Energy protection method, device and equipment for AMT clutch and storage medium

A clutch and energy technology, applied in clutches, mechanical equipment, transmission control and other directions, can solve problems such as increased wear rate, reduce the wear rate, reduce the burden of friction and heat, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

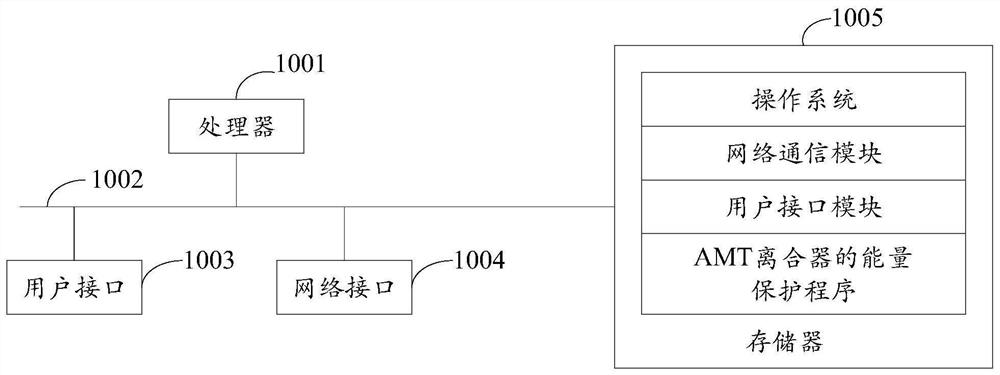

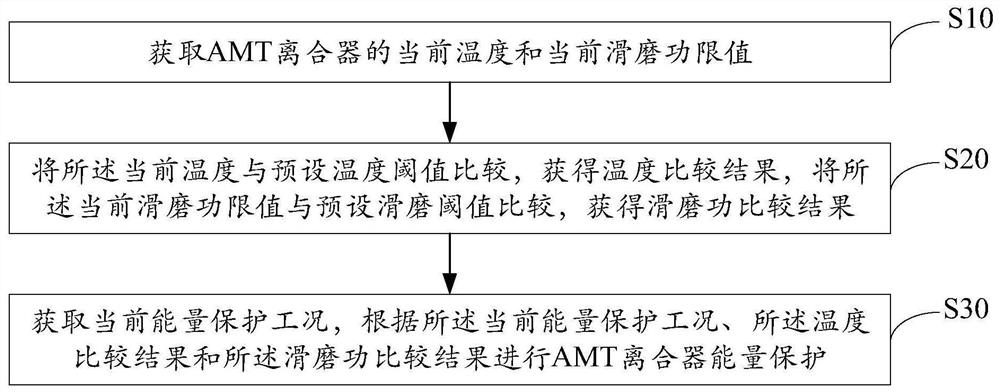

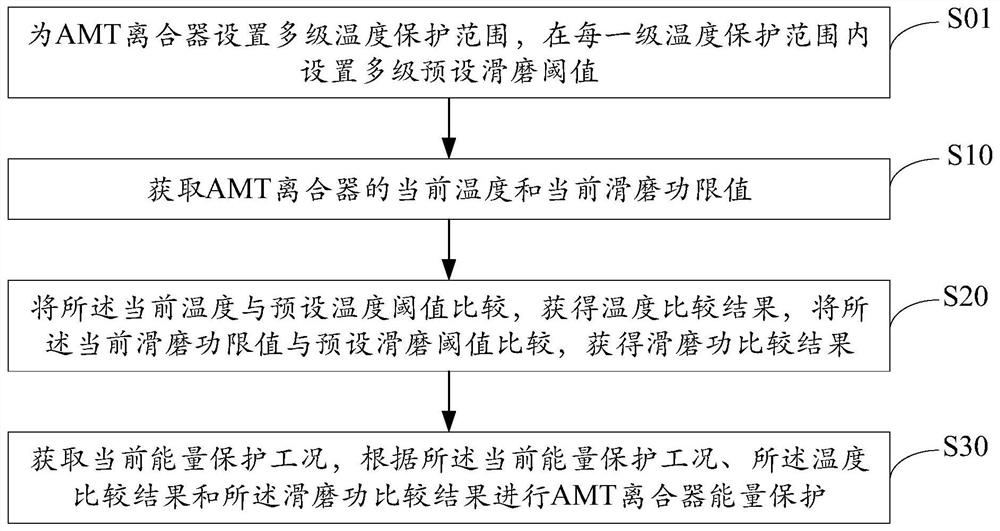

[0051] The solution of the embodiment of the present invention is mainly: by obtaining the current temperature and the current sliding work limit of the AMT clutch; comparing the current temperature with the preset temperature threshold to obtain a temperature comparison result, and calculating the current sliding work limit value is compared with the preset slipping threshold to obtain the comparison result of slipping work; obtain the current energy protection working condition, and perform AMT clutch energy protection according to the current energy protection working condition, the temperature comparison result and the slipping work comparison result , can adopt different coping strategies for different working conditions, avoid dry grinding when the friction plate slips, reduce the burden of friction and heat gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com