Graphene-containing frictional regulator and preparation method thereof

A friction modifier, graphene technology, applied in additives, petroleum industry, lubricating compositions, etc., can solve the problems of chemical corrosive wear, coagulation and precipitation, difficulties, etc., achieve excellent self-lubrication, stable chemical properties, reduce The effect of wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

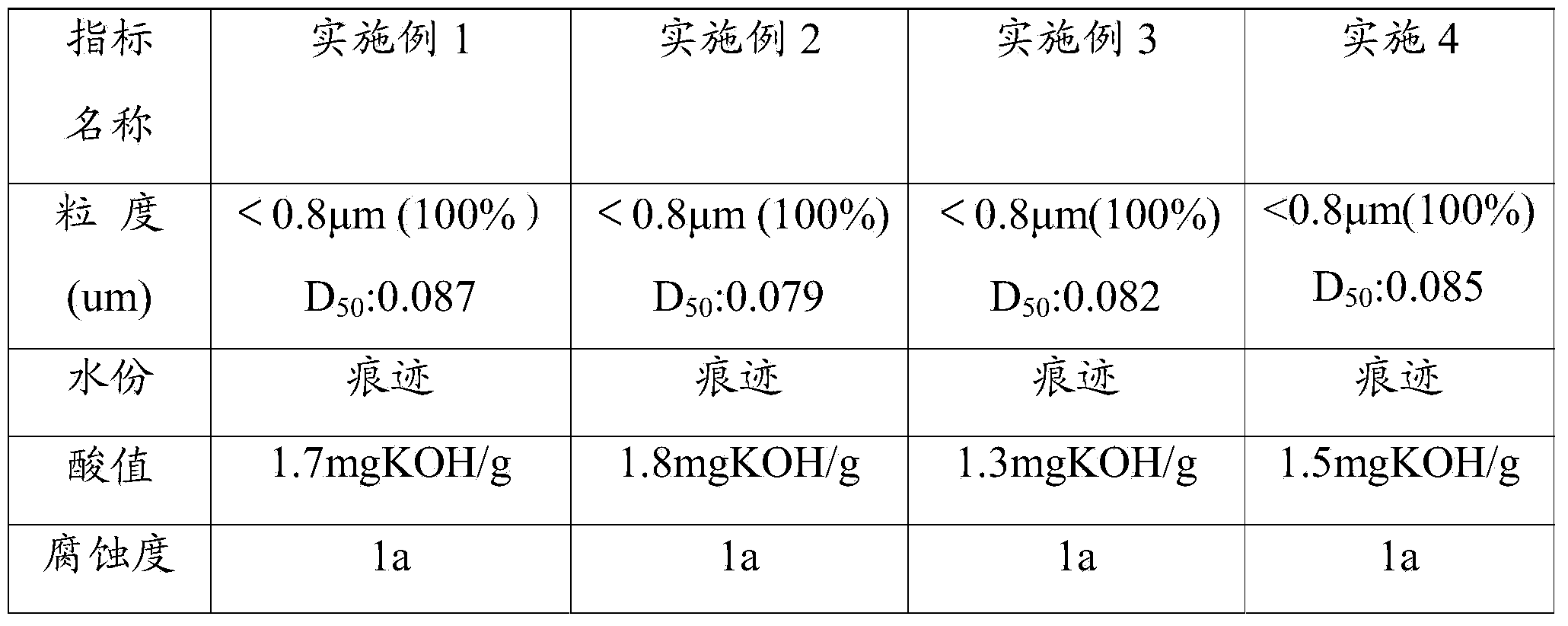

Examples

Embodiment 1

[0050] A friction modifier containing graphene, which is prepared from the following raw materials in mass percent:

[0051] Nanographene: 0.3%;

[0052] Nano graphite particles: 3%;

[0053] Ethylene-propylene copolymer 0.5%:

[0054] Bis-succinimide: 3.5%;

[0055] Base Oil: 95%

[0056] Specific steps are as follows:

[0057] 1) Preparation of nano-graphite particles

[0058]Abrasive preparation: 20% of graphite powder, 0.1% of cellulose, 0.5% of sodium methylene bis-naphthalene sulfonate, 0.5% of 25% ammonia water, and the balance of pure water in mass percent;

[0059] Crushing: the above-mentioned abrasives are ground and pulverized in a horizontal sand mill;

[0060] Classification: the above-mentioned graphite powder is classified by high-speed centrifugation at a speed of 5000 rpm;

[0061] Purification: add hydrochloric acid to the above-mentioned classified graphite powder to purify and condense, and adjust the pH to 2.3, press filter after condensing, and ob...

Embodiment 2

[0068] A friction modifier containing graphene, which is prepared from the following raw materials in mass percent:

[0069] Nano graphene: 0.5 parts

[0070] Nano graphite particles: 5 parts

[0071] Styrene-diene copolymer: 1%

[0072] Succinate / Benzylamine: 2%

[0073] Base oil: balance;

[0074] Specific steps are as follows:

[0075] 1) Preparation of nano-graphite particles

[0076] Abrasive preparation: 25% of graphite powder, 0.3% of cellulose, 0.2% of sodium methylene bis-naphthalene sulfonate, 0.7% of 25% ammonia water, and the balance of pure water in mass percent;

[0077] Pulverization: the above-mentioned grinding material is circularly ground and pulverized by a horizontal sand mill; classification: the above-mentioned graphite powder is classified by high-speed centrifugation at a speed of 6000 rpm;

[0078] Purification: add hydrochloric acid to the above-mentioned classified graphite powder to purify and condense, and adjust the pH to 2.5, press filter ...

Embodiment 3

[0085] A friction modifier containing graphene, which is prepared from the following raw materials in mass percent:

[0086] Nanographene: 1%

[0087] Nano graphite particles: 5%

[0088] Cetyl-N-vinylpyrrolidone copolymer: 5%

[0089] Succinate: 3%

[0090] Base oil: balance;

[0091] The specific preparation method is carried out according to the steps of Example 1; in the grinding material preparation step, graphite powder 27.6%, cellulose 0.4%, sodium methylene bis-naphthalene sulfonate 0.3%, 25% ammonia water 0.6%, pure The water balance; in the step of dispersing and degumming, it is calculated by weight percentage: graphite filter cake: 29%, cellulose: 0.3%, polyvinyl alcohol: 0.2%, 25% ammonia water: 0.7%, pure water: the balance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com