Patents

Literature

64results about How to "Avoid Dry Grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

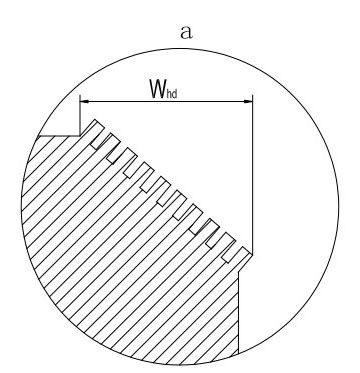

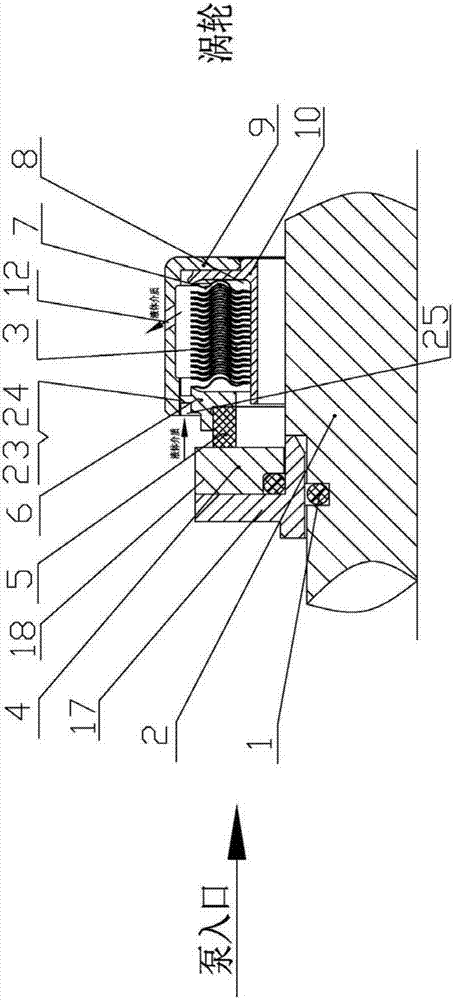

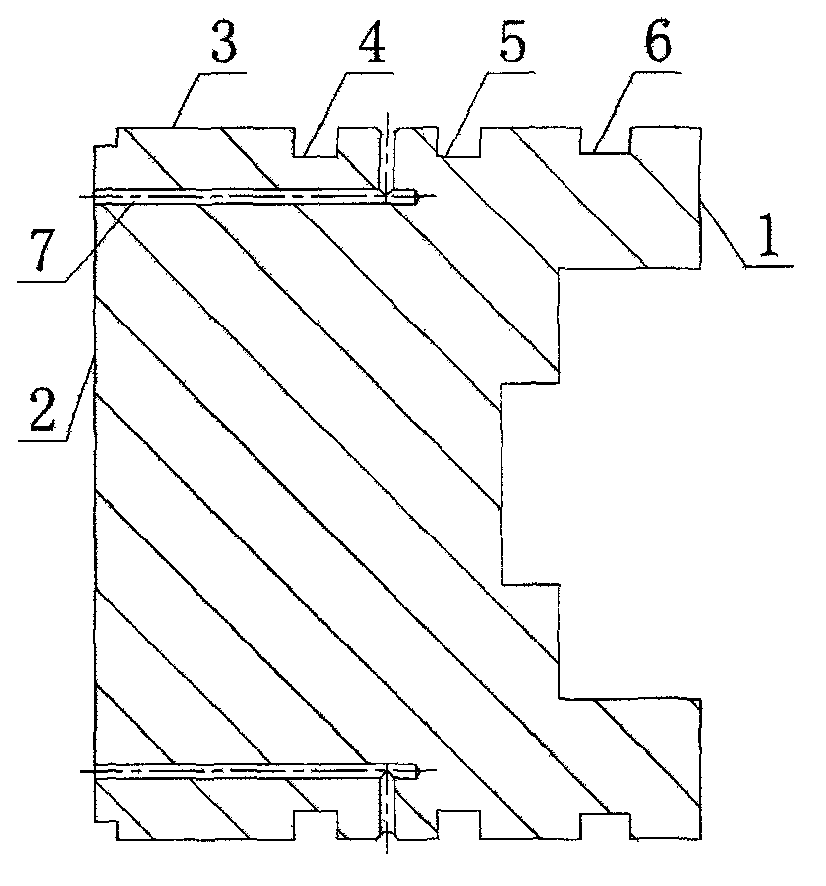

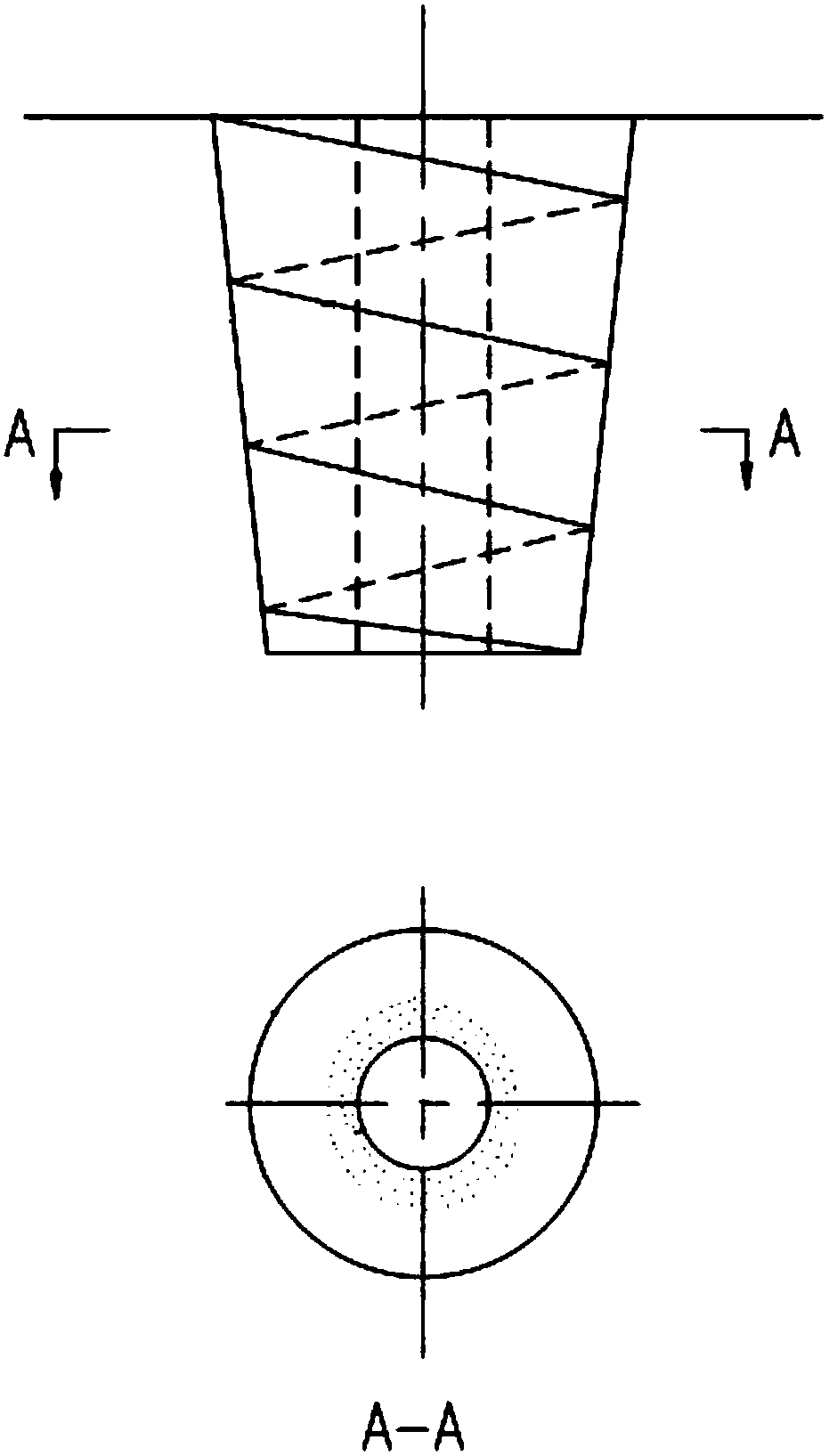

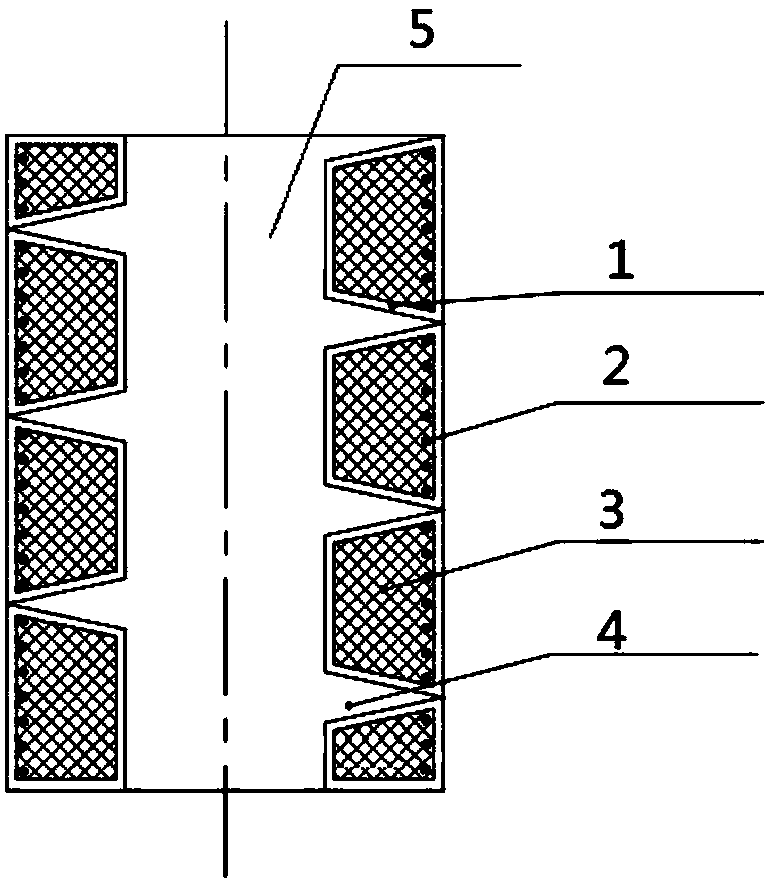

Self-sealed zero leakage hydrophobic molded surface mechanical sealing end face structure

ActiveCN101975274AReduce leakageReduce or avoid wear and tearEngine sealsDynamic pressureFace structure

The invention discloses a self-sealed zero leakage hydrophobic molded surface mechanical sealing end face structure, which comprises a dynamic ring and a static ring which are mechanically sealed, wherein at least one sealed end face of the dynamic ring or the static ring is a composite molded surface consisting of a microgroove dynamic pressure ring belt, a sealed dam and a hydrophobic molded surface distributed in turn from high to low direction. The structure has the advantages that: the self-sealing property of the narrow hydrophobic molded surface can obviously reduce the leakage and even reaches zero leakage; by adopting one or more hydrophobic molded surfaces, the abrasion of the end faces can be reduced or avoided, and the integral sealing property and the abrasion resistance of mechanical seal can be greatly improved; and by adopting the combination mode of the microgroove dynamic pressure ring belt and the hydrophobic molded surface, a lubricating medium can be stored in the end faces to prevent dry grinding of the end faces when the machine is started and improve the opening property and the reliability of mechanical seal.

Owner:SICHUAN ZIGONG IND PUMP

External reverse gear unit of speed variator for motorcycle engine

InactiveCN1356235APrevent leakageImprove lubrication statusCycle actuatorsEngineeringMechanical engineering

An external reverse gear unit for the speed variator of motorcycle is composed of a case assemblage for changing the rotational direction of driven axle, a manipulating mechanism installed on case body for driving the driven axle to change its rotational direction, and a reverse gear controlling drive for controlling the said manipulating mechanism. It features that the reverse gear can only be performed at low gear position, that is, reverse gear position "I", resulting in higher safety.

Owner:谢光荣 +1

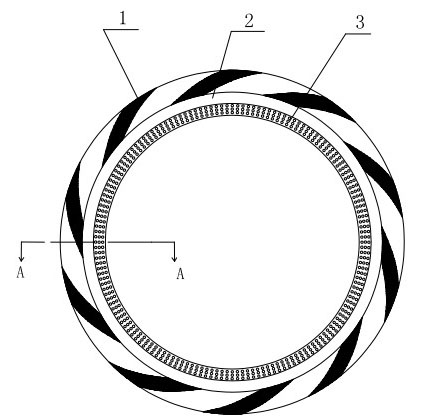

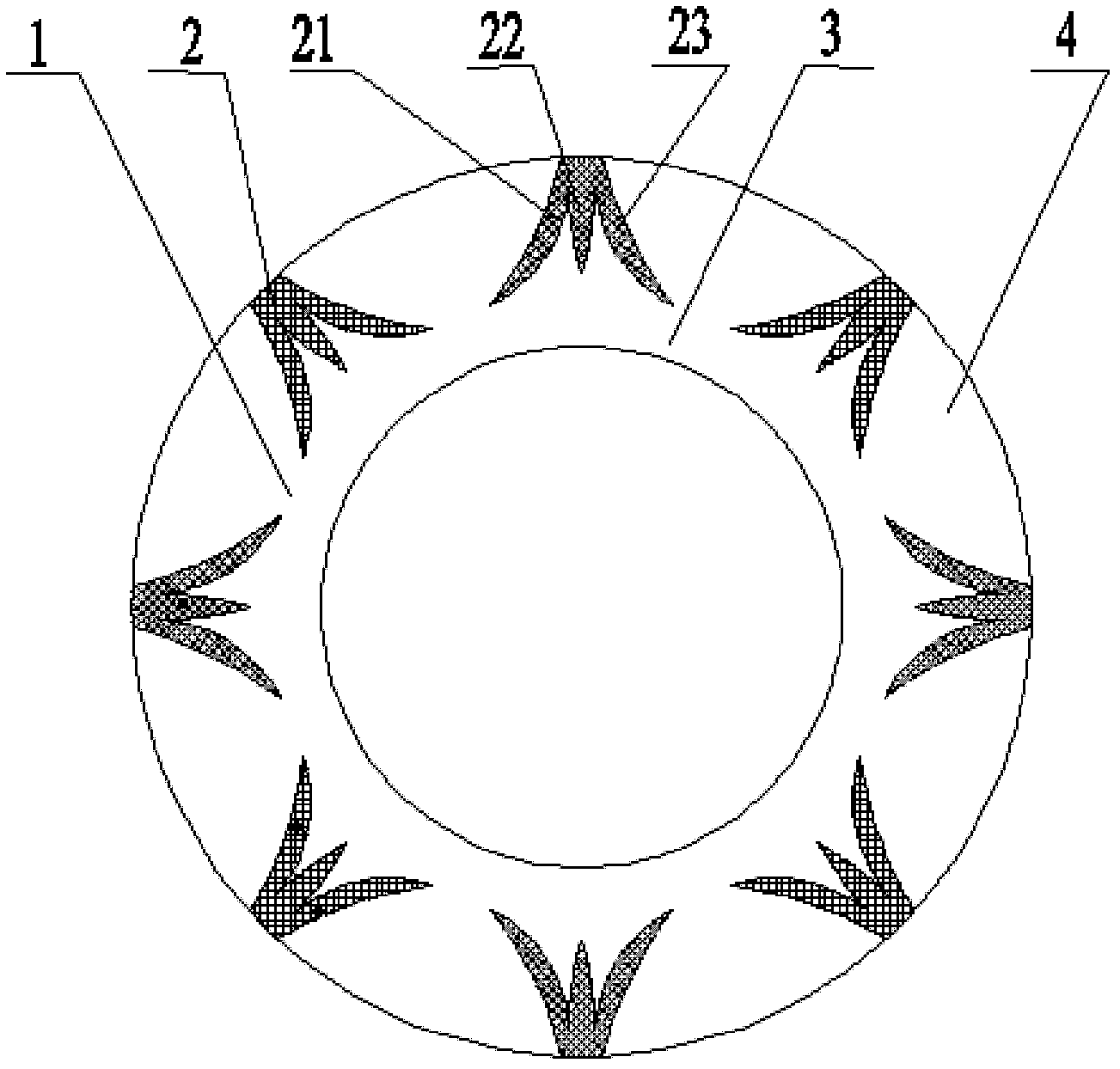

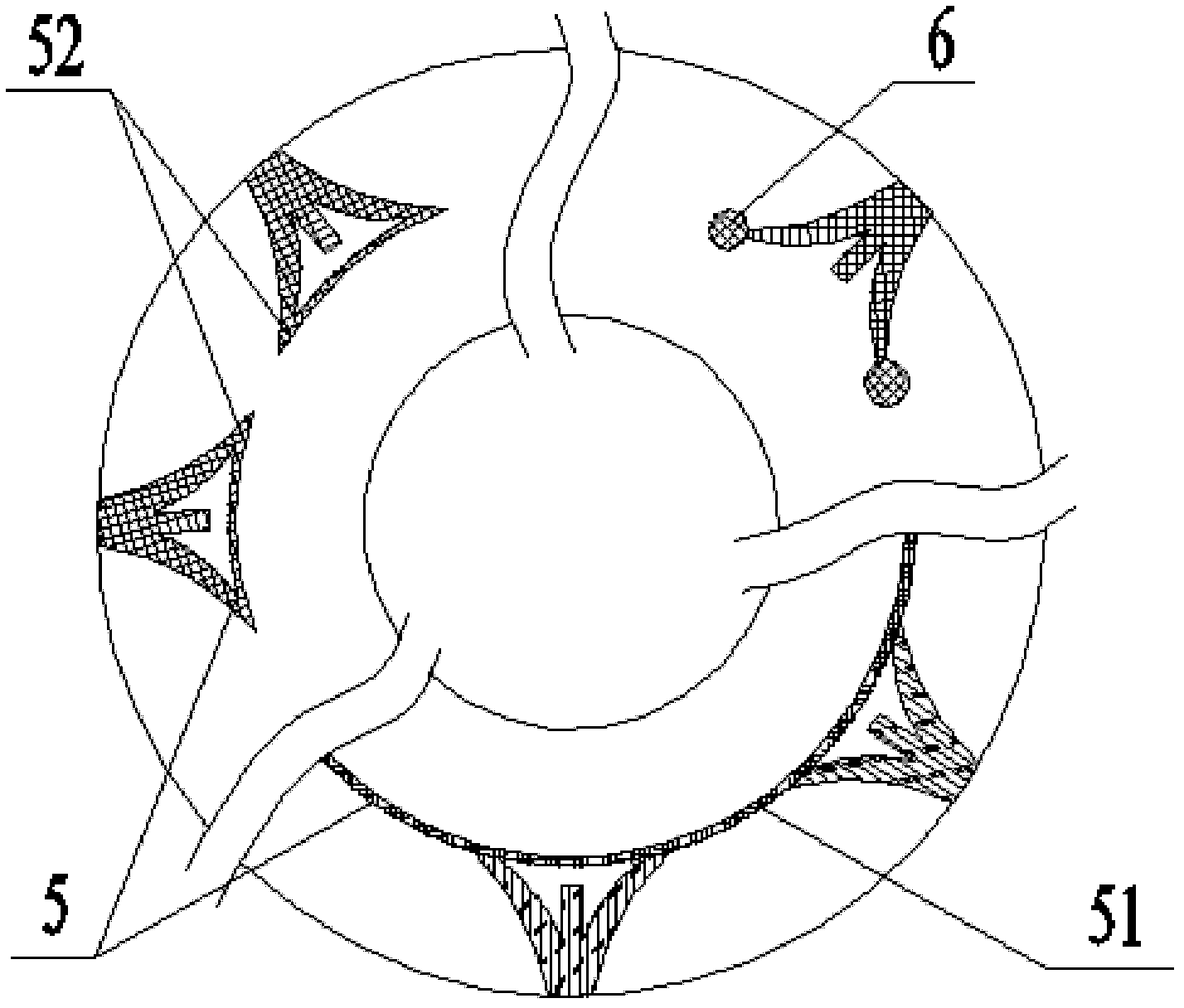

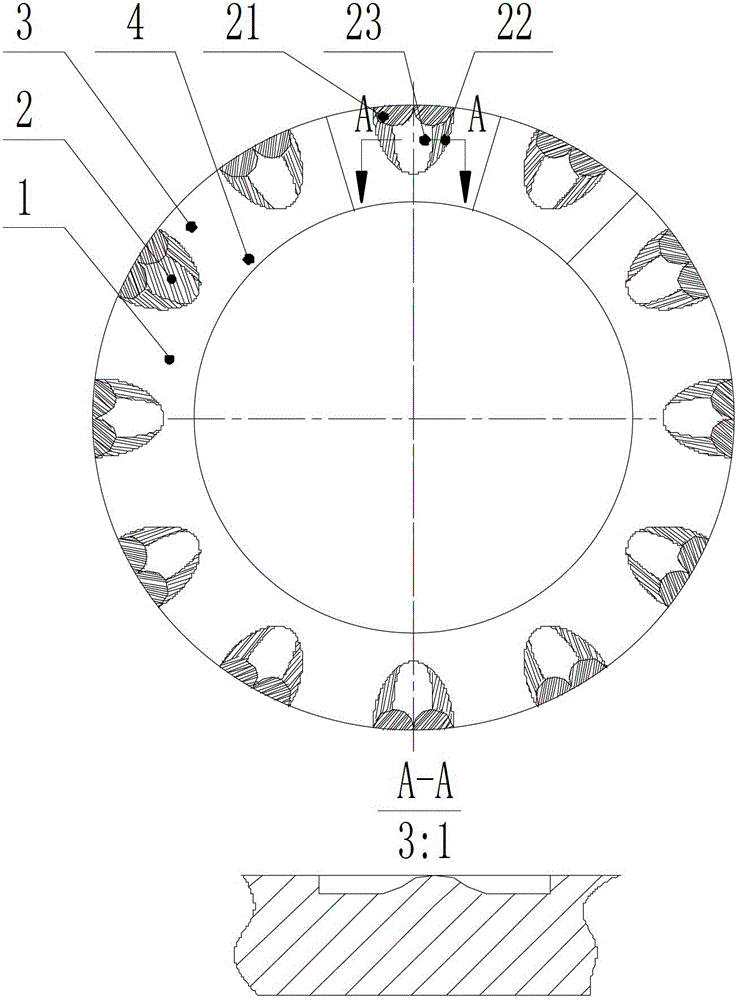

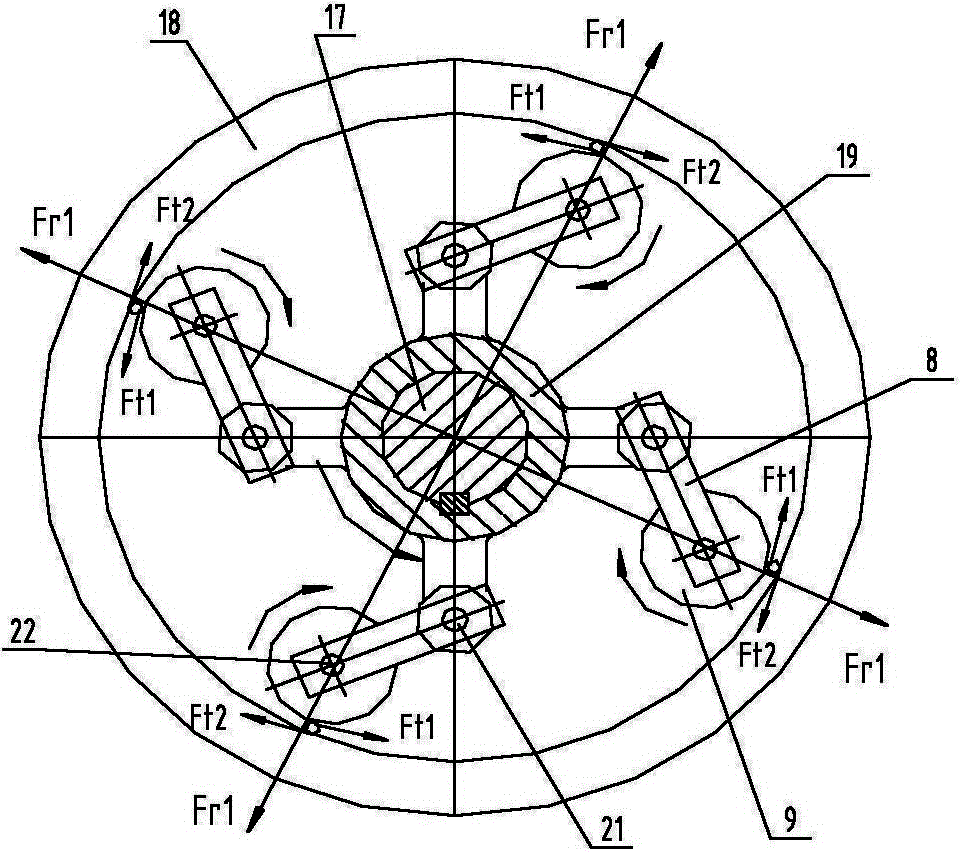

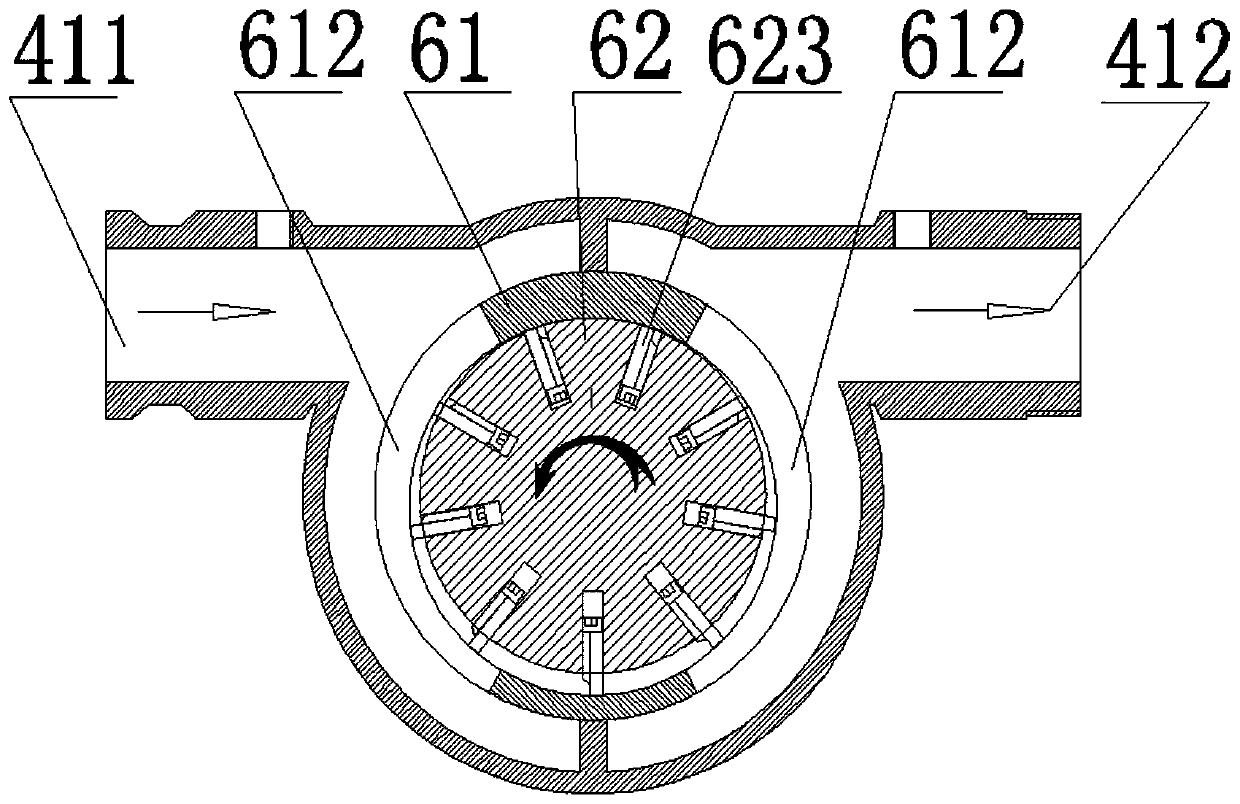

Mechanical sealing structure with flower and plant simulating fluid type groove end surfaces

The invention discloses a mechanical sealing structure with flower and plant simulating fluid type groove end surfaces. The mechanical sealing structure comprises a mechanical sealing movable ring and a mechanical sealing stationary ring; one sides of the end surfaces of the movable ring and the stationary ring are high-pressure sides, i.e. advanced positions; the other sides of the end surfaces of the movable ring and the stationary ring are low-pressure sides, i.e. backward positions; the backward positions of the end surfaces are provided with circular sealing dams with smooth flat surfaces; the mechanical sealing structure is characterized in that a plurality of fluid type grooves, which are uniformly distributed along the circumference direction, are formed by drainage grooves, left profiled grooves and right profiled grooves centering around the drainage grooves and take the shape of flowers and plants in appearance, are arranged on at least one of the end surfaces of the movable ring and the stationary ring, the drainage grooves are radial grooves; the fluid type grooves are distributed on an annular belt in accordance with the centers of the end surfaces, the circular belt is arranged at the advanced positions of the end surfaces; and no slotting regions between the flower and plant simulating fluid type grooves form a sealing weir. The mechanical sealing structure has better fluid guiding effect; the pressures of the root regions of the fluid type grooves are higher and more uniformly distributed; and the bearing capacity of a seal and the rigidity of a fluid membrane are increased.

