External reverse gear unit of speed variator for motorcycle engine

An external engine technology, applied in bicycle gear transmission mechanism, transportation and packaging, bicycle accessories, etc., can solve problems such as engine bearing damage, reverse gear disengagement engine abnormal noise, traffic accidents, etc., to prevent lubricating oil leakage , avoid dry grinding phenomenon, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

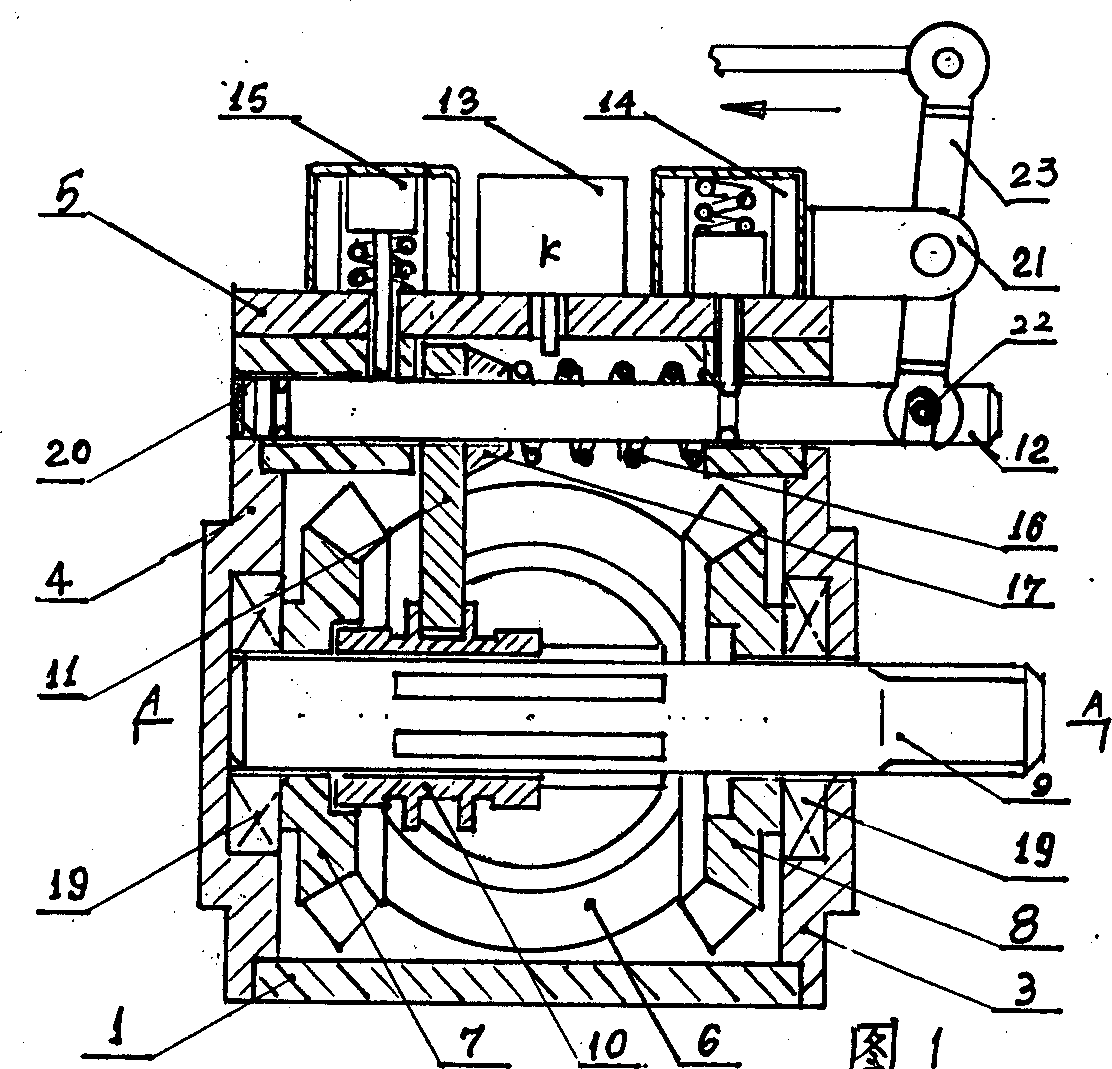

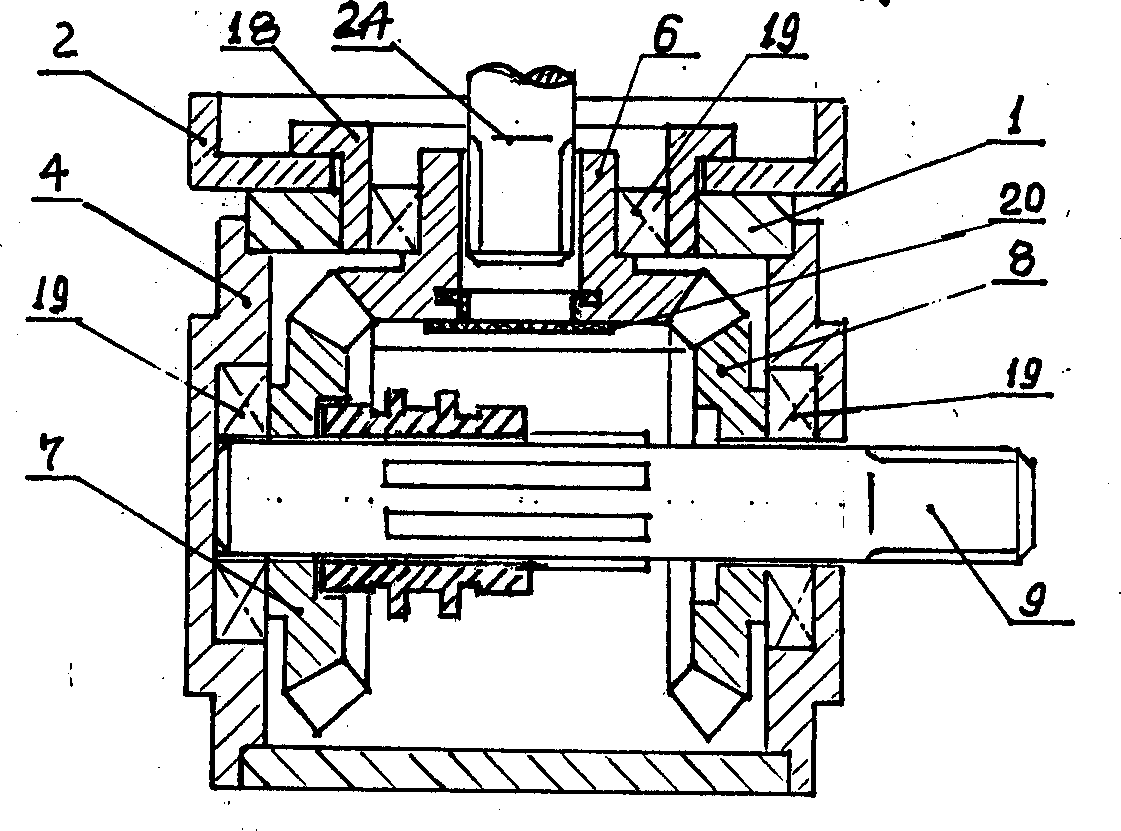

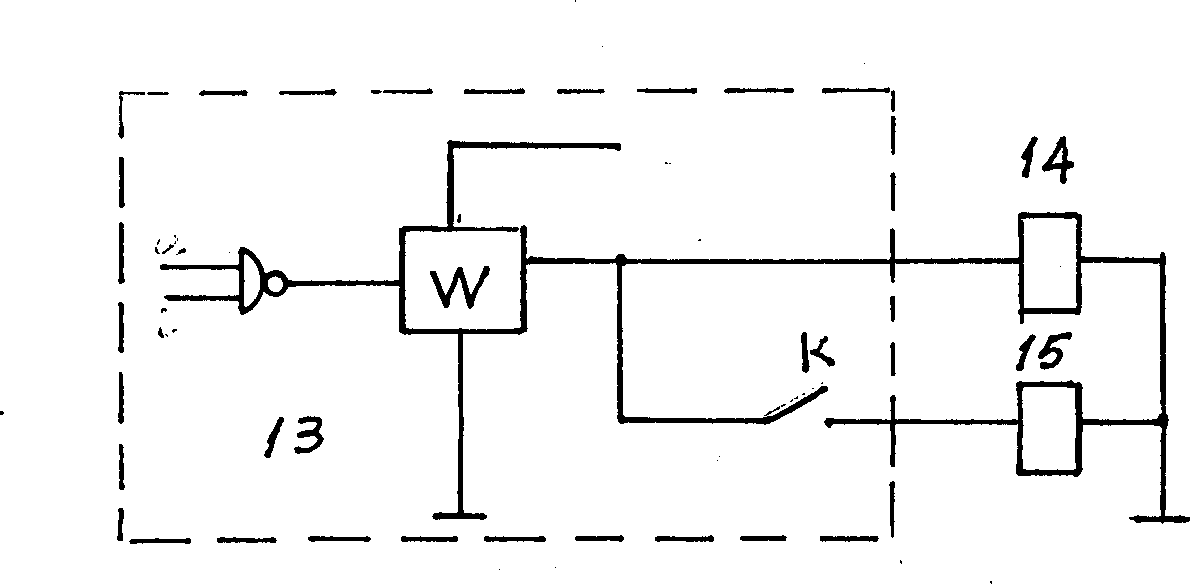

[0018] See Figure 1, figure 2 The external reverse gear device of the motorcycle engine transmission of the present invention consists of a casing assembly capable of changing the steering of the driven shaft, an operating mechanism mounted on the casing to drive the driven shaft (9) to change direction, and a control mechanism for controlling the steering The mechanism consists of a reverse gear control drive. in:

[0019] The box assembly is composed of the box body 1 connected with the stuffy cover 4 and the transparent cover 3, the bearings 19 respectively installed in the stuffy cover 4 and the transparent cover 3, and the driven shaft 9 supported by the bearing 19 is installed in the driven The two driven bevel gears 7, 8 and the spline clutch sleeve 10 on the shaft 9 are spline-connected with the main shaft 24 and the driving bevel gear 6 meshed with the two driven bevel gears 7, 8, so that the inner hole of the driving bevel gear 6 The sealing rubber sleeve 20 isolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com