Mechanical sealing structure with flower and plant simulating fluid type groove end surfaces

An end face mechanical seal and mechanical seal technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as unsatisfactory start-up performance or low-speed and low-pressure performance, fluid film bearing capacity and rigidity limitations, etc., to improve dynamic pressure Opening characteristics, safe and reliable sealing operation, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

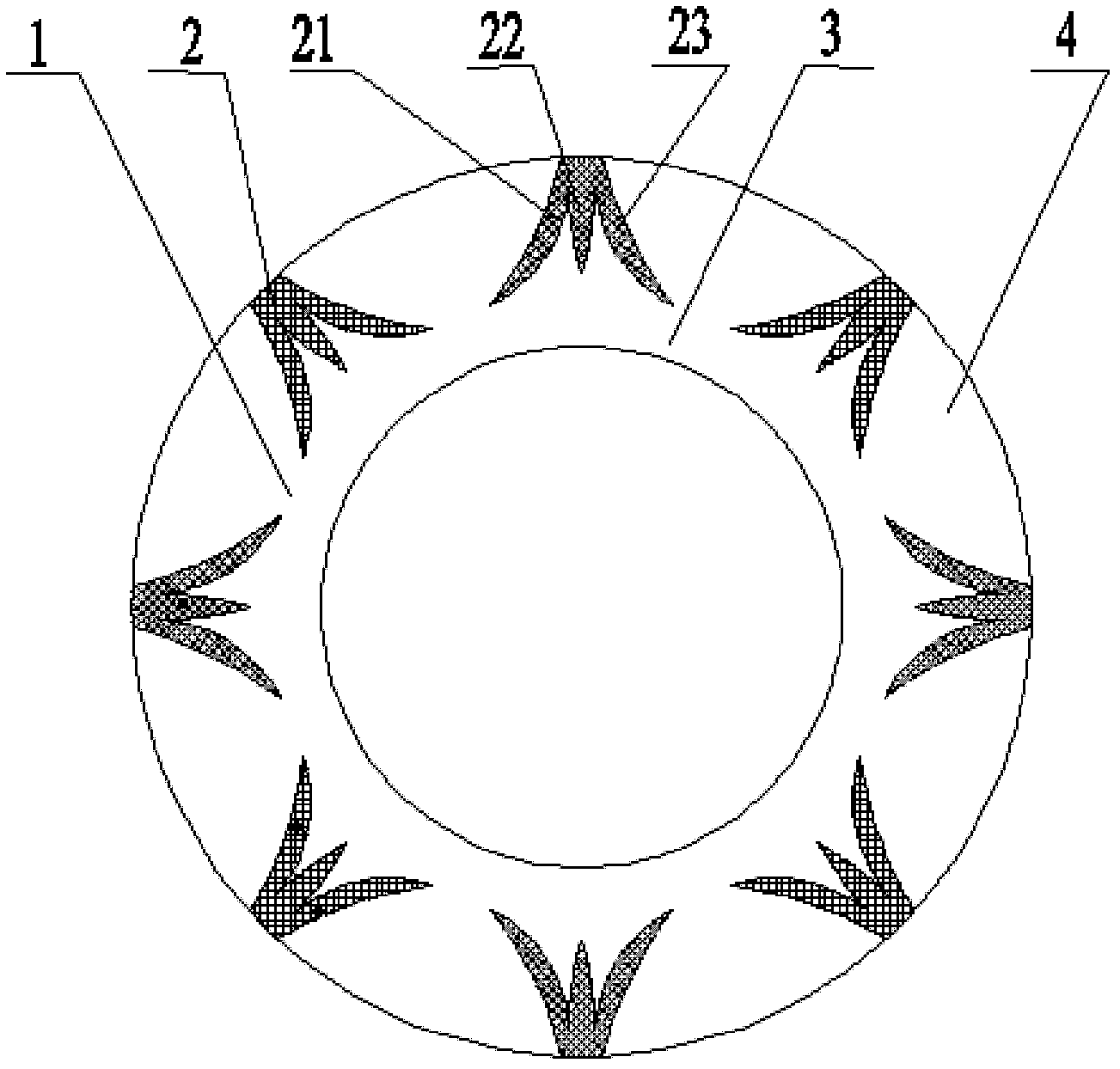

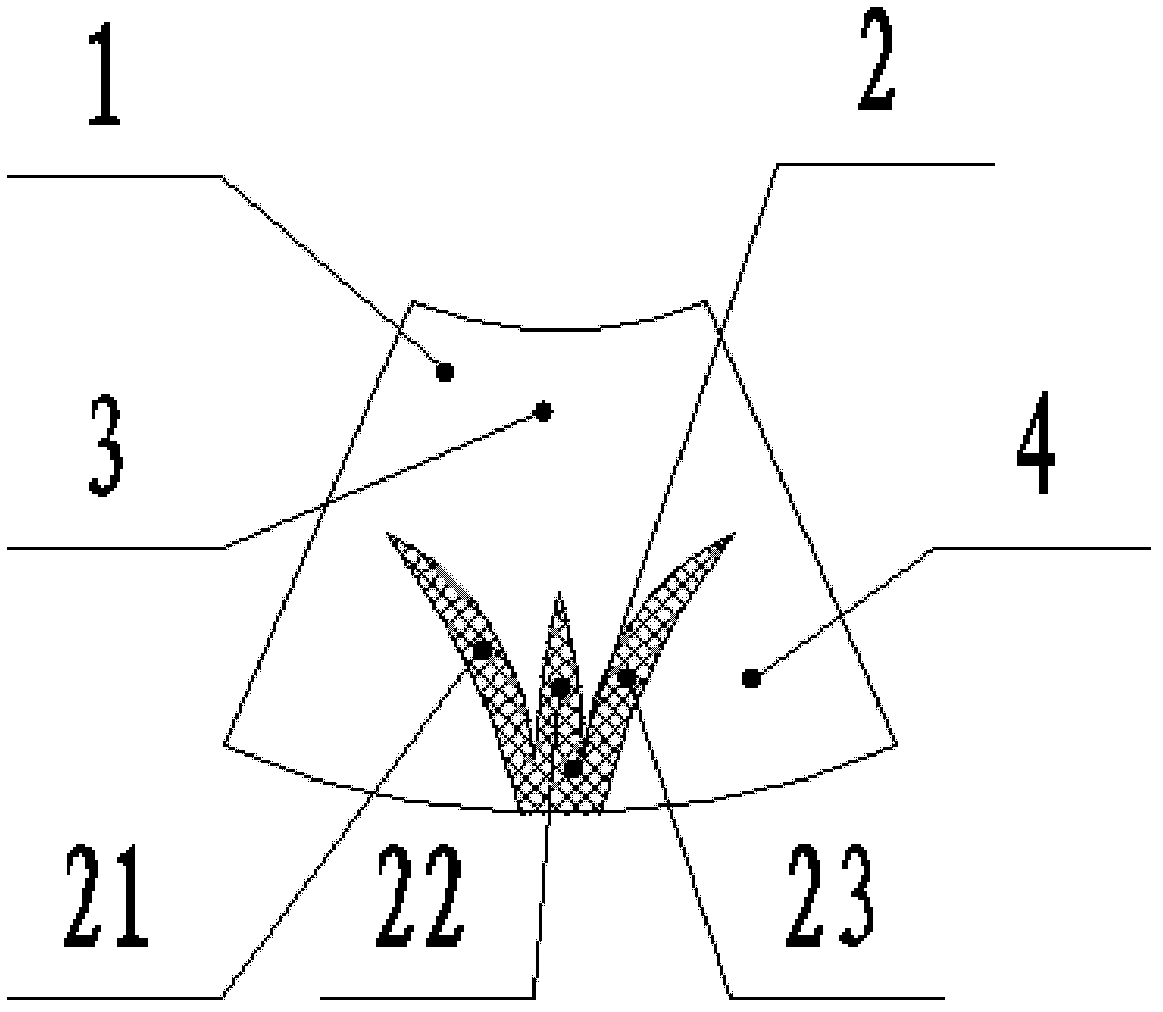

Embodiment 1

[0031] refer to Figure 1-2 , a mechanical seal structure imitating flowers and grass fluid type groove end faces, including a moving ring and a static ring of a mechanical seal, one side of the end faces of the moving ring and the static ring is the high pressure side, that is, the upstream, and the end faces of the moving ring and the static ring The other side is the low-pressure side, that is, the downstream, and the downstream of the end face is provided with a smooth and flat annular seal dam 3, which is characterized in that at least one end face of the moving ring or static ring is provided with a plurality of uniformly distributed circumferential seals. The drainage groove 22 and the left and right grooves 21, 23 centered on the drainage groove 22 form a fluid-type groove 2 similar in shape to flowers and plants. The drainage groove 22 is a radial groove, and the fluid-type groove 2 is distributed in accordance with On an annular belt at the center of the end surface ...

