Deterministic processing system for high-precision optical surface with random surface shape

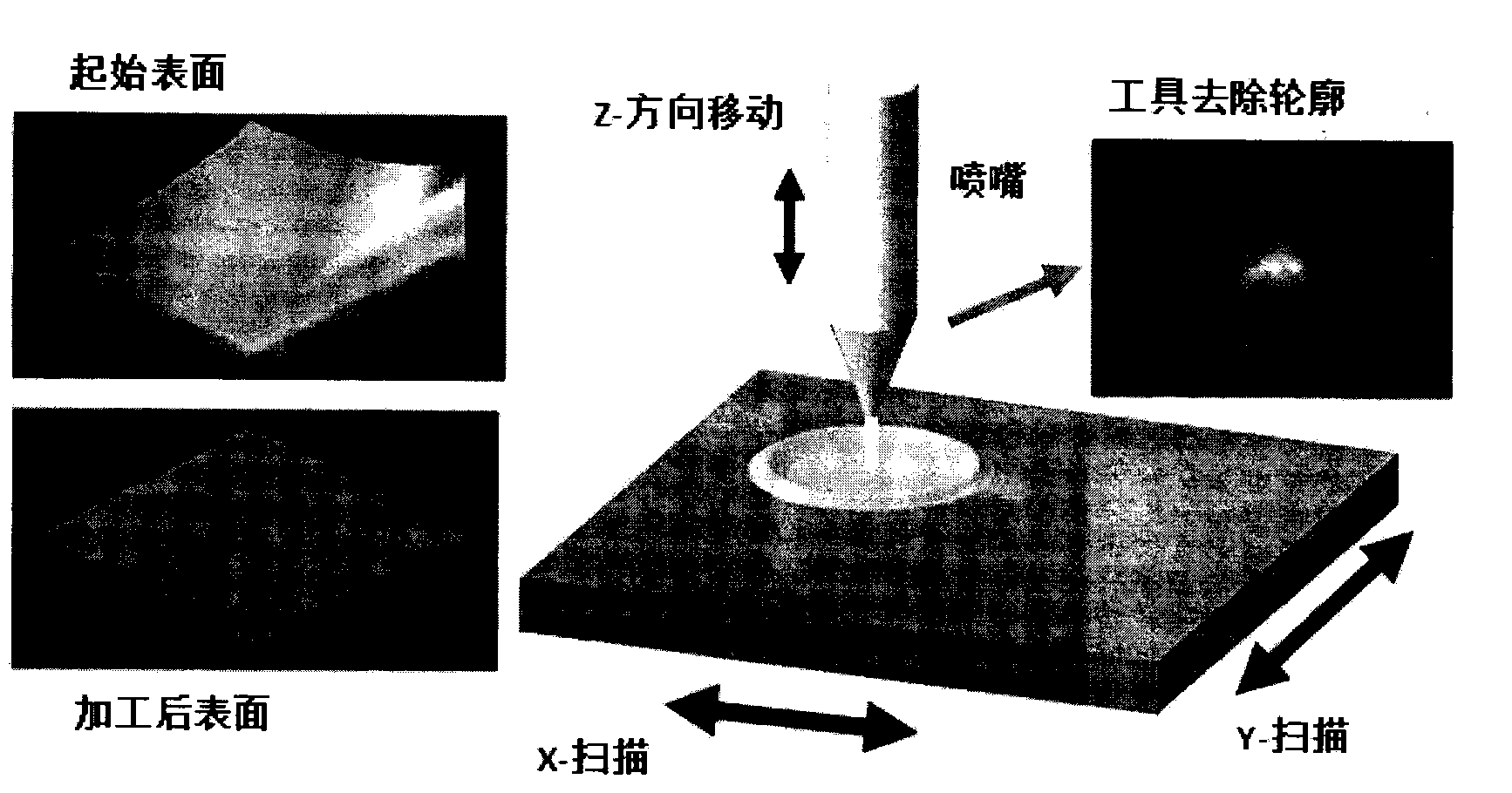

A high-precision processing and optical surface technology, which is applied in the field of high-precision semiconductor material surface processing and high-precision optical surface processing of any shape, to achieve the effects of convenient operation, low operating cost, and convenient expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

