Floating oil seal with oil storage micropore abrasion-resistant faces

A floating oil seal and microporous technology, applied in the mechanical field, can solve the problems of short service life of the floating oil seal, and achieve the effects of reducing friction and wear, facilitating heat dissipation, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

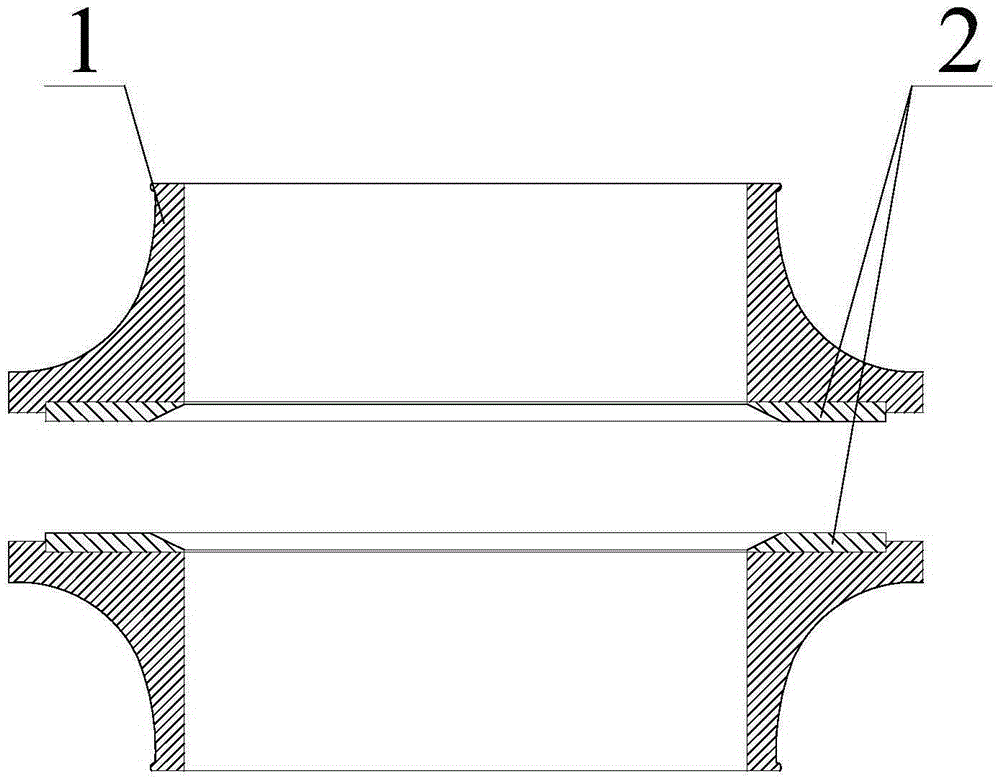

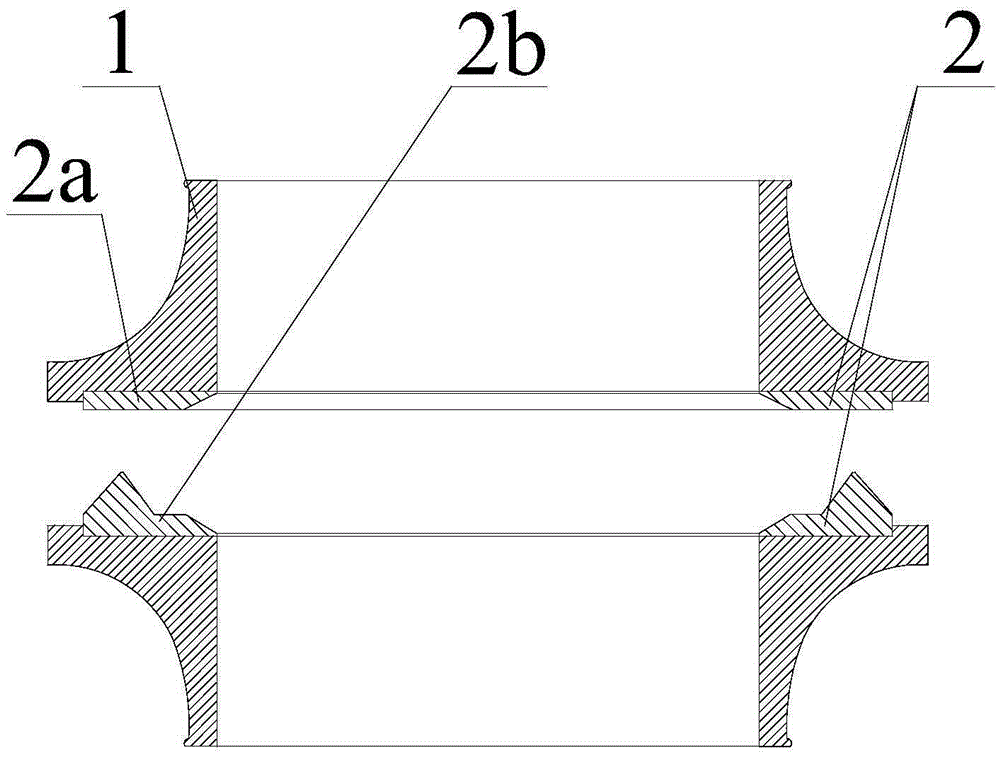

[0021] Such as figure 1 As shown, the floating oil seal with oil storage microporous wear-resistant surface designed by the present invention includes a pair of sealing ring bodies 1 with symmetrical upper and lower structures, and friction assemblies