Slag dragging machine and chain guiding device thereof

A technology of guide device and slag removal machine, which is applied in the field of slag removal machine and chain guide device, which can solve problems such as economic loss, aggravated chain wear, and grinding damage of bearing 13, so as to improve economic benefits, reduce economic losses, and avoid dry grinding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

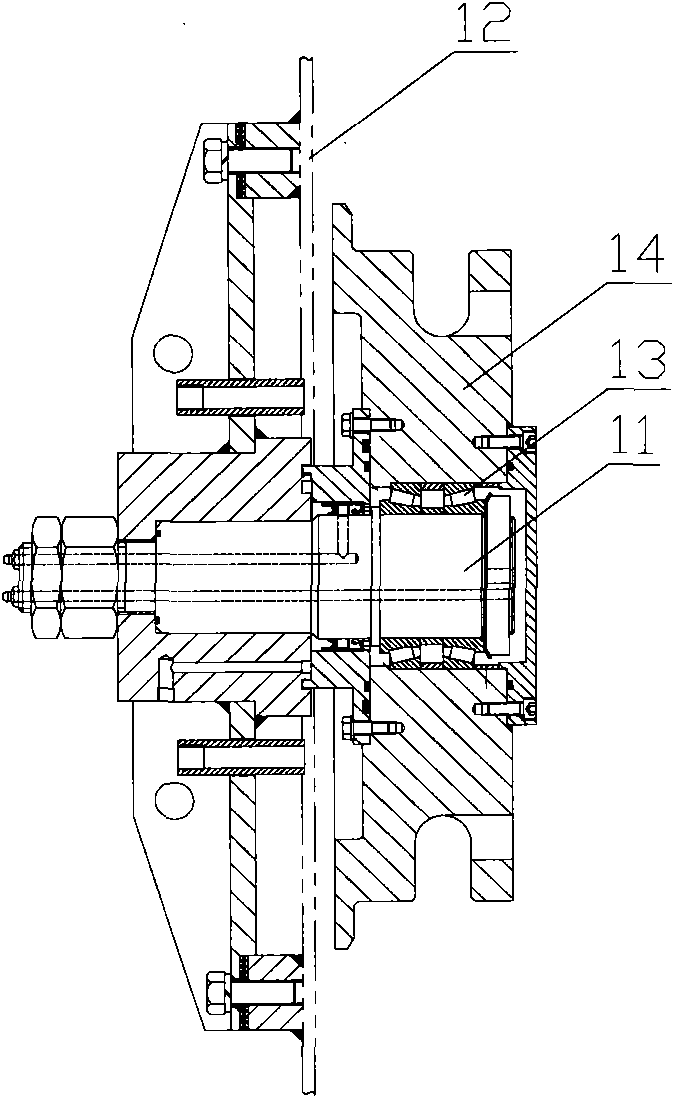

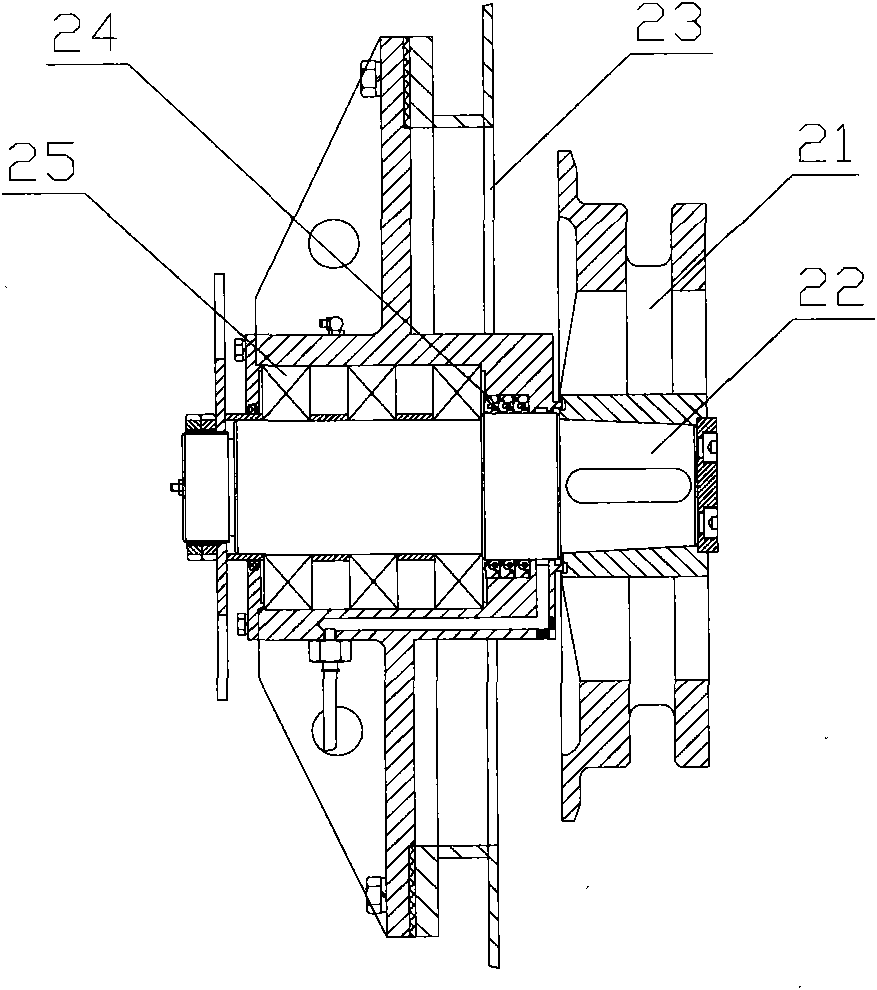

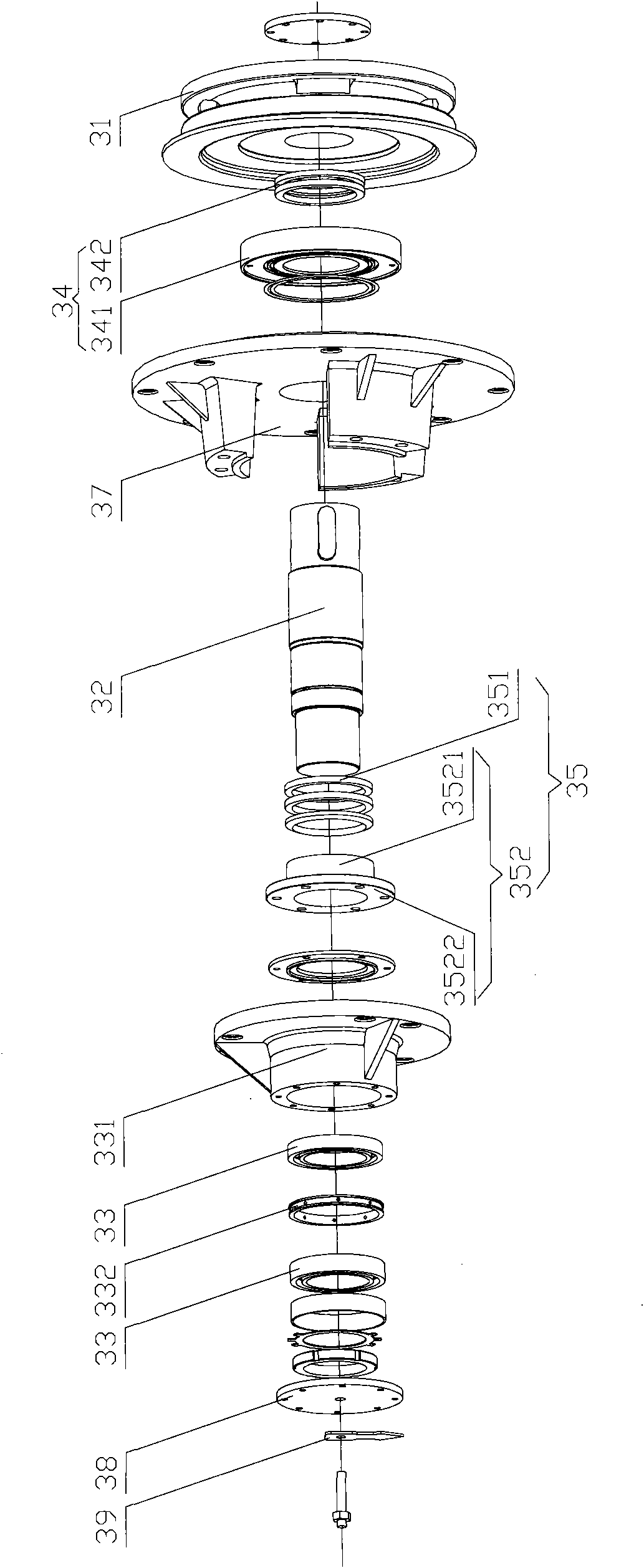

[0040] The core of the present invention is to provide a chain guide device for slag removal machine, the chain guide device can realize on-line maintenance, good reliability, avoid maintenance of the chain guide device instead of normal shutdown maintenance, reduce economic losses, improve economic benefits of the enterprise. Another core of the present invention is to provide a slag removing machine including the above-mentioned chain guide device, the reliability of which is improved.

[0041] The orientation words such as inside and outside involved in this article are defined based on the shell of the slag extractor. The working space filled with slag water formed by the shell of the slag extractor is the inside, and the space opposite to its internal space is the outside. It should be understood that the orientation words used herein shall not limit the protection scope of this patent.

[0042] In order to enable those skilled in the art to better understand the solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com