Inertia activated wound rope shock absorption device for continuous beam bridge

A shock absorbing device and inertial technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of high operation and maintenance costs, limitations of bridge anti-seismic applications, complicated inspection and maintenance, etc., to achieve easy inspection and maintenance, low cost, Good effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following will be described in further detail in conjunction with examples and accompanying drawings, but not as a limitation to the present invention.

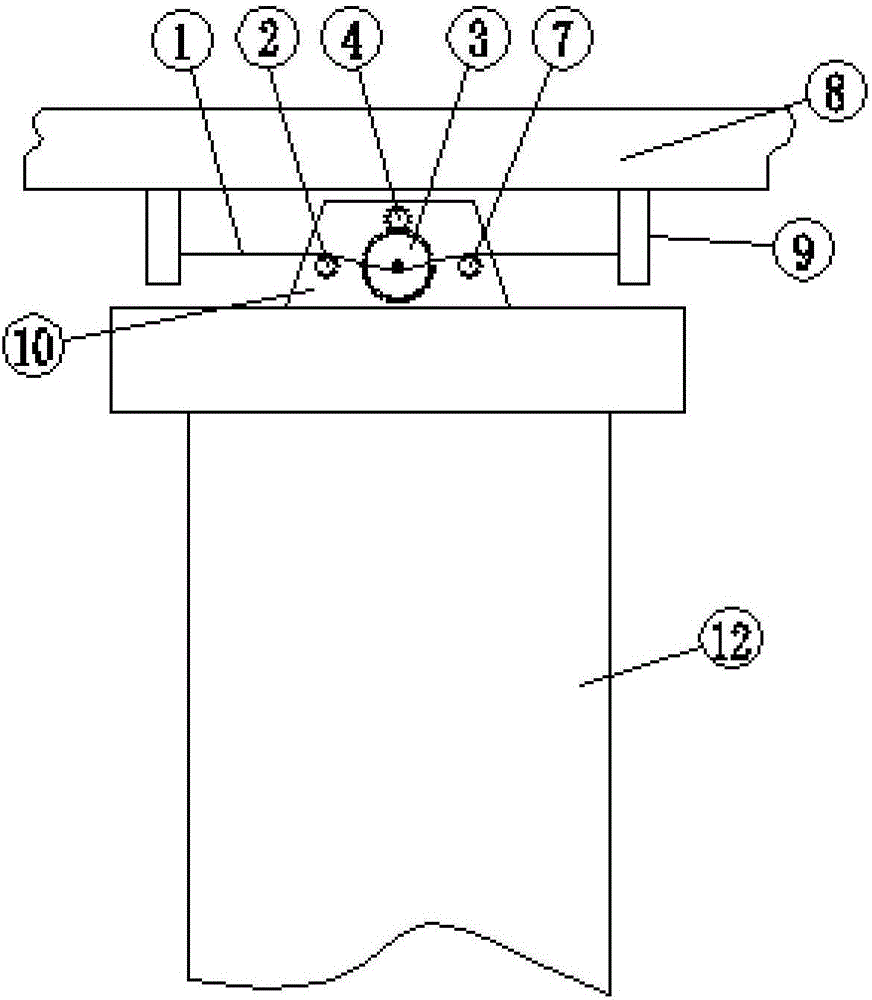

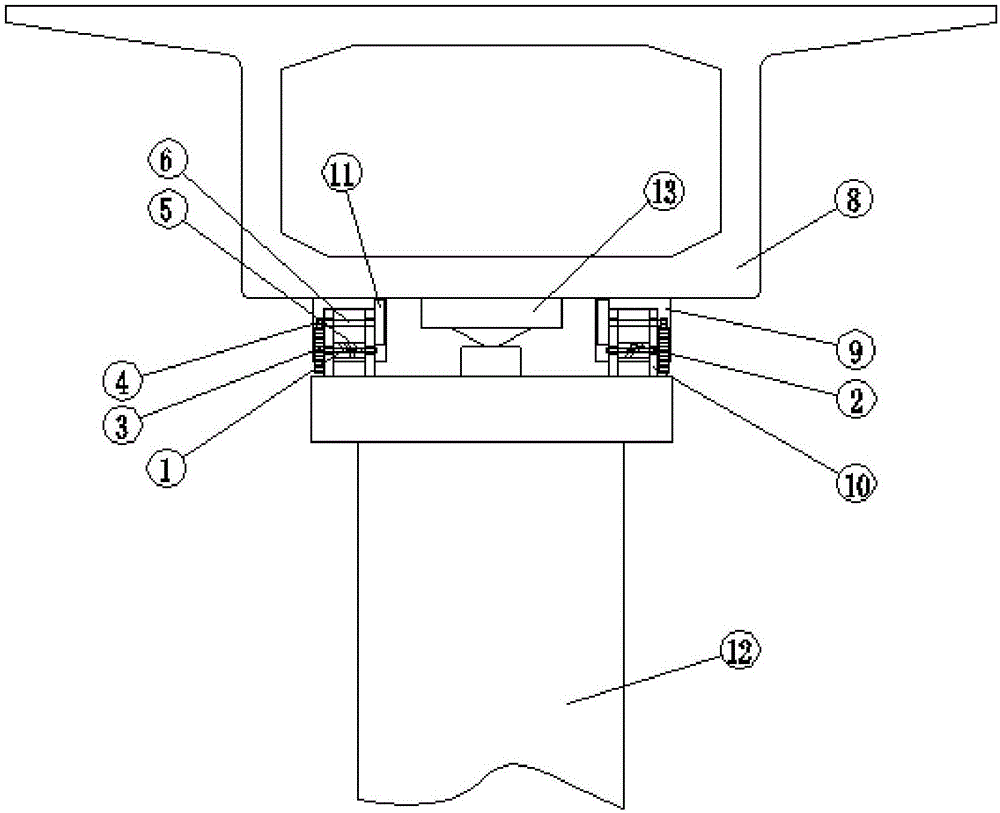

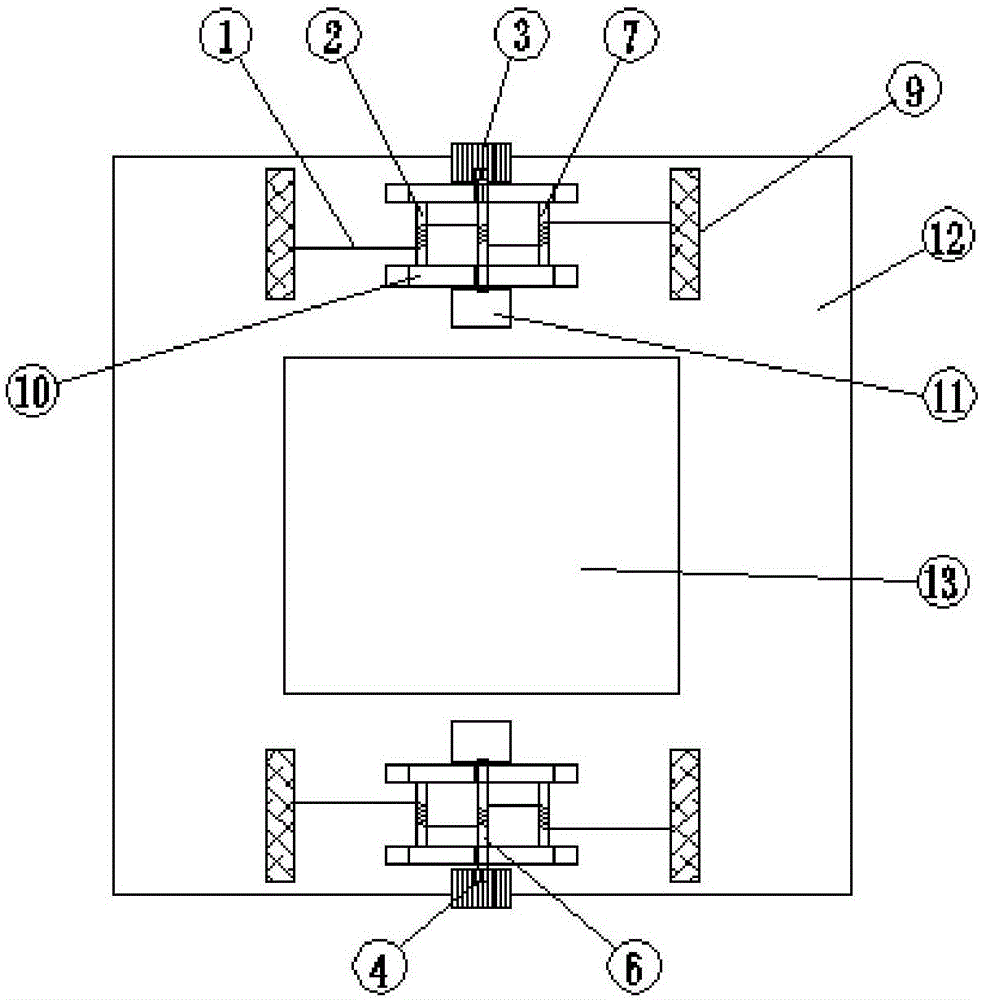

[0042] The structure of this example is as follows figure 1 , 2 , 3, and 4 show the inertial activation of the wound cable damping device for continuous girder bridges. Among them: 1. Cable; 2. Left friction shaft; 3. Large transmission gear (including counterweight); 4. Small transmission gear; 5. The first transmission shaft (1 / 2 of the first transmission shaft has a The through hole perpendicular to the axis of the cylinder is the central hole for the cable to pass through, and the cable is wound on the cylindrical surface of the first transmission shaft after passing through, and the winding is symmetrically wound on both sides of the through hole); 6. Two transmission shafts; 7. Right friction shaft; 8. Beam body; 9. Connector; 10. Support; 11. Counterweight; 12. Movable pier; 13. Sliding support;

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com