Double crank two-stroke engine

A double crank mechanism and engine technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve problems such as low reliability, and achieve the effect of reducing friction loss, improving mechanical efficiency, and increasing power and torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment the present invention is further described.

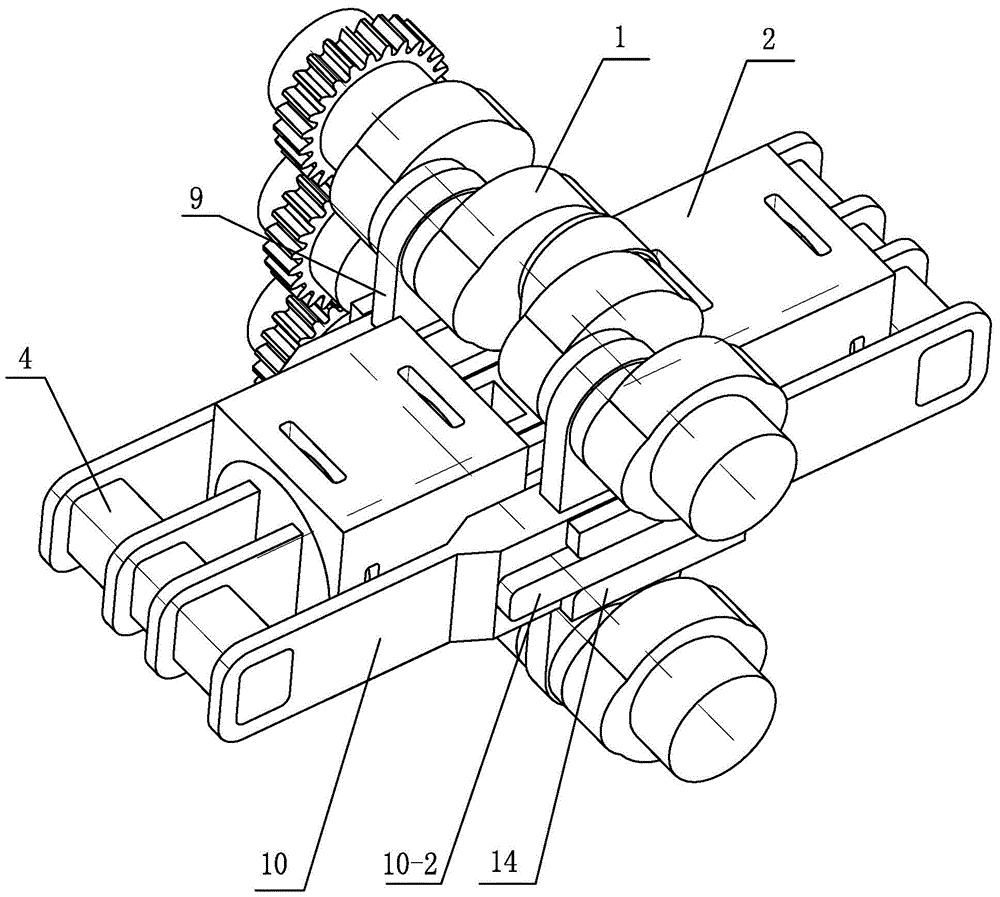

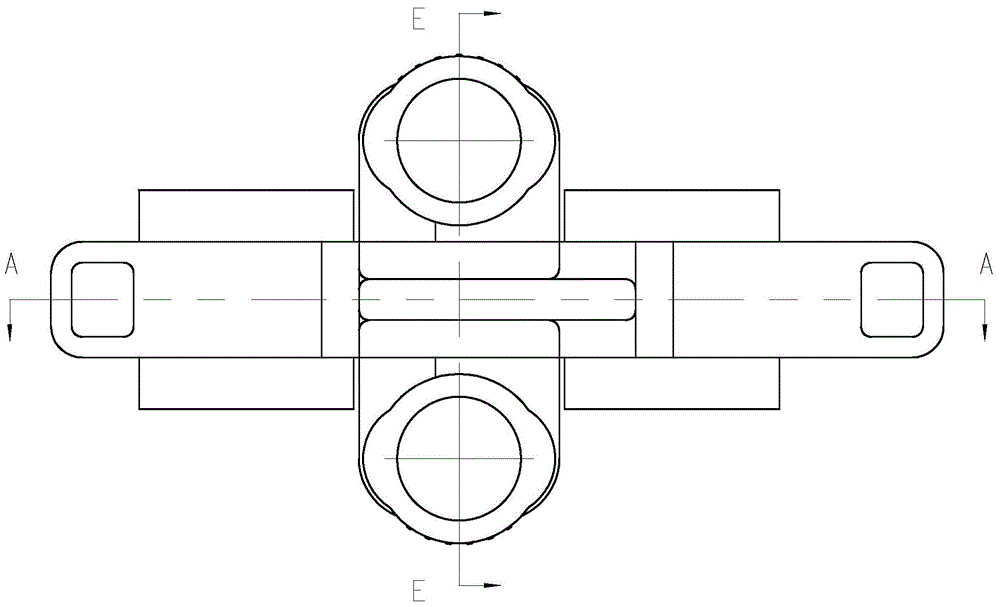

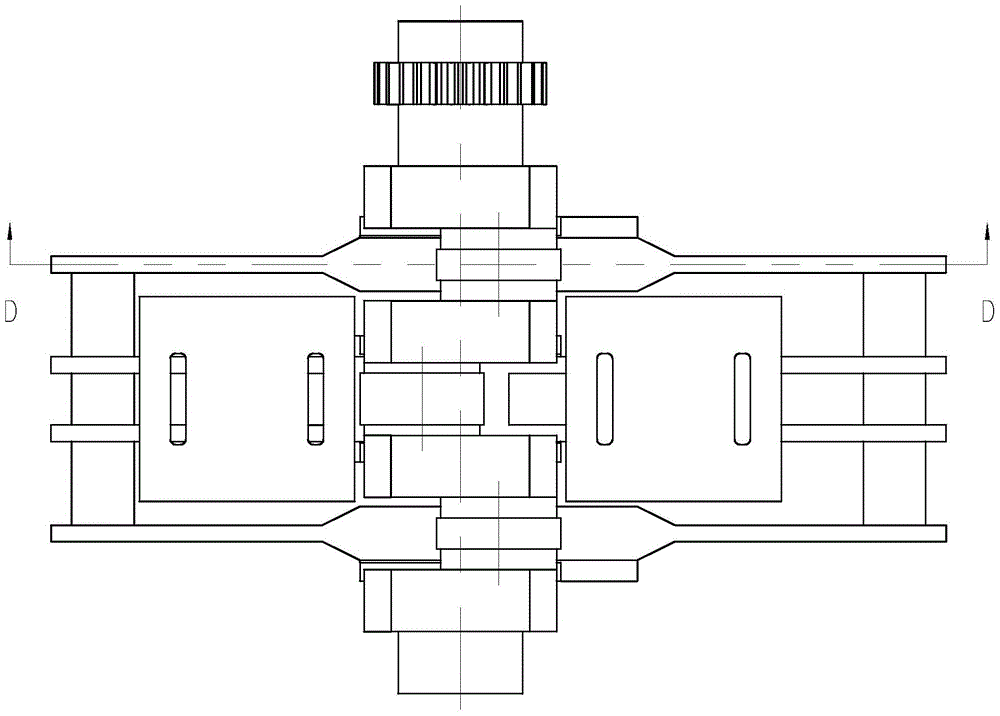

[0038] As shown in the accompanying drawings, a two-stroke engine with a double crank mechanism includes a cylinder 2 and a piston capable of rectilinear reciprocating motion in the cylinder,

[0039] It comprises two crankshafts 1 facing up and down, the axes of the two crankshafts 1 are parallel, and the specifications are the same. There are three crankshafts 1-1 on each crankshaft 1. The phase angle at which the piston 7 and the outer piston 5 move in the opposite direction is theoretically 180 degrees. In practice, this angle should be corrected according to the actual situation due to the ignition advance angle, intake and exhaust advance angle, etc. A connecting rod 9 is hinged between the crank throws 1-1 corresponding to the two crankshafts 1, and there are three connecting rods 9 in total, forming a double crank mechanism;

[0040] There are two cylinders 2, the central axes of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com