Tool spindle for a device for fine machining optically active surfaces on workpieces

An optically effective surface, tool spindle technology, used in metal processing equipment, optical surface grinders, grinding/polishing equipment, etc., can solve the problem that the axial mobility of the tool mounting head is not so fine and sensitive, and achieve easy movement and smoothness. The effect of improved running smoothness, high polishing quality and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

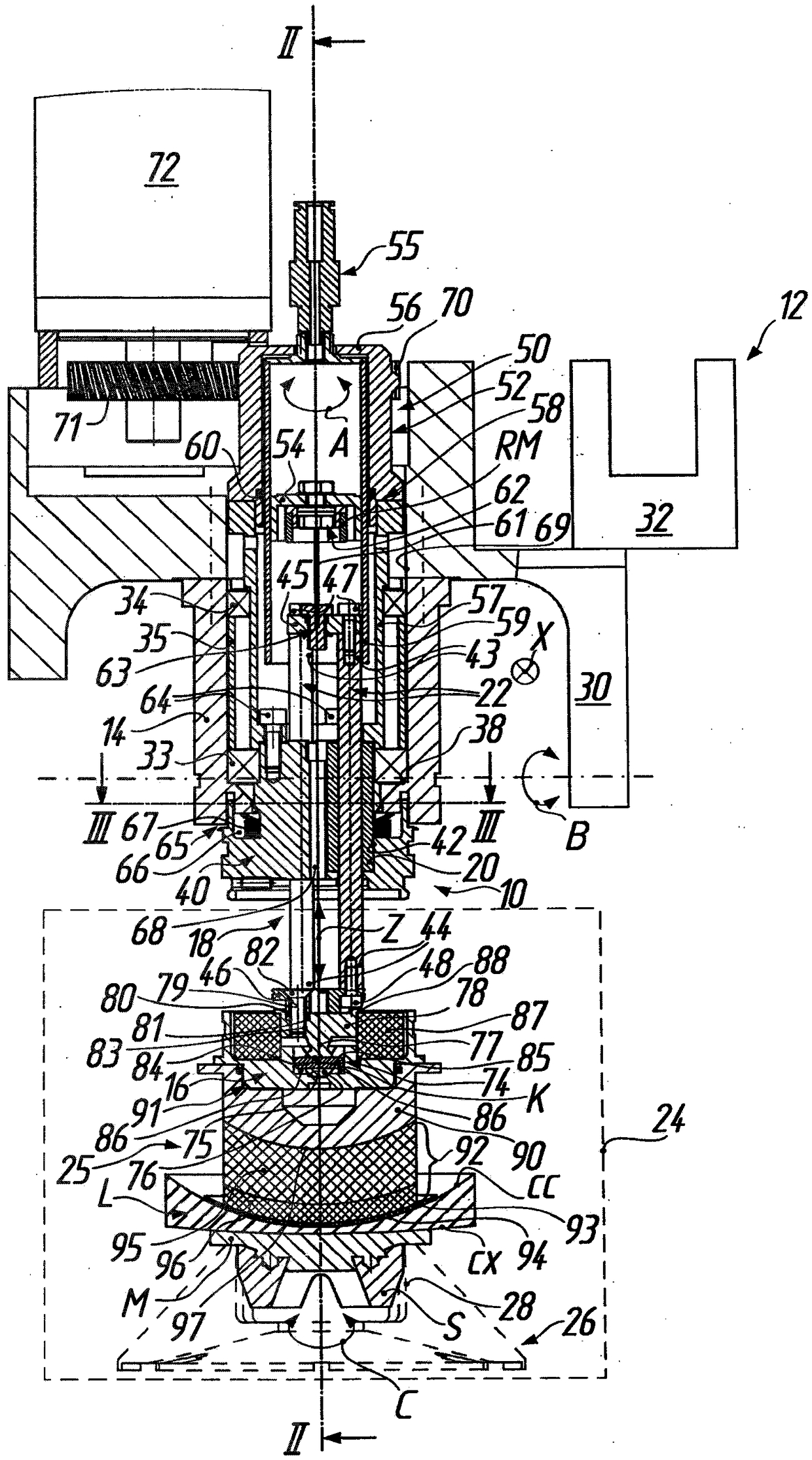

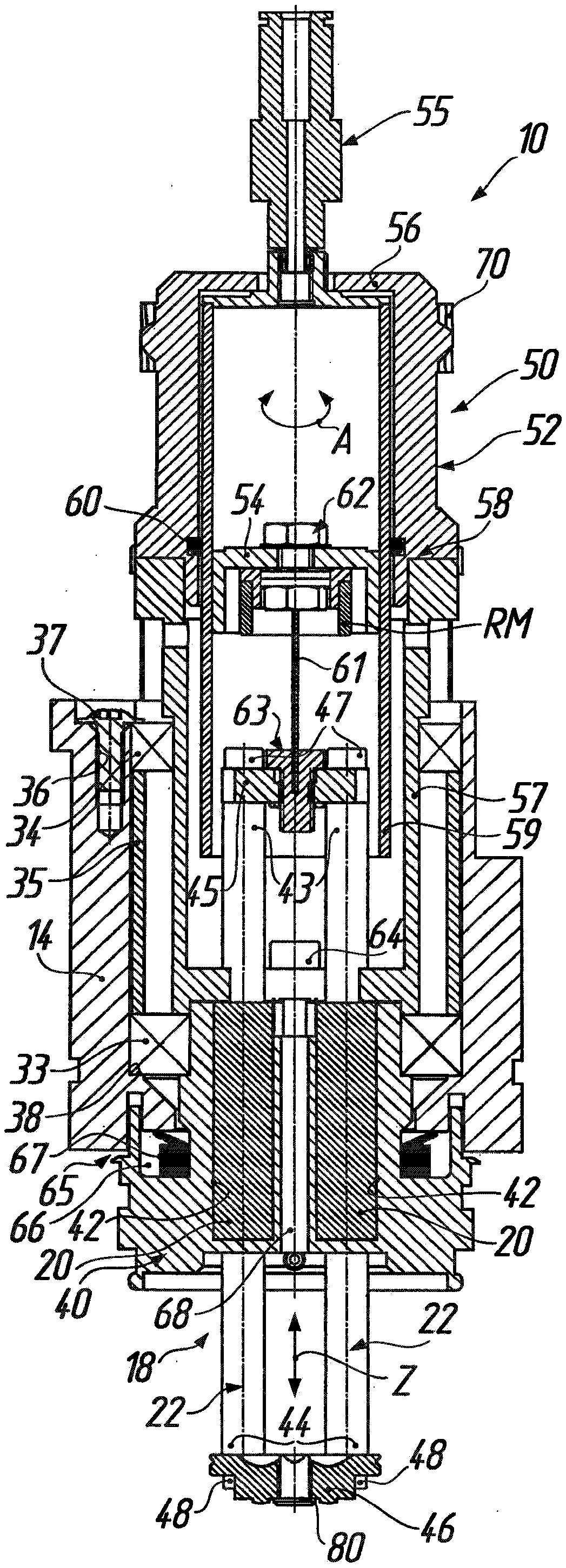

[0040] As a possible application or place of use of the tool spindle 10 according to the invention, in figure 1 In general, 12 denotes a device for finishing the optically effective surfaces cc, cx of a workpiece such as a spectacle lens L. As shown