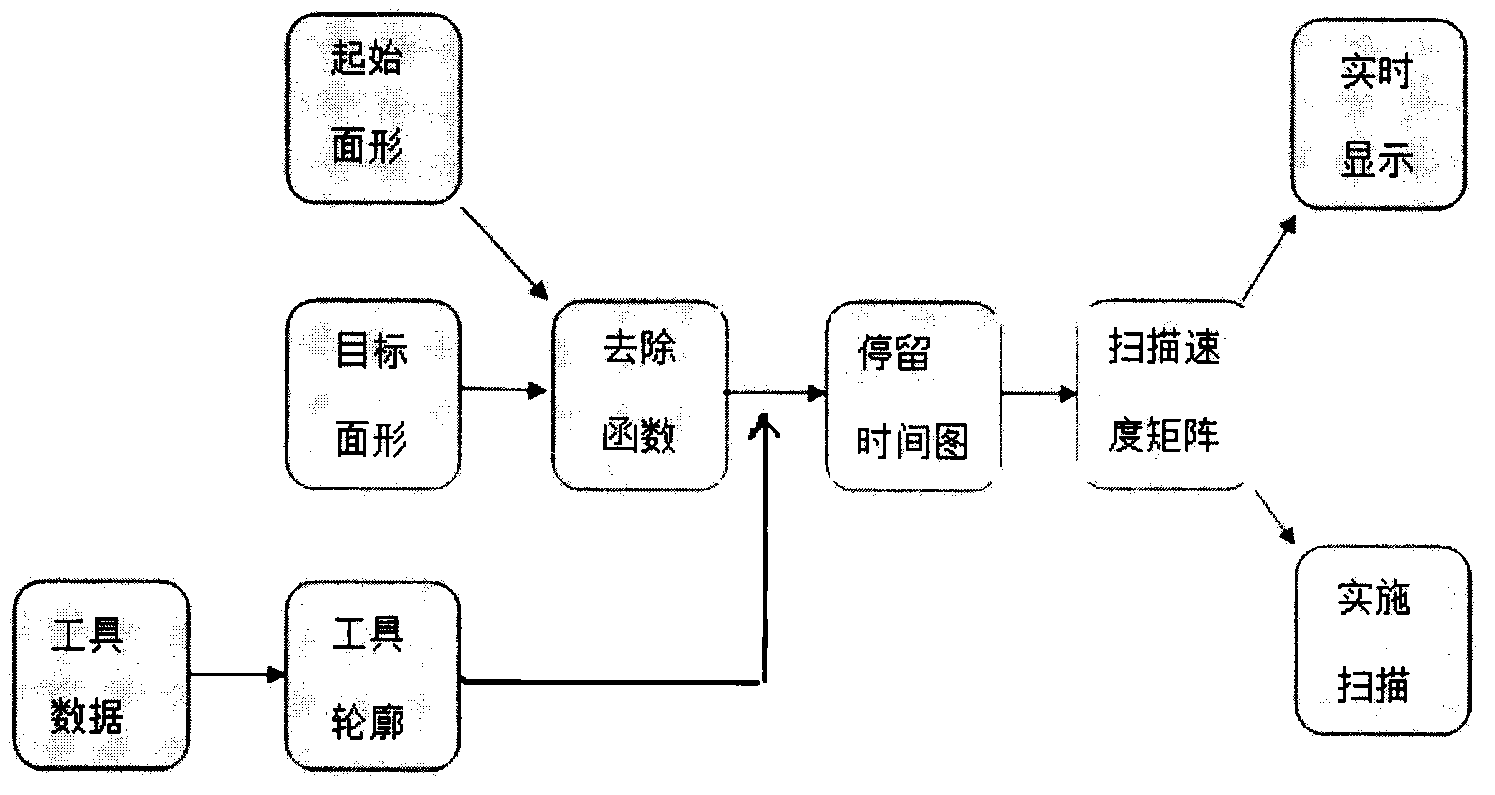

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail through the following specific embodiments and with reference to the accompanying drawings.

