A strip position detection device for water cooling section

A detection device and segment technology, which is applied to length measuring devices, metal processing equipment, metal rolling, etc., can solve problems such as the inability of electrical position sensors to obtain accurate electrical signals, poor electrical position sensors, and safety production accidents. Accurate calibration signal, reliable effect, accurate cooling strategy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

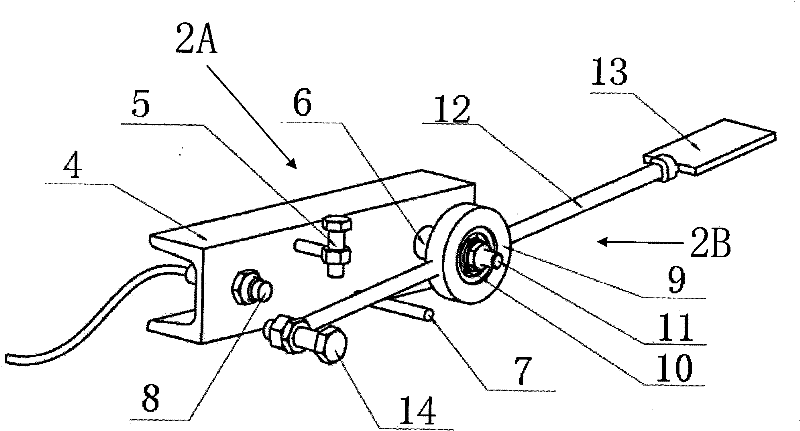

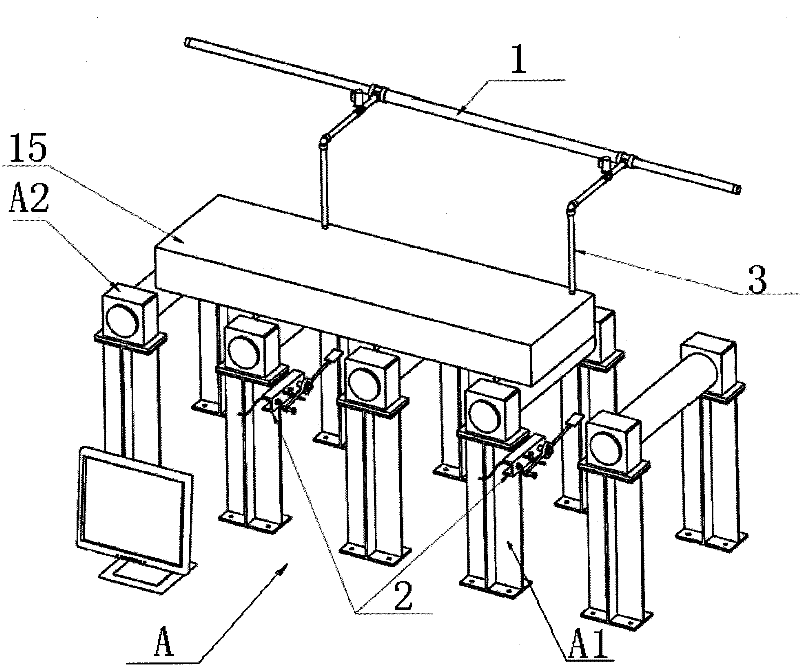

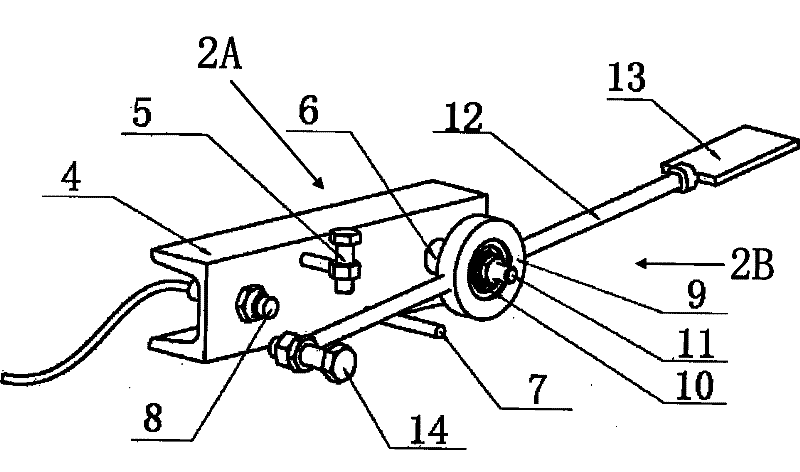

[0035] Such as figure 1 and figure 2 As shown, a strip position detection device for a water-cooling section of the present invention, the installation steps are as follows:

[0036] 1. First, determine the specific quantity of the strip position detection device for the water-cooling section of the present invention that needs to be installed according to the length of the water-cooling section frame group A, and the number is 2 in this embodiment;

[0037] 2. Weld and install the strip position detection device for the water-cooling section of the present invention on the roller table support A1 below the roller table A2, without affecting the position of the existing lower water spray nozzle; The water plate 13 is facing the nozzle of each water spray pipe 3 of the spray water pipe group 1 above.

[0038] It is ready to use after installation.

[0039] Such as figure 1 and figure 2 As shown, a strip position detection device for a water-cooling section of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com