Owner:ZHEJIANG UNIV OF TECH

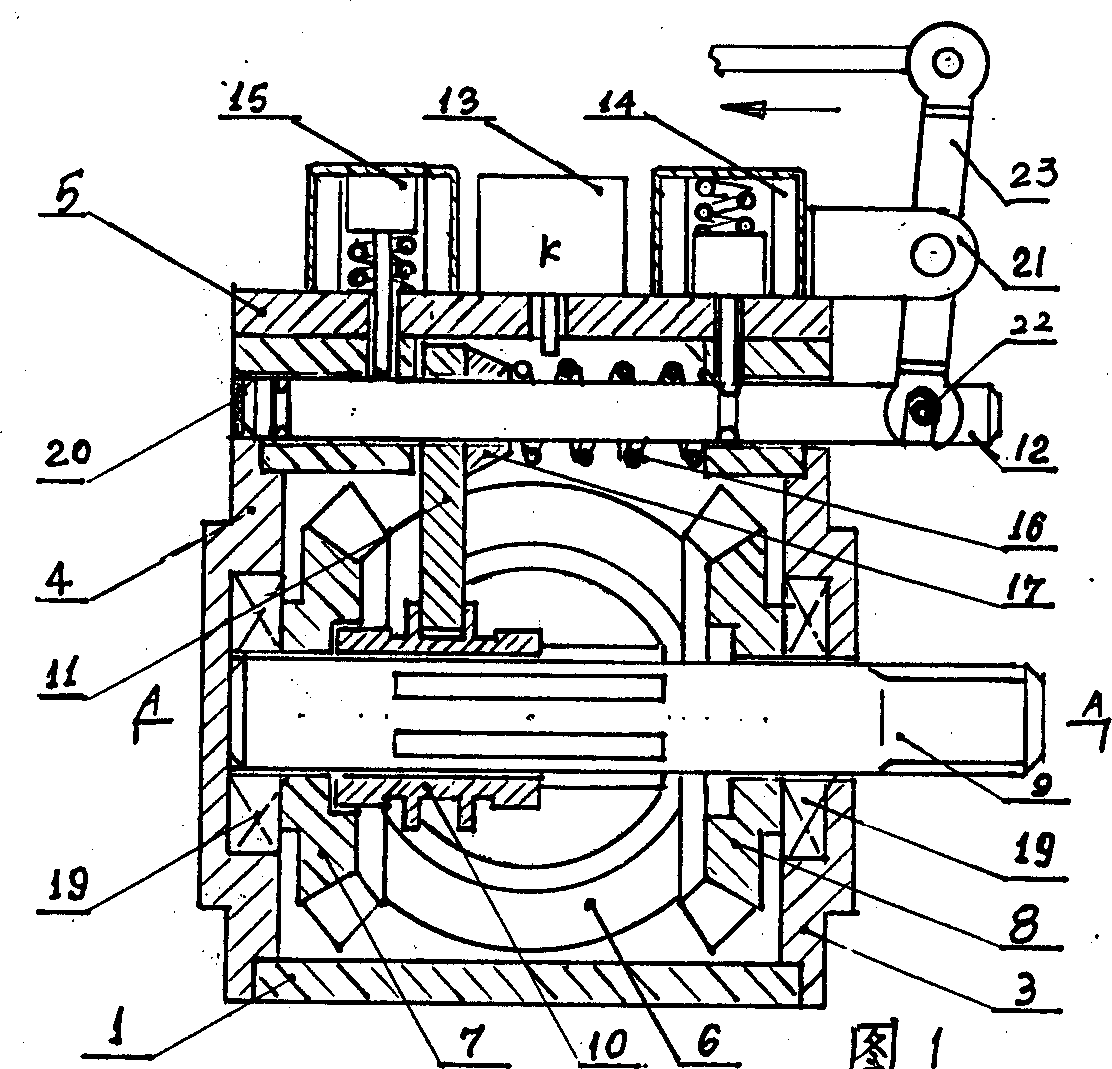

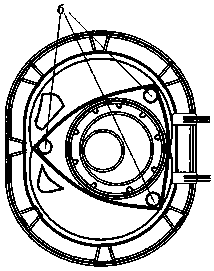

Top end sealing and lubricating device of rotary engine

ActiveCN106224121AReduce air leakageAvoid dry grindingSealing arrangements for enginesLubricant conduit arrangementsHigh pressureOil film

The invention discloses an upper end sealing and lubricating device for a rotary engine. The top end sealing and lubricating device at least comprises a high pressure lubricating oil pump, an oil conveying pipe, a high pressure spraying nozzle, a lubricating oil spraying hole, an oil return pipe, an axial oil pipe, a radial oil pipe, an top end sealing fin, a corner sealing strip, an top end sealing groove and a side shell. The lubricating oil spraying hole is formed in the side shell of the engine; and the high pressure spraying nozzle is installed in the lubricating oil spraying hole. The top end sealing fin comprises three sealing fins; the two sealing fins on the outer side are the rigid sealing fins; and the middle sealing fin is the flexible sealing fin. When the engine is at work, the top end sealing fin radially extrudes a profile of an air cylinder to form a sealed working face. Sucked lubricating oil is sprayed into the axial oil pipe through the high pressure spraying nozzle at high speed after being pressurized by the high pressure oil pump; and the lubricating oil enters the radial oil pipe through the centrifugal force and finally forms a continuous even lubricating oil film on the contact surface of the top end sealing fin and the profile of the air cylinder. The lubricating oil in the axial oil pipe diffuses outward into the gap between the end face of a rotor and the inner wall of the side shell from bilateral pipe mouths to be in action of lubricating a side sealing face.

Owner:上海洲跃生物科技有限公司

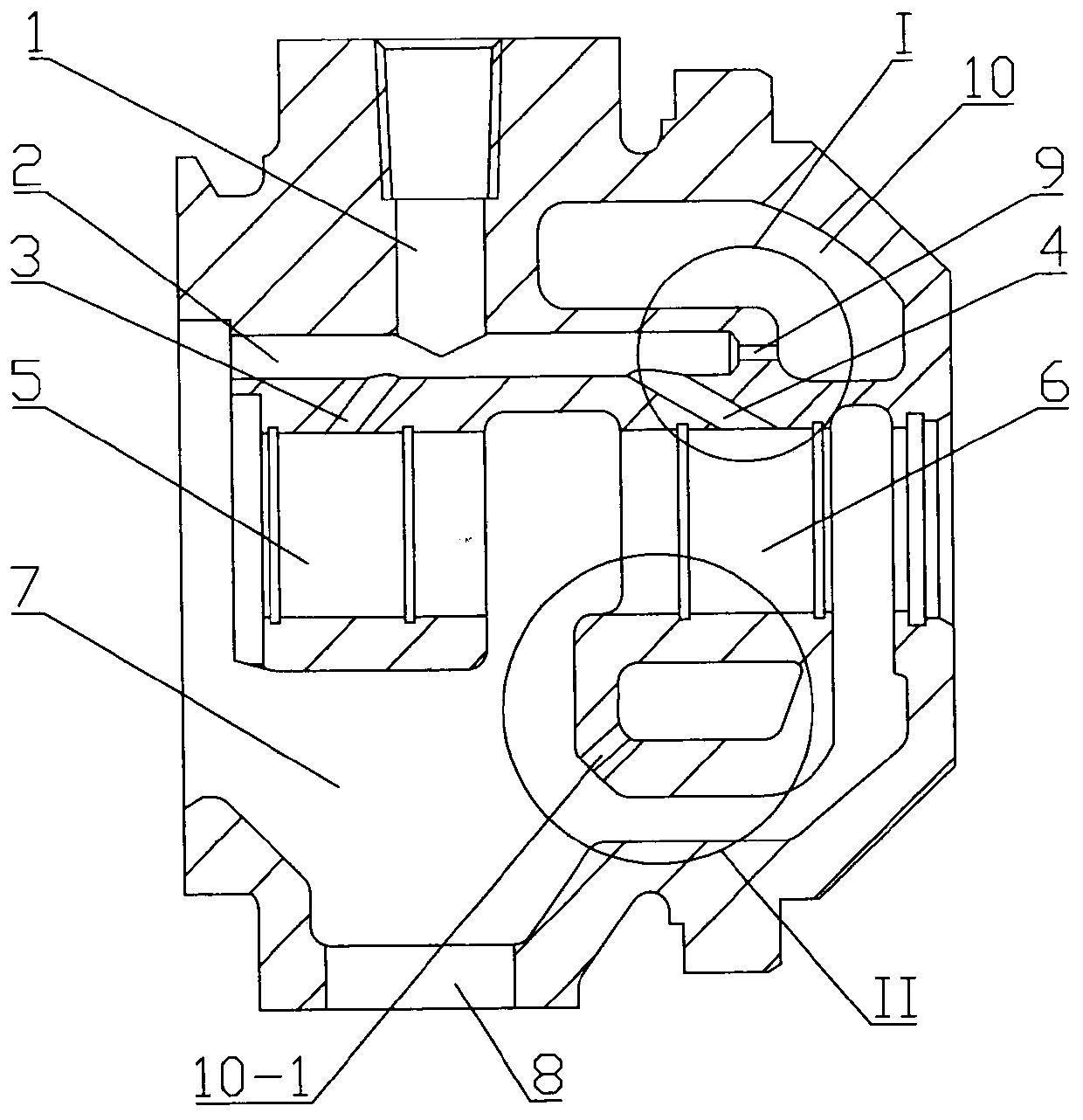

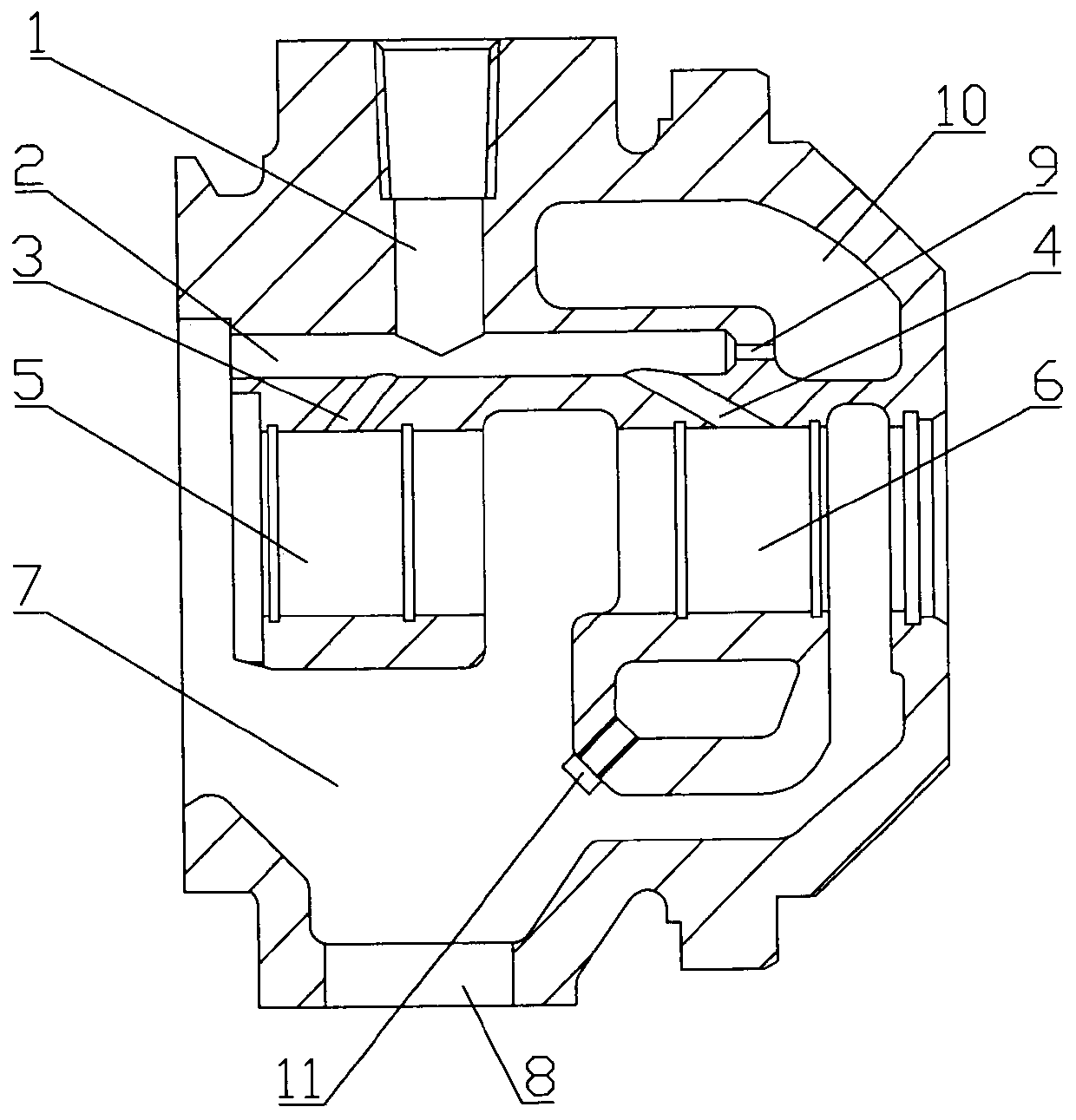

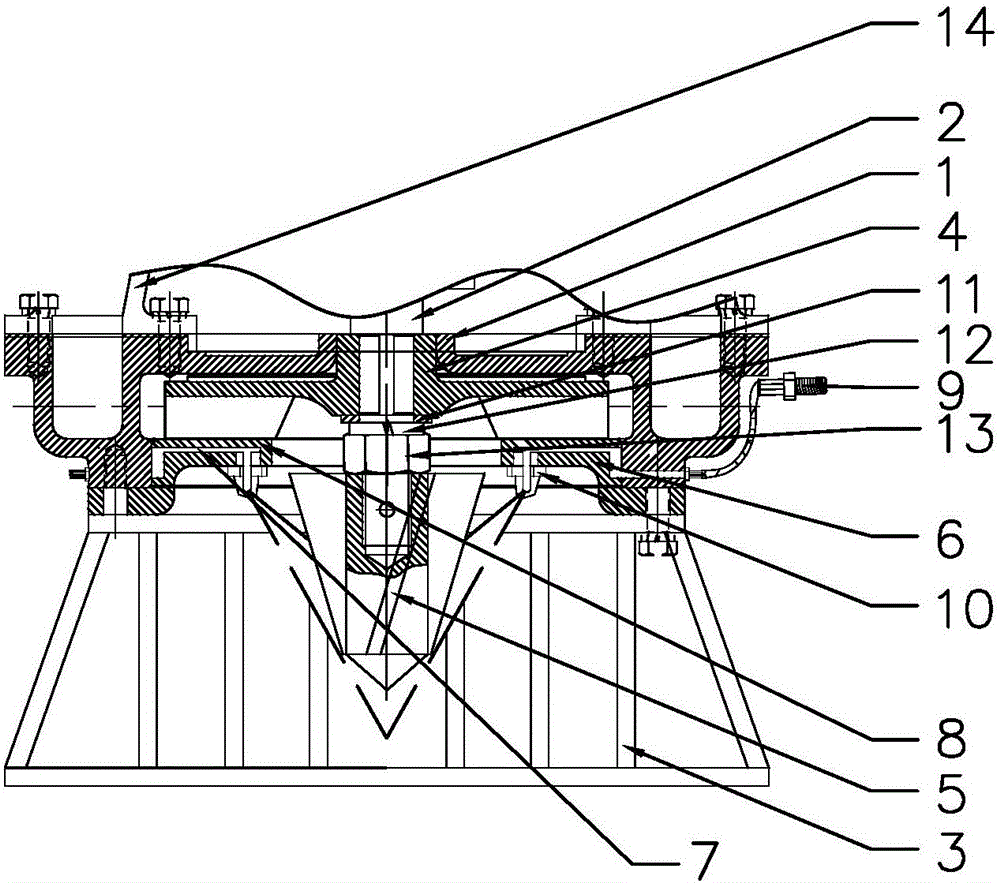

Self-forcing cooling high-temperature resisting mechanical sealing device

The invention relates to a self-forcing cooling high-temperature resisting mechanical sealing device. A movable ring, a static ring seat and a heat insulation ring of the sealing device are mounted ona rotating shaft in a sleeving mode; a flow guiding groove is formed in the movable ring; an annular shell is mounted on the heat insulation ring and the static ring seat in a sleeving mode, one sideof the annular shell and the heat insulation ring are fixed and sealed, a liquid medium annular inlet is formed by the inner wall of the other side of the annular shell and the surface of the outer circle of the static ring seat, an annular membrane piece group is mounted on the heat insulation ring in a sleeving mode, a gap is formed between the annular membrane piece group and the outer ring wall of the heat insulation ring, and the outer edges of the two sides of the annular membrane piece group and the static ring seat as well as the heat insulation ring are subjected to full-length welding in the circumferential direction, so that a cavity is formed between the annular shell and the annular membrane piece group; a small hole communicating with the cavity is formed in the outer wall of the annular shell; and a cooling channel is formed by the liquid medium annular inlet, the cavity and the small hole. The problems that unstable work, leakage of a sealing face and even sealing failure of mechanical seal occur due to the fact that vaporization appears on a liquid medium are solved by arranging the flow guiding groove and the cooling channel.

Owner:XIAN AEROSPACE PROPULSION INST

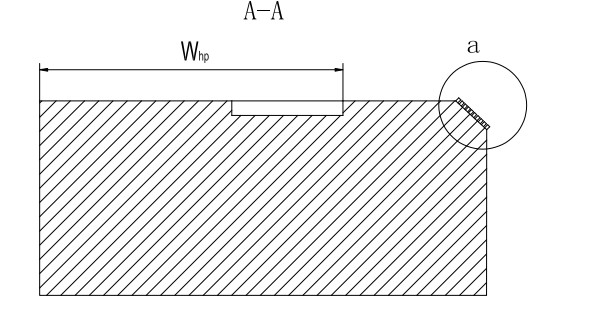

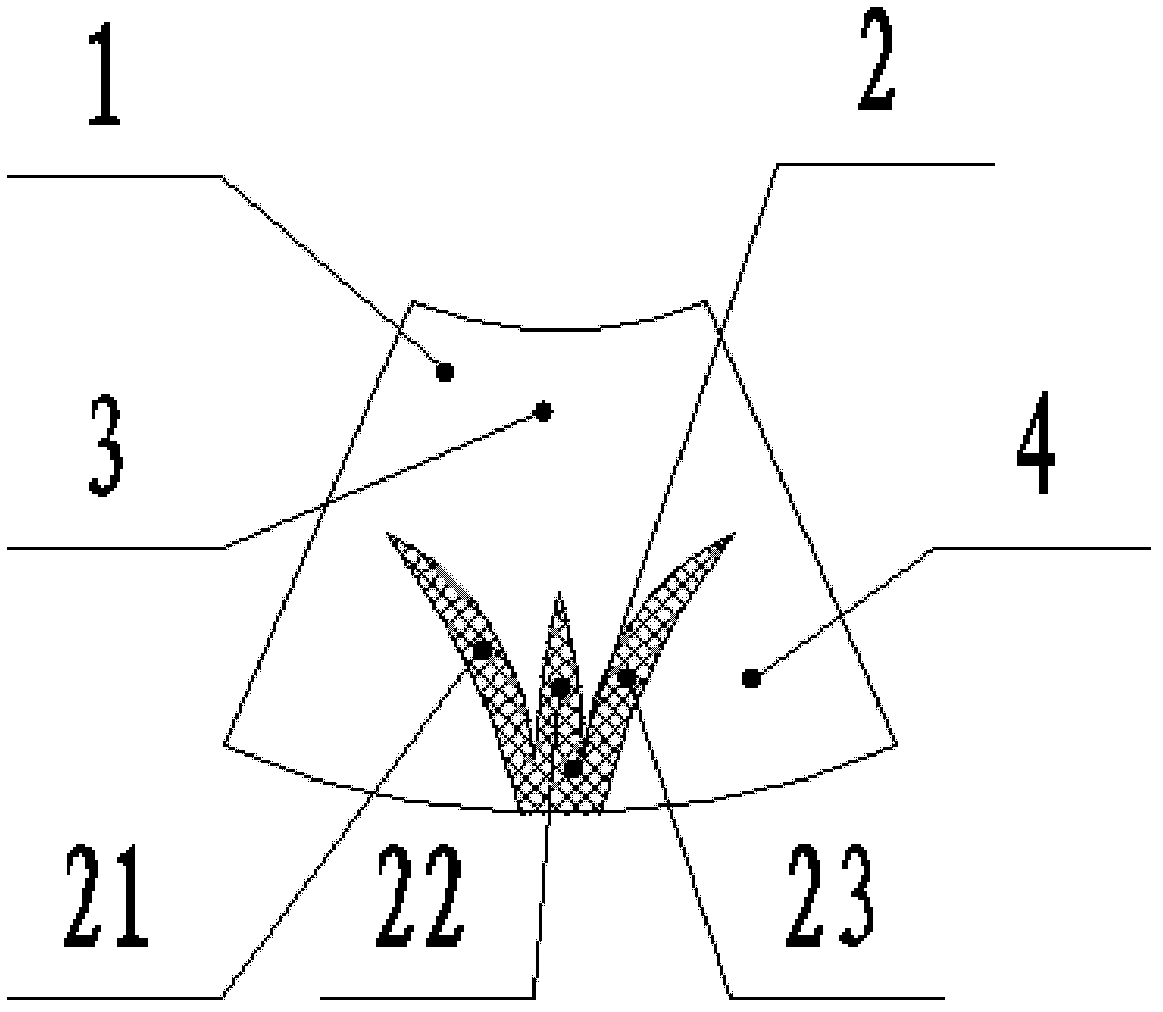

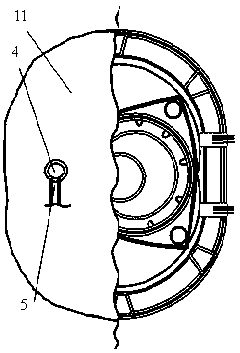

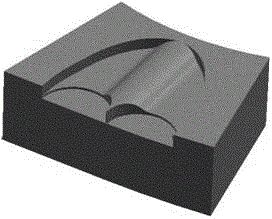

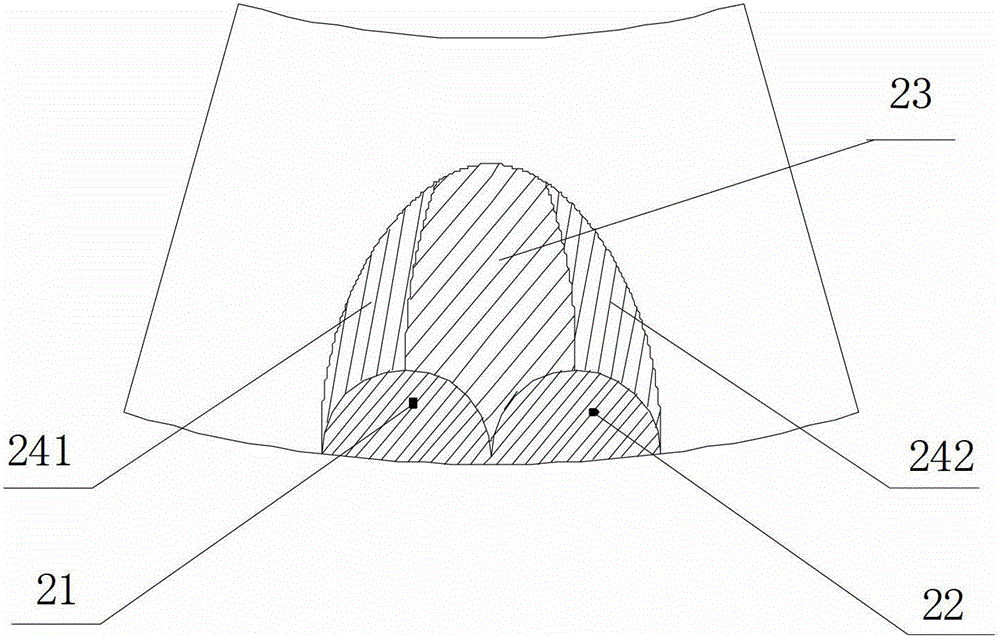

Imitation shark skin streamlined groove end face mechanical seal structure

ActiveCN103122998BImprove the lubrication effectUniform pressure distributionEngine sealsHigh pressureEnd face mechanical seal

Disclosed is a streamline groove end face mechanical sealing structure imitating a creased appearance of the surface of sharkskin. The streamline groove end face mechanical sealing structure comprises two mechanical sealing rings, namely a moving ring and a static ring, plural groups of streamline grooves imitating the creased appearance of the surface of the sharkskin and arranged along the peripheral direction are arranged at least one end face of the sealing rings of the moving ring and the static ring. Each biomimetic groove comprises a left circular groove and a right circular groove, a convex platform along the pressure drop direction in the groove and transitional parts between two sides of the convex platform and an outer contour line of the groove, so that the streamline grooves, namely sharkskin imitation streamline grooves, with the appearance imitating the creased surface of the sharkskin are formed. The sharkskin imitation streamline grooves are arranged on a high pressure side of an end face medium, namely an upper stream. The whole outlines of the sharkskin imitation streamline grooves are in a contracting shape along the pressure drop direction. The sharkskin imitation streamline grooves are arranged to form a groove annular belt along the circumference of the end face, and a plane annular belt area without grooves on the outer end face other than the groove annular belt is a sealing dam.

Owner:ZHEJIANG UNIV OF TECH

Turbocharger bearing body assembly

PendingCN107869364AReduce the temperatureGuaranteed operating conditionsMachines/enginesEngine componentsTurbochargerOil cooling

The invention relates to a turbocharger bearing body assembly. A bearing body is provided with an oil inlet hole, a main oil guide hole, an air-pressure-end oil guide inclined hole, a turbine-end oilguide inclined hole, an air-pressure-end floating bearing hole, a turbine-end floating bearing hole, a main oil chamber and an oil outlet hole. An independent cooling oil cavity is arranged at the turbine end of the bearing body, and penetrates through the upper and lower structures of the turbine end of the bearing body. An oil injection hole is arranged at the turbine end of the main oil guide hole, and communicates with the independent cooling oil cavity. A lubricating oil pressure relief hole is arranged at the bottom, near the oil outlet hole, of the independent cooling oil cavity, and communicates with the main oil chamber to facilitate the timely discharge of lubricating oil in the cooling oil cavity to the main oil chamber.