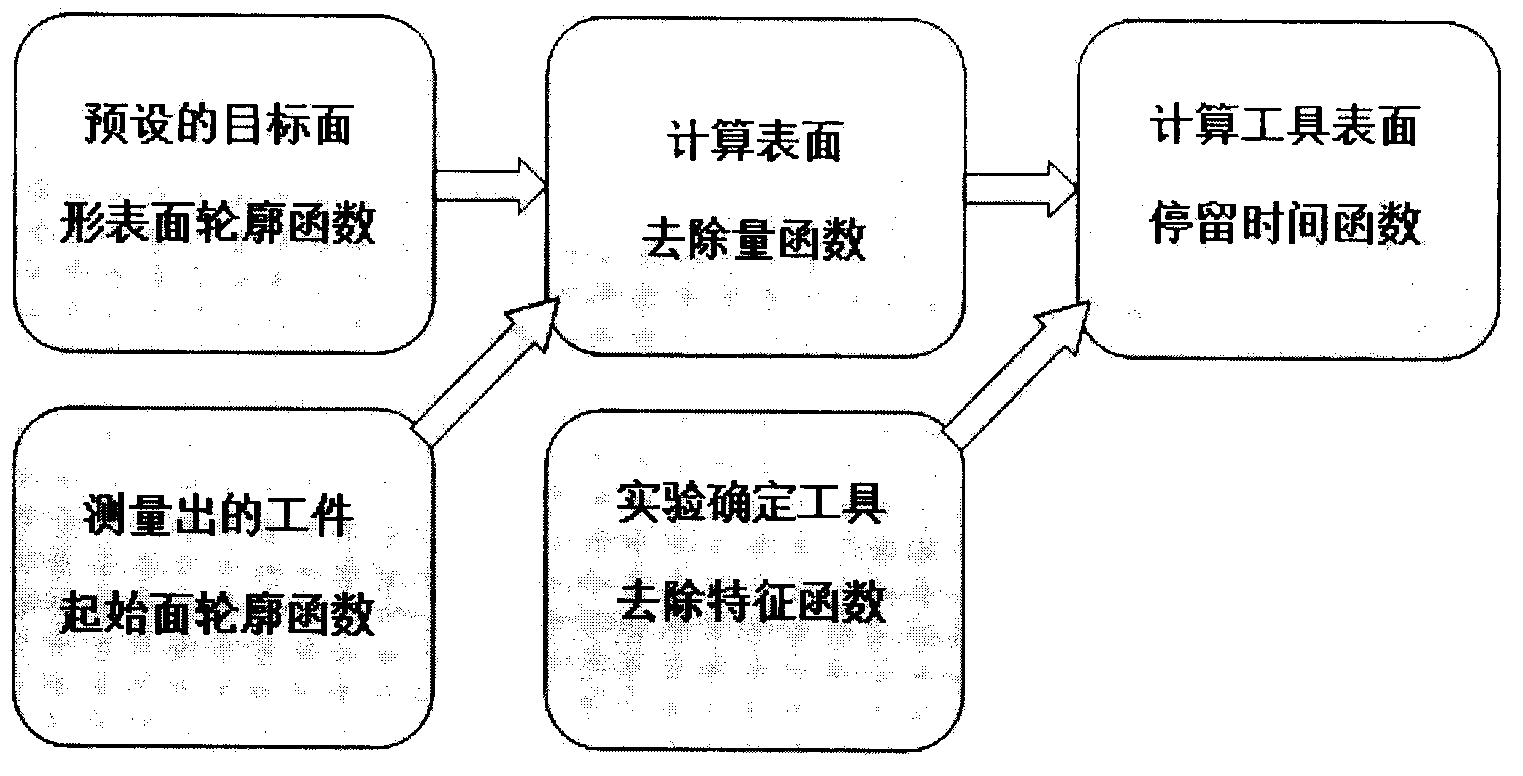

[0021] The first step, the residence time function algorithm is determined

[0022] figure 2 A flowchart of the algorithm for the residence time function is shown. For ultra-high-precision optical surface processing, it is first necessary to measure the current surface state of the workpiece, which is called the starting surface. This is usually done using ZYGO interferometers or other ultra-high precision measurement techniques. The starting surface function is denoted by S(X,Y). The target surface function is denoted as G(X, Y), and the required surface removal function ΔZ(X, Y) is obtained by subtracting the target surface from the starting surface:

[0023] ΔZ(X, Y)=S(X, Y)-G(X, Y)+d (1)

[0024] where d is an arbit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com