Rebar head portion upsetting machine and use method thereof

An upsetting machine and upsetting technology, applied in the field of cold upsetting machines, can solve problems such as inaccurate positioning, achieve stable performance of the whole machine, improve stability and accuracy, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

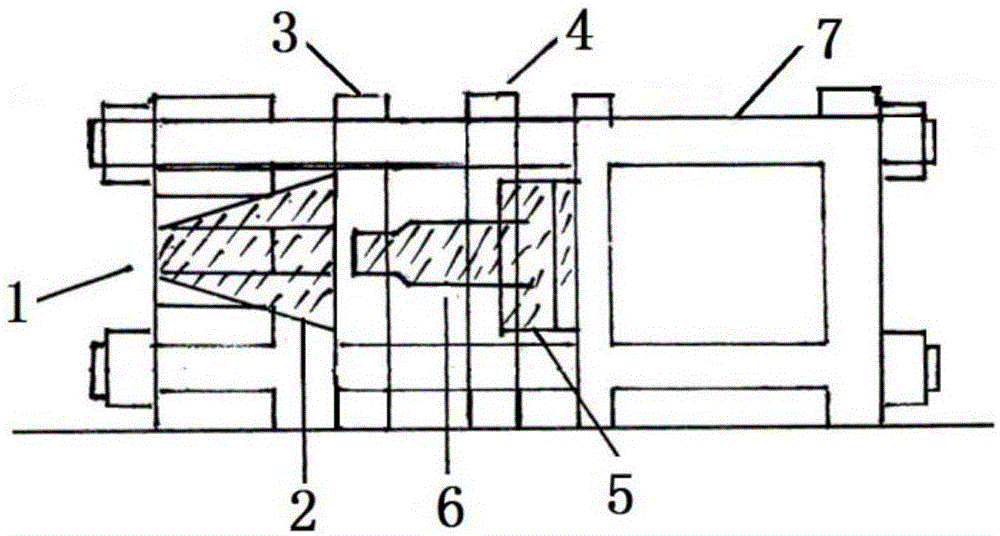

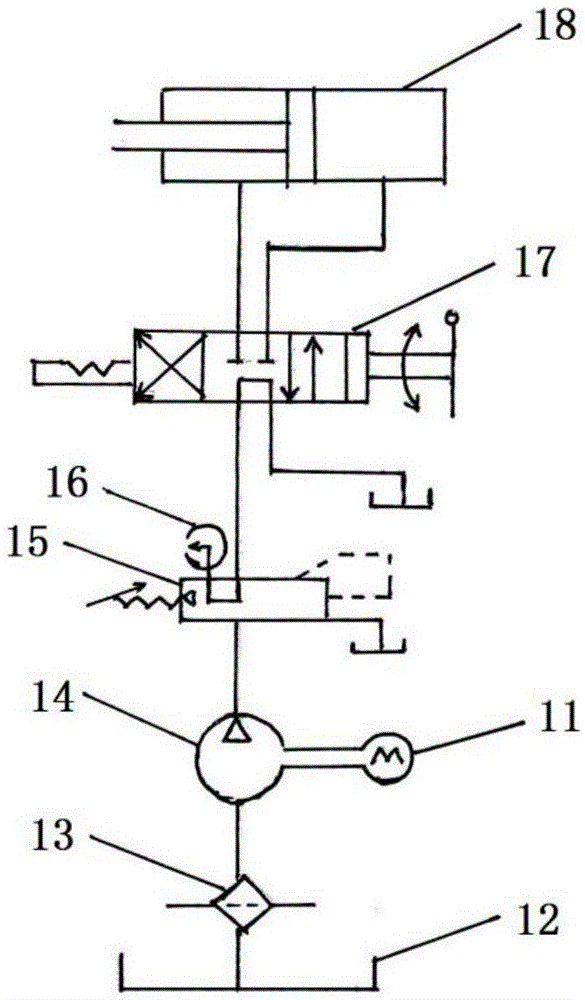

[0042] An upsetting machine for the head of a steel bar, an upsetting die, an upsetting device, and a guide rod 7 are installed on the frame, and the upsetting die and the upsetting device are arranged on the frame through the guide rod 7 in sequence from left to right, The frame is used to fix the upsetting die and upsetting device. When the upsetting device squeezes the steel bars in the upsetting die, the guide rod 7 plays the role of positioning guide. The upsetting die in the prior art does not have the positioning guide of the guide rod 7. After long-term operation, the upsetting die and the upsetting Dislocation of the device, the present invention utilizes the positioning and guiding function of the guide rod 7 to ensure that the end face of the steel bar in the upsetting mold and the upsetting head 6 on the upsetting device will not be dislocated, and improve the stability and accuracy of the impact of the upsetting head 6 , thereby improving the service life of the u...

Embodiment 2

[0057] The structure and use method of this embodiment are the same as those of Embodiment 1, wherein the working stroke of the piston rod is 60mm, the maximum stroke is 152mm, the rated upsetting force is 1880kN, the maximum upsetting force is 2820kN, and the motor power is 4kW, which is different from the conventional super Compared with the motor power of the high-pressure pump, no additional cooling system is required, and the flow rate of the high-pressure oil pump 14 is 5.6L / min, which improves work efficiency and reduces costs. When the conventional upsetting machine works, one piece of equipment can generally process one hundred steel bars per shift. To speed up the progress can only be realized by increasing the number of equipment, which consumes a lot of manpower and material resources. The steel bar of the present invention can process three hundred steel bars, which improves the work efficiency. Efficiency, saving manpower and material resources. Its operation ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com