Owner:HUNAN TYEN MACHINERY

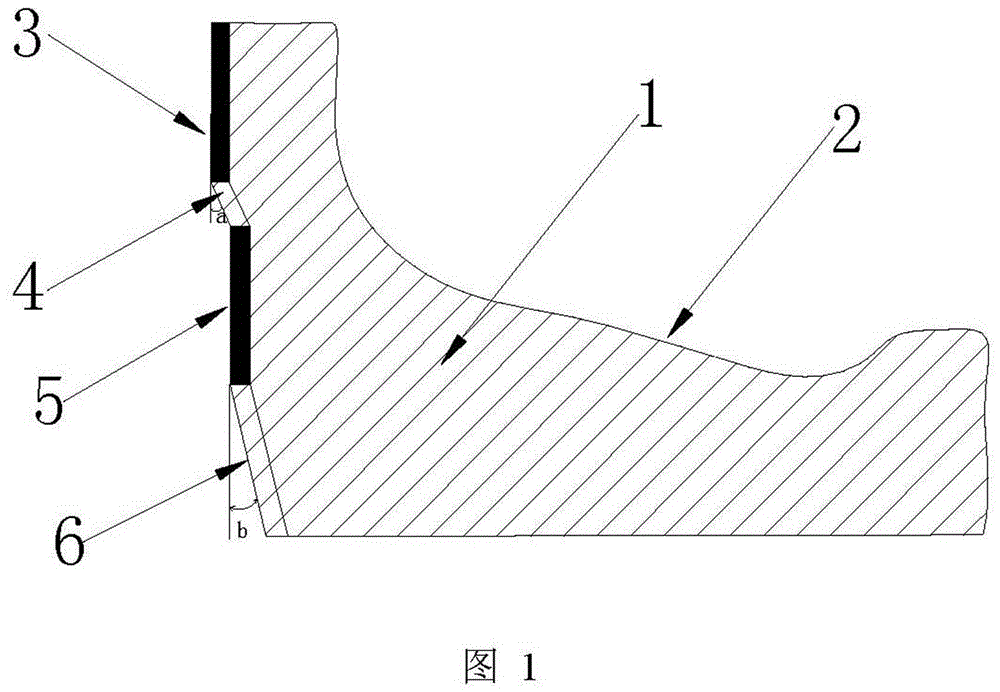

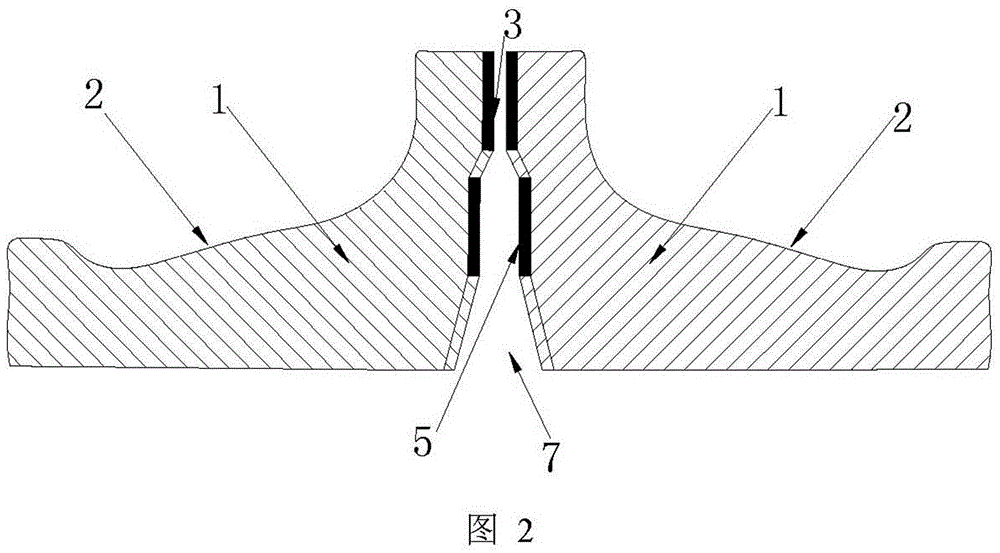

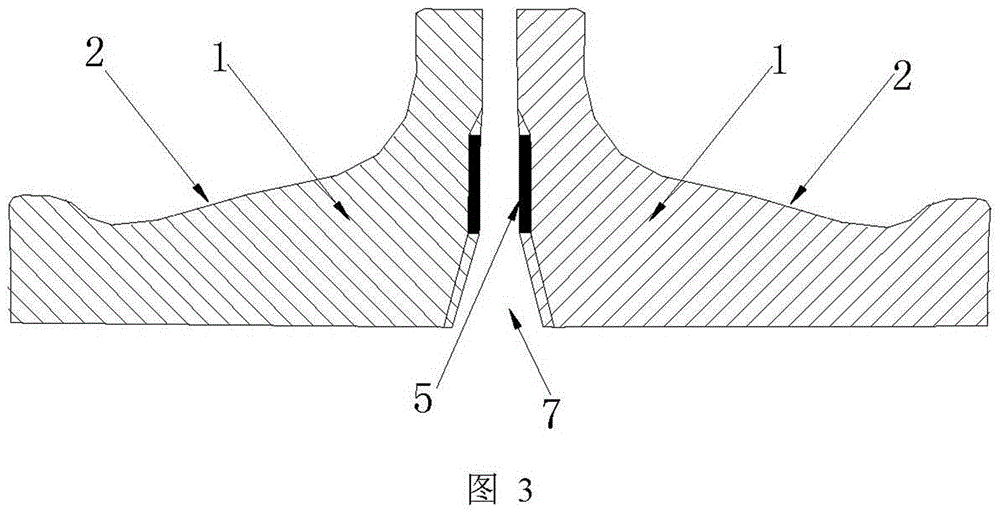

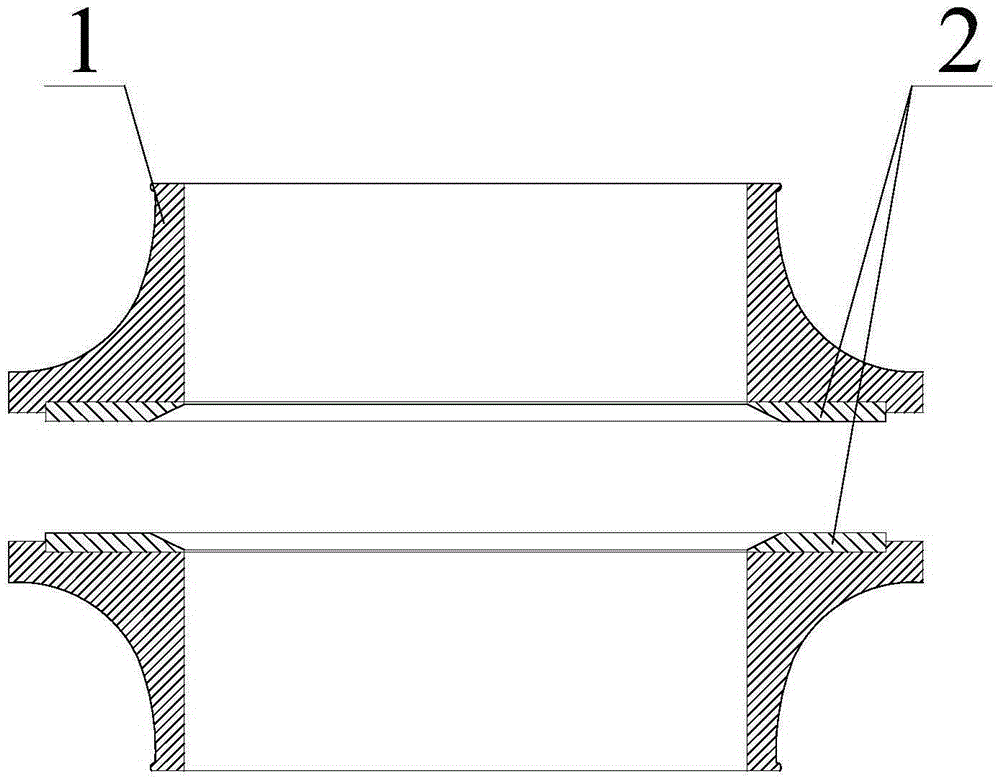

Super wear-resisting floating oil seal ring and producing and machining method thereof

The invention provides a super wear-resisting floating oil seal ring and a producing and machining method thereof. According to the super wear-resisting floating oil seal ring, a first working surface of an oil seal ring body is provided with a first circle of metal wear-resisting layer, the lower portion of the first circle of metal wear-resisting layer is provided with a first slope, the included angle between the first slope and the first circle of working surface is a, a second circle of working surface is arranged under the first slope and provided with a second circle of metal wear-resisting layer, a second slope is formed under the second circle of metal wear-resisting layer, and the included angle between the second slope and the second circle of working surface is b. The friction contact surface of the floating oil sealing ring is machined into the two stepped metal wear-resisting layers, so that the service life of the floating oil seal ring is doubled. During producing and machining, the metal wear-resisting layers are machined through a quenching process or a flame spraying process so that the hardness of the wear-resisting layers can be effectively improved, and the service life of the floating oil seal ring is further prolonged.

Owner:WUHAN XINHUAFENG MASCH MFG CO LTD

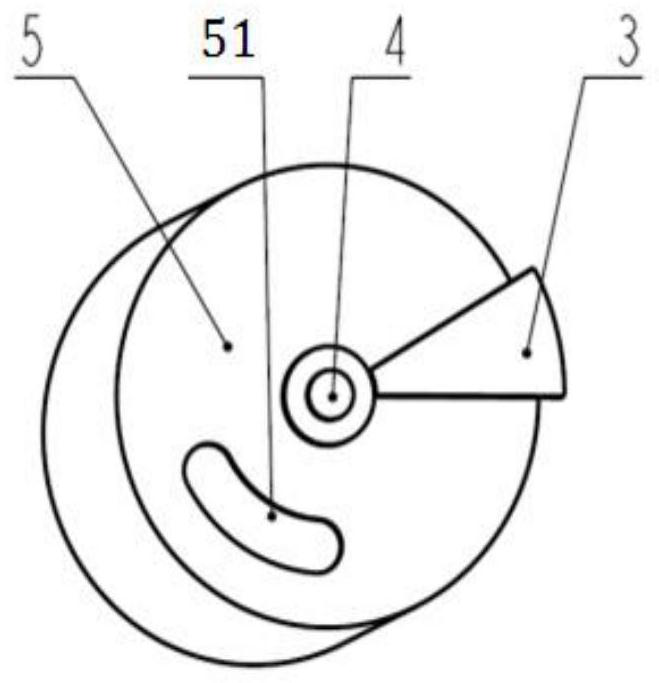

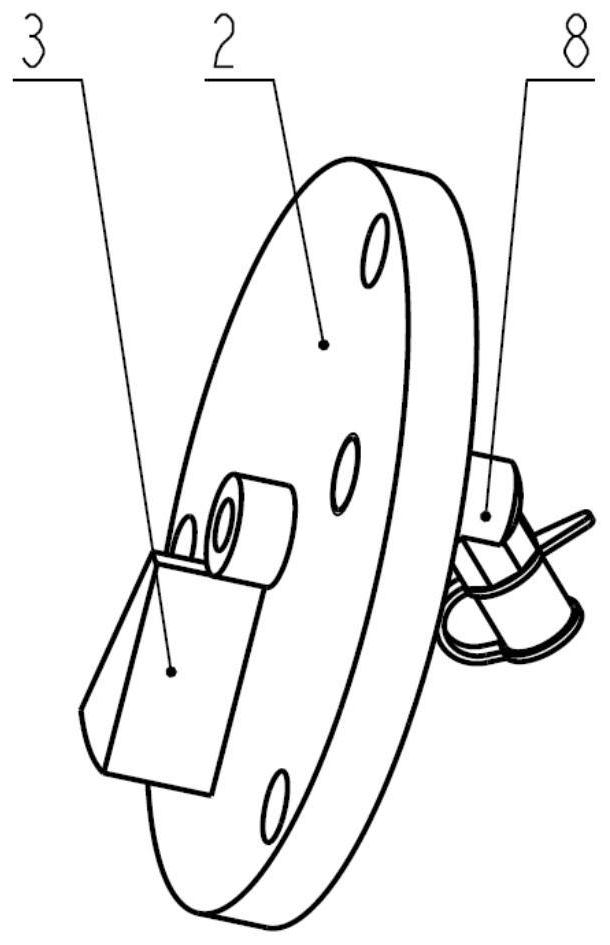

Stirring, cutting and breaking device of slurry pump

The invention relates to a centrifugal fluid conveying pump, in particular to a stirring, cutting and breaking device of a slurry pump. The slurry pump comprises a pump body, a pump shaft and a pump base. An impeller and a stirring and breaking device are sequentially arranged on the pump shaft. The pump body and the pump base are fixedly connected through a front end cover. At least one cleaning water channel is correspondingly arranged at the lower end of the pump body and the upper end of the front end cover. Sealing rings corresponding to the cleaning water channels are arranged between the pump body and the front end cover. Water inlets of the cleaning water channels are connected with a water inlet pipe. Water outlets of the cleaning water channels are connected with high-pressure nozzles. The high-pressure nozzles correspond to the stirring and breaking device. According to the stirring, cutting and breaking device, locked rotating and dry grinding of the slurry pump can be effectively avoided, and the service life of equipment can be prolonged; and the impeller and the stirring and breaking device can cut and break various impurities, including solids, long and soft fibers and the like, contained in sewage, and the phenomena of difficult starting, overloading and dry grinding of the device are eradicated.

Owner:山东汉菩农业科技有限公司

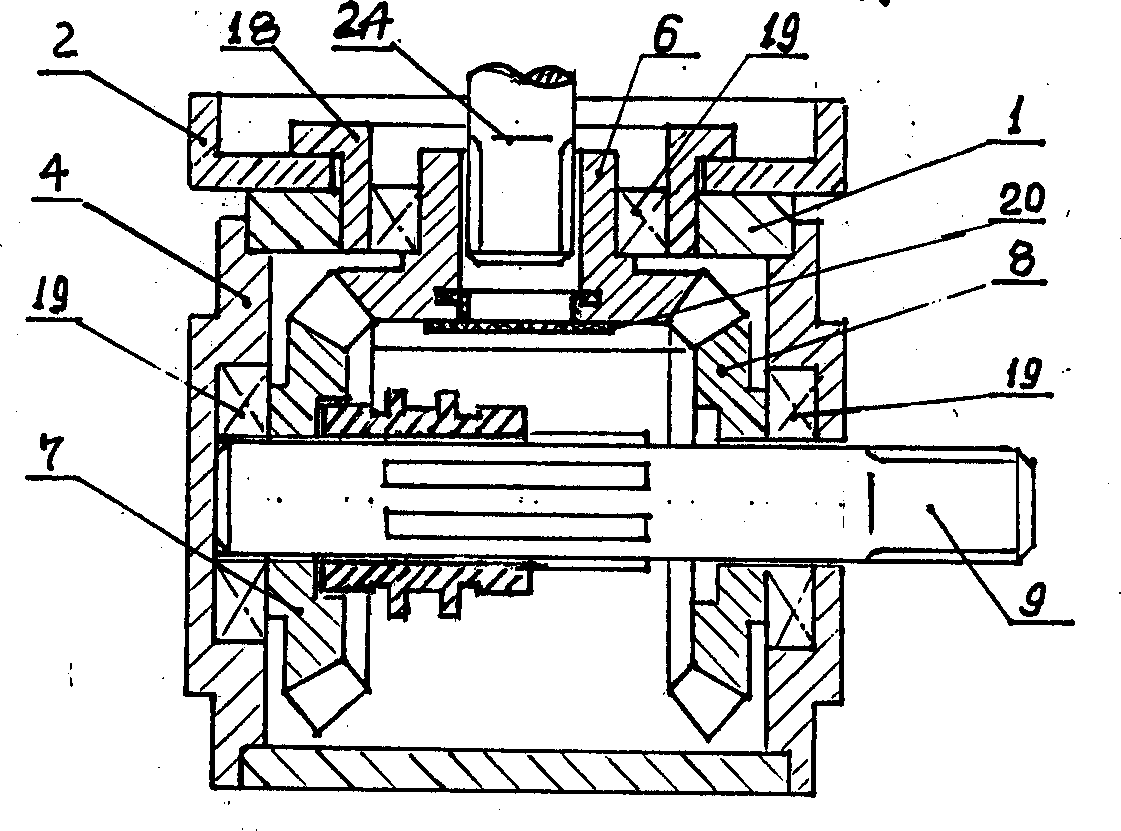

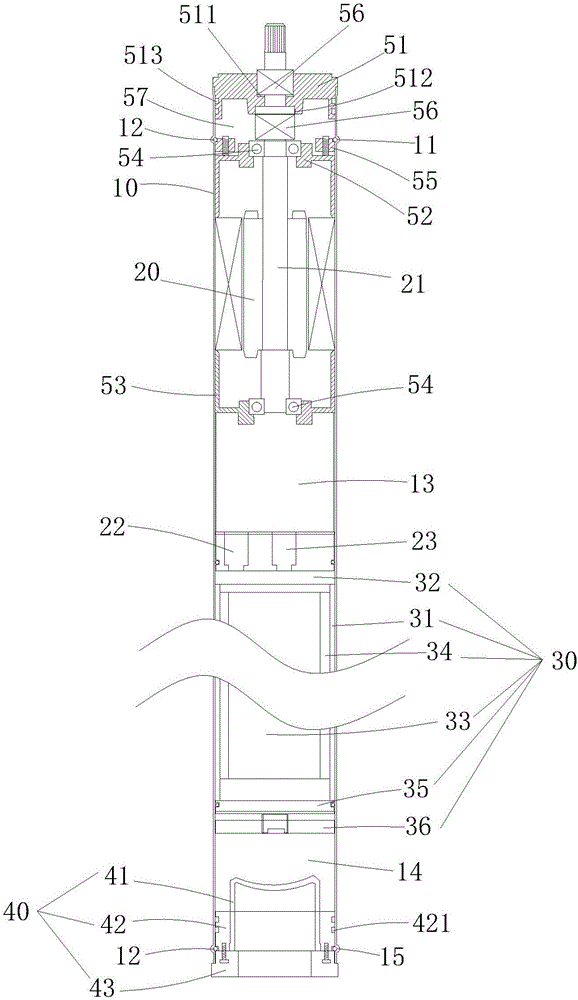

Intelligent submersible motor with built-in controller

PendingCN106533026AReduce depthAvoid Dry GrindingAssociation with control/drive circuitsSupports/enclosures/casingsFrequency conversionEngineering

The invention discloses an intelligent submersible motor with a built-in controller. A brushless direct current fixed / rotor assembly, a frequency conversion sealing device, a base sealing assembly and an end cap sealing assembly are arranged in the motor body. The frequency conversion sealing device matches the brushless direct current fixed / rotor assembly and the base sealing assembly. The end cap sealing assembly is provided with a shaft hole used for positioning a rotation shaft, and comprises a motor end cap, an upper bearing seat, a lower bearing seat, bearings, a pressing plate and mechanical oil seals. The motor end cap is provided with upper and inside mechanical oil seal grooves. The mechanical oil seals are located in upper and inside mechanical oil seal grooves. The pressing plate abuts against a tension bead ring. Upper and lower bearing seats abut against the end part of the brushless direct current fixed / rotor assembly. The bearings are located in the upper bearing and the lower bearing seat, and are used in conjunction with the rotation shaft. The intelligent submersible motor provided by the invention has the advantages that the sealing effect is good; the concentricity of the rotation shaft of the motor can be effectively guaranteed; heat can be effectively eliminated; and internal and external pressure of the motor can be balanced.

Owner:台州市百施度工贸有限公司

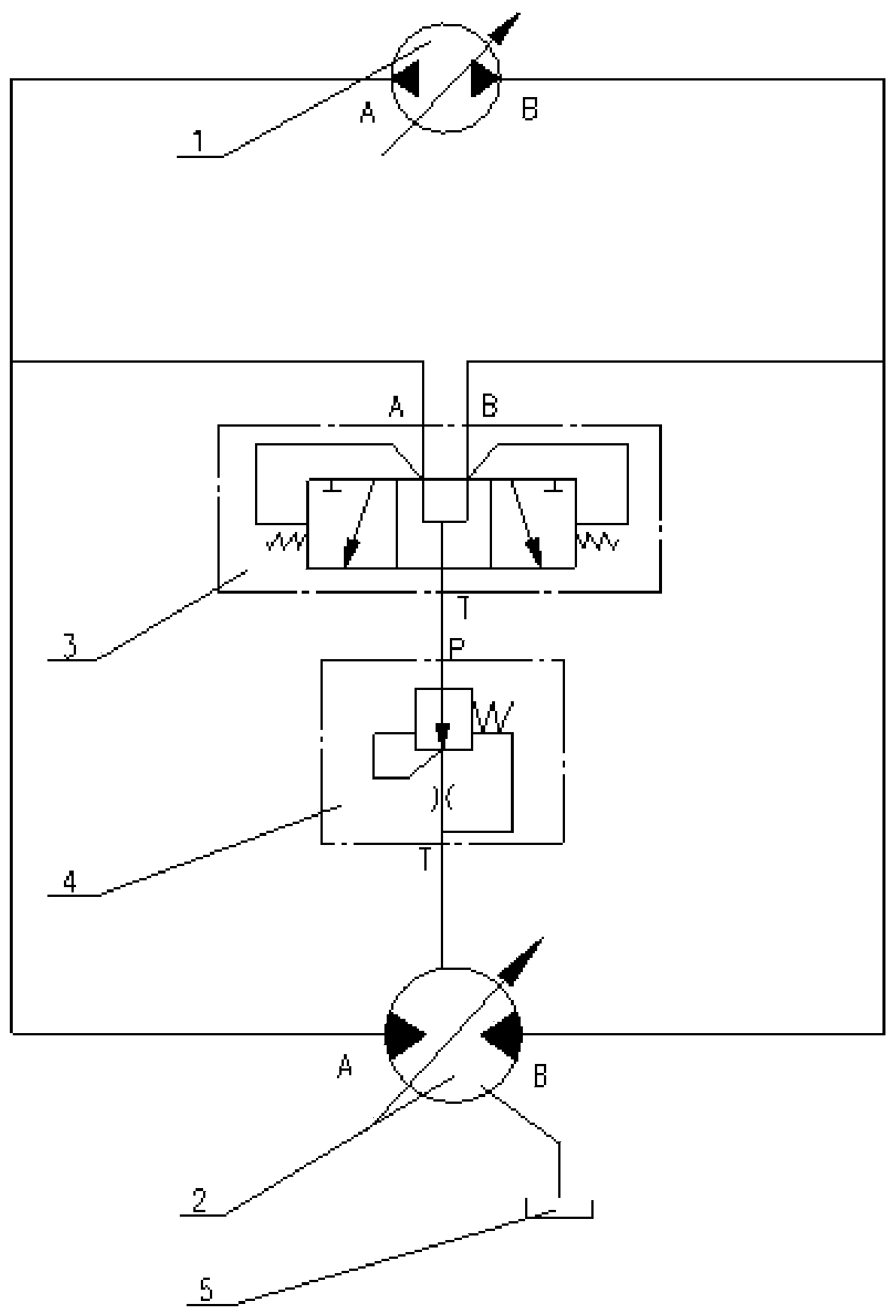

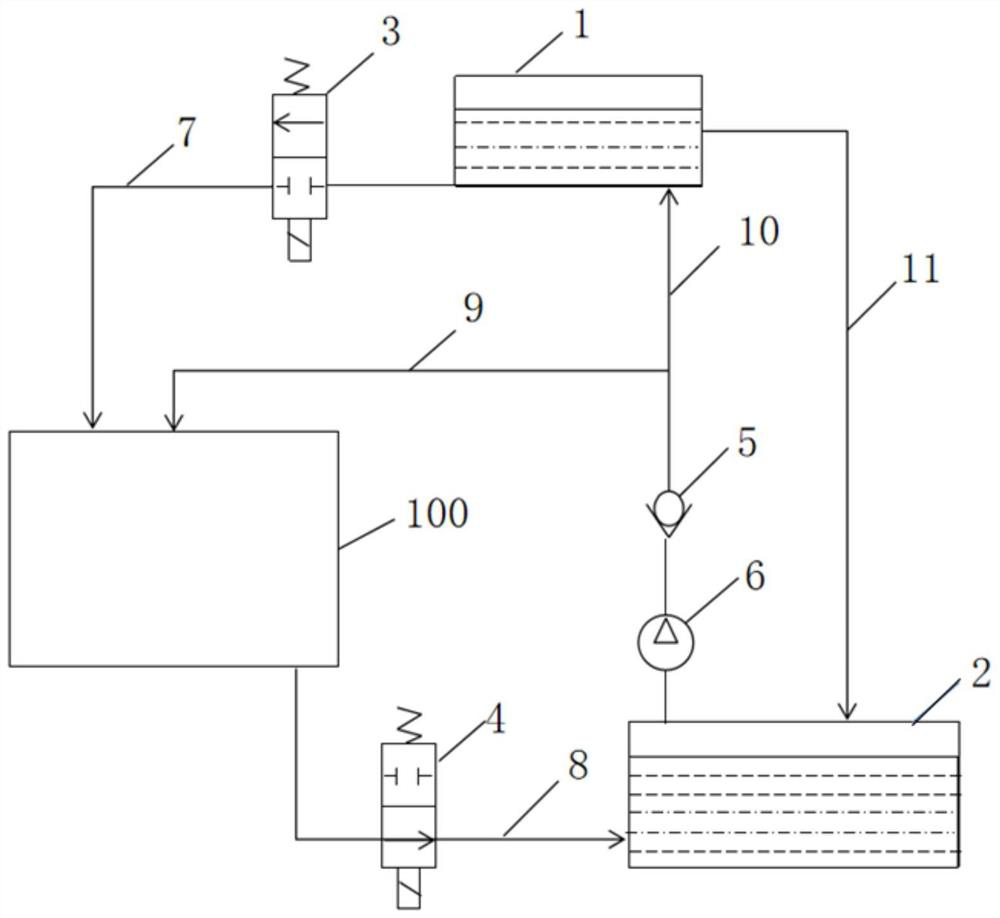

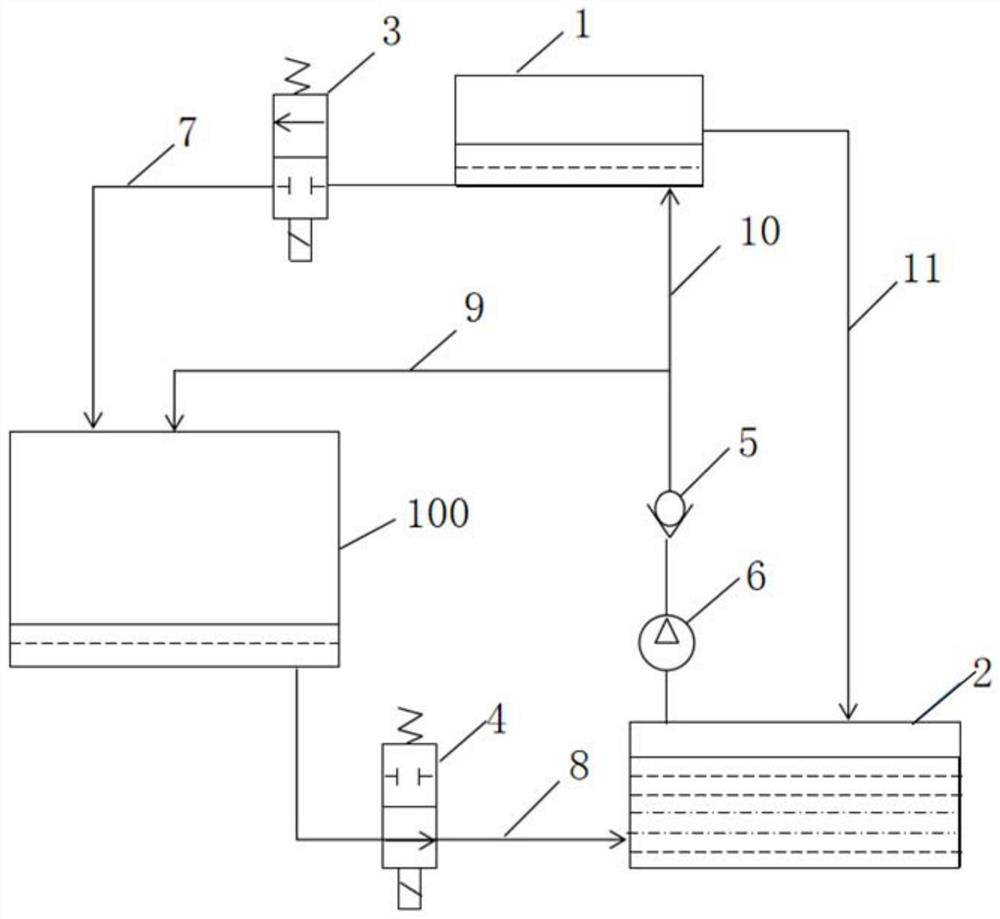

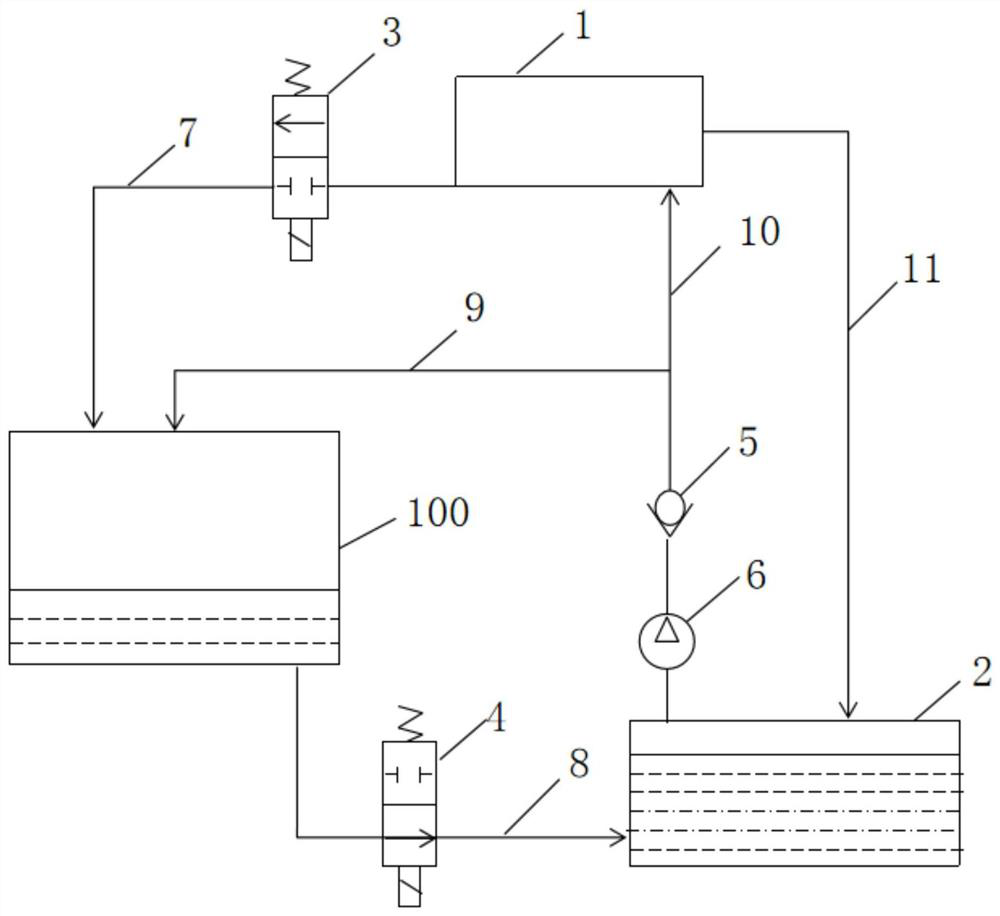

Hydraulic closed type flushing loop

PendingCN110159618AAvoid dry grindingAvoid the disadvantages of not being able to heatFluid-pressure actuator componentsHydraulic motorControl engineering

