Oil supplementing system for gearbox

A gearbox and oil replenishment technology, which is applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the unavoidable dry grinding state of gear bearings, the difficulty in ensuring gearbox lubrication, and the inability to meet large flow applications Requirements and other issues, to achieve the effect of simple structure, improve operating efficiency, and avoid dry grinding state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

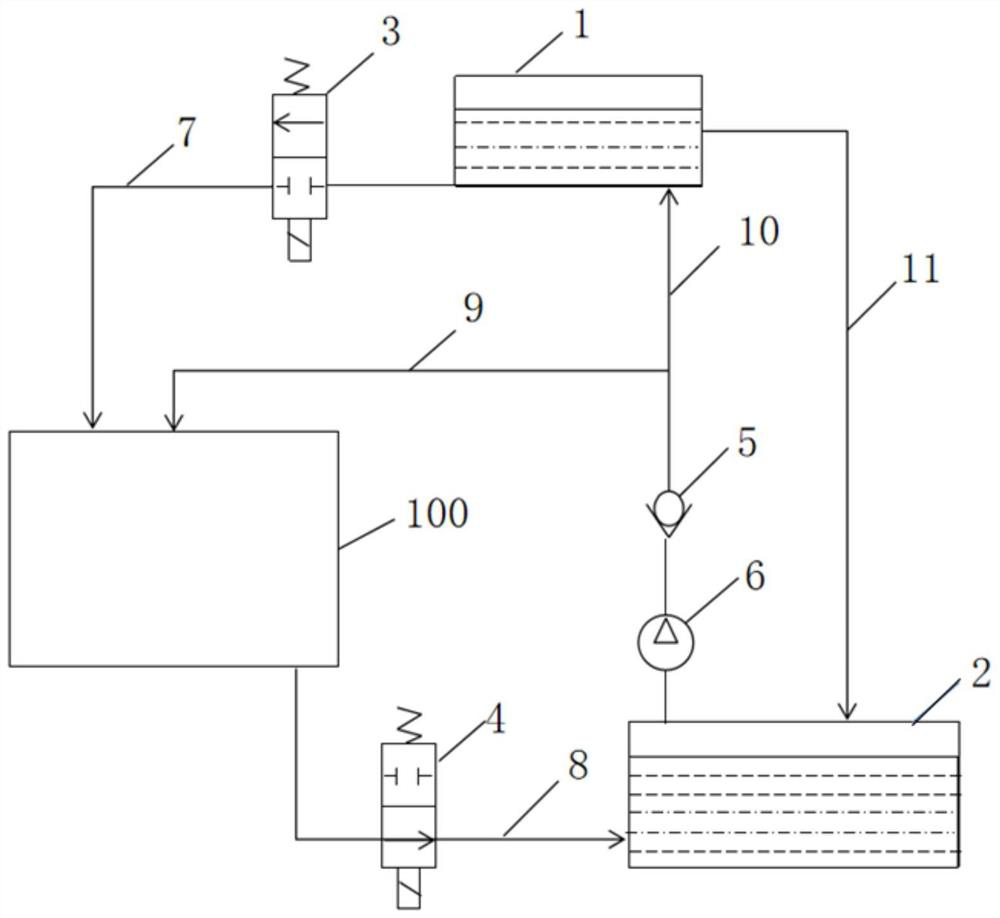

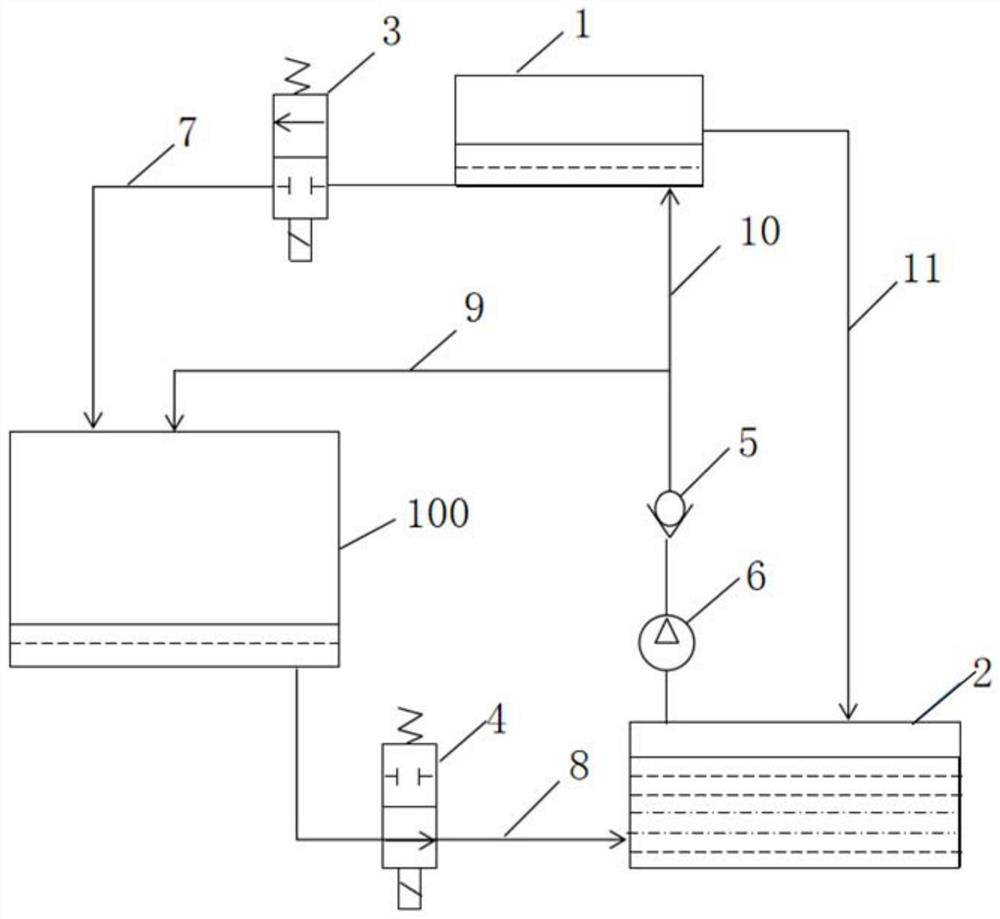

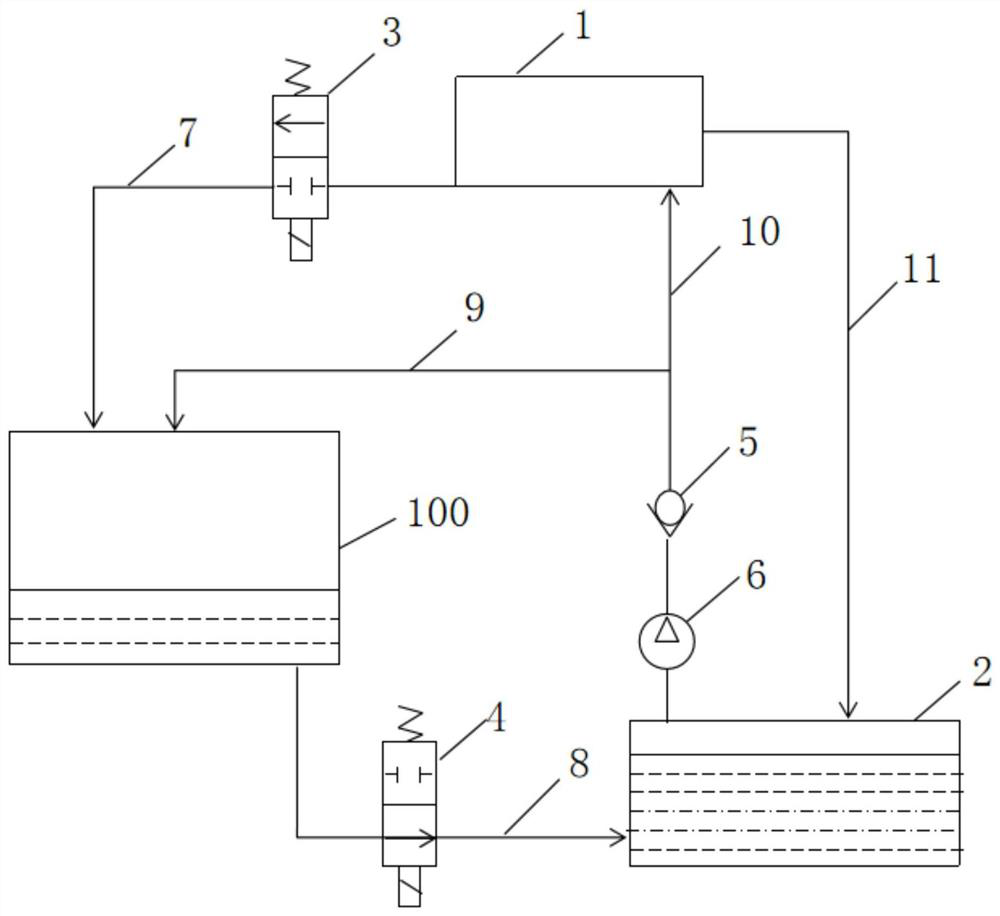

[0022] Refer below Figure 1 to Figure 3 The specific structure of the oil supply system of the gearbox of the embodiment of the present invention is described.

[0023] like Figure 1 to Figure 3 As shown, the present embodiment provides an oil replenishment system of a gearbox 100, the gearbox 100 has a first oil inlet, a second oil inlet and an oil outlet, and the oil replenishment system of the gearbox 100 includes an oil tank, a control valve , a one-way valve 5 and an oil pump 6. The oil tank includes a first oil tank 1 and a second oil tank 2. The first oil tank 1 is set at a high position relative to the gear box 100, and the second oil tank 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com