Double-cylinder two-stroke cylinder engine

A twin-cylinder two-stroke engine technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as low reliability, and achieve the effects of reducing friction loss, improving mechanical efficiency, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with embodiment the present invention is further described.

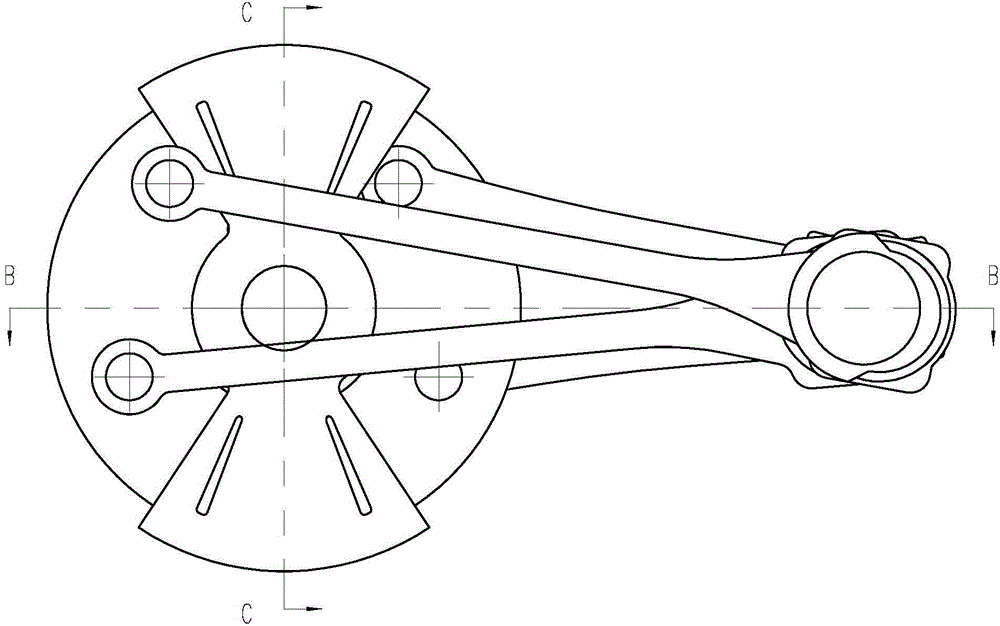

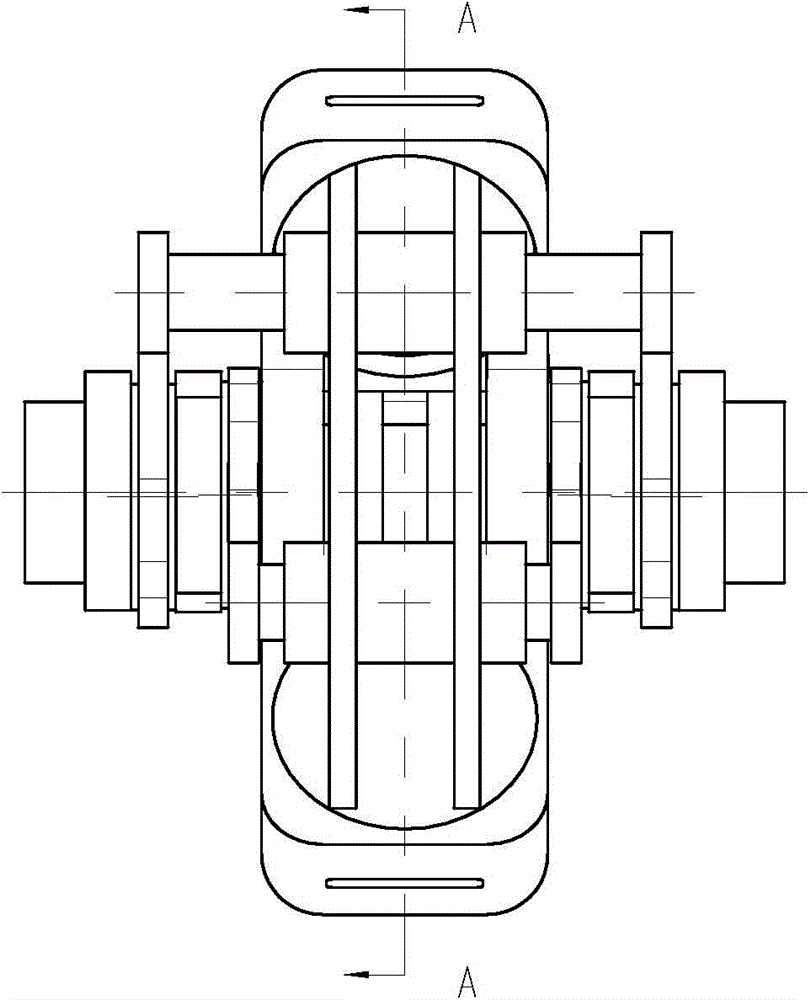

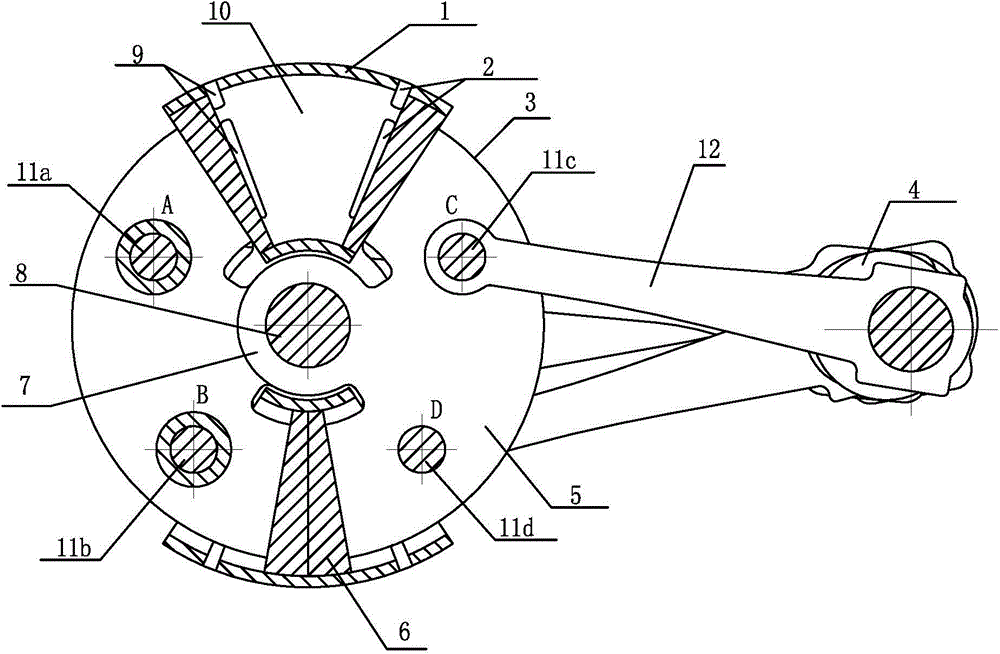

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of two-cylinder two-stroke ring cylinder engine, it comprises:

[0043] Two oppositely arranged cylinders 1, the inner cavity of the cylinder 1 is made into a ring-shaped curved surface, and the ring-shaped curved surface refers to: a space curved surface formed by a circle in a plane rotating around an axis in the plane, the inner cavity of the cylinder 1 in the plane The circle is called the creation circle of the circular surface, the axis is called the creation axis, and the vertical distance from the center of the circle to the creation axis is called the creation radius; the two ends of the cylinder 1 have piston inlets,

[0044] A central shaft 8 is arranged between the two cylinders 1, and the axis of the central shaft coincides with the creation axis;

[0045] Two double-headed pistons 3 arranged in pairs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com