The invention relates to a hydraulic closed type flushing loop and belongs to the technical field of hydraulic equipment. The hydraulic closed type flushing loop comprises a hydraulic oil pump, a hydraulic motor, a hot oil shuttle valve and a speed adjustment valve. An opening A of the hydraulic oil pump communicates with an opening A of the hydraulic motor and a first oil inlet A of the hot oil shuttle valve. An opening B of the hydraulic oil pump communicates with an opening B of the hydraulic motor and a second oil inlet B of the hot oil shuttle valve. An oil outlet T of the hot oil shuttlevalve communicates with an oil inlet P of the speed adjustment valve. An oil outlet T of the speed adjustment valve communicates with a first oil drainage opening of the hydraulic motor. A second oildrainage opening of the hydraulic motor communicates with a hydraulic oil tank. After a closed type system is started, the nominal flushing flow can be generated no matter whether people operate thesystem or not; when the hydraulic motor is at the high position, part of hydraulic oil enters a shell of the hydraulic motor after start, and dry rubbing is avoided; the defect that heating cannot beconducted after start can be avoided; the flushing flow is forced to be constant through the speed adjustment valve; and the problem that the flushing flow is excessively large when a high-pressure oil opening A and a high-pressure oil opening B are switched rapidly can be avoided.

Owner:无锡市钻通工程机械有限公司

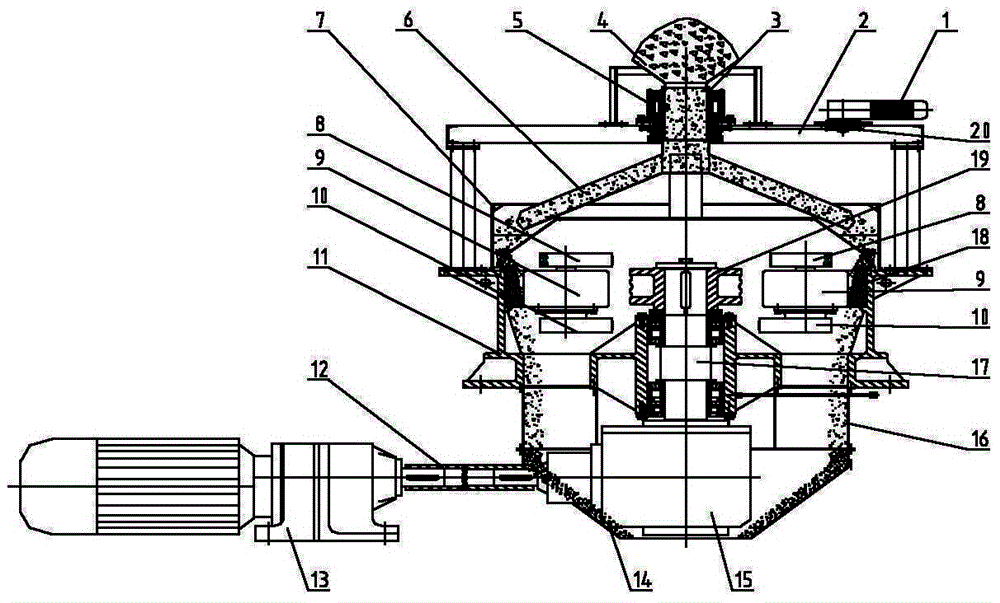

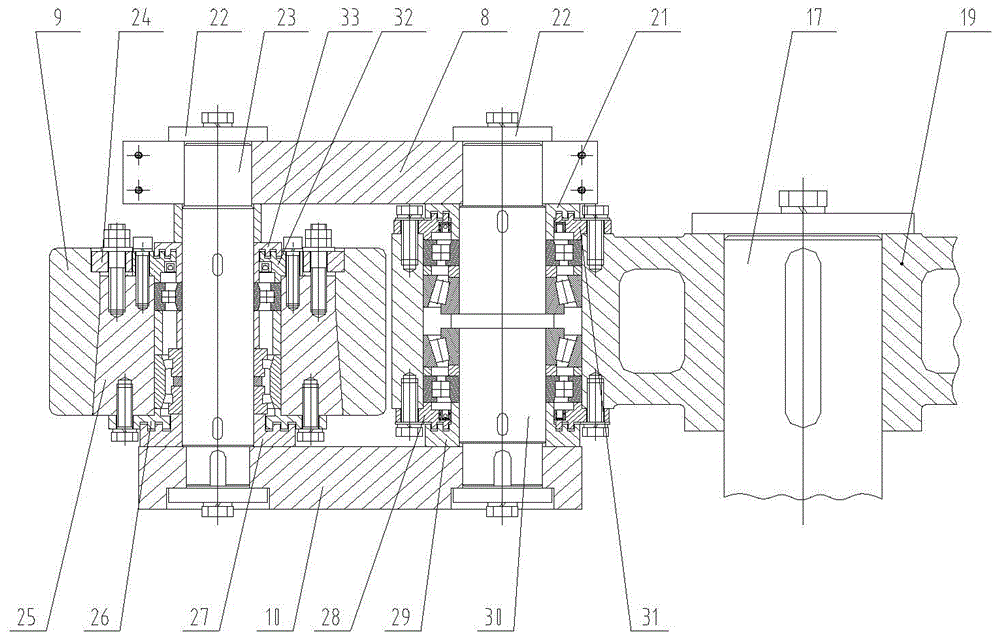

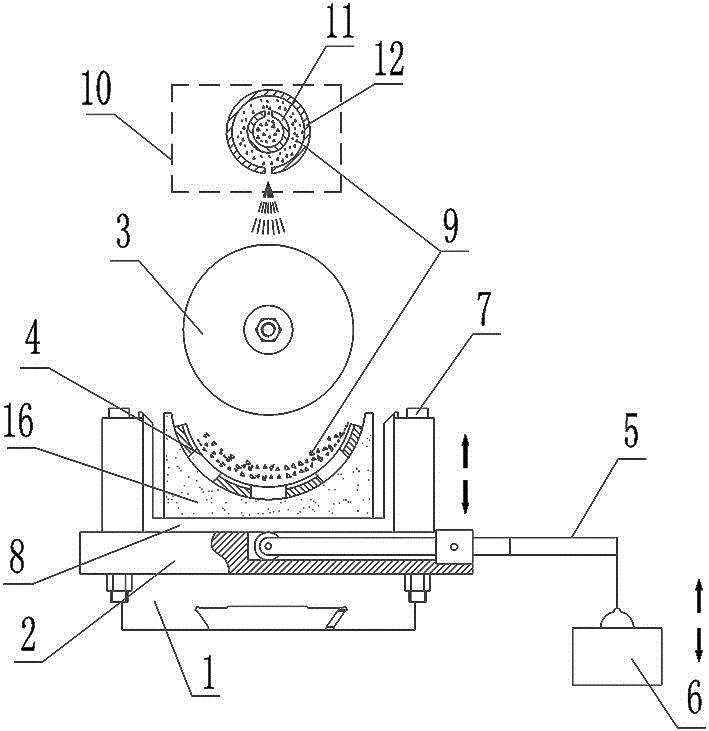

Vertical centrifugal mill

The invention discloses a vertical centrifugal mill, and relates to an energy-saving single-layer vertical centrifugal mill to overcome the defects of existing floating powder grinding machines, planet vertical mills, Raymond mills and other multi-layer annular powder grinding machines. A feeding device rotating at constant speed is arranged on the upper portion of the vertical centrifugal mill. A star-shaped support is arranged on a spindle and provided with four or more roll wheels capable of swinging freely. A commutator is arranged on the lower portion of the spindle and connected with a gear motor through a universal coupler. The vertical centrifugal mill can be suitable for crushing materials of different hardnesses and meanwhile can produce products of different finenesses, sand can be manufactured, and powder can be ground as well. The vertical centrifugal mill has the beneficial effects that even feeding is achieved, and dry grinding of the roll wheels and grinding rings can be avoided; the rotating speed of a feeding hopper is low, so that the impact of materials on a barrel is small, and noise is low; and the speed of the roll wheels can be adjusted, centrifugal force can be adjusted according to the hardness conditions of the materials, and the application range of the products is wide.

Owner:郭怀铭

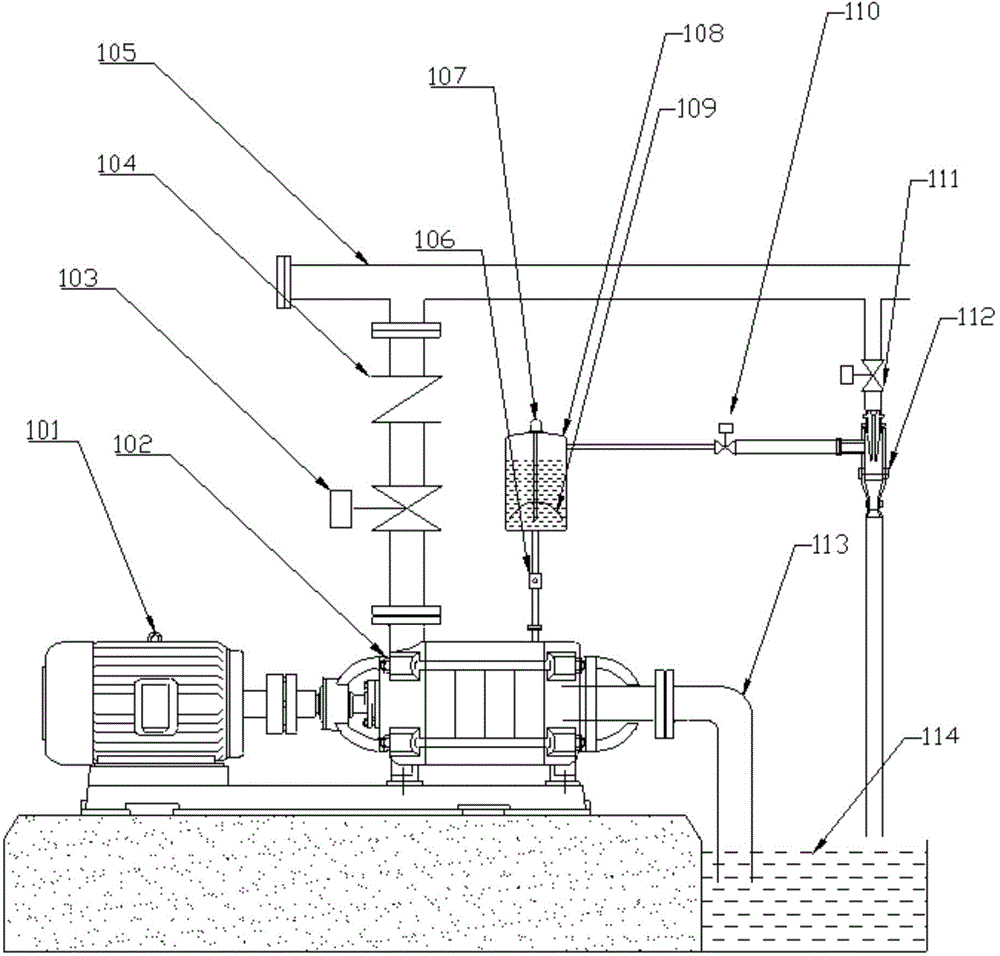

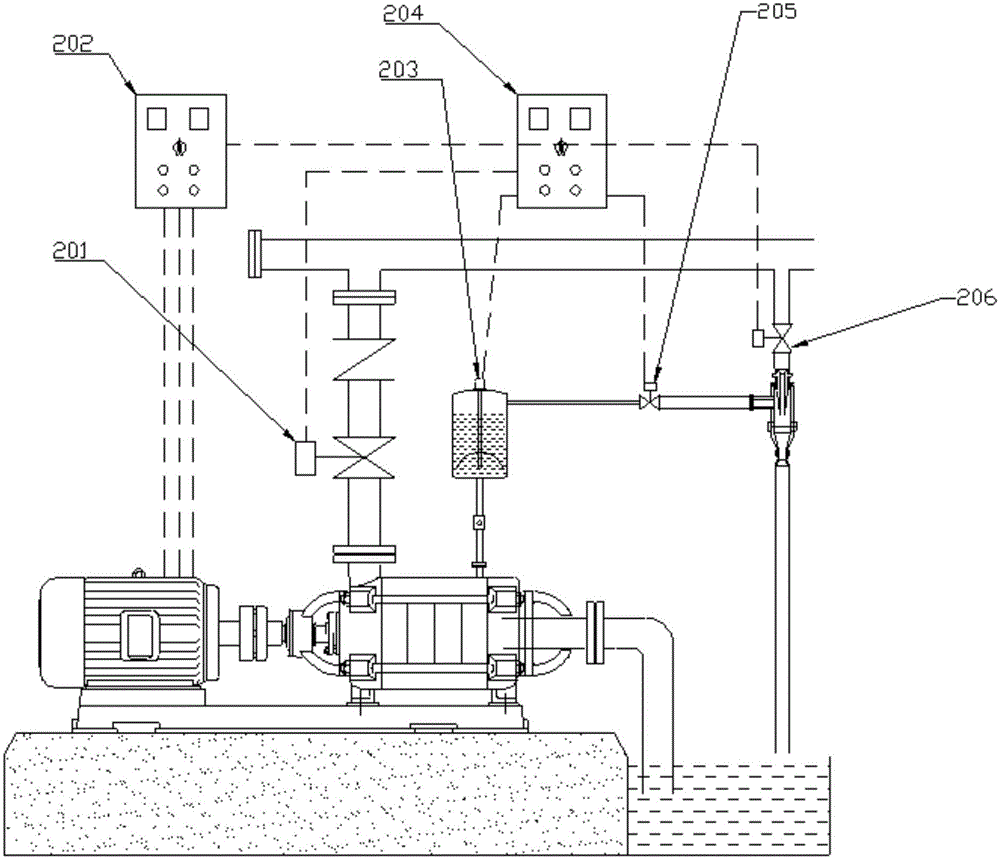

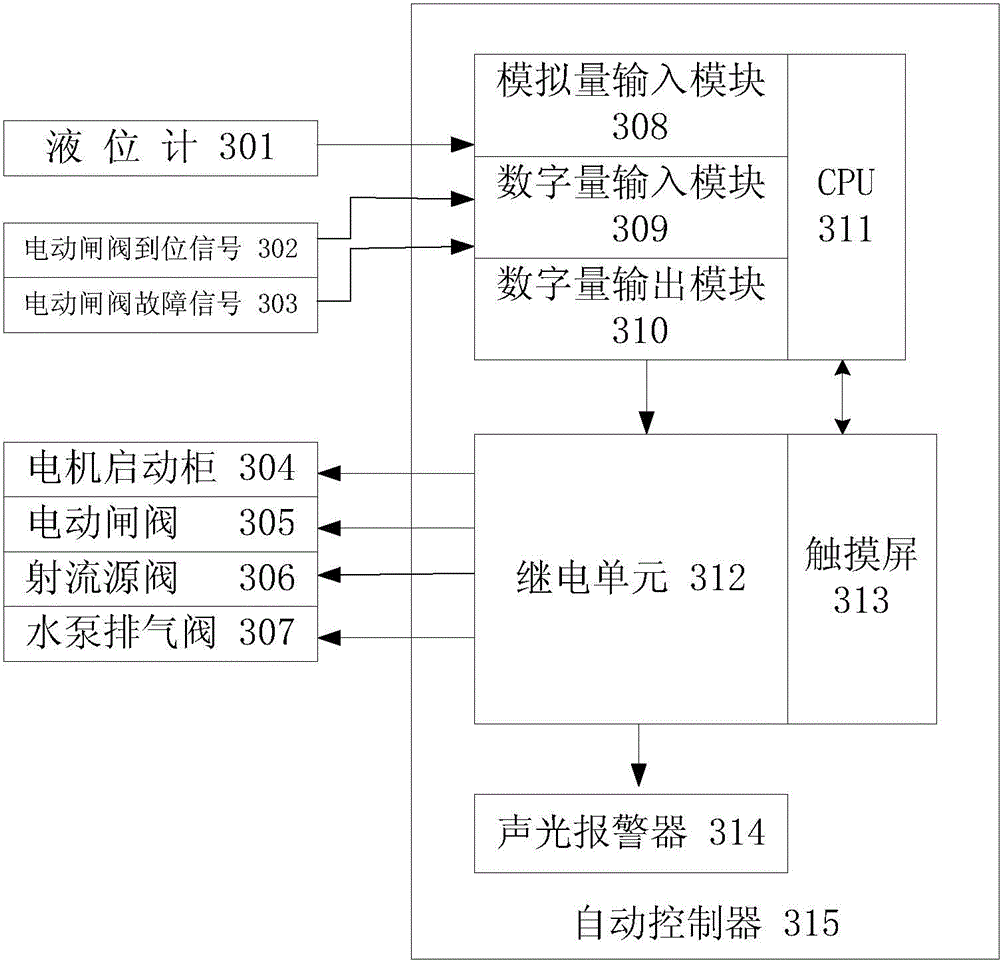

Water and gas separation detection protection device for precisely judging water diversion state of mine draining pump

InactiveCN104912813AAvoid dry pumpingExtended service lifePriming pumpPump controlBall valveGas separation

The invention discloses a water and gas separation detection protection device for precisely judging the water diversion state of a mine draining pump. The water and gas separation detection protection device is mainly used in the condition that the water diversion state of the pump needs to be monitored before the pump is started under the premise that a water source is lower than the pump in the process of mine underground draining. The device is composed of an automatic controller, a vacuum tank, a liquid level meter, a pump exhaust valve, a jet device, a jet flow source valve, a filter, a water baffle and a matched pipeline. According to the water and gas separation detection protection device, due to the fact that the unique vacuum tank and the installation position of the vacuum tank are designed, the liquid level meter is added to the top of the vacuum tank to detect the water level of the vacuum tank, after the water level in the vacuum tank is detected to reach a set point, the controller sends out a pump starting order, with the method, the water diversion state of the draining pump can be precisely judged, and the pump can be protected against dry sucking and dry grinding when water diversion does not reach the condition; an exhaust electric ball valve is made to get away from the water source in a water and gas separation vacuum pumping detection mode, and therefore the correct action and the service life of the ball valve are greatly ensured.

