Container gas spraying fire extinguishing device

A technology of fire extinguishing device and container, applied in fire rescue and other directions, can solve the problems of quick installation of pipelines that are inconvenient to connect, other structural adhesives cannot be installed, and the utilization rate of containers is reduced, so as to achieve the functions of easy inspection, maintenance and replacement, and fast and safe fire extinguishing. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

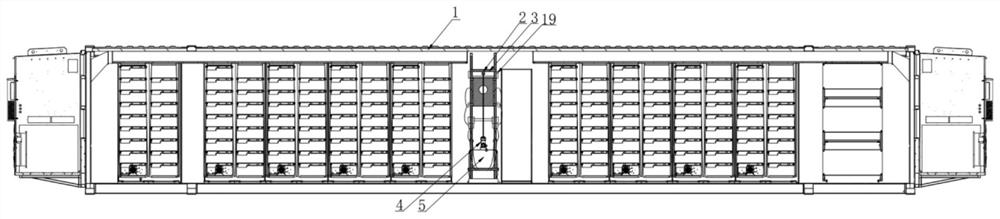

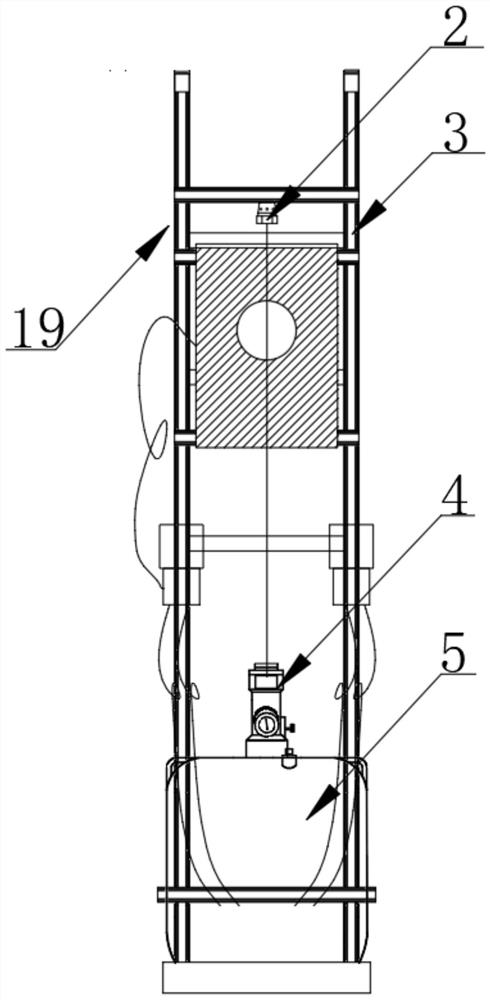

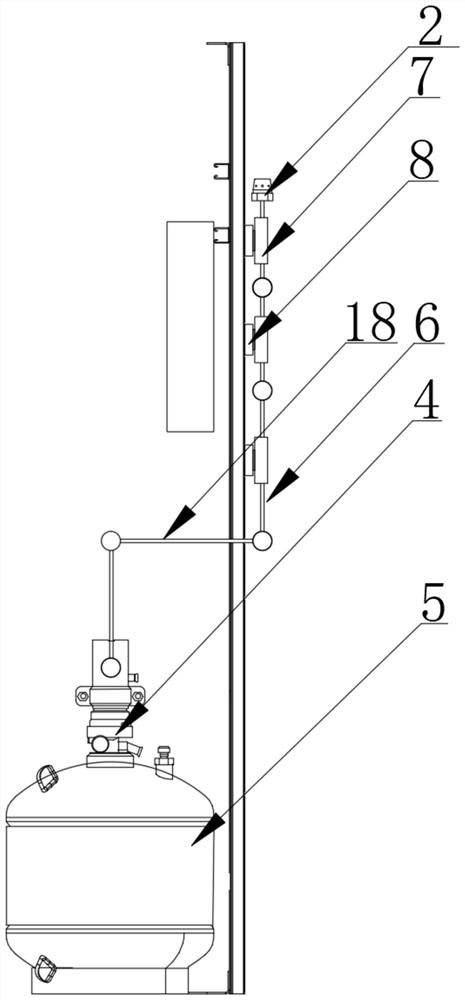

[0026] Such as Figure 1-7 As shown, a container gas sprinkler fire extinguishing device of the present invention includes a container 1, a fire cabinet 3 is installed at the center of the bottom end of the container 1, a gas cylinder 5 is installed on the bottom end surface of the fire cabinet 3, and the top of the gas cylinder 5 The surface is connected with a solenoid valve 4 by bolts. The side of the fire cabinet 3 away from the gas cylinder 5 is provided with a spray head 2. The spray head 2 can rotate 360 degrees. The top of the spray head 2 is drilled with a round hole.

[0027] When a fire occurs inside the container 1, the solenoid valve 4 on the top of the gas cylinder 5 opens the gas to the sprinkler 2 through the connected pipeline, and the 360-degree sprinkler 2 is quickly sprayed to fill the entire container 1, and the rapid fire extinguishing can be realized Features.

[0028] In order to extinguish the fire in the container 1, a connecting pipe 6 is fixedly ...

Embodiment 2

[0037] Such as Figure 5 and 7 As shown, in order to prevent the arc-shaped fixing plate 7 from being damaged when the connecting pipe 6 is fixed, the end surface of the arc-shaped fixing plate 7 near the center of the limiting plate 8 is bonded with buffer rubber 9 .

[0038]When the arc-shaped fixing plate 7 and the connecting pipe 6 are limited and fixed, the buffer rubber plate 9 is in contact with the connecting pipe 6. At this time, the buffer rubber plate 9 can be used to protect the connecting pipe 6 when it is fixed and clamped. Effect, thereby avoiding the impact force generated when the arc-shaped fixing plate 7 moves to cause extrusion damage to the connecting pipe 6 .

[0039] Such as figure 2 As shown, in order to monitor whether there is a fire in the container 1, temperature sensors 19 are arranged on both sides of the fire cabinet 3, and the temperature sensors 19 are fixedly connected to the side walls of the fire cabinet 3 by bolts. The inductor 19 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com