Cutter grinding machine

A knife sharpener and knife edge sharpening technology, applied in grinding/polishing equipment, grinding/polishing safety devices, other manufacturing equipment/tools, etc. Debris splashing and other problems can improve the sharpening effect, lubricate the tool annealing, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

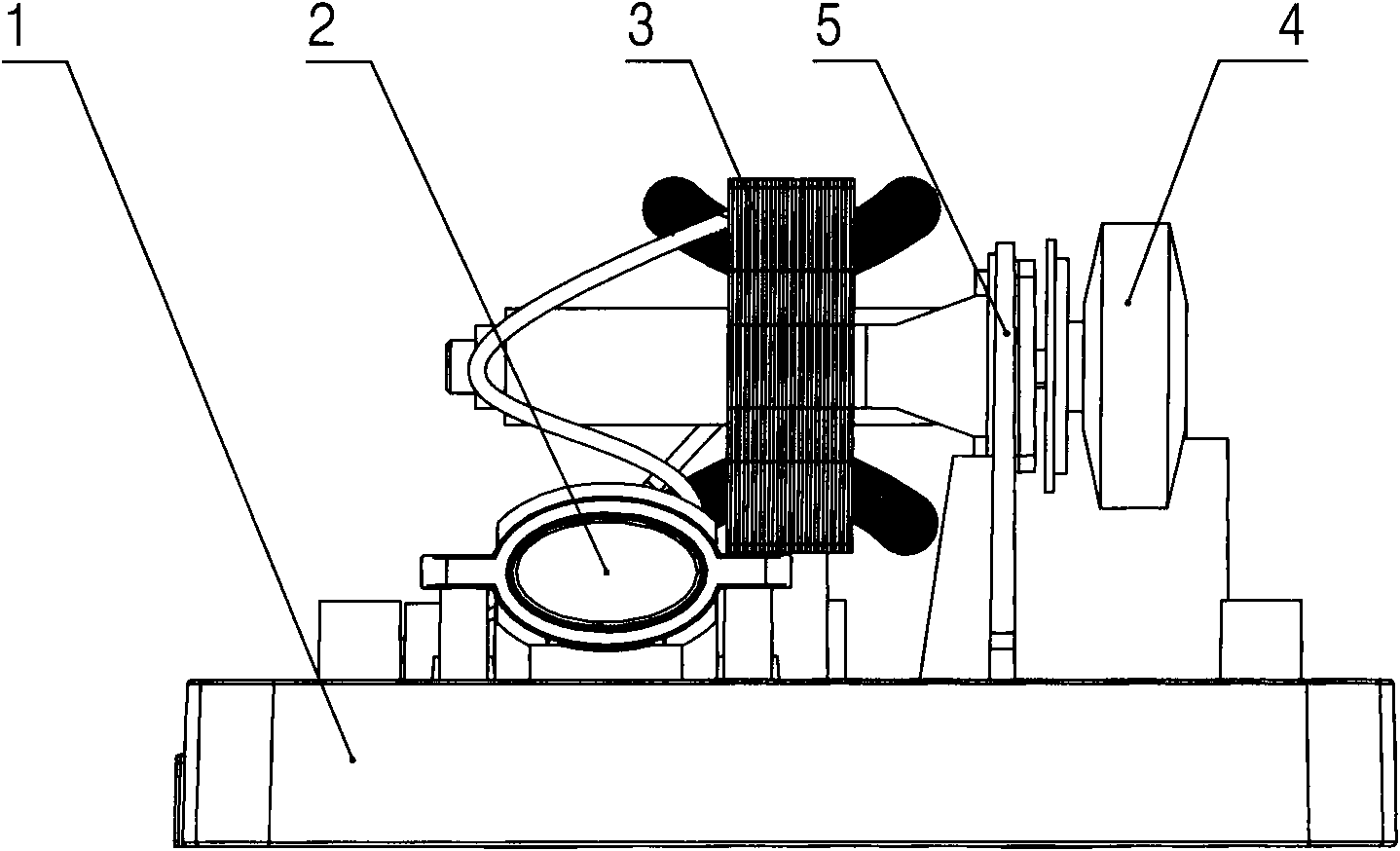

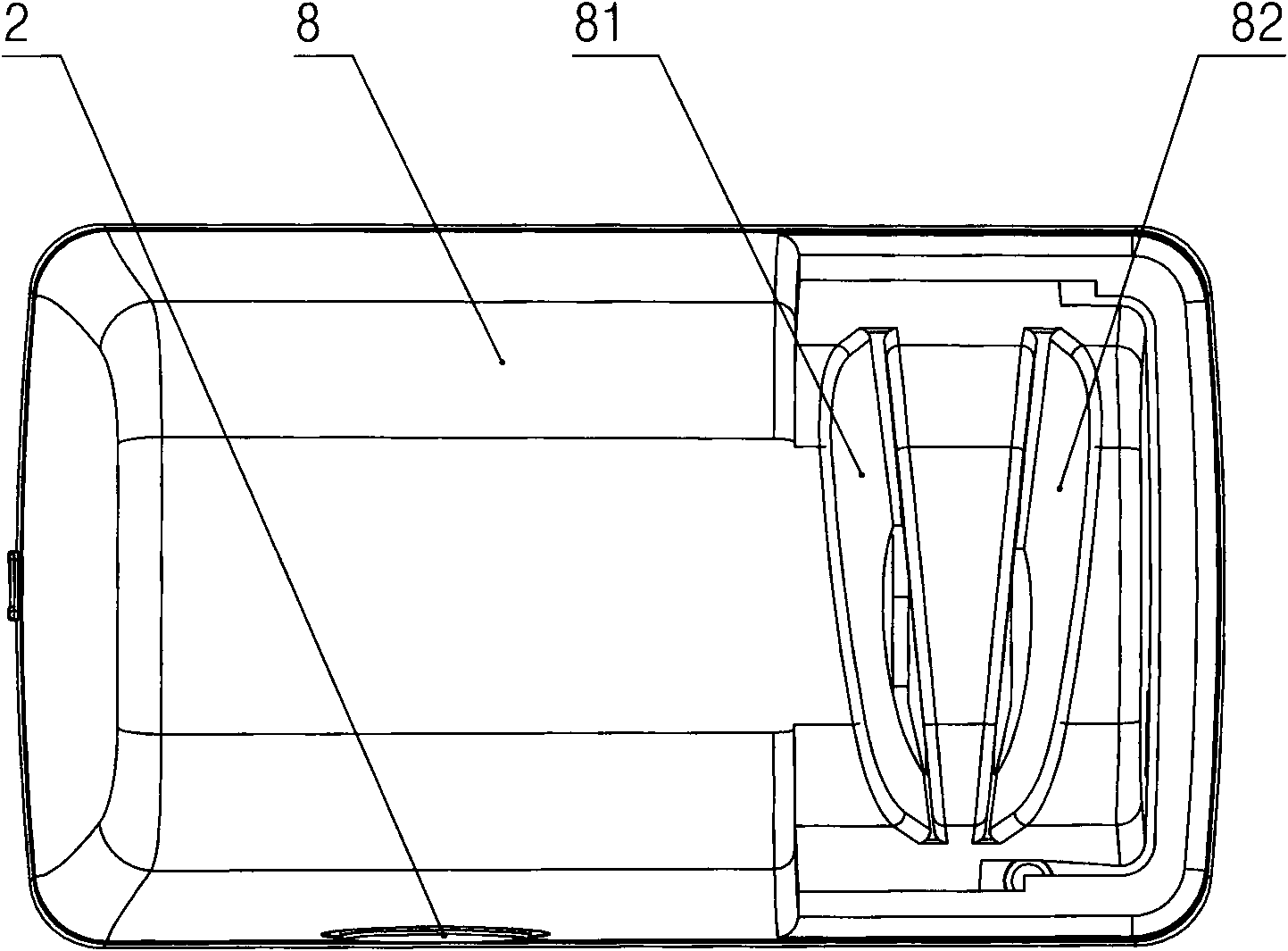

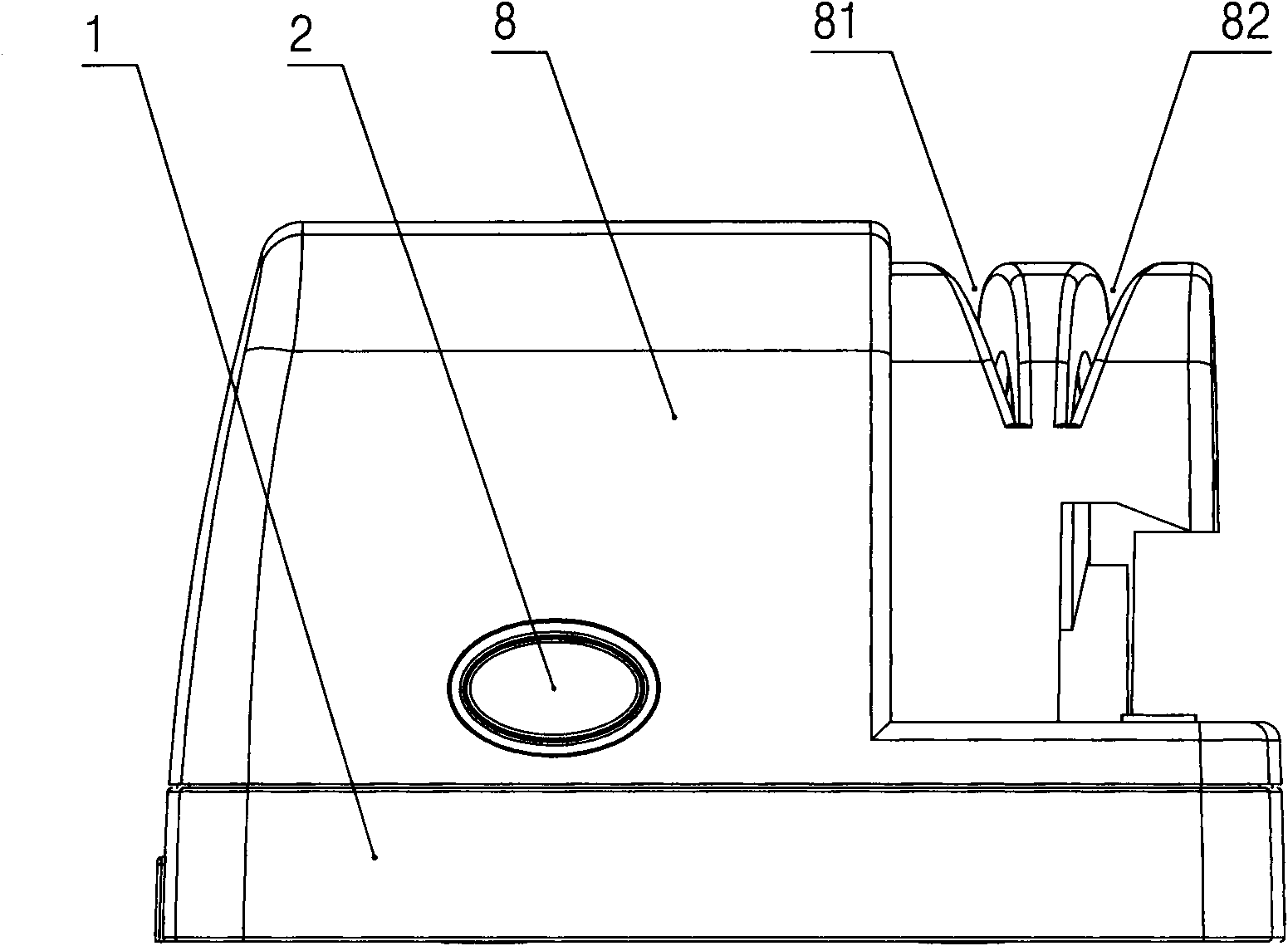

[0018] Such as figure 1 , figure 2 with image 3 As shown, the knife grinder of the present invention includes: a base 1, a motor 3 is arranged on the base 1, and a grinding wheel 4 is arranged on the output shaft of the motor 3. In order to make the rotation of the grinding wheel 4 more stable, a motor 3 is arranged on the base 1. There is a support frame 5, and the output shaft of the motor 3 is movably supported in the support frame 5. The base 1 is also provided with a housing 8, and the switch 2 of the motor 3 is movably arranged in the housing 8. The motor 3 and the emery wheel 4 are all completely covered in the shell 8, and the top of the shell 8 is provided with left and right sharpening edges 81 and 82 that match the left and right sharpening surfaces on both sides of the emery wheel 4; the left and right sharpening edges 81 and 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com