in FIG. exist figure 1 The device 12 , only partially illustrated in , constitutes a subassembly of the polishing machine described in more detail in the earlier international application PCT / EP2015 / 001857 (WO 2016 / 058663 A1 ). The apparatus 12 and polisher will be described below only to the extent necessary to understand the invention. In addition, here, in order to avoid repetition, regarding the structure and function of the device 12 and the polishing machine, reference may be explicitly made to the earlier international application PCT / EP2015 / 001857 (WO 2016 / 058663 A1).

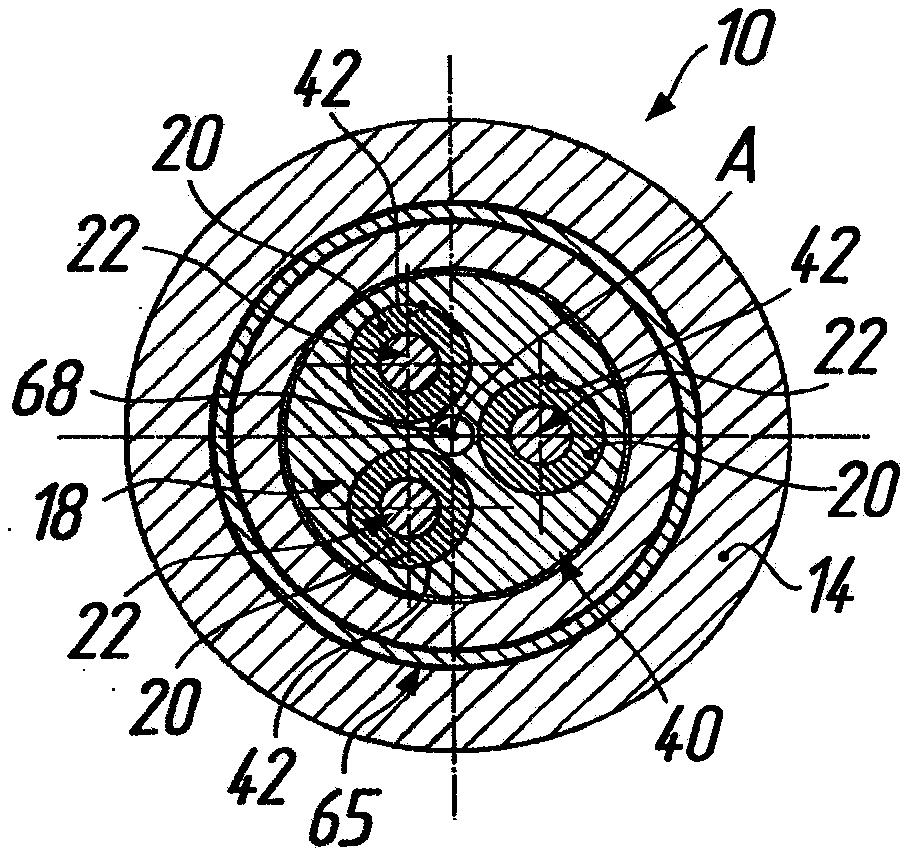

[0041] The tool spindle 10 comprises a spindle housing 14 and a tool holding section 16 which protrudes beyond the spindle housing 14 and is axially adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com