Cross-mounting bottom frame device

A technology of underframe and straddle installation, which is applied in the direction of relative movement between the underframe and the bogie, bogie, transportation and packaging, etc., which can solve the problem of large labor and time costs, long cycle, and integrated four-axis The bogie design is difficult to achieve the effect of improving vehicle dynamics, reducing direct wear, saving labor costs and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

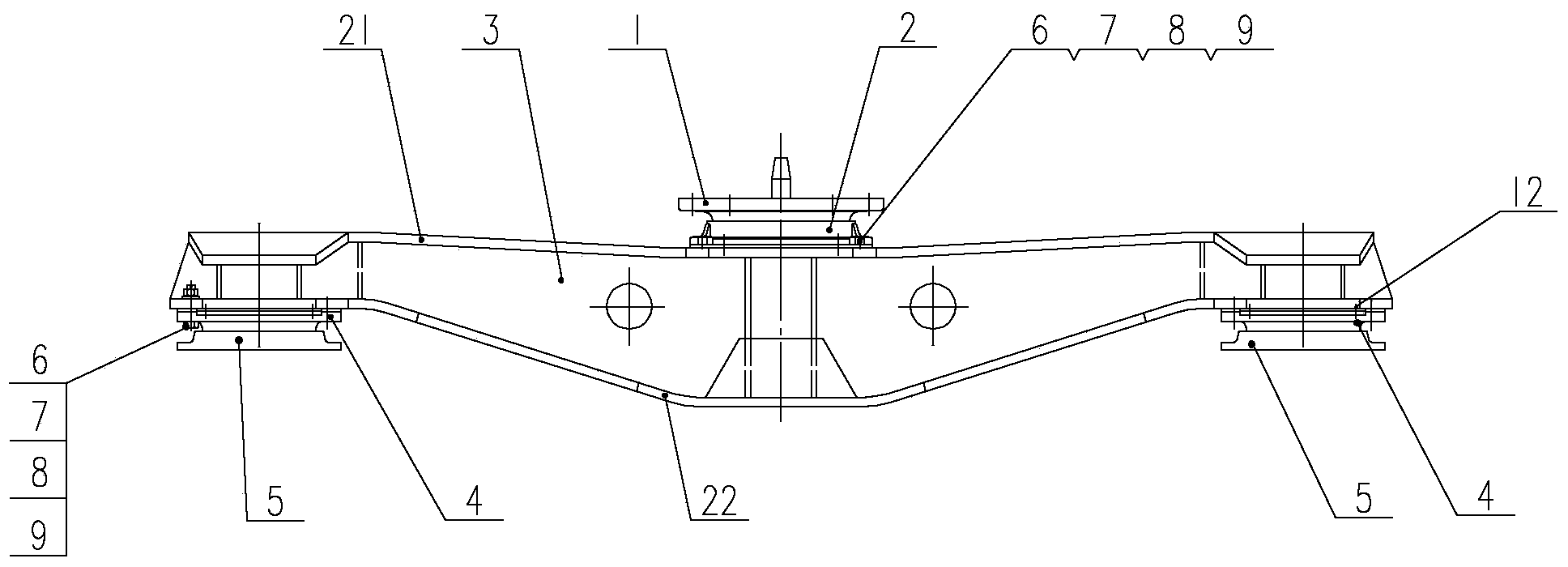