Owner:HUNAN SHANYUANAN AUTOMATIC CONTROL SYST

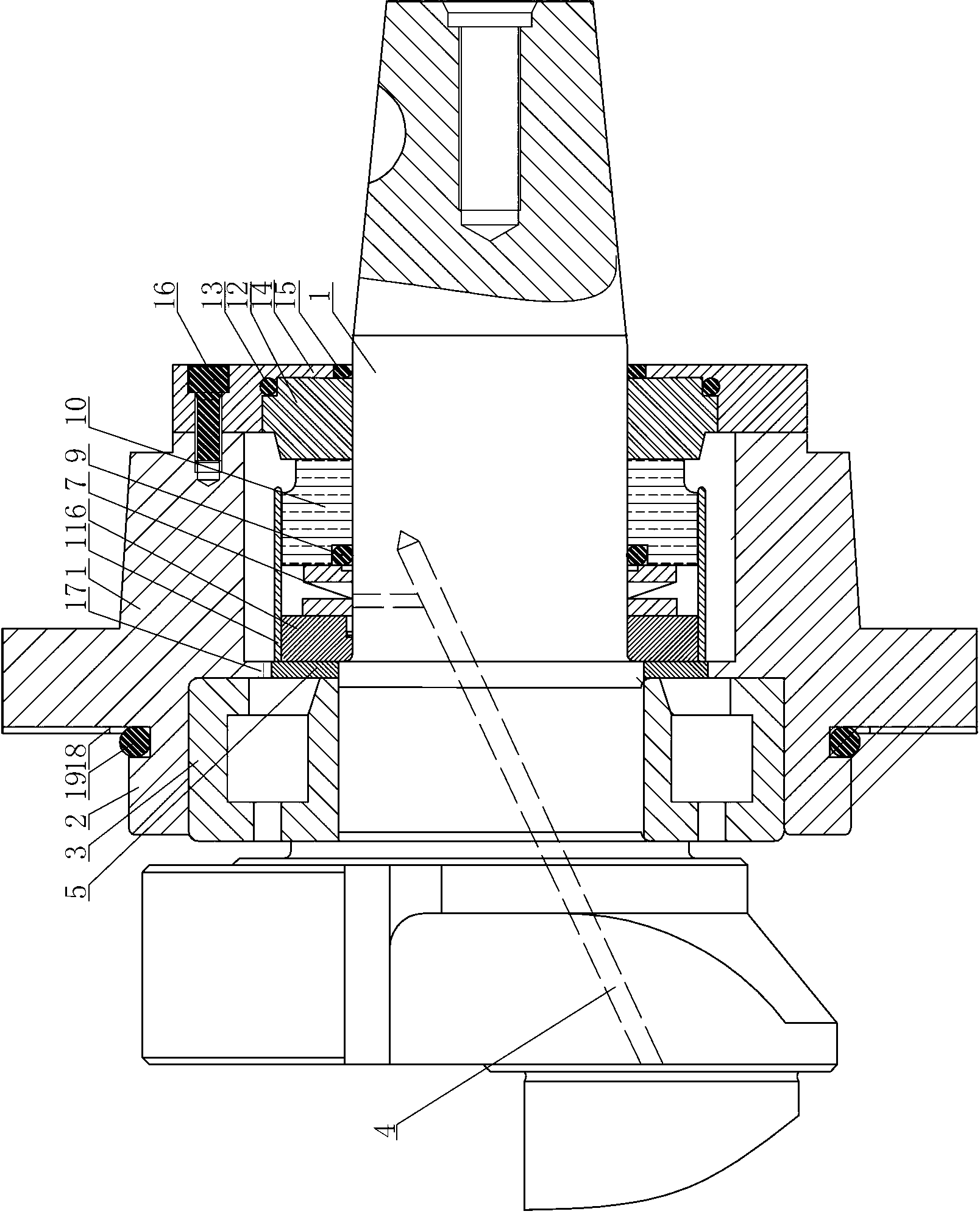

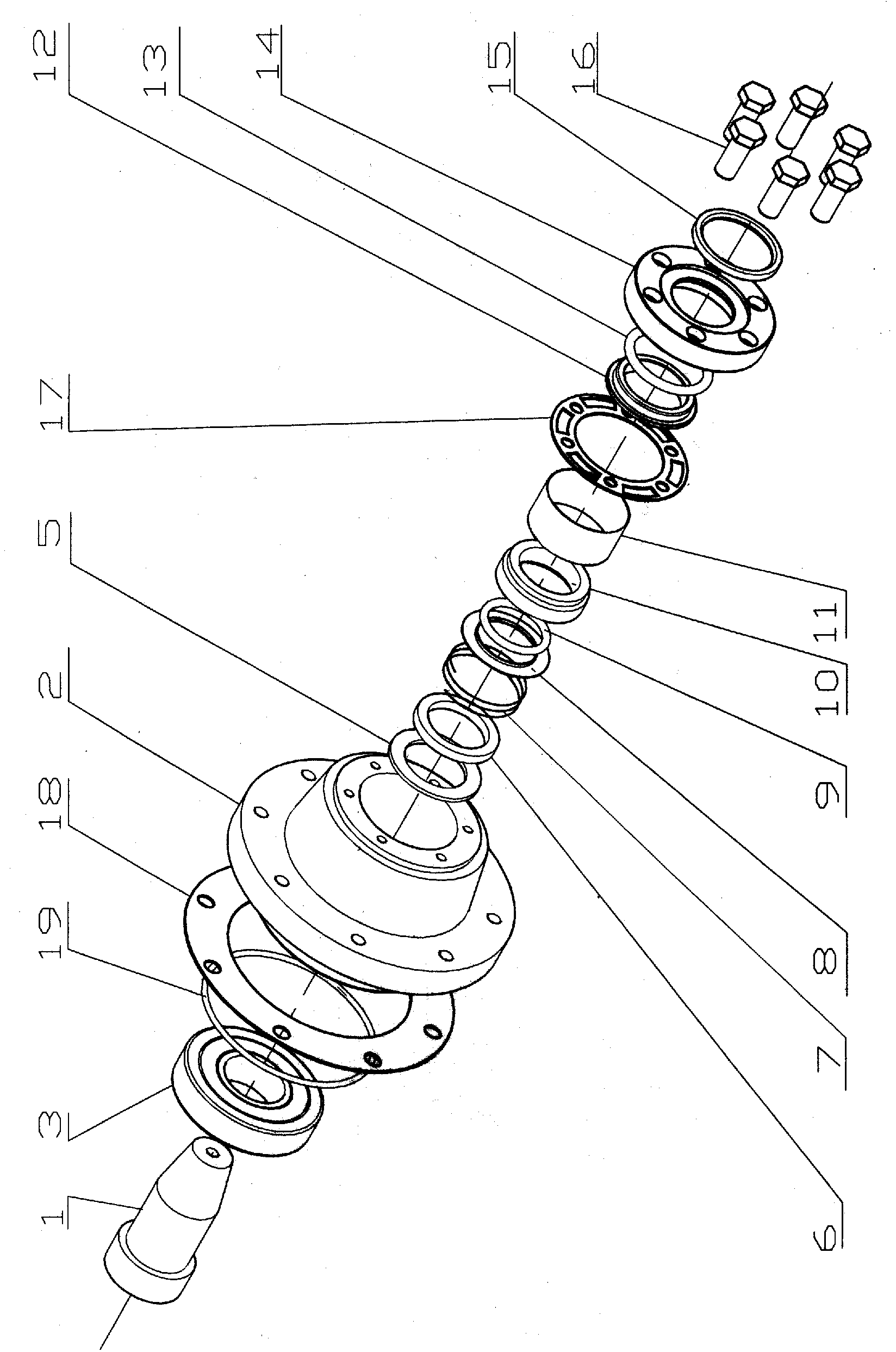

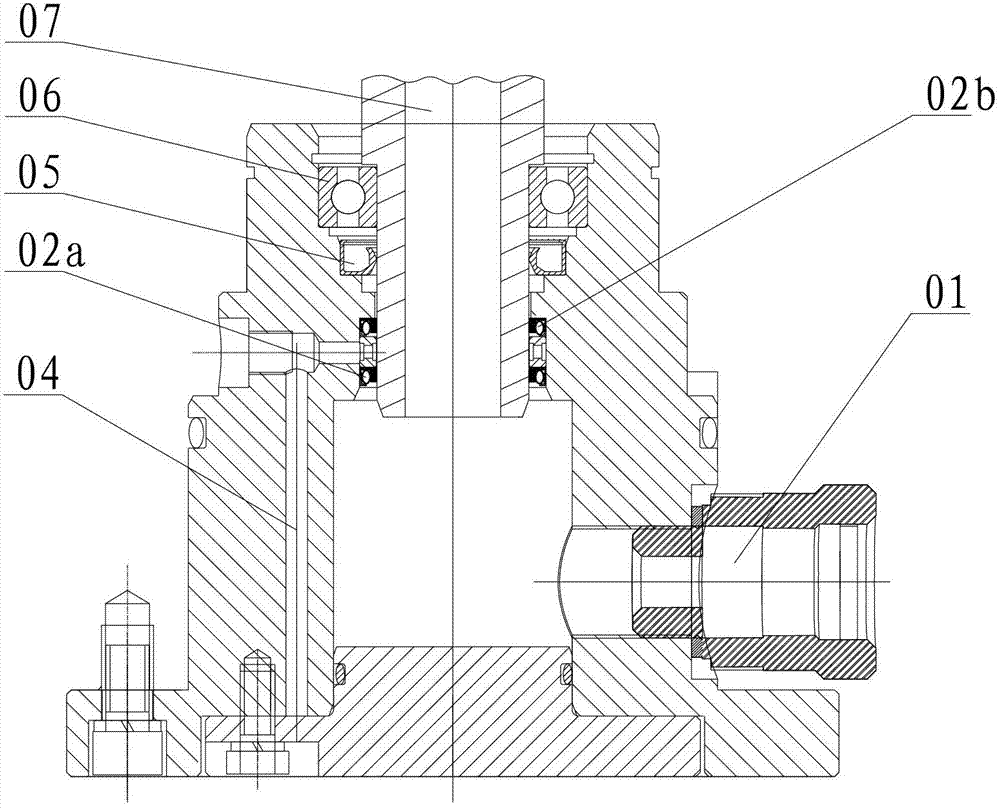

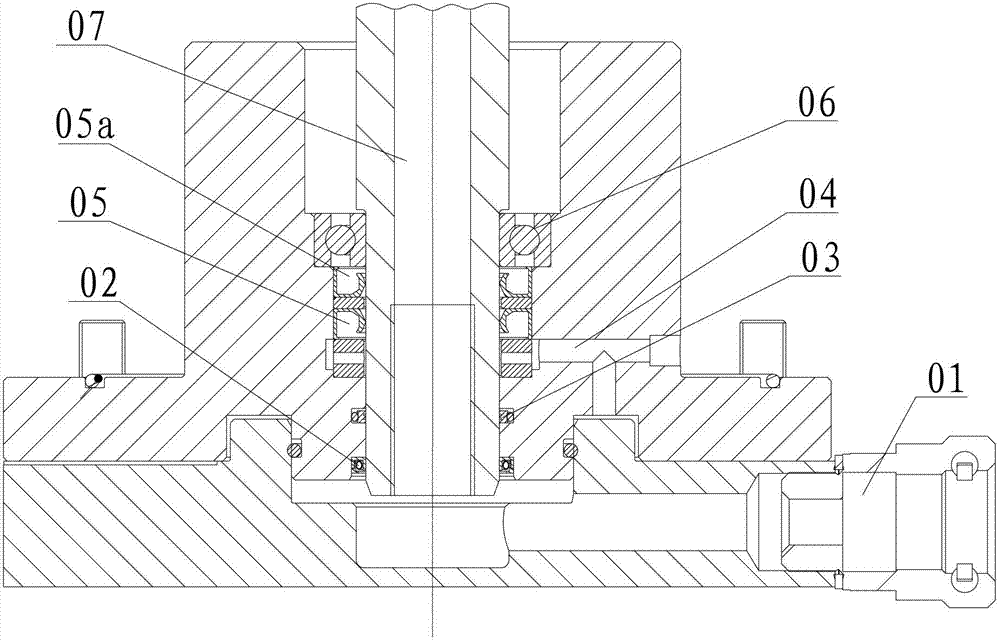

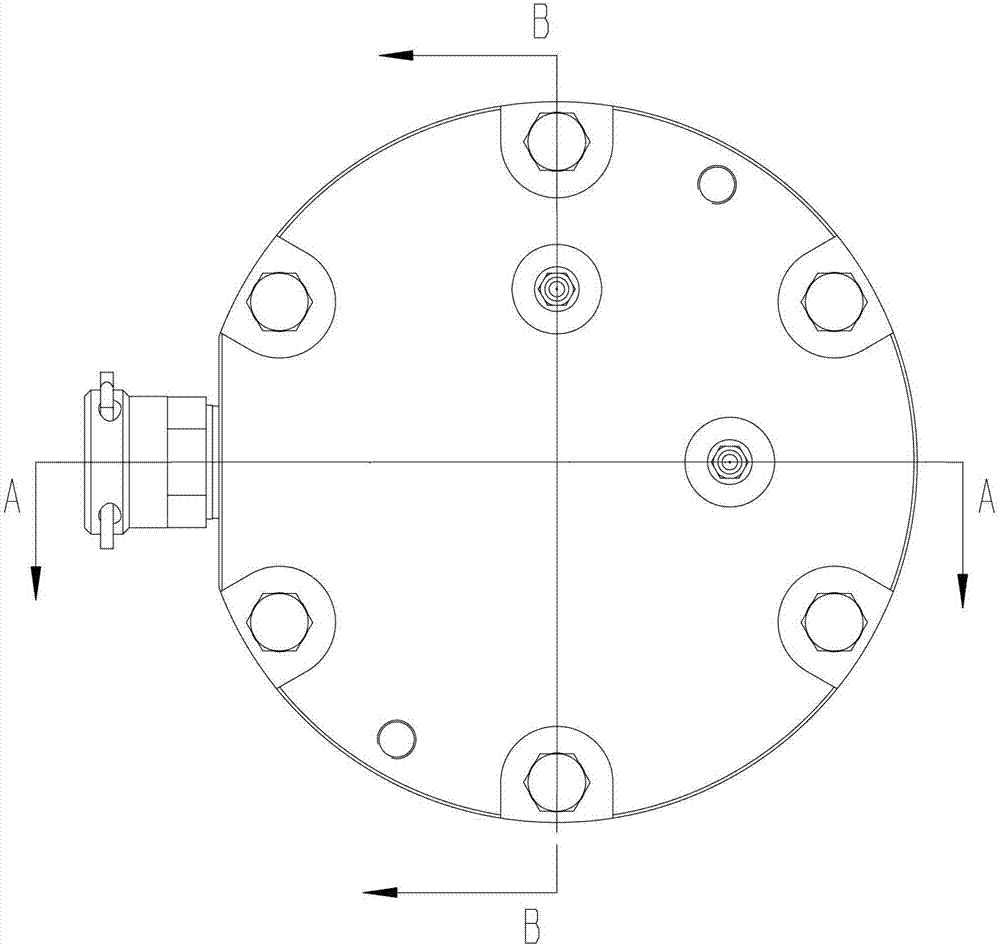

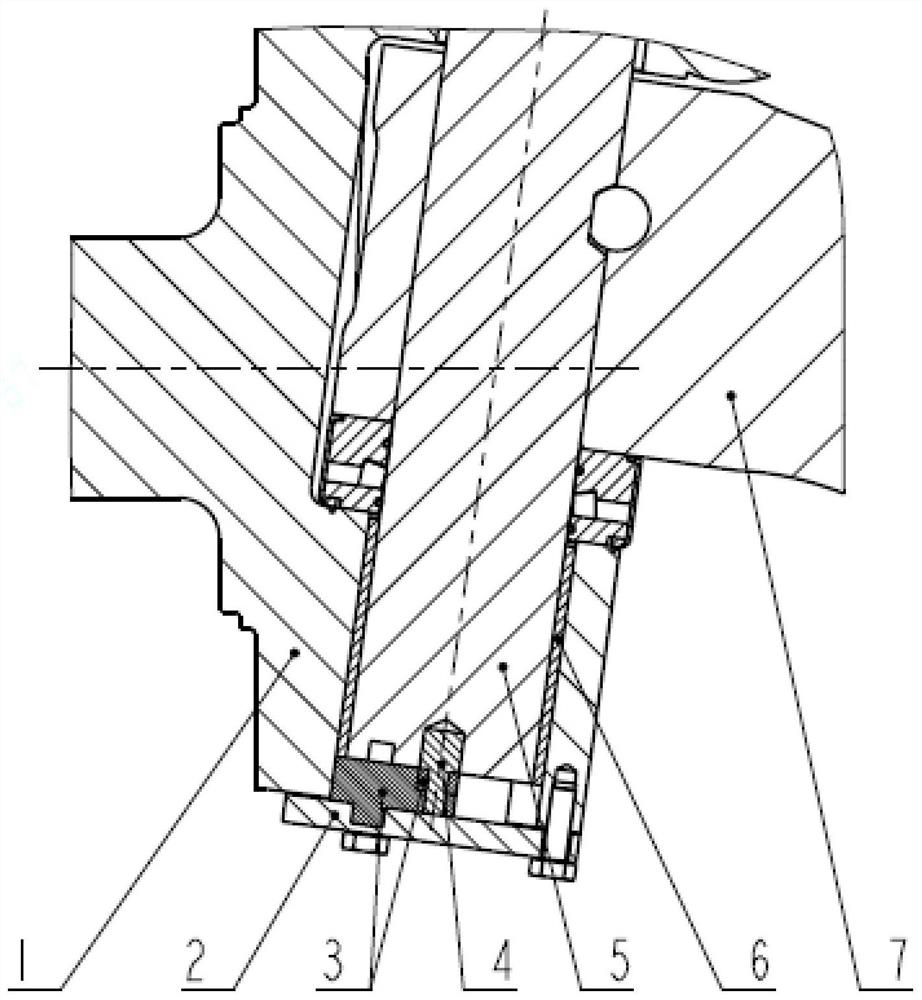

Shaft seal of oil seal machinery

InactiveCN103234044AAvoid Dry GrindingAvoid the disadvantage of short service lifeEngine sealsEngineeringMechanical engineering

The invention relates to a shaft seal of oil seal machinery. The shaft seal comprises a crankshaft, a front bearing seat, a movable friction ring component and a fixed friction ring component, wherein the middle of the front bearing seat is a cavity; the crankshaft which is internally provide with an oil path is arranged in the cavity of the front bearing seat in an insertion manner through a bearing; an oil baffle is arranged at the right end face of the bearing; the inner radial surface of the oil baffle is stuck with the crankshaft; the movable friction ring component is arranged at the right end of the oil baffle; the fixed friction ring component is arranged at the right end of the movable friction ring component; the oil baffle and the fixed friction ring component form an annular oil pond in the cavity inside the front bearing seat; an oil outlet of the oil path is formed at the sidewall of the crankshaft; oil discharged by the oil outlet enters into the oil pond; steps which protrude inwards is arranged at the inner wall of the cavity of the front bearing seat; the outer diameter surface of the oil baffle is stuck with the step surface; and at least two through holes for discharging oil are arranged at the steps at the upper part. The shaft seal of the oil seal machinery has long service life, low cost and no leakage.

Owner:方高云

Automatic partial pressure lubrication piston for filling device

The invention discloses an automatic partial pressure lubrication piston for a filling device. The automatic partial pressure lubrication piston comprises a cylindrical piston body, wherein the front end surface of the piston body is a piston pressure-bearing surface which is contacted with a filling material; the side wall of the piston body is an annular outer wall which is connected with the inner wall of a charging barrel in a sliding fit mode; at least two sealing ring mounting grooves are formed on the annular outer wall; a sealing ring is arranged in each of the sealing ring mounting grooves; the rear end of the piston body is a piston rod connecting end; a diversion through hole from the pressure-bearing surface of the piston body to the annular outer wall of the piston body is formed on the piston body; and an outlet of the diversion through hole on the annular outer wall of the piston body is positioned between the two adjacent sealing ring mounting grooves. When the automatic partial pressure lubrication piston works, a pasty body of the charging barrel enters a gap between two sealing rings by the diversion hole; and pressure of the pasty body is distributed to the later sealing ring, so that two sealing rings commonly bear the pressure of the pasty body; and therefore, the condition that the previous sealing ring bears the total pressure of the previous pasty body is effectively changed; and because of the lubrication function of the pasty body, the piston is rotated freely, so that the service life of the device is prolonged.

Owner:广州市美驰化妆品有限公司

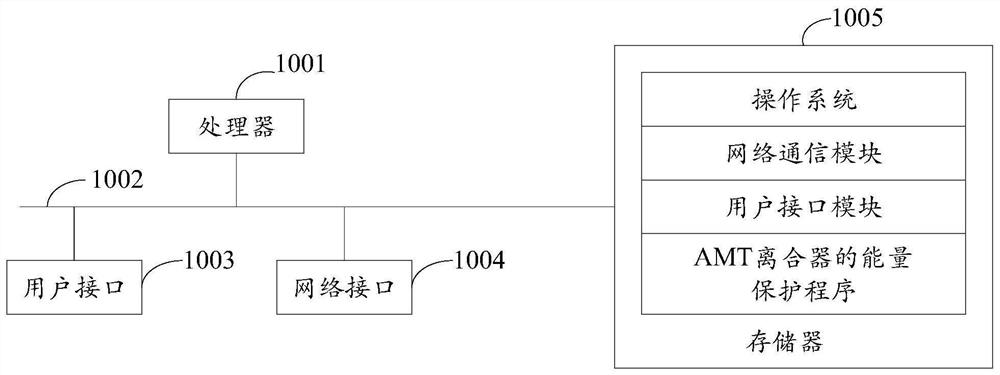

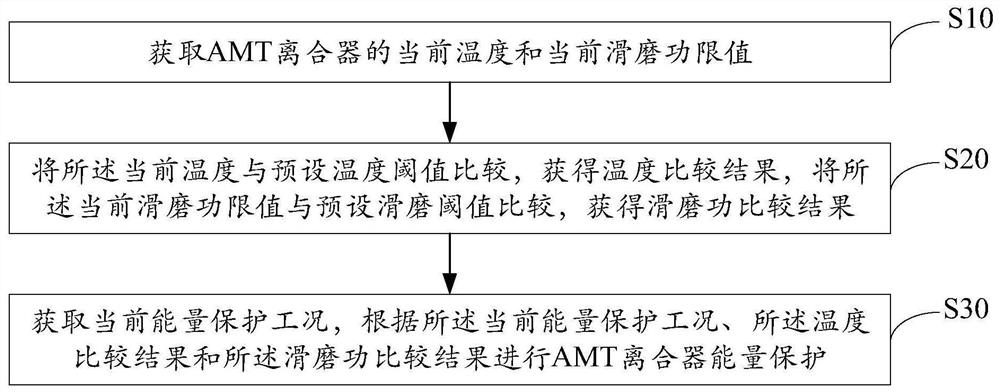

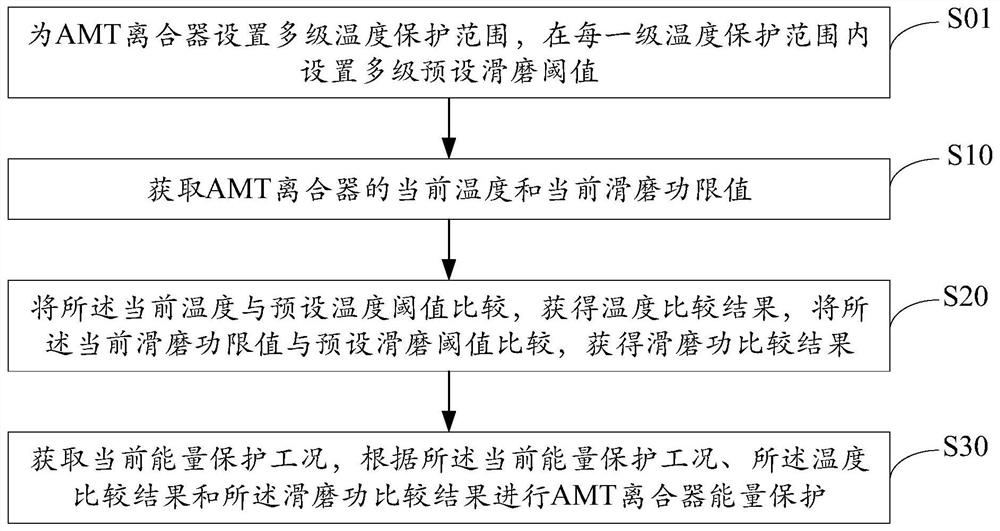

Energy protection method, device and equipment for AMT clutch and storage medium

ActiveCN113586624AReduce the burden of frictional heatReduce wear rateClutchesGearing controlPower limitsControl theory

The invention discloses an energy protection method, device and equipment for an AMT clutch and a storage medium. The method comprises the steps that the current temperature and the current sliding friction power limit value of the AMT clutch are obtained; the current temperature is compared with a preset temperature threshold value to obtain a temperature comparison result, and the current sliding friction power limit value is compared with a preset sliding friction threshold value to obtain a sliding friction power comparison result; and a current energy protection working condition is obtained, AMT clutch energy protection is conducted according to the current energy protection working condition, the temperature comparison result and the sliding friction power comparison result, different coping strategies can be adopted for different working conditions, dry wear during friction plate sliding is avoided, the friction heating burden of the clutch is relieved, the wear rate of the clutch is reduced, the safety of the clutch is ensured, and the service life of the clutch is prolonged.

Owner:DONGFENG COMML VEHICLE CO LTD

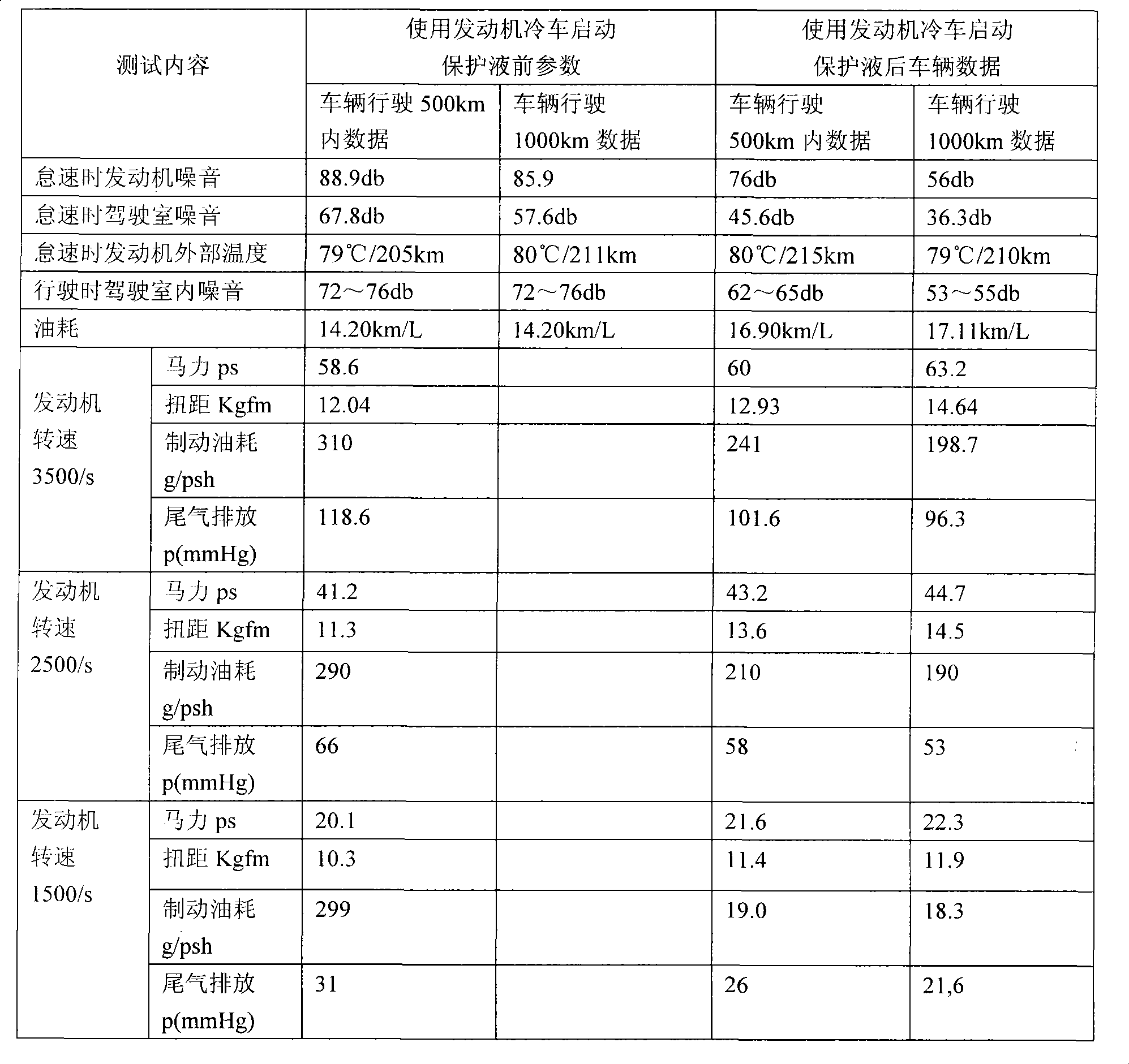

Cold start protective solution for engine and preparation thereof

The invention provides protective solution for cold starting of an engine and a preparation method thereof, which belong to the field of lubricant additive. At present, any lubricant or lubricant additive can not completely solve the phenomena of 'dry friction' or 'semi-dry friction' for the engine. The protective solution consists of the following substances in weight percentage: 6.10 percent of zirconium oxide, 5.50 percent of yttrium oxide, 73.50 percent of soybean oil, 13.00 percent of antiwear composition polyfluortetraethylene, and 1.90 percent of additive, wherein the additive comprises 0.95 percent of molybdenum borate and 0.95 percent of nanometer rare earth fluoride. The preparation method comprises the following steps: pouring the soybean oil in a reaction kettle to be heated to 60 DEG C; adding the zirconium oxide and the yttrium oxide in the reaction kettle to stir and heat up to 65 DEG C; adding the polyfluortetraethylene in the reaction kettle to stir and heat up to 70 DEG C; adding the 1.90 percent of the additive to the reaction kettle to stir and heat up to 95 DEG C, and stopping heating; cooling the reaction product to room temperature; and performing sub-packaging. With the protective solution, a vehicle can be started through ignition without preheating so as to save time. The protective can prolong service time of the lubricant over 50 percent relatively, and has the advantages of environmental protection, energy conservation and resource conservation.

Owner:杨从海

Oil supplementing system for gearbox

PendingCN111734817AImprove operational efficiencyAvoid dry grindingGear lubrication/coolingGear wheelControl valves

The invention discloses an oil supplementing system for a gearbox, and belongs to the technical field of gearbox lubricating systems. The oil supplementing system for the gearbox comprises oil tanks,control valves, a one-way valve and an oil pump. The first oil tank is arranged at a high position relative to the gearbox, and the second oil tank is arranged at a low position relative to the gearbox. The first control valve is arranged on a first oil guide way where the first oil tank communicates with a first oil inlet and used for controlling the first oil guide way to be blocked or unblocked. The second control valve is arranged on a second oil guide way where an oil outlet communicates with the second oil tank and used for controlling the second oil guide way to be blocked or unblocked.The one-way valve is arranged on a third oil guide way where the second oil tank communicates with a second oil inlet and used for controlling lubricating oil to flow out of the second oil tank to reach the gearbox through the third oil guide way, and the oil pump is arranged on the third oil guide way. The oil supplementing system for the gearbox can achieve the purpose that the gear box can still be lubricated under the power-off working condition and the no-load working condition, and therefore a gear bearing is prevented from being in a dry grinding state.

