Pyrolysis furnace decoking gasification and purification as well as heat energy and material recovery device

A recovery equipment, cracking furnace technology, applied in lighting and heating equipment, cracking, non-catalytic thermal cracking, etc., can solve the problems of environmental pollution, waste of heat energy, large exhaust gas emissions, etc., to reduce pollution and improve economic benefits , The effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

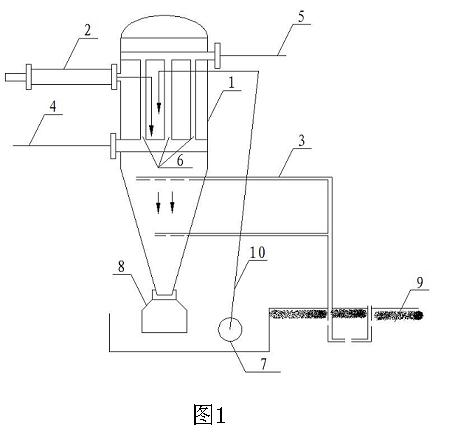

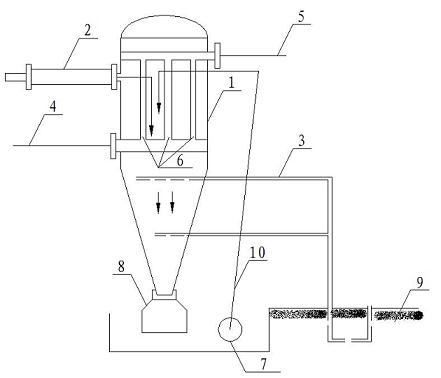

[0023] see figure 1 , the present invention provides a cracking furnace burnt steam purification and heat energy and material recovery equipment, comprising a tank body 1, the tank body is provided with a heat absorbing pipe 6 and a water inlet pipe 4 and an outlet pipe 5 connected to the heat absorbing pipe , The tank body is provided with a steam inlet pipe 2 and an exhaust pipe 3 communicating with its inner cavity, and the bottom end of the tank body is provided with a solid-liquid material outlet. Preferably, the steam outlet on the steam inlet pipe for communicating with the inner chamber of the tank is located above the air inlet for communicating with the inner chamber of the tank on the exhaust pipe.

[0024] The solid-liquid material outlet is preferably equipped with a detachable material recovery bag 8 that is water-permeable and air-permeable but impermeable to solid material. The material recovery bag can be made of various cloths with corresponding characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com