Sheet for led light cover application

A technology of light scattering and particles, applied in the field of polymer boards, can solve problems such as difficult hiding power and light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

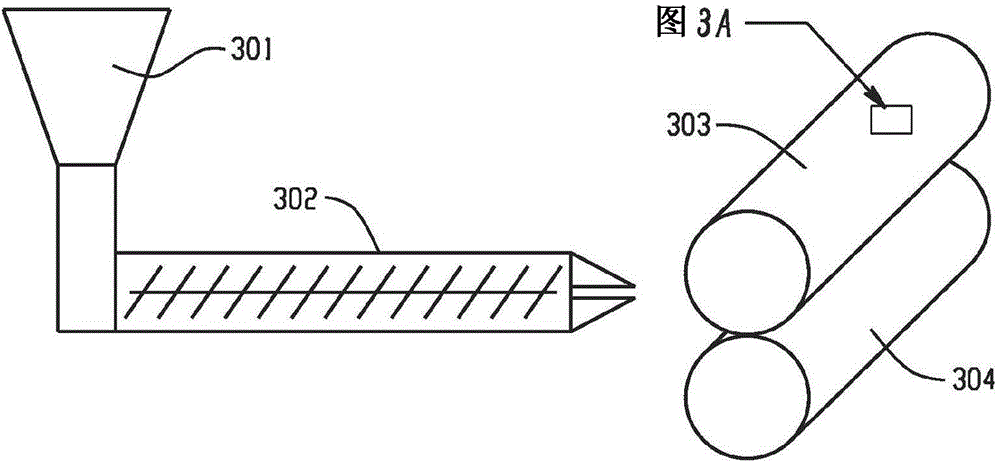

Method used

Image

Examples

Embodiment approach 1

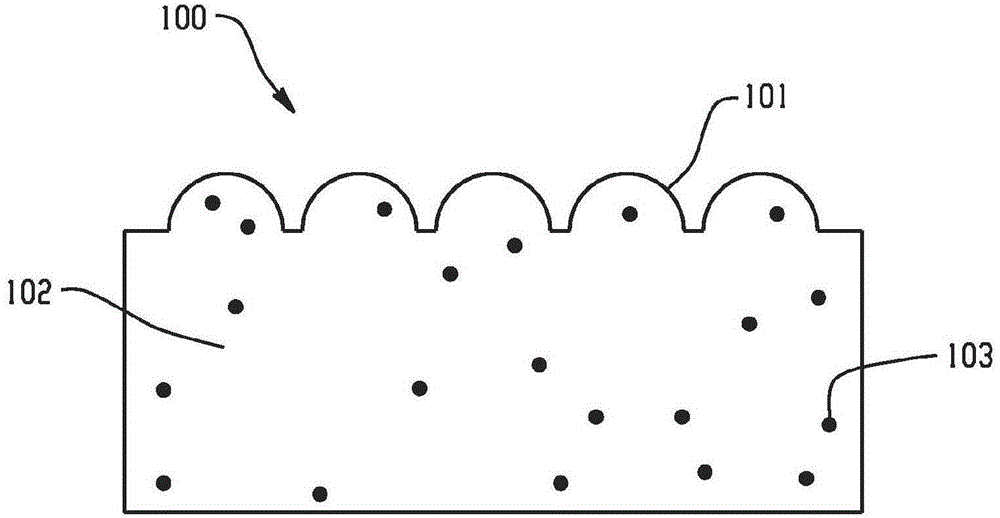

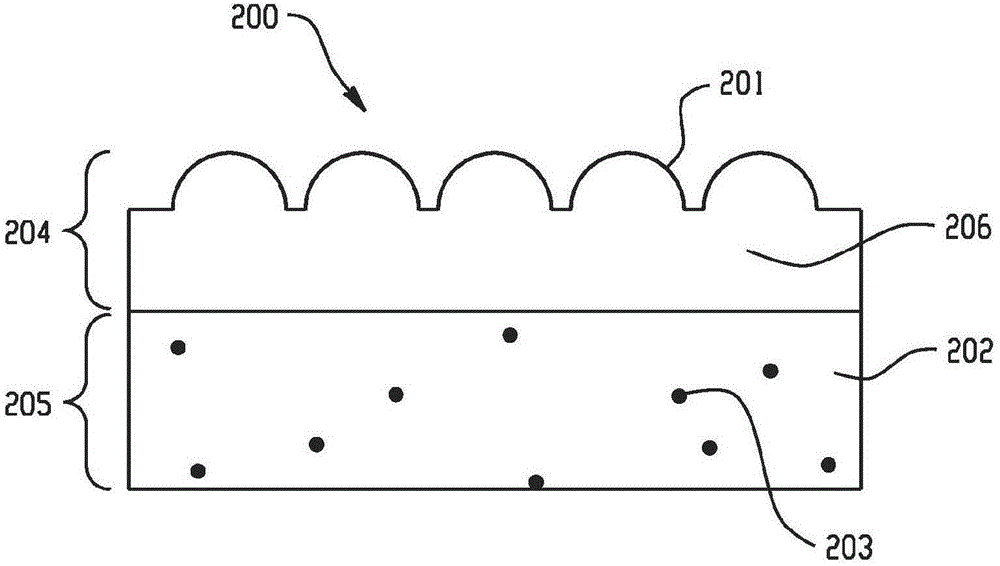

[0035] Embodiment 1: A thin plate, comprising: a polymeric material; light scattering particles disposed in the polymeric material; and a non-disordered surface texture formed by a unit structure on the surface of the thin plate; wherein the surface texture includes a hemispherical structure, a partial hemisphere Shaped structure, ellipsoidal structure, impregnated spherical beads, ellipsoidal beads, "bell-shaped" protrusions, compound lens-shaped structures, pyramidal structures, inverted pyramidal structures, or combinations comprising at least one of the foregoing; wherein the unitary structure have an aspect ratio of 0.15 to 0.5 and a pitch greater than or equal to 100 μm.

Embodiment approach 2

[0036] Embodiment 2: The sheet of Embodiment 1, wherein the sheet has a thickness of 0.5 mm to 4 mm.

Embodiment approach 3

[0037] Embodiment 3: The sheet of any of Embodiments 1-2, wherein the surface texture includes light scattering particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com