Kingpin bushing dynamic lubrication structure

A technology of power lubrication and bushing, which is applied in the field of auto parts, can solve the problems of bushing wear, parking delay, heavy load, etc., and achieve the effect of avoiding dry grinding and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

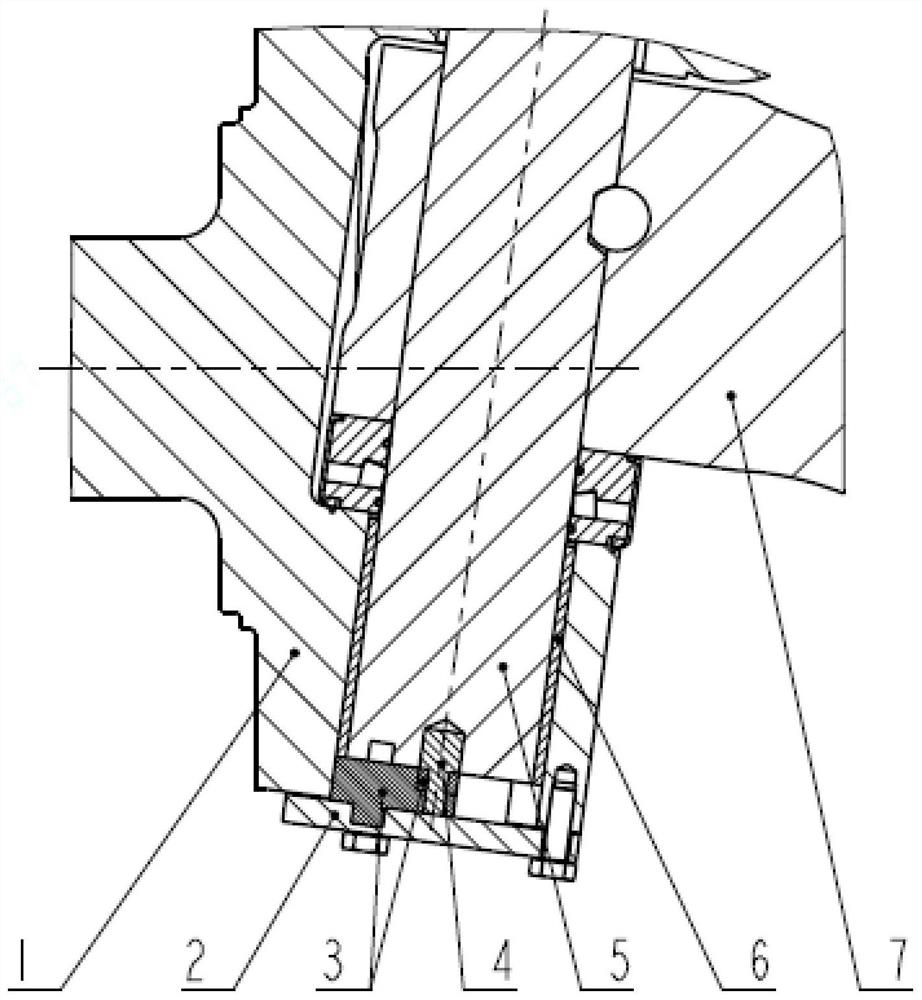

[0018] figure 1 Shown is the structural representation of the present invention.

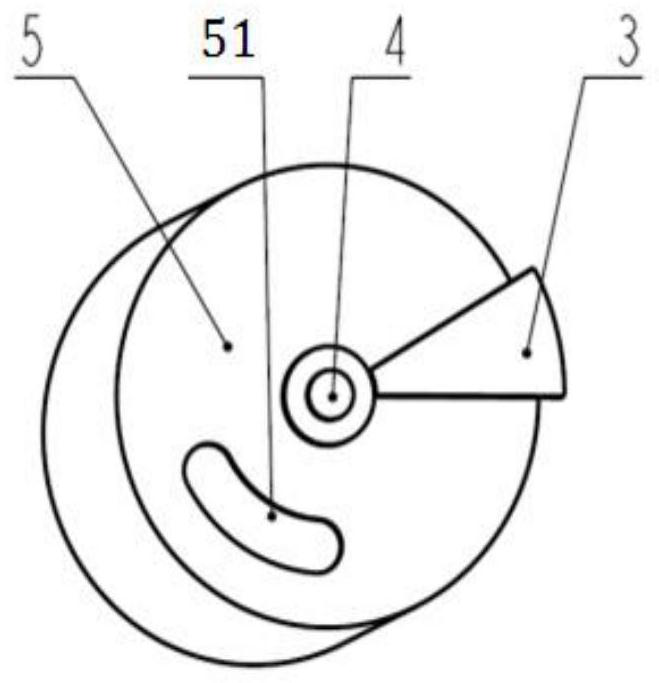

[0019] figure 2 Shown is the structural representation of kingpin assembly of the present invention.

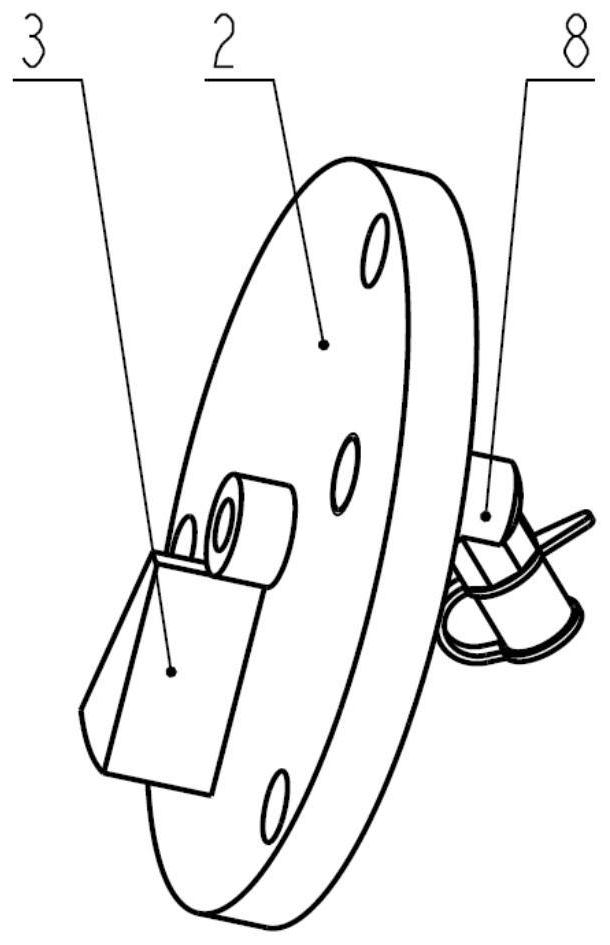

[0020] image 3 Shown is a schematic structural view of the kingpin cover assembly of the present invention.

[0021] The present invention provides a dynamic lubricating structure for kingpin bushing, which includes front beam 7, steering knuckle 1, bushing 6, kingpin assembly and kingpin cover assembly. There is a lubricating grease passage on the bushing 6. press into the kingpin hole of the steering knuckle in the way of interference; the kingpin assembly includes the kingpin 5, the partition block 3 and the partition block pin shaft 4, the oil groove 51 is processed on the end surface of the kingpin 5, and the kingpin assembly Penetrate the kingpin hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com