Automatic partial pressure lubrication piston for filling device

A filling device and automatic technology, applied in the field of pistons, can solve the problems of shortening the service life of pistons and filling devices, wear of sealing rings, etc., and achieve the effect of avoiding dry grinding, prolonging service life and running freely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

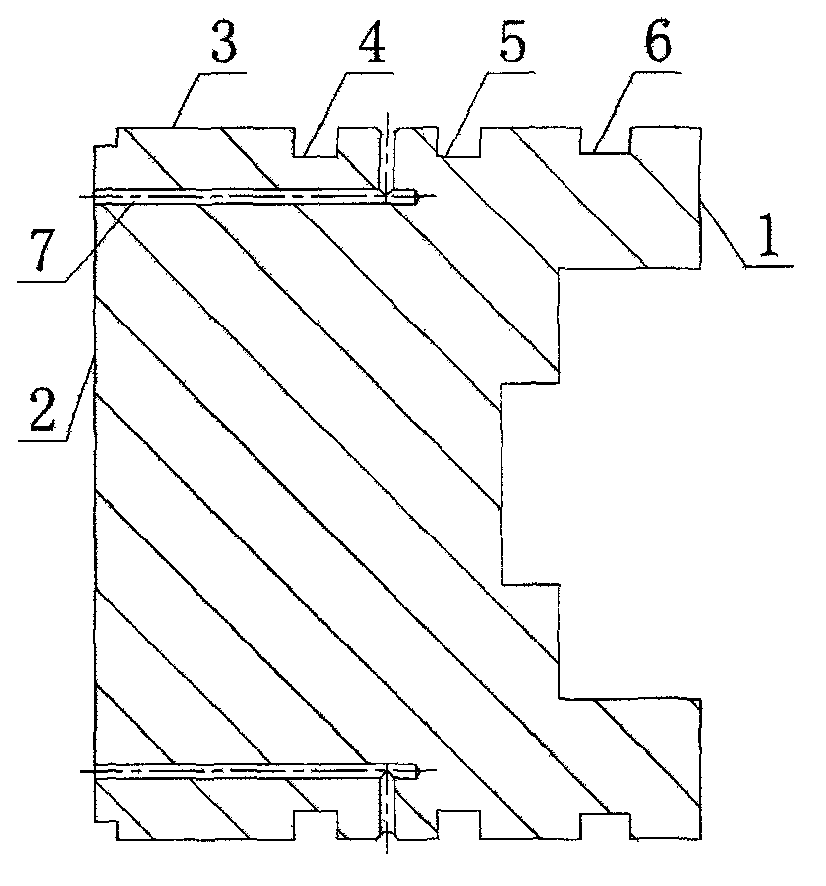

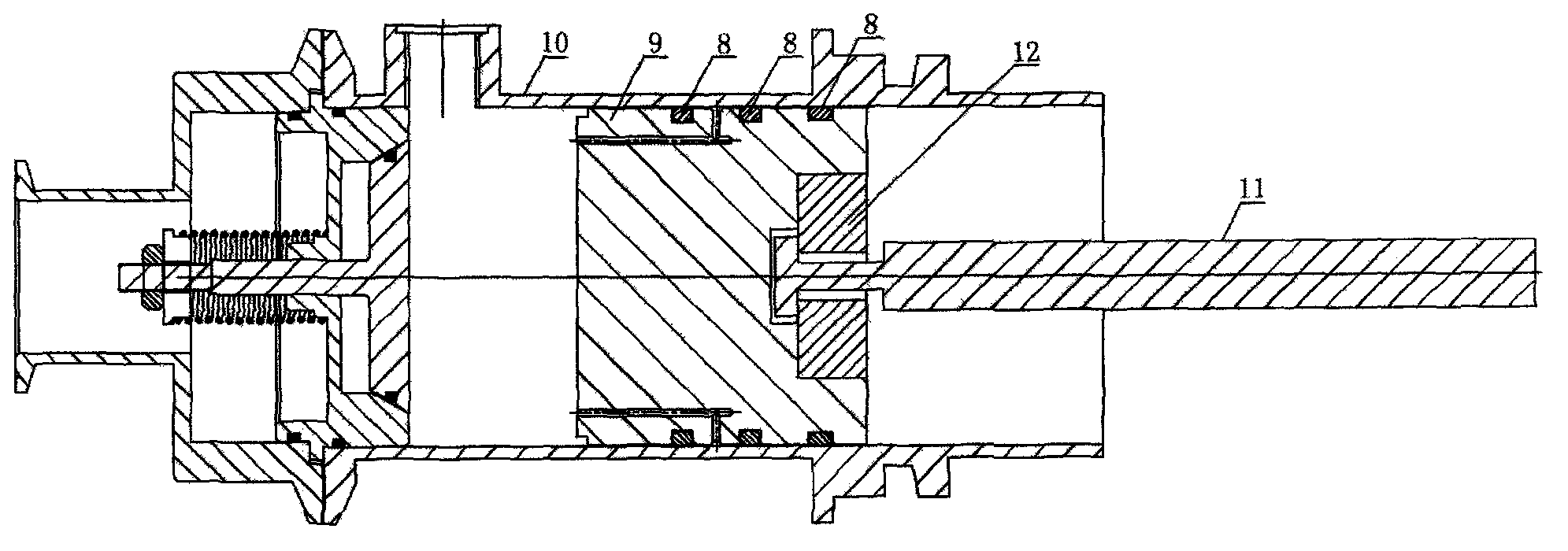

[0013] As shown in Fig. 1, an automatic partial pressure lubrication piston of a filling device includes a cylindrical piston body 1, the front end of the piston body 1 is a pressure bearing surface 2 in contact with the filling material, and the side The wall is an annular outer wall 3 that slides and fits with the inner wall of the barrel 10. The annular outer wall 3 is provided with at least two sealing ring installation grooves, and a sealing ring is arranged in the sealing ring installation grooves. The rear end of the piston body 1 is the connecting end of the piston rod 11. The piston body 1 is provided with a guide flow hole 7 leading from the pressure bearing surface 2 of the piston body 1 to the annular outer wall 3 of the piston body 1, and the outlet of the guide flow hole 7 on the annular outer wall 3 of the piston body 1 is located at two Between adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com