Owner:NANJING HIGH SPEED GEAR MFG

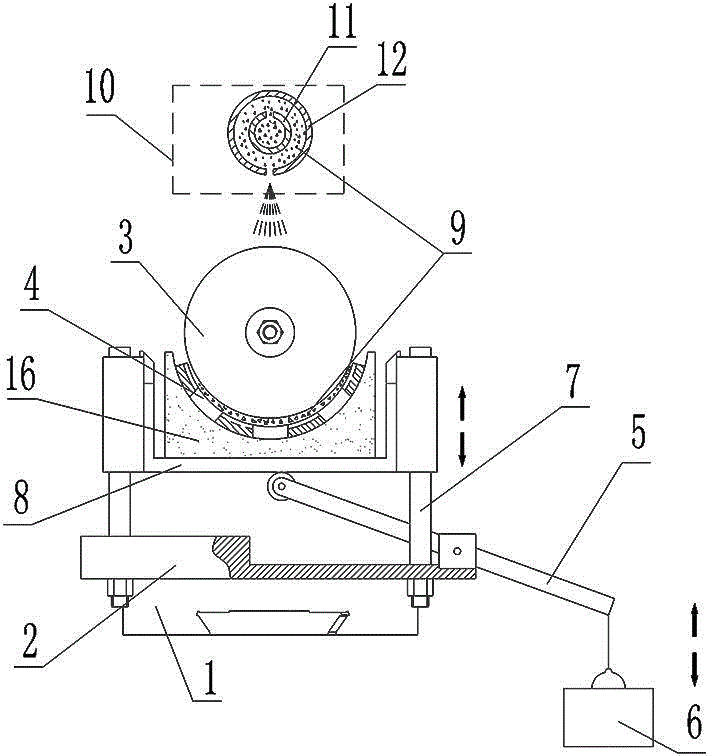

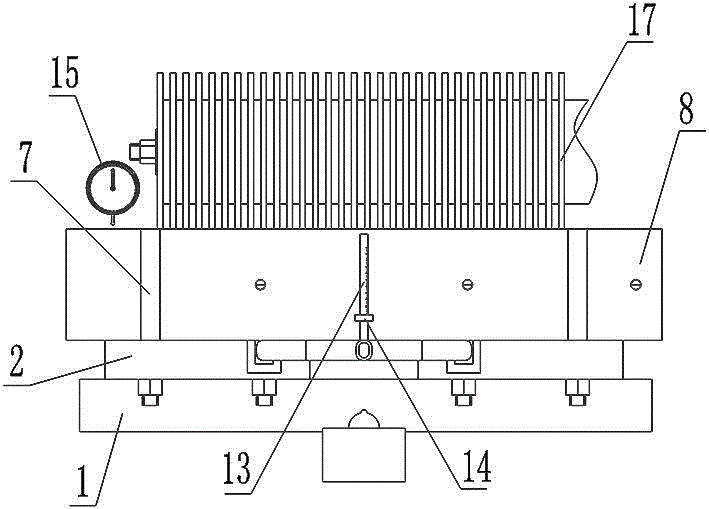

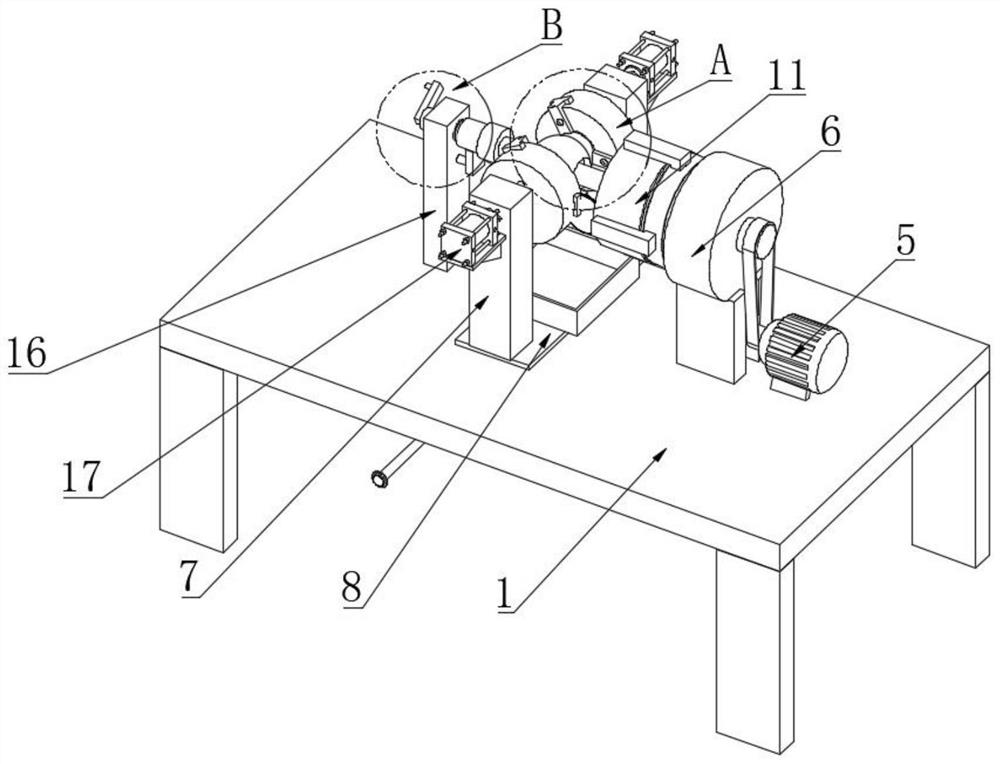

Precision grinding process of high-purity silicon crystal material

ActiveCN106181590AEvenly distributedAvoid Dry GrindingLapping machinesWork carriersActive agentGraphite

The invention discloses a precision grinding process of a high-purity silicon crystal material. The precision grinding process includes the steps of S1, preparing grinding slurry, wherein the grinding slurry comprises micro diamond powder, water, grinding aids and active agents and the micro diamond powder, the water, the grinding aids and the active agents are proportioned and prepared according to the mass; S2, setting the grinding rotation speed according to the speed of the rotation axis of a grooving tool 3; S3, carrying out installation, pasting a work-piece to be grooved to a graphite carrier, adjusting the position of a supporting plate of a machine tool, placing the work-piece to be grooved right below the grooving tool and hanging a heavy punch at the end of a lever outside the machine tool; S4, carrying out debugging, starting the machine tool, observing the motion state of a pointer of a dial indicator and repeatedly adjusting the coaxiality of the grooving tool and a rotating shaft of the machine tool; and S5, preparing for grinding, starting the machine tool, closing an outer cover and carrying out grinding on the condition of guaranteeing the grinding feed speed of the work-piece. The precision grinding process has the beneficial effects that the grinding effect is good and the grinding pressure is stable.

Owner:CHENGDU QINGYANG ELECTRONICS MATERIAL CO LTD

Novel rubber packing for oil field pumping wellhead seal

PendingCN110056324AGuaranteed cleanlinessExtended service lifeSealing/packingBiochemical engineeringOil field

The invention discloses novel rubber packing for an oil field pumping wellhead seal. The novel rubber packing comprises a packing body of a cylindrical spiral structure, a polished rod through hole isformed in the middle of the packing body, the packing body is wrapped with one or more fabric layers, and an inner hole is formed in the packing body. The novel rubber packing is simple and ingeniousin structure, and simple in preparation process, the service life of the wellhead seal is greatly prolonged, cleanliness of a wellhead is kept, the operation efficiency is improved, the yield loss isreduced, economic benefits are increased, the labor intensity of oil field employees is relieved, and the labor insurance expenditure of the oil field employees is reduced.

Owner:银川塞昊橡胶有限公司

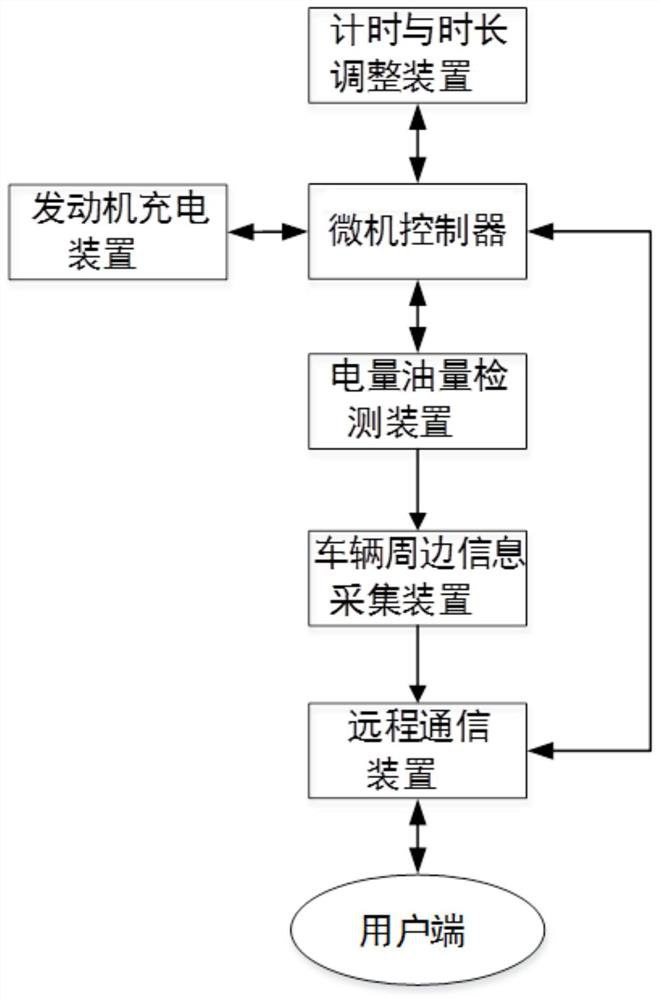

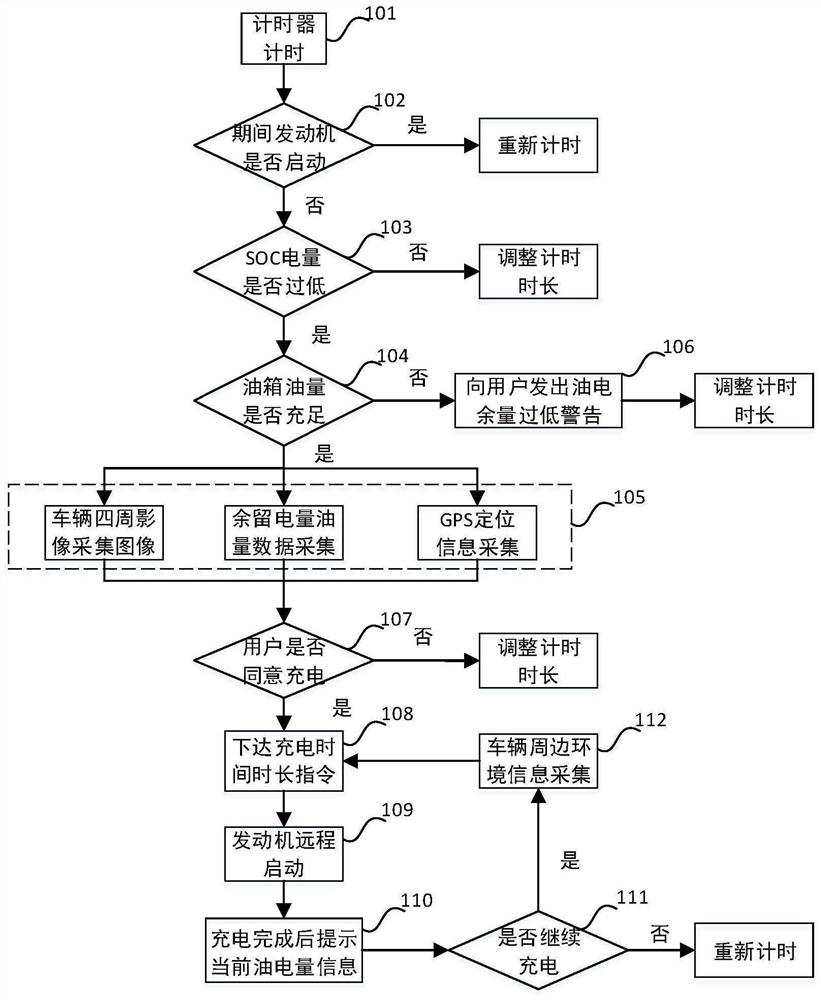

Automobile power shortage protection control system and method provided with remote start-stop control device

ActiveCN112373422AExtend your lifeAvoid dry grindingBatteries circuit arrangementsElectrical testingMicrocomputerIn vehicle

The invention provides an automobile power shortage protection control system and method provided with a remote start-stop control device. The method comprises the steps that when a timing and duration adjusting device reaches a preset time period and an engine is not started in the period, a microcomputer controller controls an electric quantity and oil quantity detection device to detect the electric quantity of a storage battery; if it is detected that the electric quantity is too low, the microcomputer controller transmits the electric quantity, the oil quantity and the state information of an automobile to a user side through a remote communication device, the user side sends out related judgment information, and the user remotely controls the charging time and the charging duration of the storage battery; and if not, the microcomputer controller adjusts the next detection time period, and the situation that the storage battery is about to be lack of power and no effective measures are taken in the next long period of the system is avoided. According to the invention, the problem that the necessary electronic equipment cannot be maintained to operate and even the automobile isstarted due to power shortage of the automobile storage battery caused by long-term parking or forgetting to turn off the vehicle-mounted electronic equipment is solved, and the purposes of user reminding and storage battery protection are achieved.

Owner:DALIAN UNIV OF TECH

Machining process for valve seat of ball valve

PendingCN114700832AFull Fit GuaranteeGuaranteed tightnessSeat surface grinding machinesLapping machinesGear wheelReciprocating motion

The invention relates to the technical field of ball valve machining processes, in particular to a ball valve seat machining process which can drive a valve element to rotate continuously and rub with two valve seats, so that the valve element is completely attached to the two valve seats corresponding to the valve element, the sealing performance of a ball valve after assembly is guaranteed, and the service life of the ball valve is prolonged. When the double-shaft motor rotates, the driving gear is driven to rotate at the same time, then the connecting shaft is driven to rotate through the driving shaft, the connecting shaft continues to drive the reciprocating lead screw to move, and therefore the two sets of valve seats are driven to swing in a reciprocating mode, and meanwhile the abrasive filling pipe can be driven to do reciprocating motion; the grinding machine can be evenly attached to the surface of the valve element, workers do not need to add grinding agents manually, production accidents caused when the grinding agents are smeared manually can be avoided, attachment of the grinding agents can be more even, and the machining precision is further improved.

Owner:ZHEJIANG YOUBO VALVE TECH CO LTD

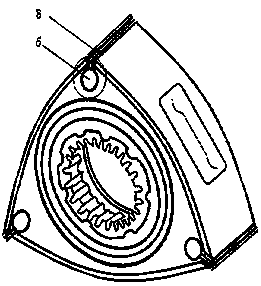

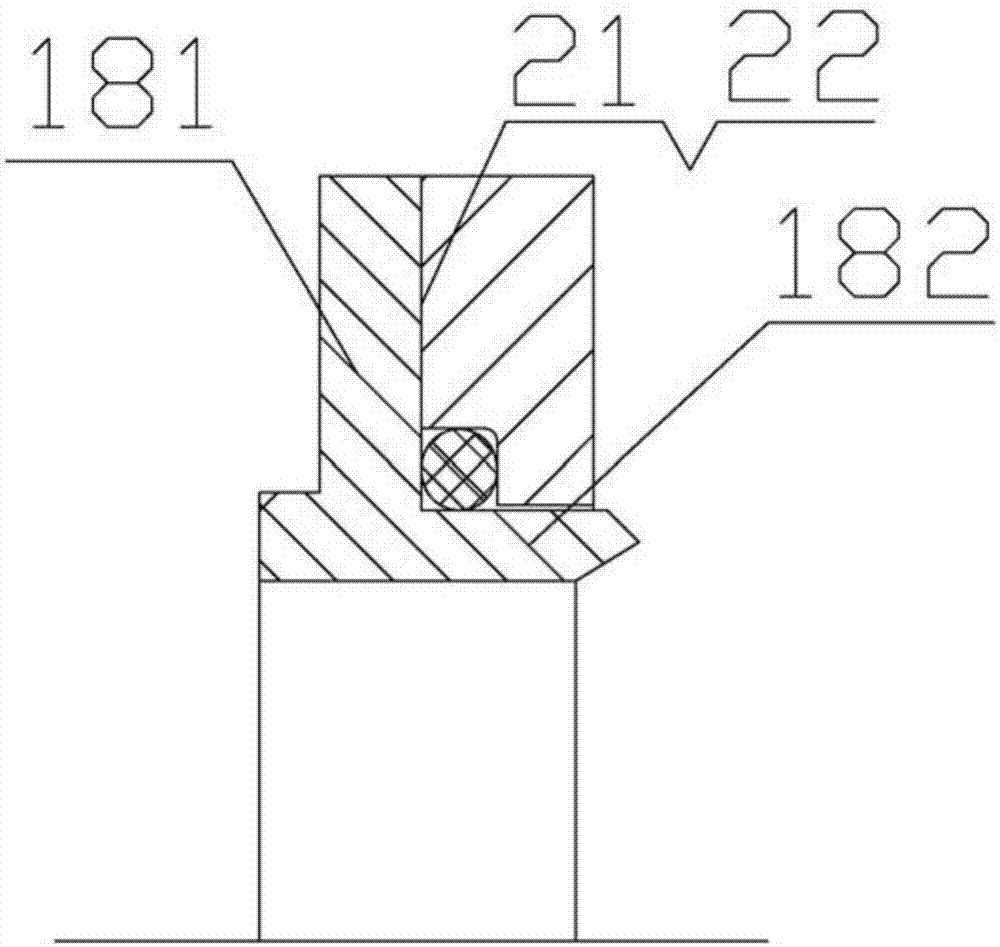

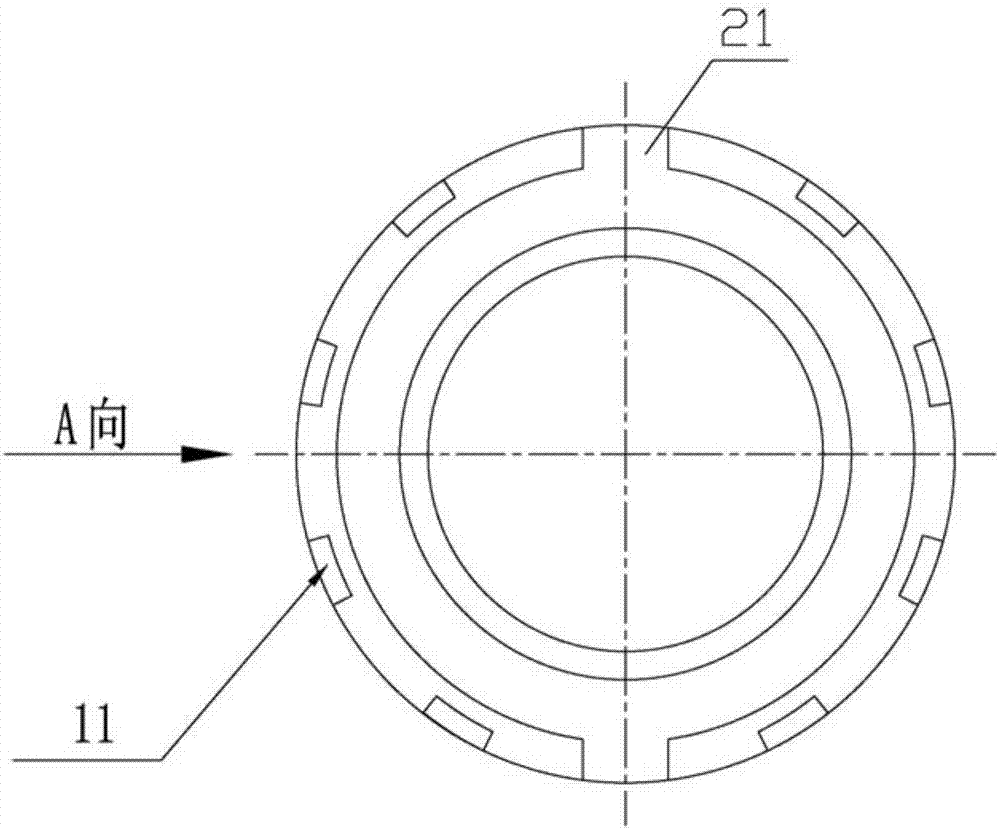

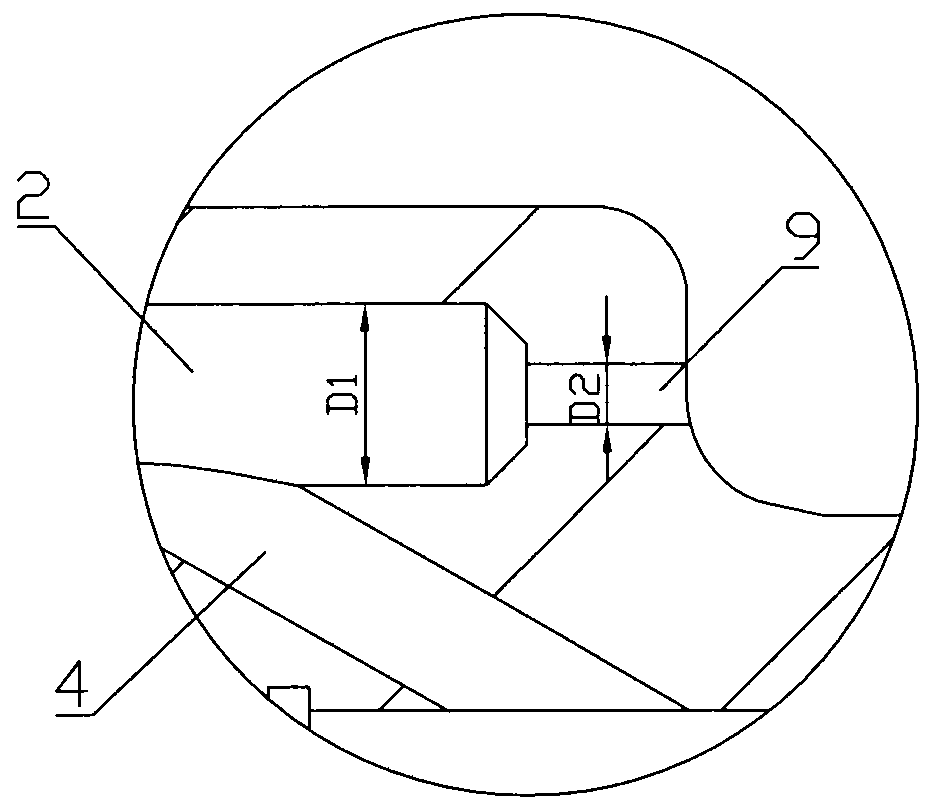

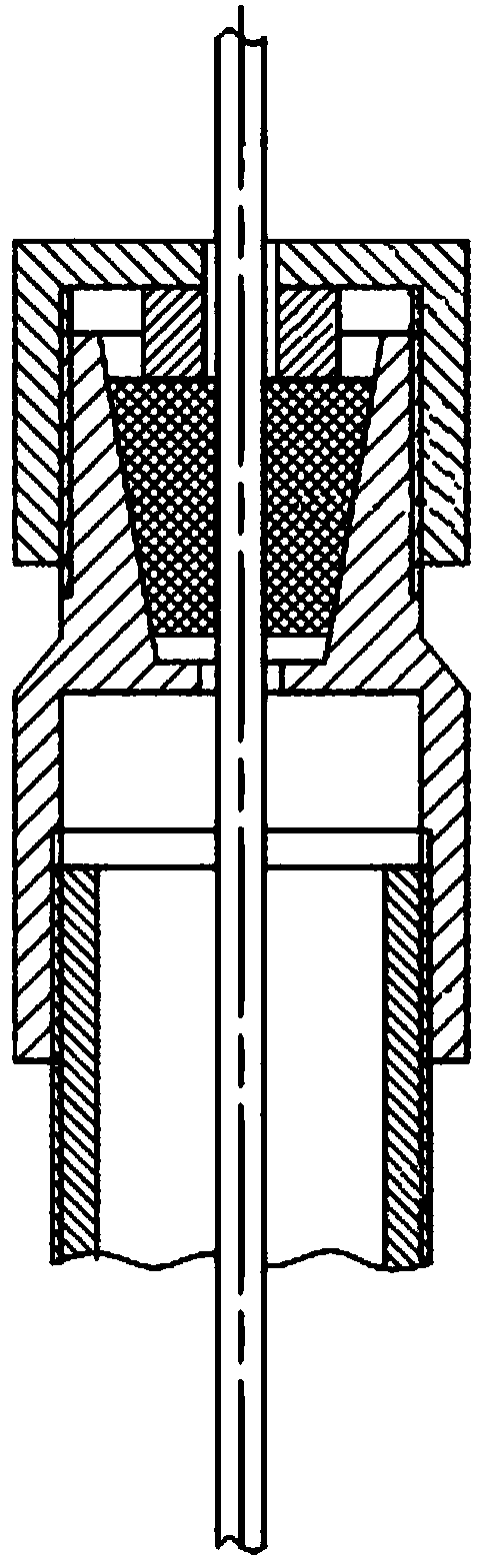

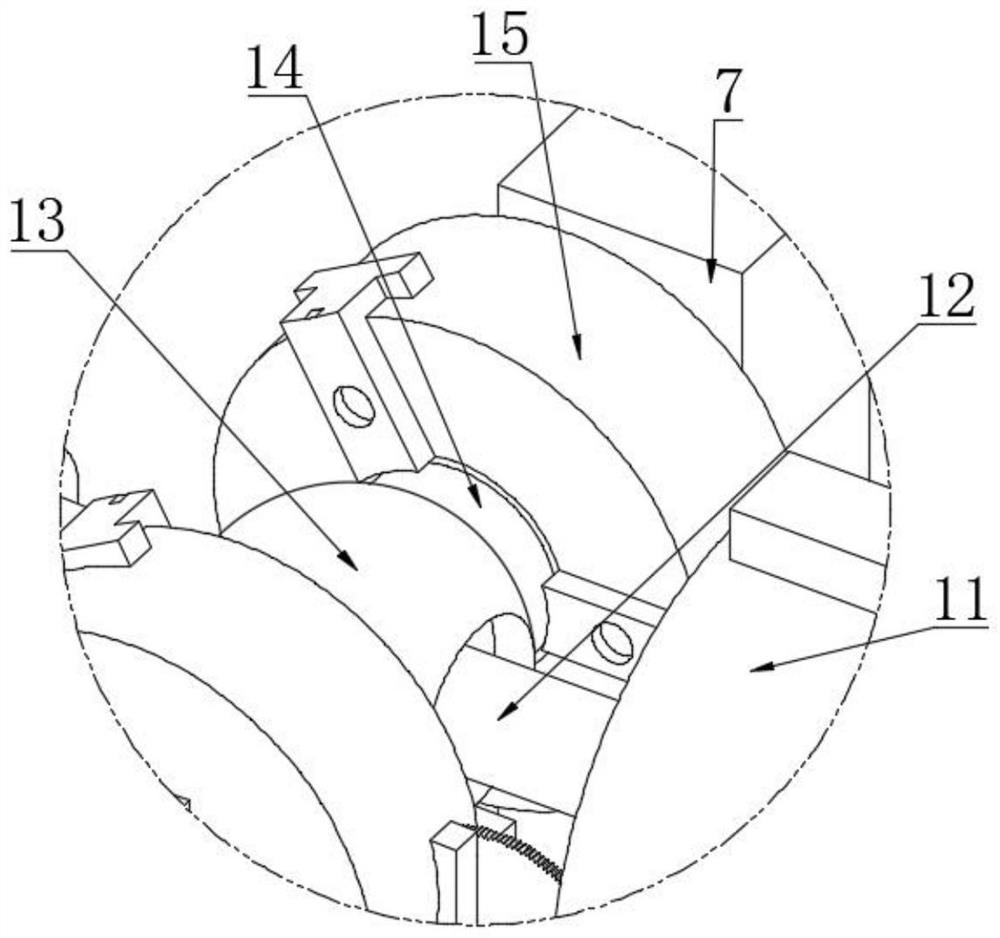

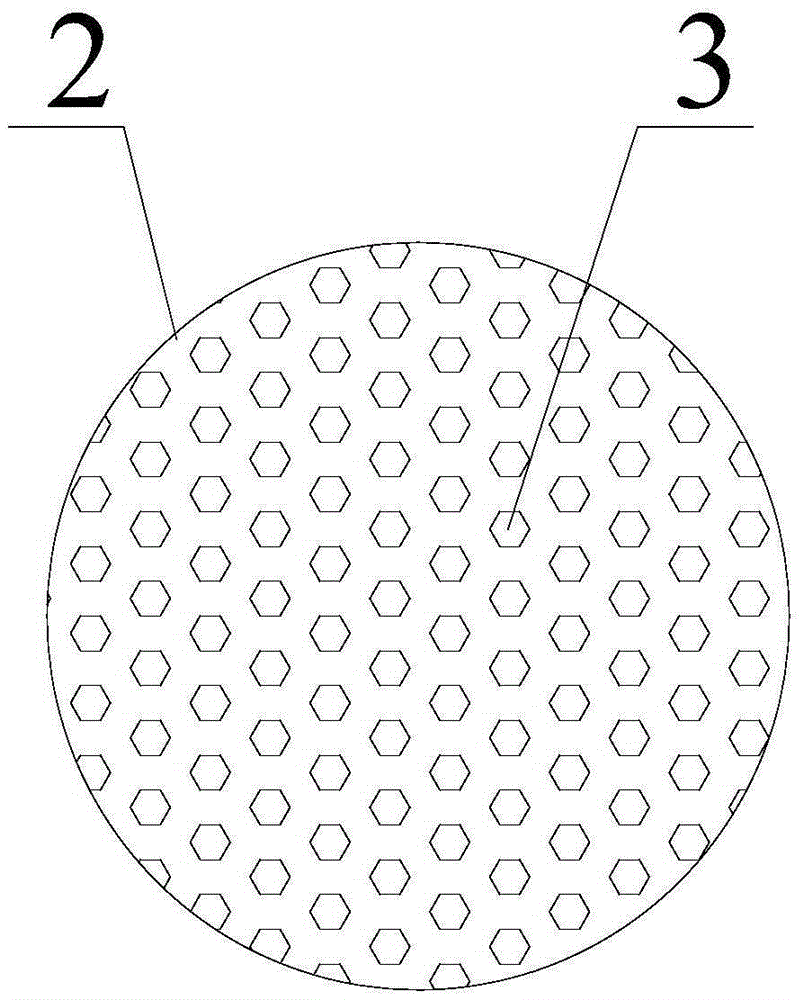

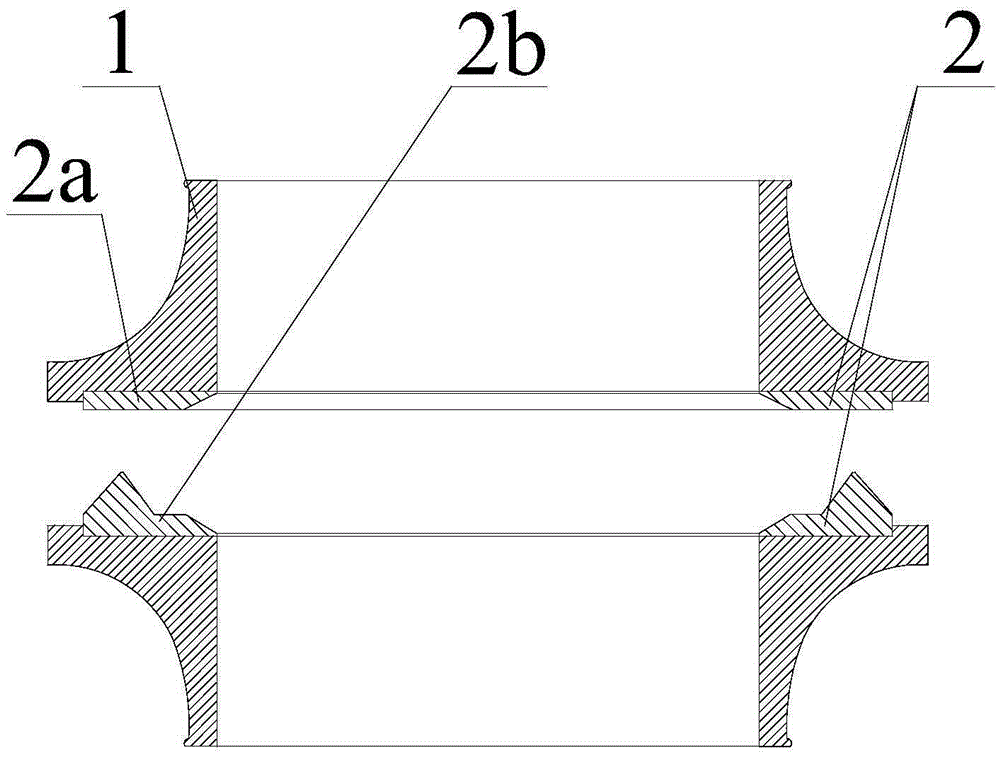

Floating oil seal with oil storage micropore abrasion-resistant faces

The invention provides a floating oil seal with oil storage micropore abrasion-resistant faces. The floating oil seal comprises a pair of sealing ring bodies. The structures of the sealing ring bodies are vertically symmetrical. Friction-resistant assemblies are arranged on the two opposite end faces of the pair of sealing ring bodies respectively. The two friction-resistant assemblies form a friction pair which is oppositely matched. The friction-resistant working faces of one or two of the friction-resistant assemblies of the friction pair are of a micro-pit or micro-groove textured structure. Micro-concave-parts which are widely distributed are formed in the surfaces of the friction-resistant working faces, are micro-pits or micro-grooves and are sued for storing lubricating oil, lubricating grease and other lubricating substances, and oil films can be formed on the surfaces of the friction-resistant working faces respectively. By means of the floating oil seal, the friction resistance of the working faces can be effectively improved, the service life is prolonged, and sealing can be effectively ensured.