Embodiment 2

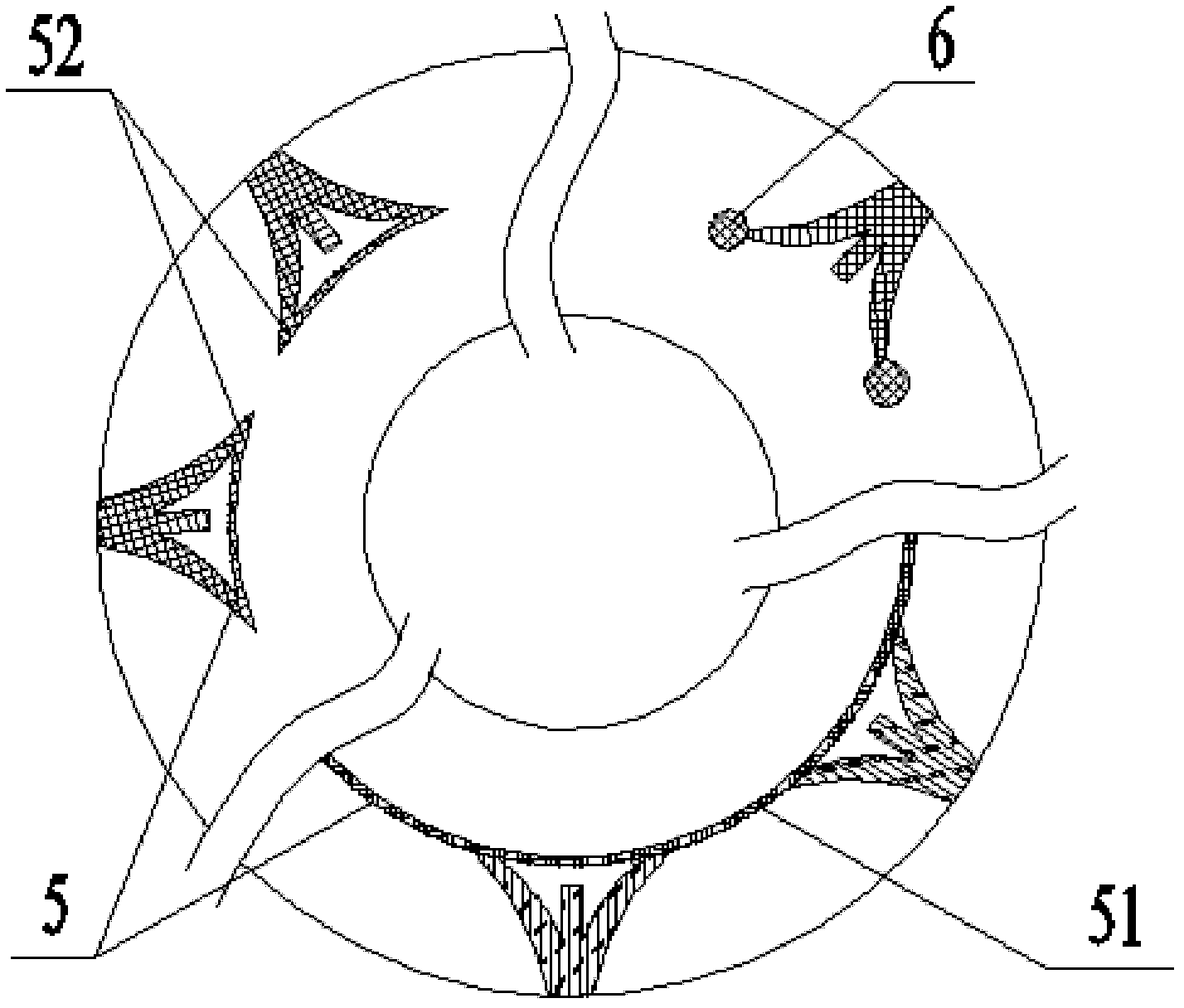

[0041] refer to image 3 The difference between the present embodiment and the first embodiment is that the downstream end of the imitation flowers and plants fluid type groove is connected with other type grooves 5 or type holes 6, so as to improve the pressure distribution in the circumferential direction of the end surface where the root of the groove is located and in the vicinity thereof Uniformity, enhance the hydrodynamic pressure effect, improve the rigidity of the fluid film, improve the start-up characteristics of the seal and the ability to operate at low speed and low pressure, and improve the wear resistance of the end face.

[0042] Described type groove 5 can be circular groove 51, arc groove 52 etc. type line groove, and the width and depth of described type groove 5 are respectively w a and h a , the value range is: w a =0.5~2.0mm, h a =h g / 10~h g / 5, where h g It is the depth of imitation flowers and plants fluid type groove; Described type hole 6 is m...

Embodiment 3

[0044] refer to Figures 4a-4c , The difference between this embodiment and Embodiment 1 is that the fluid-type groove presents a convergent stepped structure with a deep upstream and a shallow downstream. The convergent fluid groove can be one step, two steps or multiple steps, but in order to control the processing cost, it is generally better to use two or three steps under the premise of satisfying a certain cost performance. The minimum depth of the downstream side of the groove should not be less than 1.5μm (dry gas seal) or 0.1mm (liquid seal); in addition, in the case of higher requirements for sealing stability and end surface lubricity, a convergent inclined step structure can also be used. The inclination angle of the inclined steps is 2-10 degrees. The flower-like fluid type groove end face mechanical seal with a convergent step structure is to meet the needs of applications such as low speed or long start-up process or sudden changes in operating conditions, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com