Sectioning type waste cigarette treating device

A treatment device and technology for waste cigarettes, applied in the fields of tobacco, cigarette manufacturing, transportation and packaging, etc., can solve the problems of low comprehensive recovery rate of shredded tobacco, low whole shred rate, and high content of paper scraps, so as to improve comprehensive recycling utilization rate, The effect of high whole yarn rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Now in conjunction with accompanying drawing, the present invention is described in detail.

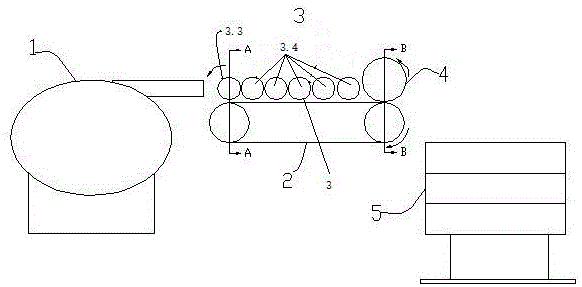

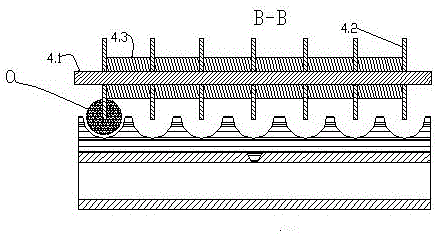

[0023] Such as figure 1 As shown in , this cutting-type waste cigarette processing device includes a smoke conveying device 2, a smoke pressing device 3, and a tobacco cutting device 4. It is characterized in that the smoke pressing device 3 is installed above the smoke conveying device 2, and the smoke cutting device 4 is installed on the top of the smoke delivery device 2 and the right side of the smoke pressing device.

[0024] The feeding device 1 is installed on the left side of the conveying device 2, and the screening device 5 is located on the right side of the tobacco cutting device 4. The feeding device 1 is a circular vibrating feeding tray, which plays the role of feeding. The screening device 5 is three The main function of the layer circular vibrating screening device is to separate the cigarette paper and shredded tobacco from the cut waste cigarettes.

[0025]...

specific Embodiment approach 2

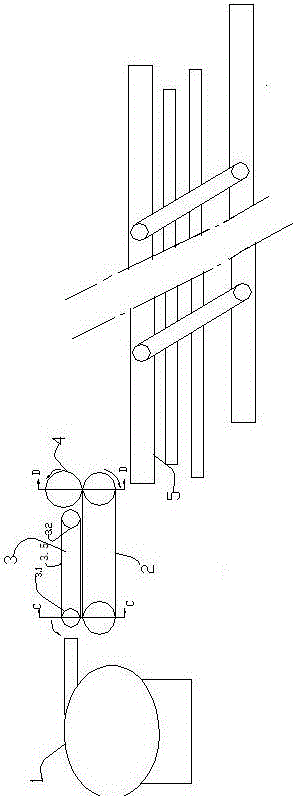

[0028] Such as Figure 4 As shown in , this cutting-type waste cigarette processing device includes a smoke conveying device 2, a smoke pressing device 3, and a tobacco cutting device 4. It is characterized in that the smoke pressing device 3 is installed above the smoke conveying device 2, and the smoke cutting device 4 is installed on the top of the smoke conveying device 2 and the rear of the smoke pressing device.

[0029] The feeding device 1 is installed on the left side of the conveying device 2, and the screening device 5 is located on the right side of the tobacco cutting device 4. The feeding device 1 is a circular vibrating feeding tray, which plays the role of feeding. The main function of the layer linear screening device is to separate the cigarette paper and shredded tobacco from the cut waste cigarettes.

[0030] combine Figure 4 , 5 As shown in: the smoke delivery device 2 is a belt conveyor, including: driving wheel 2.1, characterized in that: the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com