Precision grinding process of high-purity silicon crystal material

A grinding process, silicon crystal technology, applied in grinding devices, grinding machine tools, manufacturing tools, etc., can solve the problems of uneven grinding pressure of workpiece and abrasive, difficult to guarantee the accuracy of workpiece, uneven distribution of abrasive, etc., and achieve good grinding effect. , The effect of stable grinding pressure and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

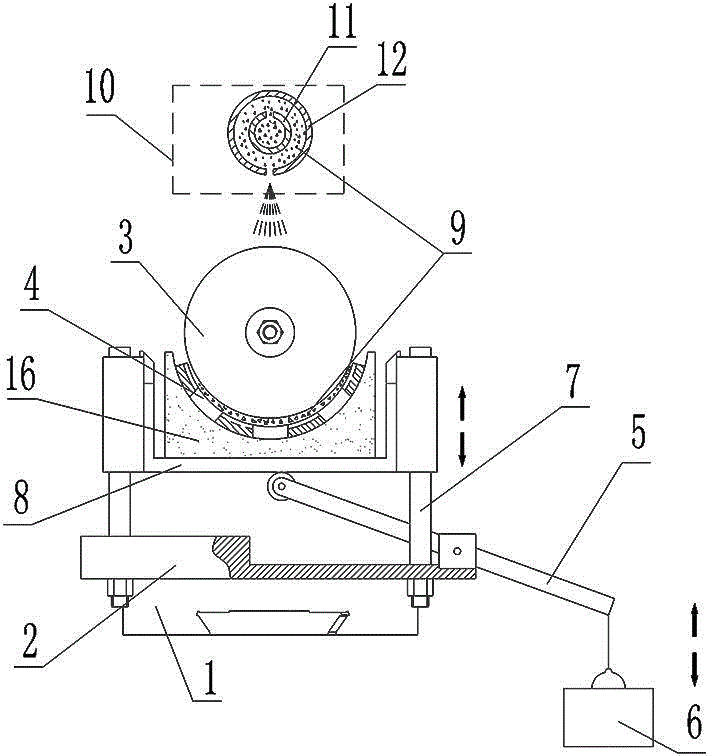

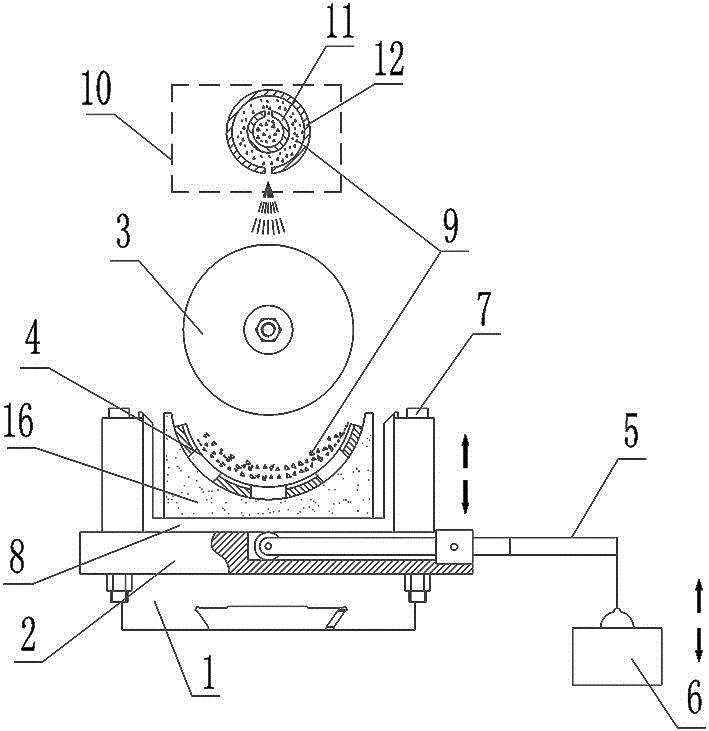

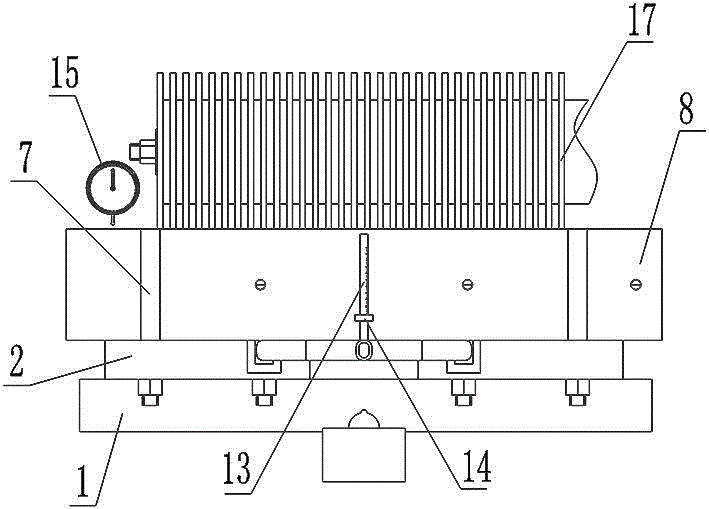

[0029] Such as Figure 1 ~ Figure 3 As shown, a high-purity silicon crystal material precision grinding process includes a machine tool, a base plate 2 , a notching tool 3 , a notching workpiece 4 , a lever 5 and a weight 6 . The base plate 2 is installed on the supporting plate 1 of the machine tool, and the position of the base plate 2 is adjusted by adjusting the position of the supporting plate 1 on the machine tool. Four sets of base plate optical axes 7 are fixed on the upper surface of the base plate 2, and a loading plate 8 is placed above the base plate 2, and a hole corresponding to the base plate optical axis 7 is opened on the loading plate 8, and the base plate optical axis 7 is inserted into the loading plate 8 holes. A graphite carrier 16 is fixed on the top of the loading plate 8 by tightening bolts, and a grooved workpiece 4 is glued on the top of the graphite carrier 16 . A grooving tool 3 is arranged above the grooving workpiece 4, and a spray pipe 10 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com