Micro-nano engine oil and preparation method thereof

An engine oil, micro-nano technology, applied in the field of lubricating oil, can solve problems such as the inability to ensure uniform dispersion of nanoparticles, and achieve the effects of reducing friction coefficient, reducing wear and enhancing cylinder pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

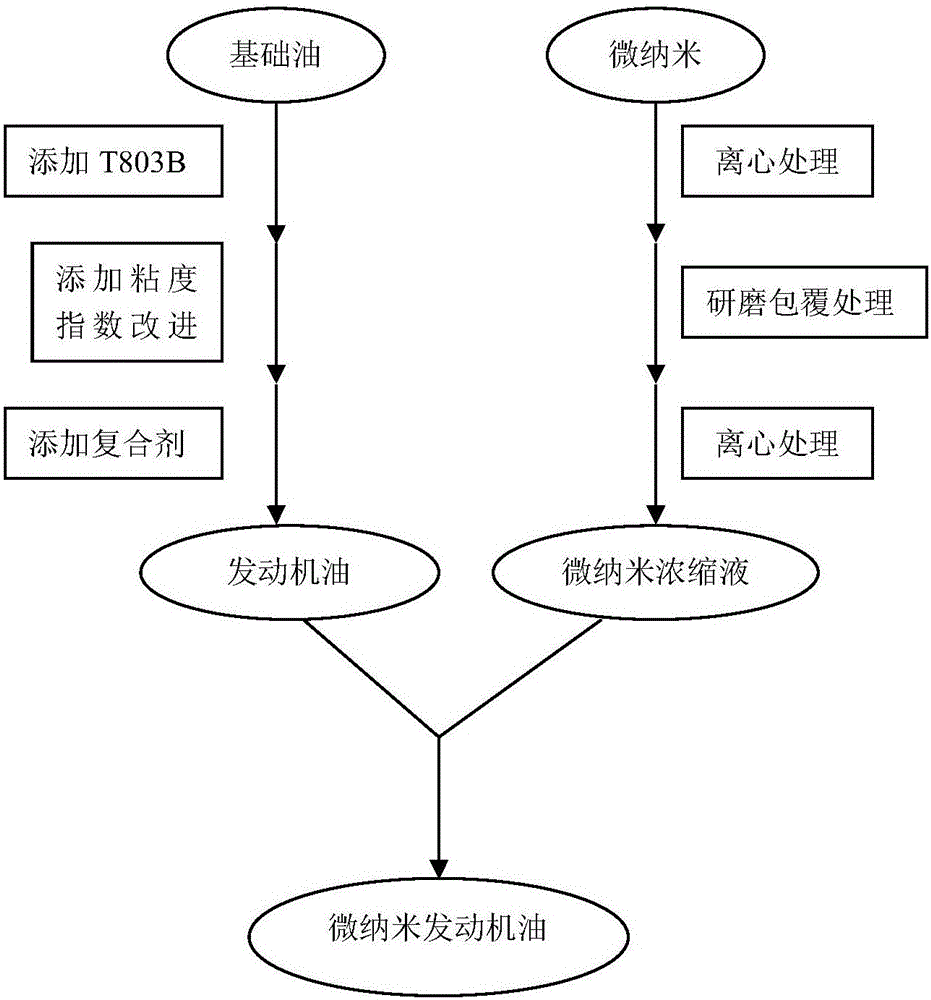

Method used

Image

Examples

Embodiment 1

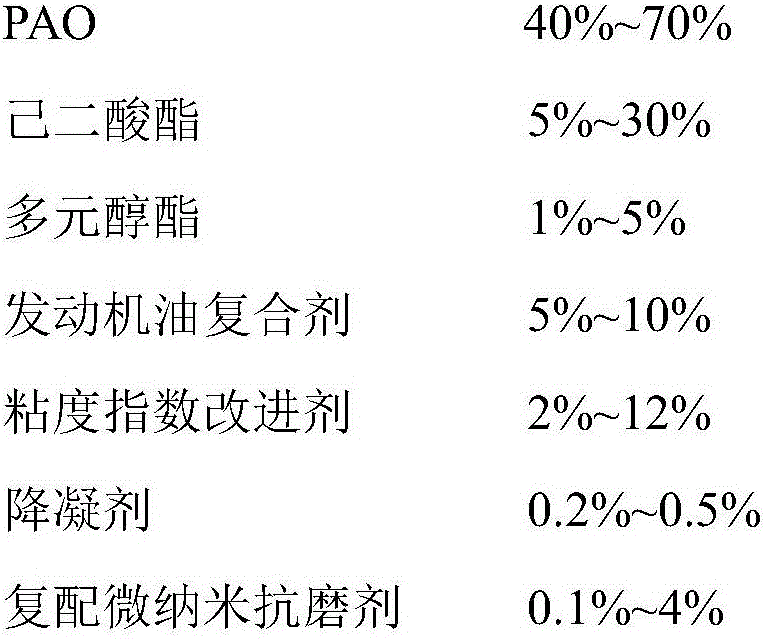

[0025] A kind of micro-nano engine oil, its component and mass percentage are:

[0026]

[0027] PAO is made by compounding PAO8 and PAO6 at a mass ratio of 9:1.

Embodiment 2

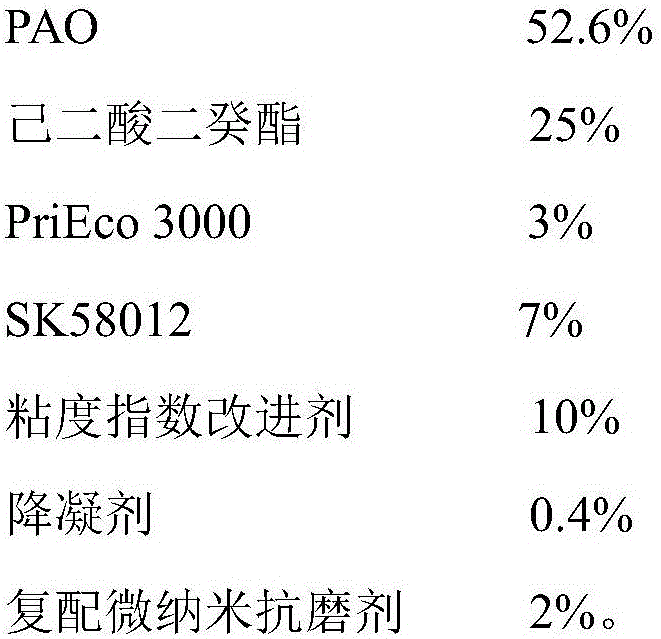

[0029] A kind of micro-nano engine oil, its component and mass percentage are:

[0030]

[0031]

[0032] PAO is made by compounding PAO8 and PAO6 at a mass ratio of 9:1.

Embodiment 3

[0034] A kind of micro-nano engine oil, its component and mass percentage are:

[0035]

[0036] PAO is made by compounding PAO8 and PAO6 at a mass ratio of 9:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com