Half-soft state connecting method between copper alloy woven meshes for cage

A copper alloy, woven mesh technology, applied in application, fish farming, climate change adaptation, etc., can solve problems such as user economic loss, escape of farmed fish, economic loss, etc., to improve quality and mechanical properties, and reasonable operation methods. Reliable, high processing speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

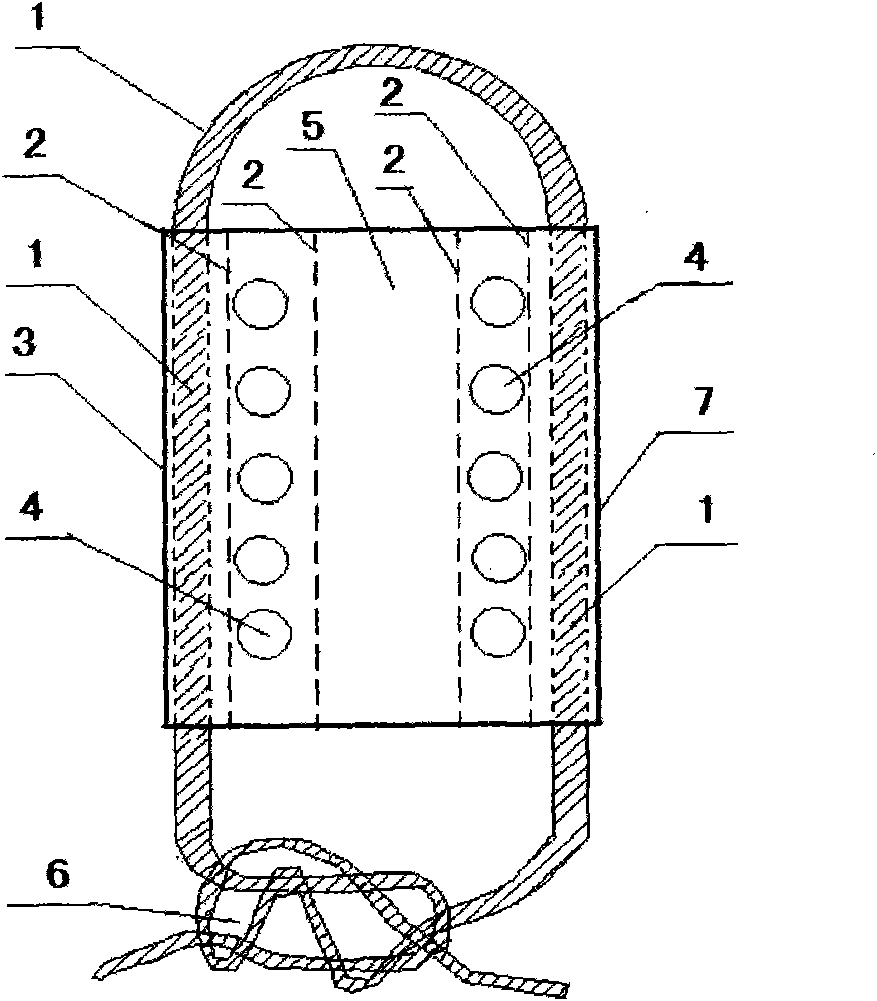

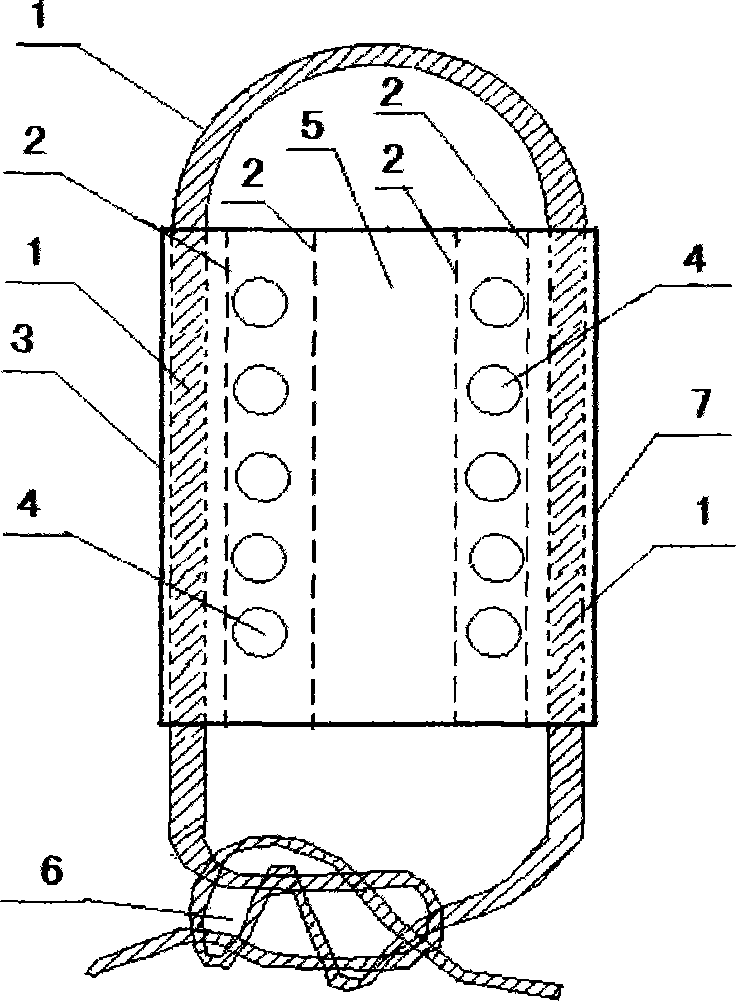

[0010] figure 1 1 in represents the rope used for making semi-soft connectors, figure 1 2 in represents suture thread for making semi-soft connectors, figure 1 The 3 in it represents the left side of the sea anchor pipe for making semi-soft connectors, figure 1 4 in represents