Owner:李纯

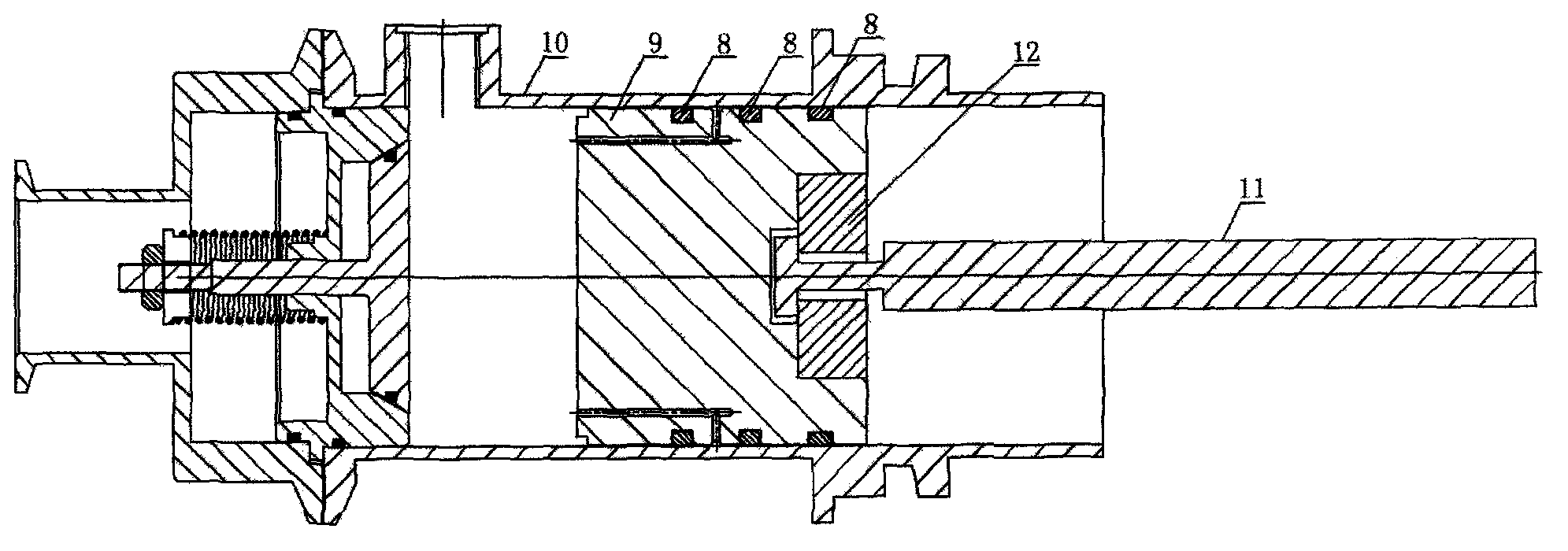

Coal mining machine and inner spraying device thereof

InactiveCN103291299AExtended service lifePrevent water leakageSlitting machinesCoal miningLubrication

The invention relates to a coal mining machine and an inner spraying device thereof. The inner spraying device of the coal mining machine comprises a self-rotating water outlet pipe in a spraying seat, and a first water seal and a second water seal which are used for hermetically blocking water for the outer wall of the water outlet pipe and installed in the spraying seat to prevent the water leakage at the water inlet end part of the water outlet pipe. Due to the sealing effect of the first water seal, the second water seal cannot contact water for a long time, and a first oil injection channel for lubricating the second water seal is formed in the spraying seat to prevent the dry grinding between the second water seal and the water outlet pipe. The structure uses the double seals, the water sealing effect of high-pressure water is ensured by the first water seal at the inlet end of the water outlet pipe, the second water seal is arranged in a second channel and subjected to grease lubrication through an oil injection pipeline so as to prevent the dry grinding between the second water seal and the water outlet pipe, prolong the service life of the second water seal, and further prolong the service life of the inner spraying device.

Owner:SANY HEAVY EQUIP

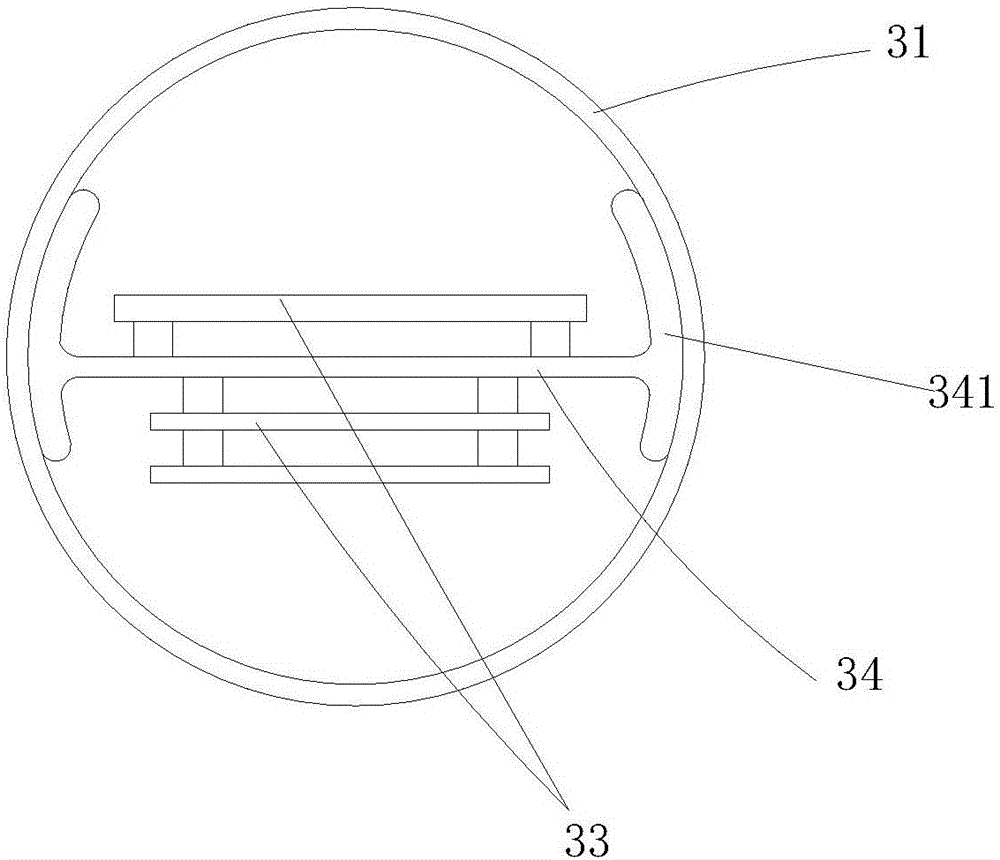

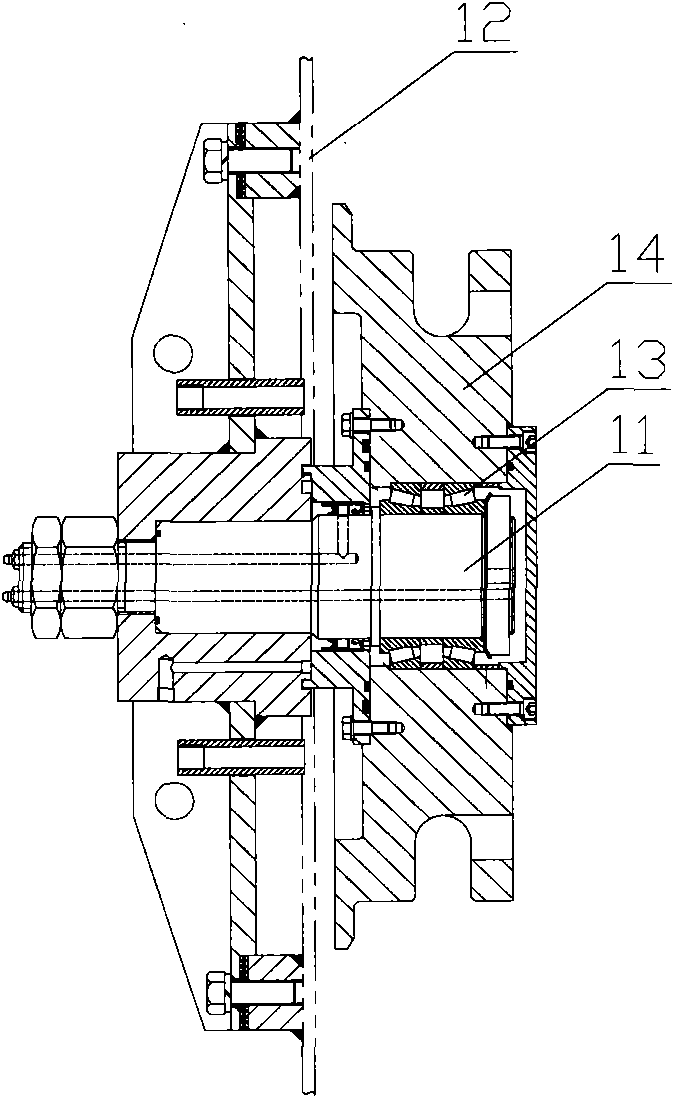

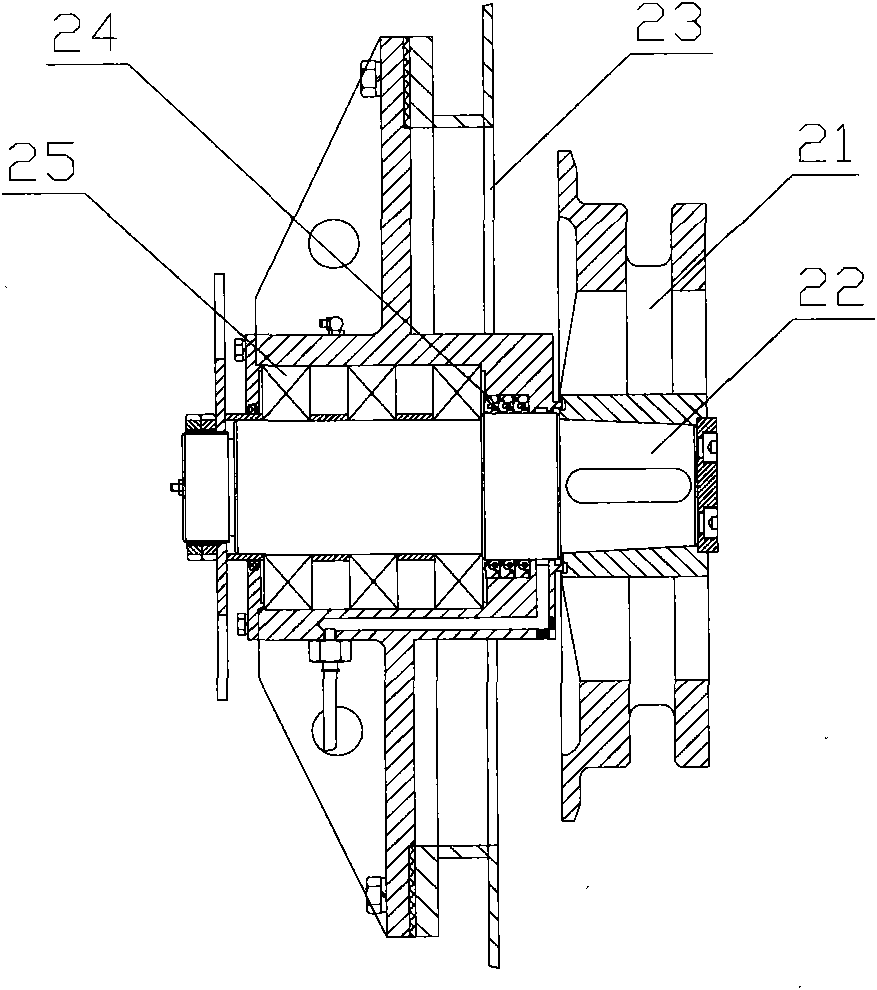

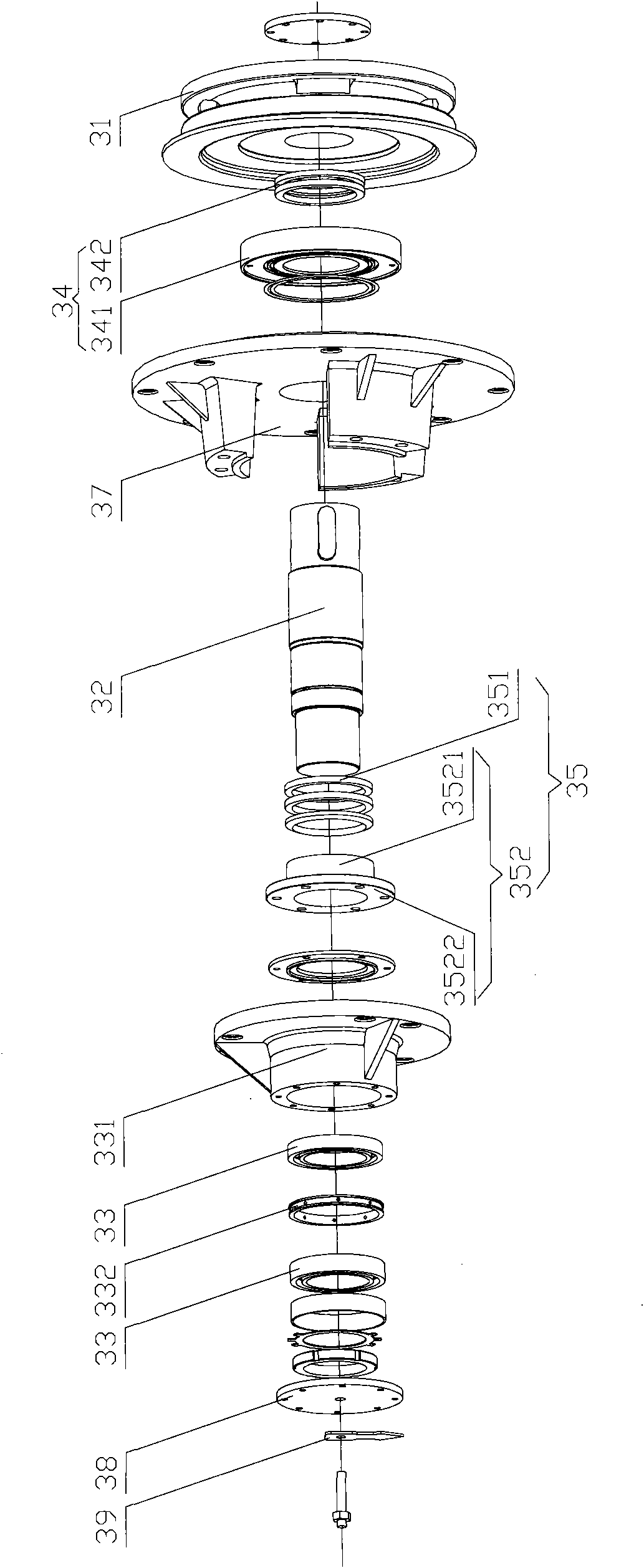

Slag dragging machine and chain guiding device thereof

The invention discloses a slag dragging machine and a chain guiding device thereof. The chain guiding device comprises a guiding wheel (31), a central shaft (32), a rolling bearing (33), a first seal assembly (34) and a base (37), wherein, the guiding wheel (31) is fixedly connected with the central shaft (32); the rolling bearing (33) surrounds the central shaft (32); the first seal assembly (34) is arranged between the guiding wheel (31) and the rolling bearing (33); the base (37) surrounds the central shaft (32) and is arranged outside a slag dragging machine shell (36); the first seal assembly (34) is also arranged between the base (37) and the guiding wheel (31); a second seal assembly (35) is arranged between the base (37) and the central shaft (32); and the rolling bearing (33) is arranged outside the second seal assembly (35). The chain guiding device can realize on-line examination and repair, has better reliability, can effectively reduce the furnace stopping times, reduce the economic loss and improve the economic benefit of enterprises.

Owner:克莱德贝尔格曼华通物料输送有限公司

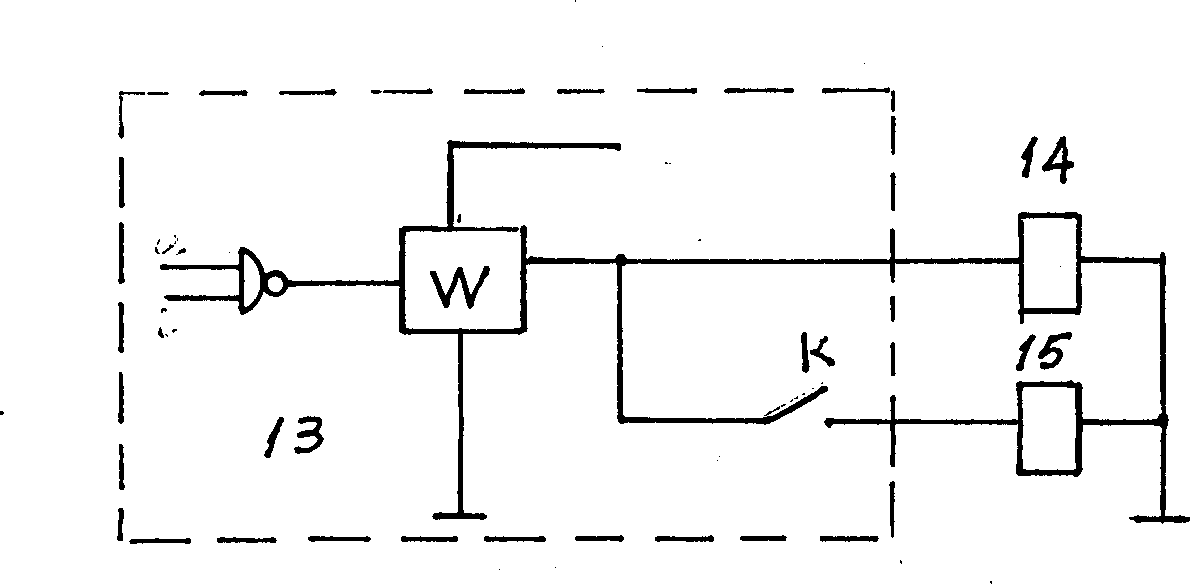

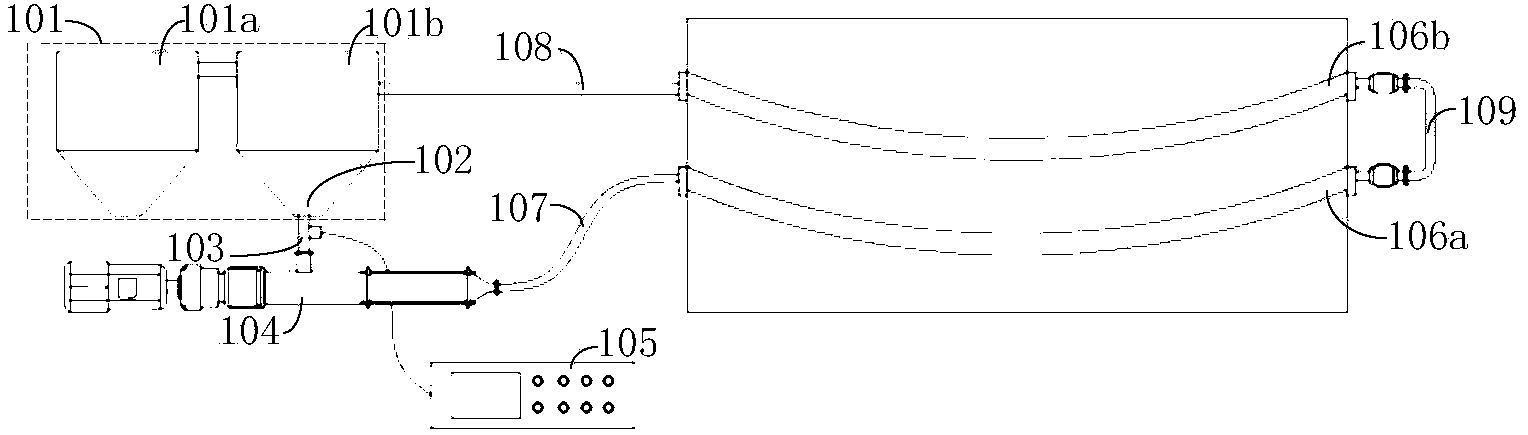

Prestress grouting device

InactiveCN104060833AAvoid dry grindingEasy to controlBridge erection/assemblyBuilding material handlingEngineeringSlurry

The invention discloses a prestress grouting device. The prestress grouting device comprises a stirring barrel used for producing and outputting sizing, a grouting pump used for pouring the sizing into prestress beam holes, a liquid level detector which is connected between the stirring barrel and the grouting pump and used for detecting the liquid level of the sizing outputted by the stirring barrel and generating a corresponding liquid level signal, and a controller which is connected with the liquid level detector and the grouting pump and used for controlling the running state of the grouting pump according to the liquid level signal. Compared with an existing prestress grouting device, the prestress grouting device is simple in structure and capable of rapidly and accurately detecting the liquid level in real time, and therefore the prestress grouting device can more accurately and reliably control the grouting pump, the dry grinding phenomenon can be effectively prevented from happening to the grouting pump, the service life of the prestress grouting device is prolonged, the after-sale maintenance cost of the prestress grouting device is greatly reduced, and construction cost is saved.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

Kingpin bushing dynamic lubrication structure

ActiveCN112032201AExtended service lifeAvoid dry grindingSteering linkagesBearing componentsLubricationOil and grease

The invention discloses a kingpin bushing dynamic lubrication structure. The kingpin bushing dynamic lubrication structure comprises a front beam, a steering knuckle, bushing, a kingpin assembly and akingpin cover assembly, a lubricating grease oil duct bush is arranged on the bushing, and the bushing is pressed into a kingpin hole of the steering knuckle in an interference mode. The kingpin assembly comprises a kingpin, a separation block and a separation block pin shaft, an oil passing groove is machined in the end face of the kingpin, and the kingpin assembly penetrates into kingpin hole in the steering knuckle and the front beam to connect the steering knuckle with the front beam and enable the steering knuckle to rotate around the front beam. The kingpin cover assembly comprises a kingpin cover, a separation block and a grease nozzle, and is screwed and fixed to the steering knuckle through a bolt. Grease is injected into a lubricating grease storage cavity from the grease nozzle, and the friction faces of the kingpin and the bushing are fully filled with the grease under the pressure effect of a grease injection gun. According to the kingpin bushing dynamic lubrication structure, under the action of the structure, the friction surfaces of the kingpin and the bushing are always kept fully lubricated, dry grinding of the kingpin and the bushing is avoided, and the servicelife of the bushing is prolonged.