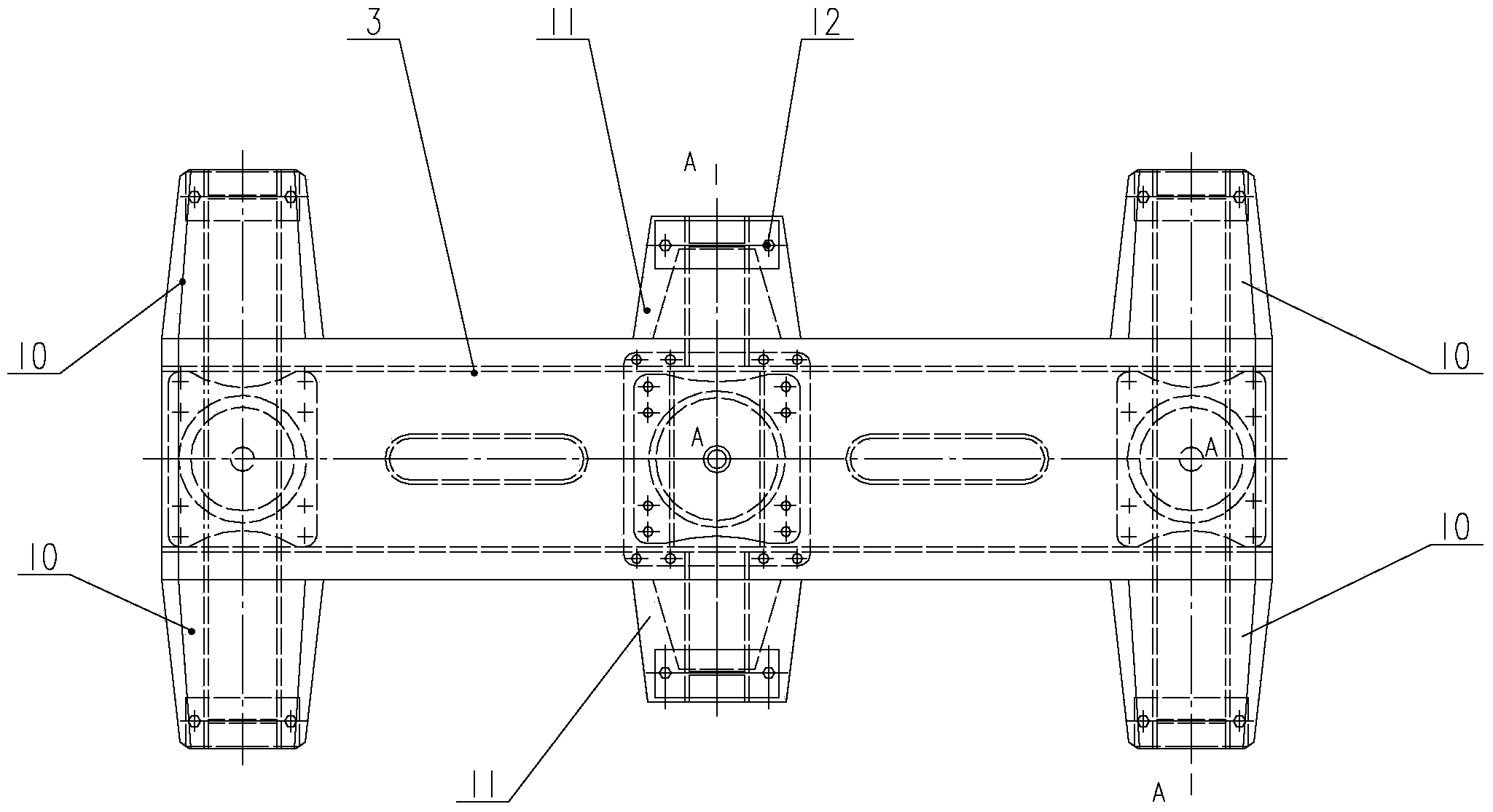

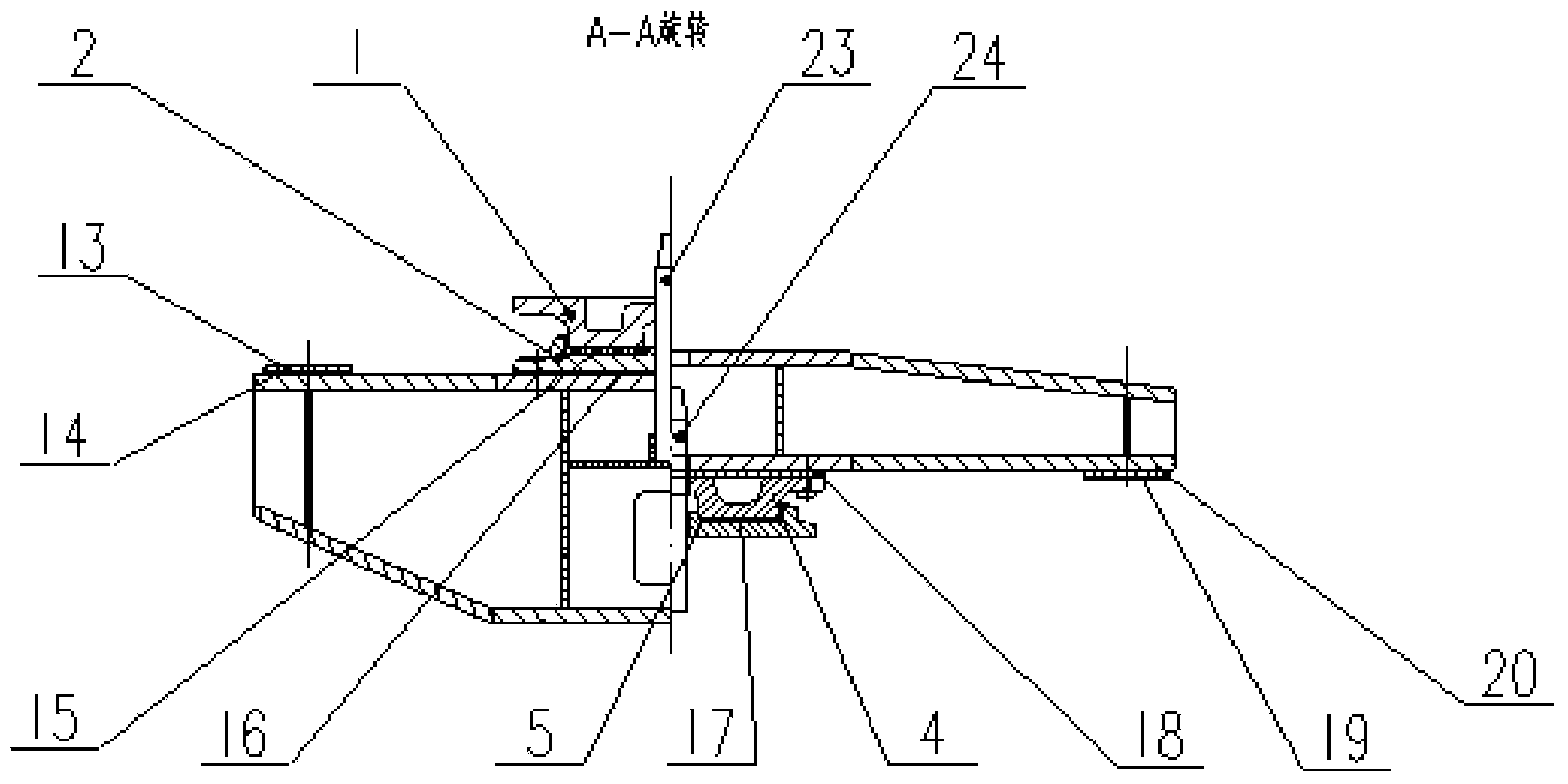

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] like Figure 1 ~ Figure 3 As shown, the present invention includes a horizontally arranged center beam composition 3, which is a fish-belly box structure that gradually becomes thinner from the middle to both ends. A corbel composition 10 is respectively connected to the front and rear sides of the two ends of the middle sill composition 3 , and a middle corbel composition 11 is respectively connected to the front and rear sides of the middle part of the middle sill composition 3 . Among them, the end bolster composition 10 and the middle bolster composition 11 are both box-shaped structures that gradually become thinner from the fixed end to the free end, and the length of the end bolster composition 10 in the horizontal direction is longer than that of the middle bolster composition 11, while in the vertical direction The height of the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com