the eye ring on the sea anchor cloth pipe, figure 1 The 5 in it represents the sea anchor pipe for the production of semi-soft connectors, figure 1 The 6 in it represents the double dead knot made by the two ends of the rope for making the semi-soft connector, figure 1 7 in the figure represents the right side of the sea anchor pipe for making semi-soft connectors.

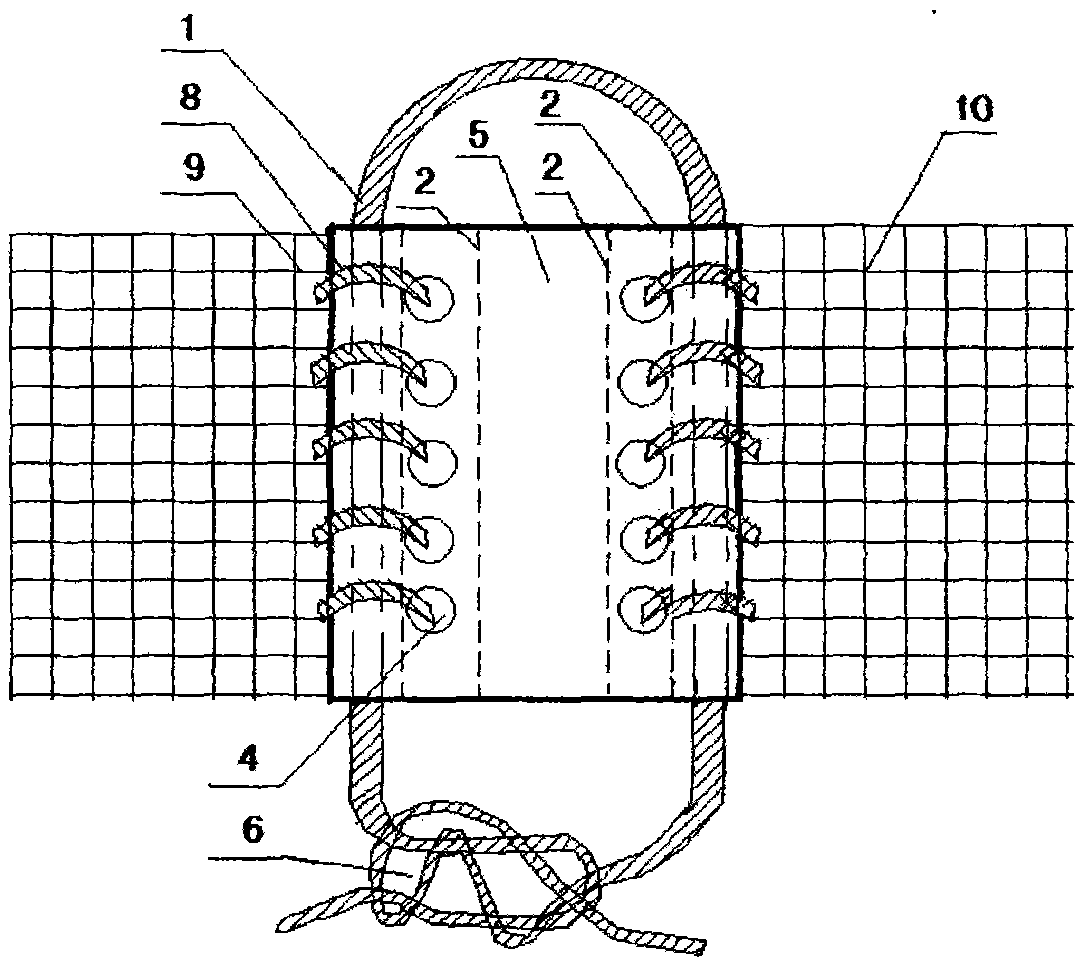

[0011] figure 2 1 in represents the rope used for making semi-soft connectors, figure 2 2 in represents suture thread for making semi-soft connectors, figure 2 4 in represents the eye ring on the sea anchor cloth pipe, figure 2 The 5 in it represents the sea anchor pipe for the production of semi-soft connectors, figure 2 The 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com