizing bacteria agent and 25% silicate inorganic gel in total, and then extrude and granulate. The particle size is 10-15mm, and then air-dried for 6 days in a ventilated environment. get aggregate;

[0031] b. Mix bamboo charcoal powder, iron red, calcium oxide and the remaining silicate inorganic gel evenly and sieve through a 200-mesh sieve to obtain powder...

Embodiment 2

[0040] Raw materials: by mass fraction, including 20% of activated sludge from urban sewage treatment plants with a water content of 80%, 0.2% of deodorant bacteria, 25% of bamboo charcoal powder, 2% of iron red, 15% of calcium oxide and silicates Inorganic gel 37.8%, described deodorant bacterial agent can be one or more combination bacteria in sulfur oxidizing bacteria, ammonia oxidizing bacteria, VOCs degrading bacteria, what adopted in the present embodiment is sulfuric bacterial bacterial agent, becomes powder;

[0041] a. Mix activated sludge, deodorizing bacteria agent and 15% silicate inorganic gel in total, then extrude and granulate. The particle size is 10-15mm, and then air-dry for 5 days in a ventilated environment. get aggregate;

[0042] b. Mix bamboo charcoal powder, iron red, calcium oxide and the remaining silicate inorganic gel evenly and sieve through a 200-mesh sieve to obtain powder;

[0043] c. Put the aggregate into the ball forming plate, sprinkle ...

Embodiment 3

[0046] Raw materials: by mass fraction, including 21% of activated sludge from urban sewage treatment plants with a water content of 80%, 1% of deodorant bacteria, 15% of bamboo charcoal powder, 5% of iron red, 8% of calcium oxide and silicates Inorganic gel 50%, described deodorant bacterium agent can be one or more combination bacteria in sulfur oxidizing bacteria, ammonia oxidizing bacteria, VOCs degrading bacteria, what adopted in the present embodiment is sulfur oxidizing bacteria, ammonia oxidizing bacteria Bacteria, VOCs degrading bacteria mixed bacterial agent of three kinds of bacteria, in powder form;

[0047] a. Mix activated sludge, deodorizing bacteria agent and 35% silicate inorganic gel in total, then extrude and granulate, the particle size is 10-15mm, and then air-dry for 7 days in a ventilated environment. get aggregate;

[0048] b. Mix bamboo charcoal powder, iron red, calcium oxide and the remaining silicate inorganic gel evenly and sieve through a 200-mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com