Cold start protective solution for engine and preparation thereof

A technology for starting protective fluids and engines, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of high price, unbearable for car owners, special chemical components cannot be attached for a long time, etc., to save resources, reduce fuel consumption, save energy Effects of social resources and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Pour 73.5% soybean oil into the reaction kettle and heat to 60°C; add 6.10% zirconia and 5.50% yttrium oxide into the reaction kettle, stir and heat to 65°C; add 13.0% anti-wear component polytetrafluoroethylene to the reaction In the kettle, stir and heat to 70°C; add 1.90% additives into the reaction kettle, stir and heat to 95°C, stop heating; cool to room temperature; pack separately. The additives are 0.95% molybdenum borate and 0.95% nano-rare earth fluoride, and nano-erbium fluoride is used in this embodiment. However, the scope of protection of the present invention is not limited to this embodiment. According to the common sense of those skilled in the art, nanometer rare earth fluorides can achieve the purpose of the present invention.

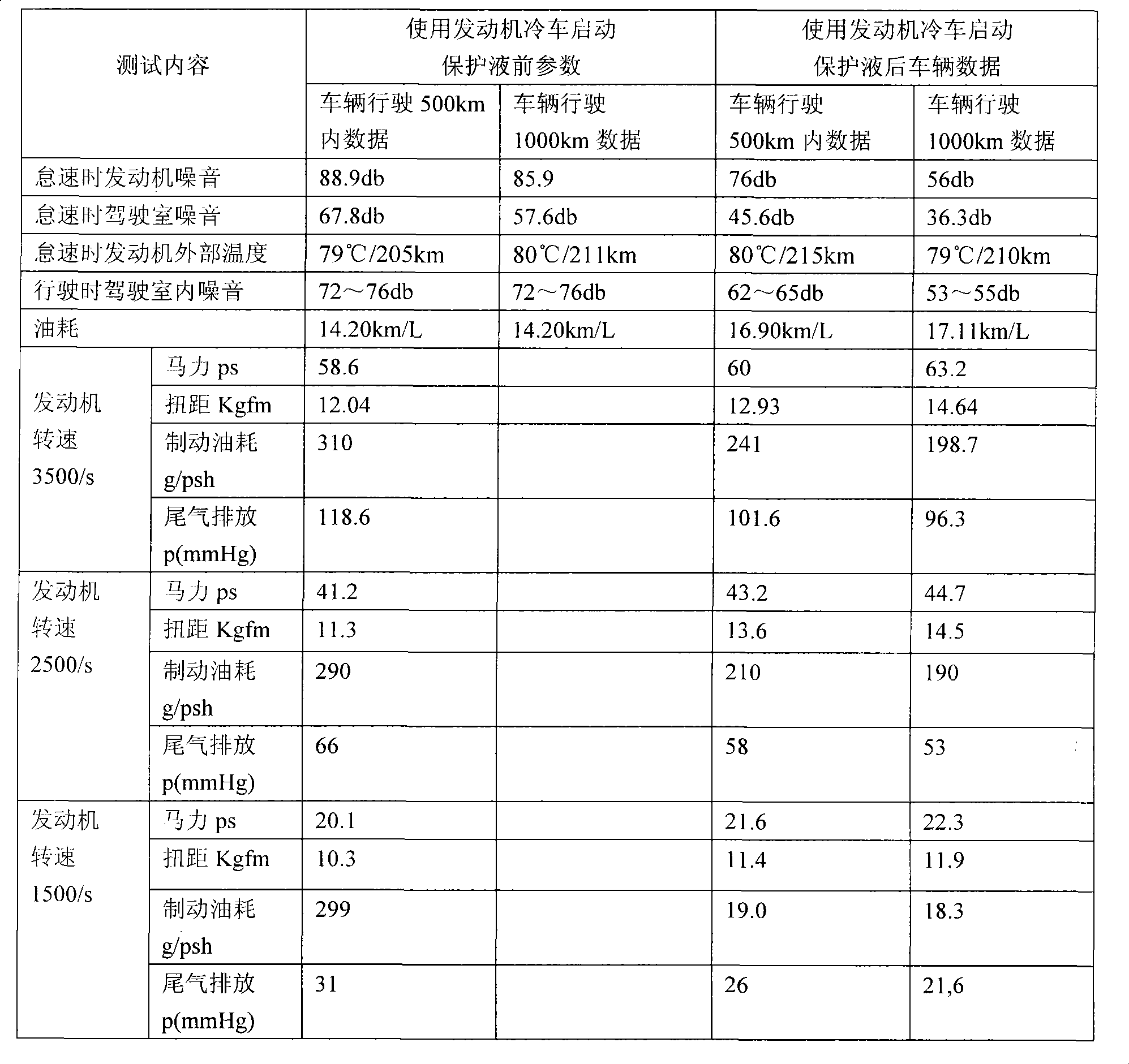

[0037] The engine cold start protection fluid produced in this example is mixed with the "yellow shell" lubricating oil produced by Shell Company of the United States at a volume ratio of 1:10. The actual vehicle test data are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com