are respectively arranged on the two opposite end faces of the sealing ring body 1, The two friction assemblies form a pair of friction pairs 2 that match in position.

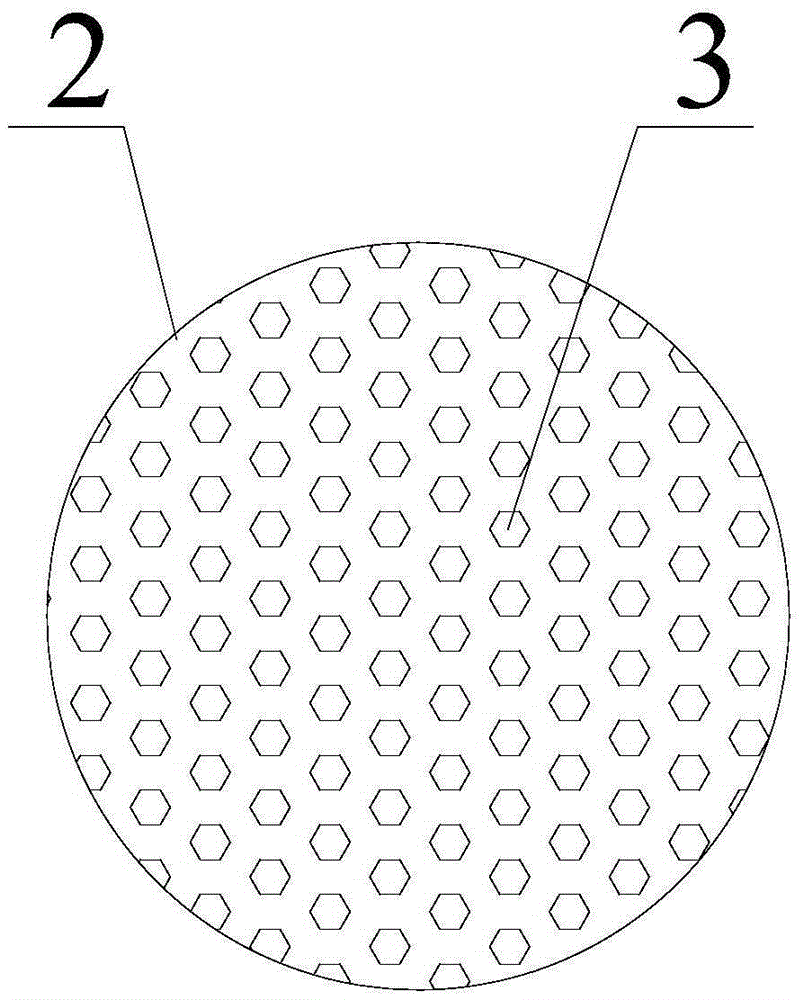

[0022] Such as figure 2 As shown, the friction surfaces of one or both of the friction components of the friction pair 2 of the present invention have undergone micro-pit or micro-groove texture treatment, and the surface has widely distributed micro-depressions 3, and the micro-depressions 3 are Micro-pits or micro-grooves are used to store lubricating oil, grease and other lubricating substances, so that an oil film can be for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com