Owner:SINO TRUK JINAN POWER

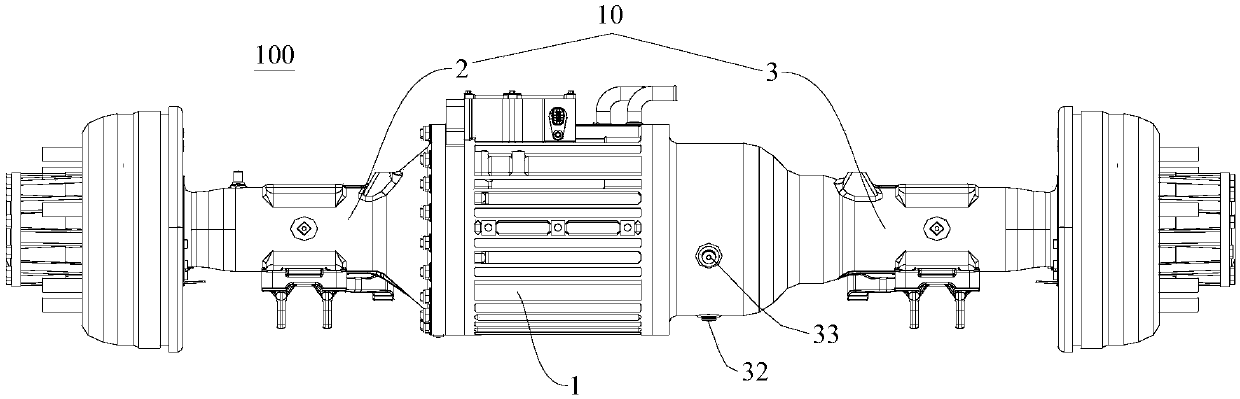

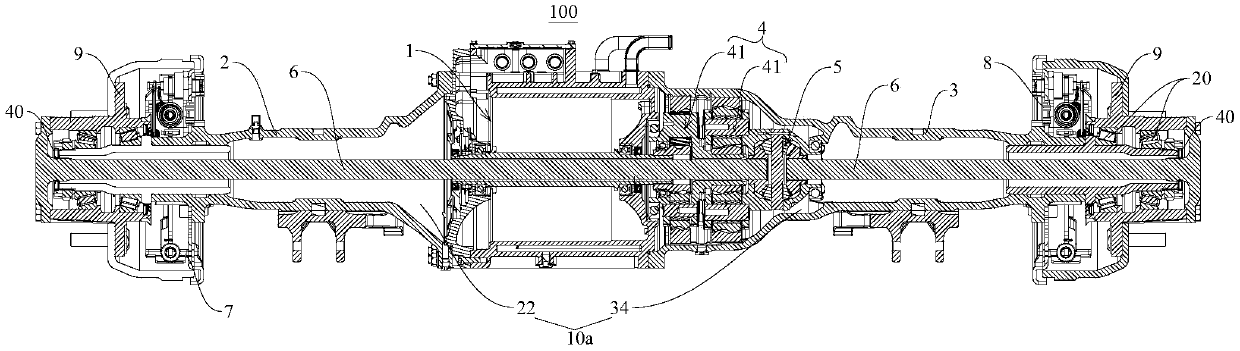

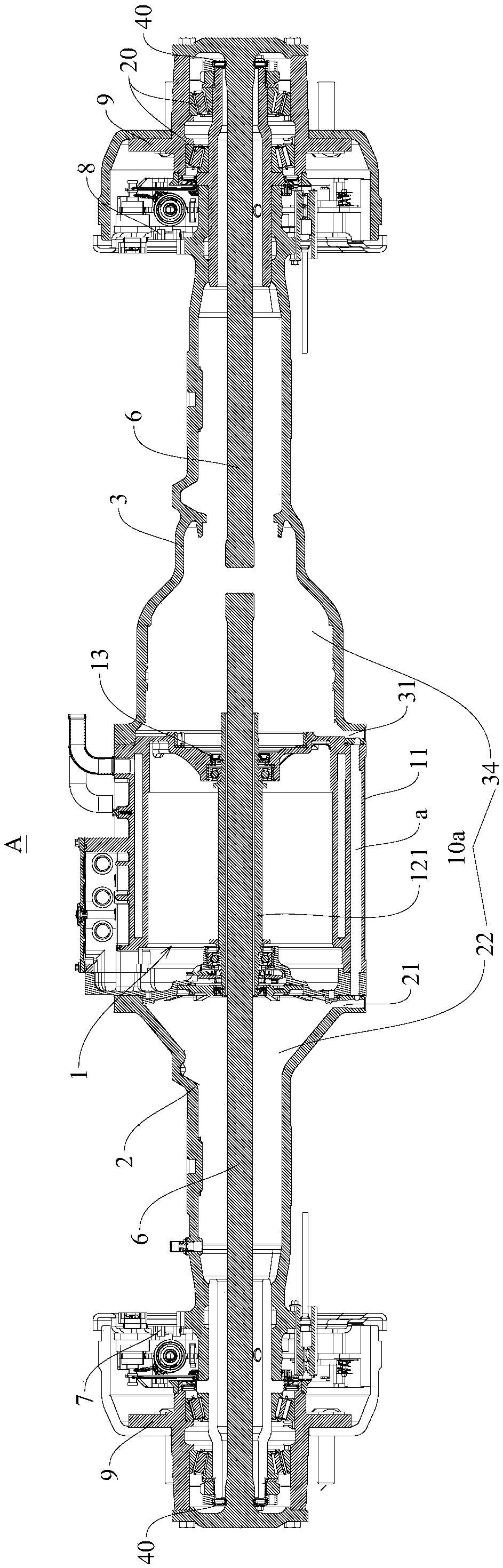

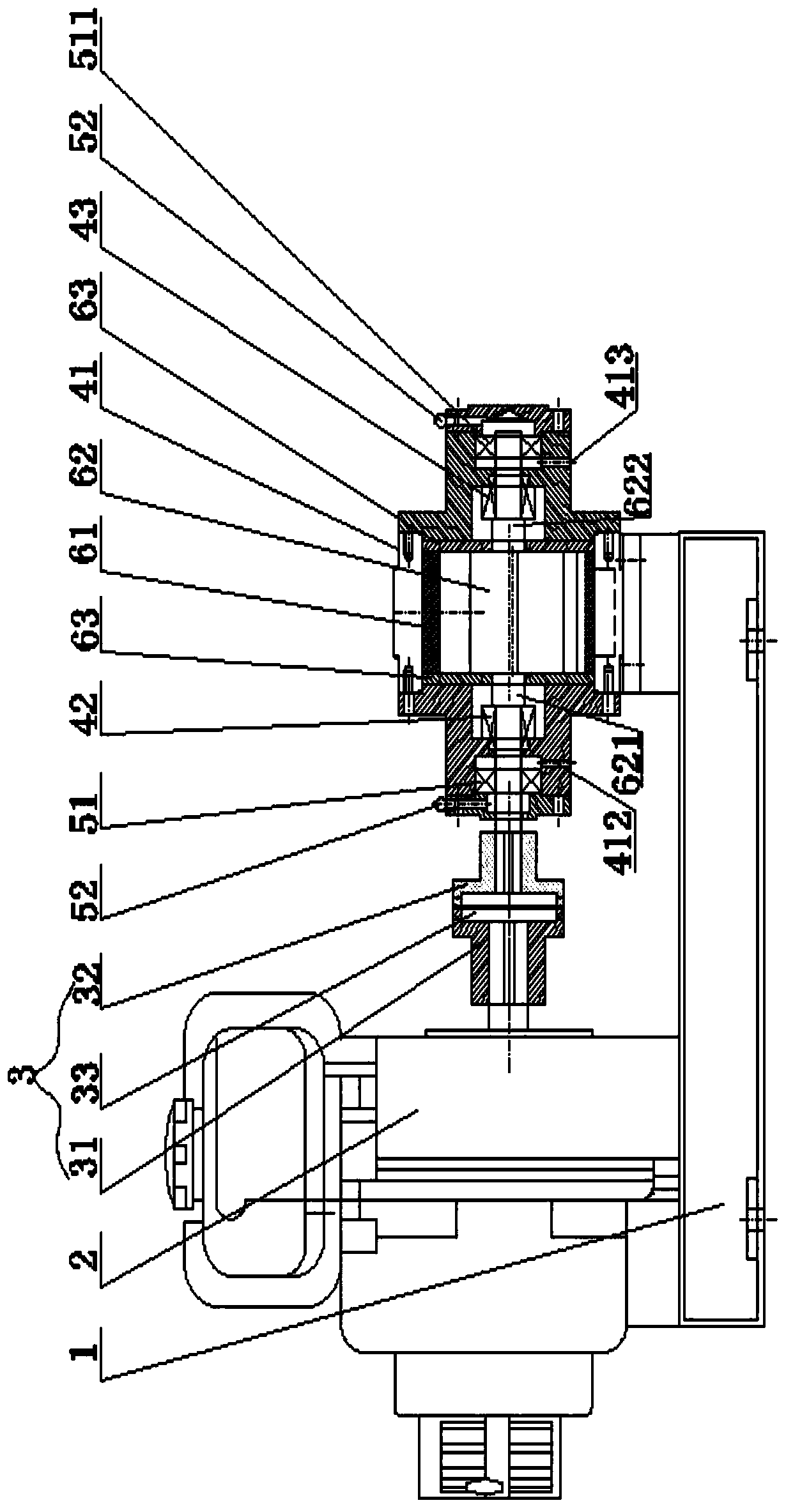

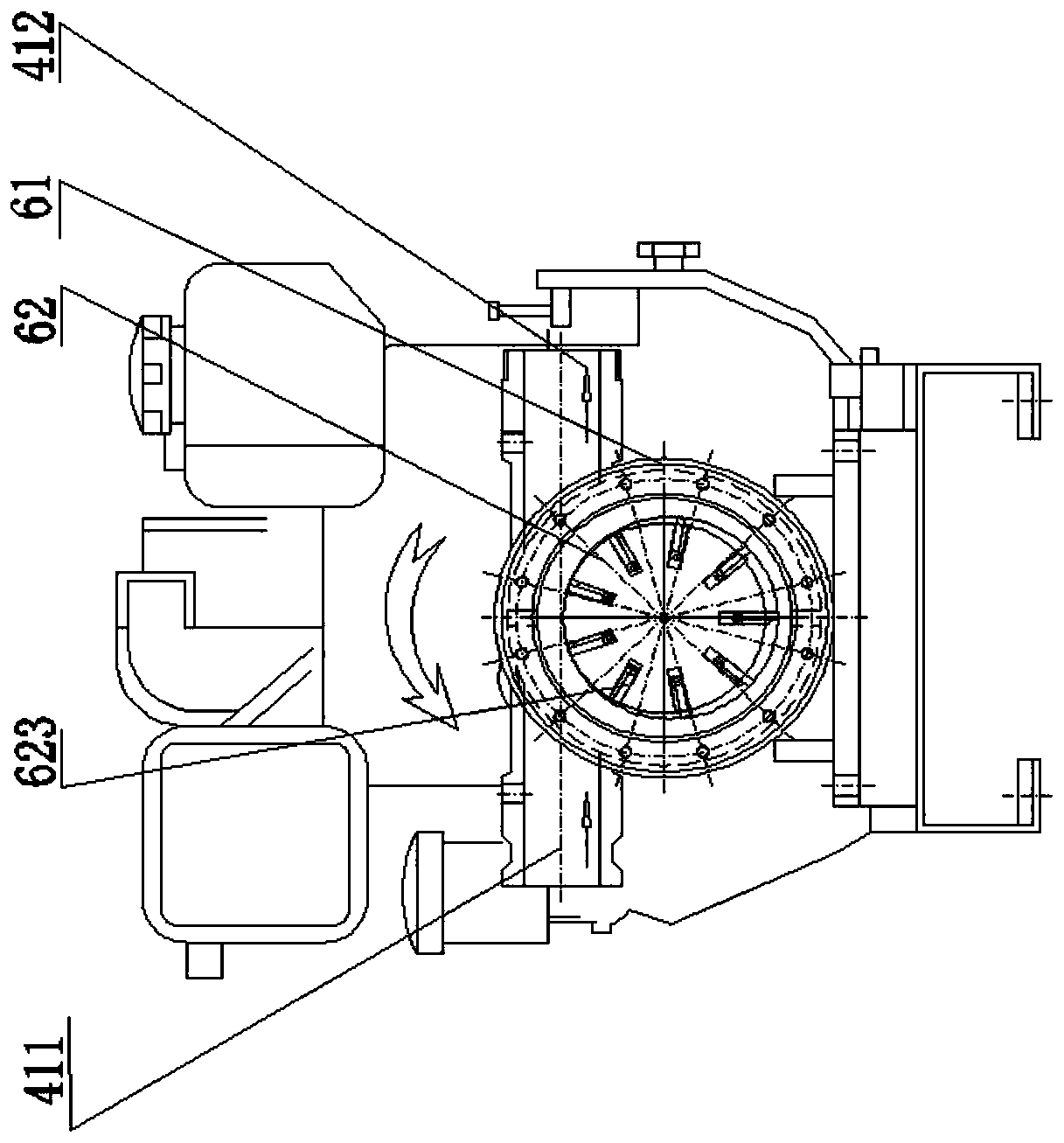

Drive axle and vehicle with same

ActiveCN110962505AImprove reliabilityExtended service lifeGear lubrication/coolingAxle unitsElectric machineryControl theory

The invention discloses a drive axle and a vehicle with the same. The drive axle comprises a motor assembly which comprises a motor shaft; an axle housing assembly which comprises an axle housing cavity; and a speed reducing device which is arranged in the axle housing cavity. The motor shaft is connected with the speed reducing device, a planet wheel and a first connecting shaft are arranged in the speed reducing device, the first connecting shaft penetrates through the planet wheel and is connected with the planet wheel through a roller bearing, and an oil inlet channel is formed in the first connecting shaft so that the axle housing cavity can be communicated with the interior of the speed reducion device. According to the drive axle, all components in the speed reducing device can be lubricated, the reliability of the drive axle is improved, and the service life of the drive axle is prolonged.

Owner:BYD CO LTD

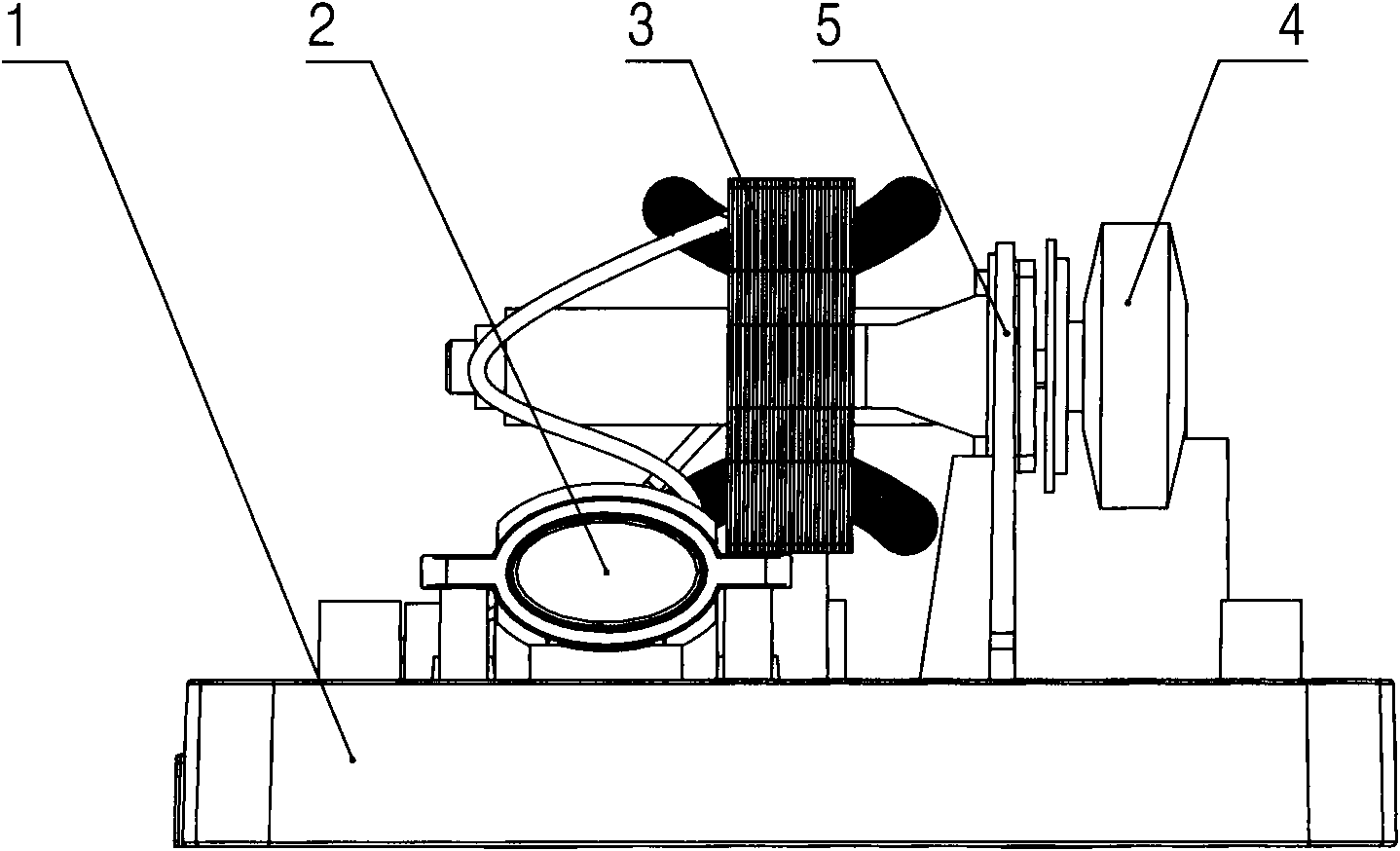

Emergency fire pump of marine diesel engine

PendingCN110242565AGuaranteed service lifeGuaranteed lubrication effectRotary piston pumpsRotary/oscillating piston combinationsGraphiteLubrication

The invention discloses an emergency fire pump of a marine diesel engine. A diesel engine is in transmission connection with a sliding vane pump through a coupler, and the diesel engine and the sliding vane pump are fixed on the base. The emergency fire pump of the marine diesel engine is simple in structure, has abilities of high suction lift and strong self priming; the working efficiency of the emergency fire pump is improved; the positive displacement pump is internally provided with graphite sliding vanes; lubrication between members in the positive displacement pump is ensured; and the probability of faults is reduced.

Owner:JIANGSU DEHUA PUMP MFG CO LTD

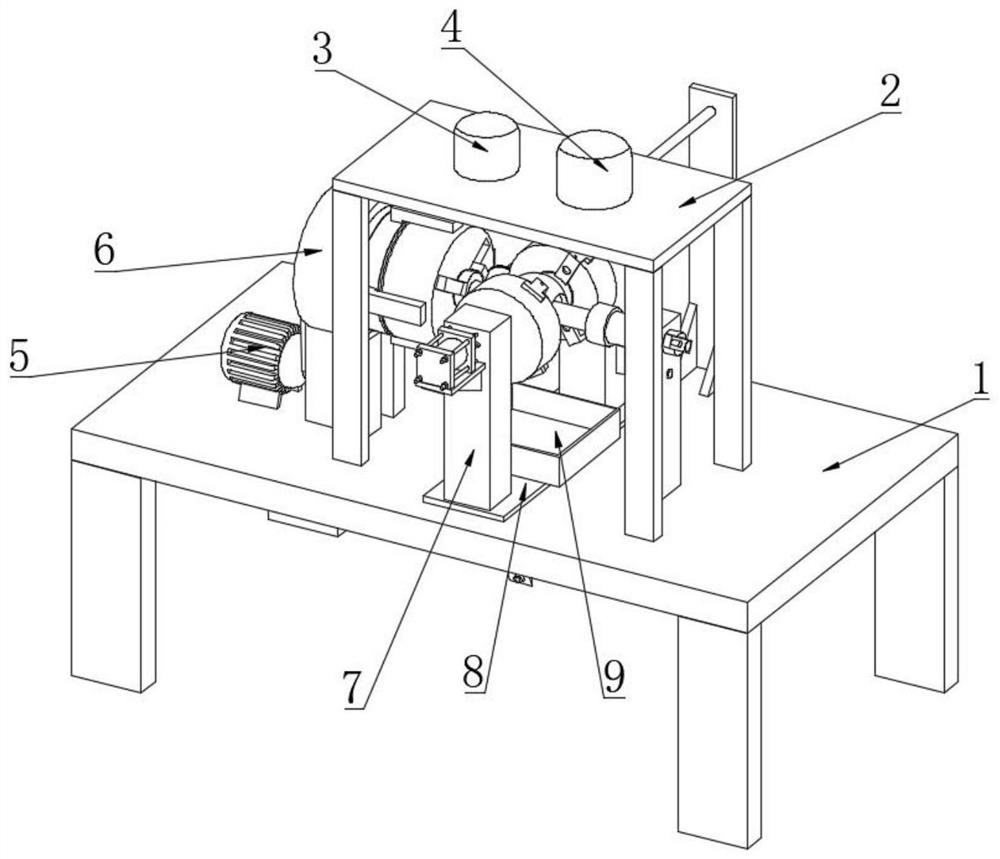

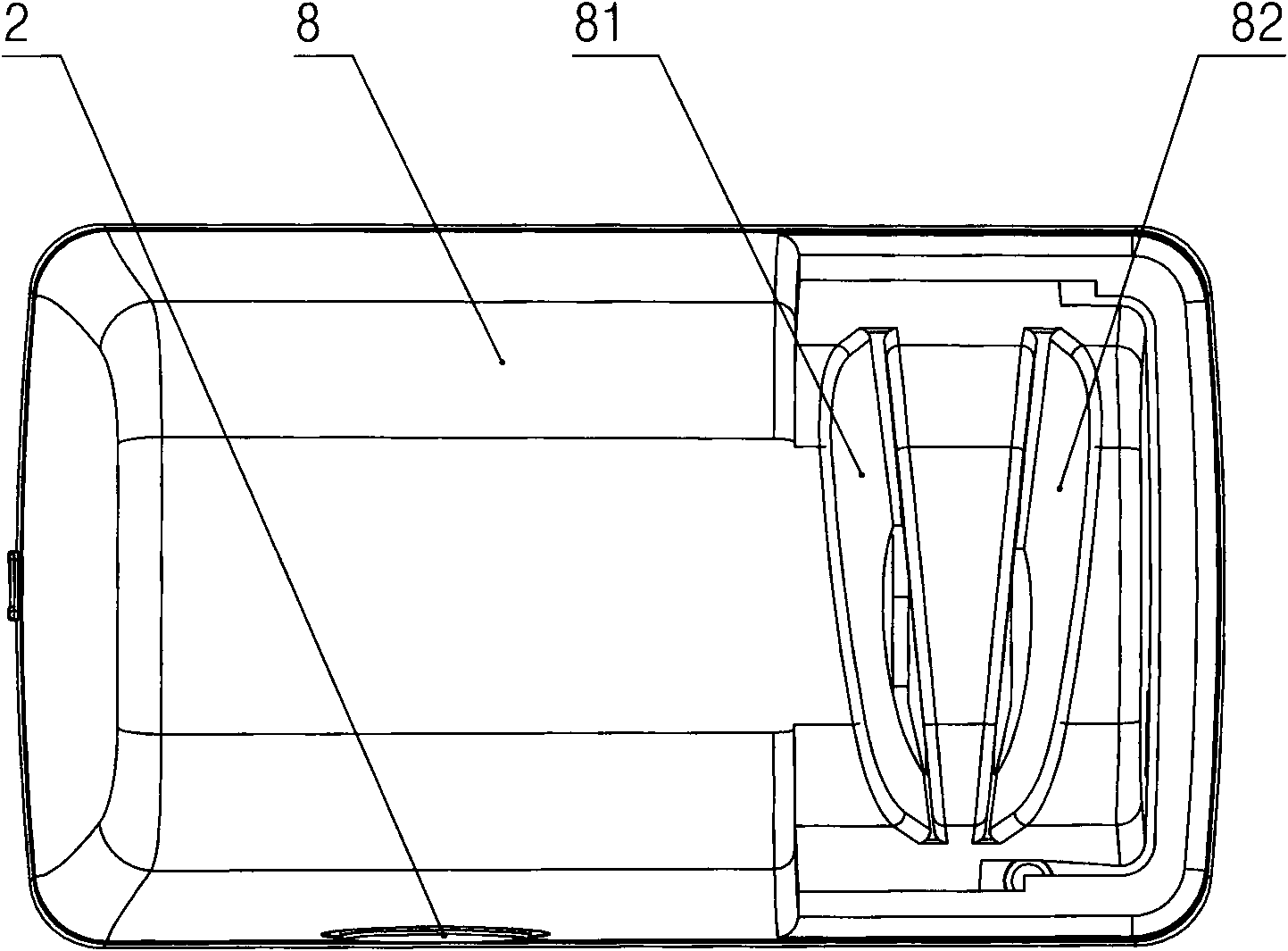

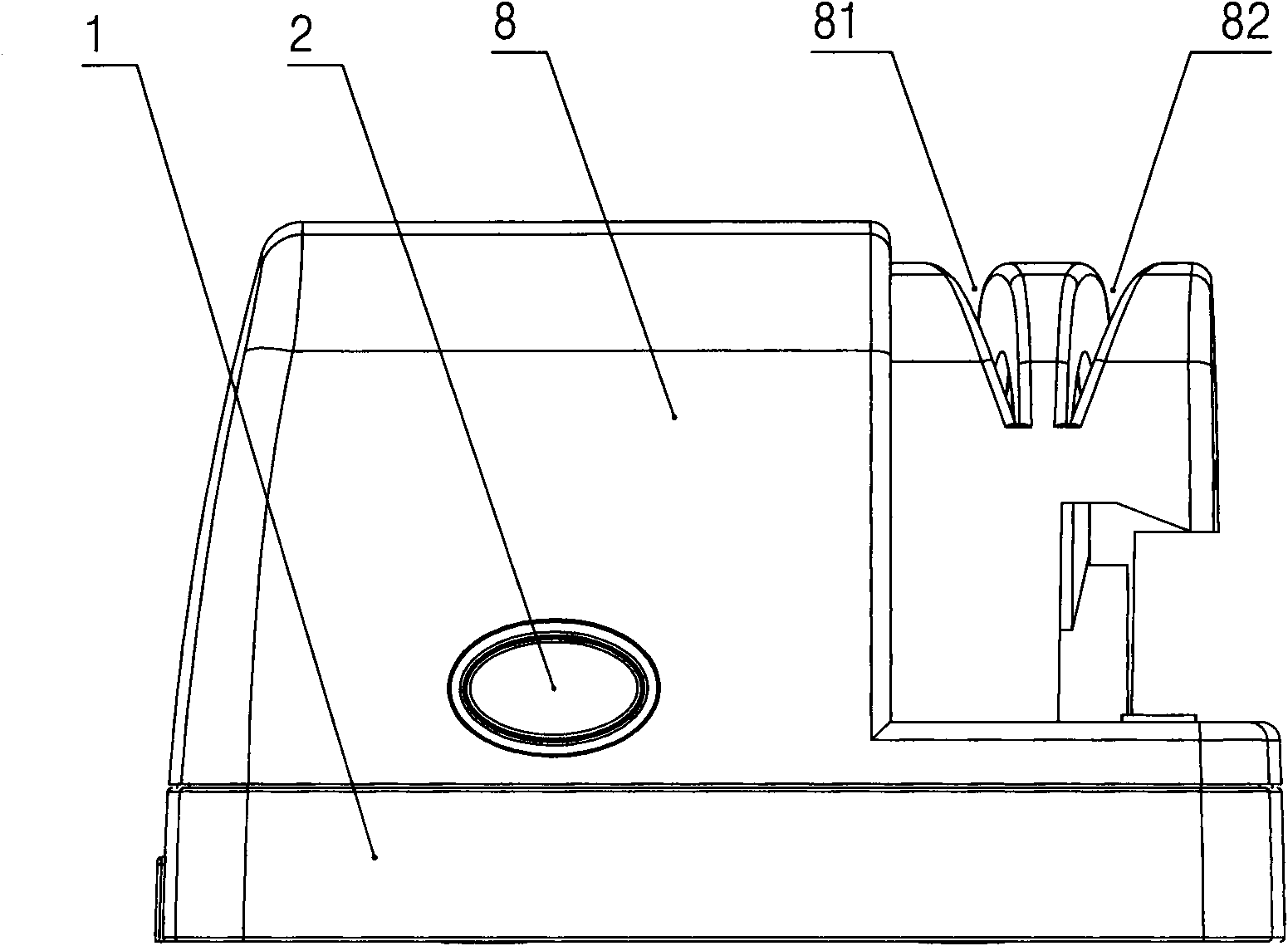

Cutter grinding machine

InactiveCN101549470AReduce pollutionPrevent annealingOther manufacturing equipments/toolsGrinding/polishing safety devicesEngineeringMetal debris

The invention discloses a cutter grinding machine which can block large part of metal debris when grinding a cutter, comprising a base; the base is provided with a motor; an output shaft of the motor is provided with a grinding wheel; the base is also provided with a shell; the motor and the grinding wheel are respectively covered in the shell; and the top part of the shell is provided with two grinding ports which are respectively matched with the grinding surfaces of the two sides of the grinding wheel. The cutter grinding machine is very suitable for being manufactured into small household appliance and enters every family.

Owner:钱国兴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com