Microscale Al-containing rare earth wrought magnesium alloy and preparation method thereof

A technology of wrought magnesium alloy and rare earth magnesium, which is applied in the fields of industrial magnesium alloy, rare earth wrought magnesium alloy and its preparation, and can solve the problems of recovery of rare earth magnesium alloy processing residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

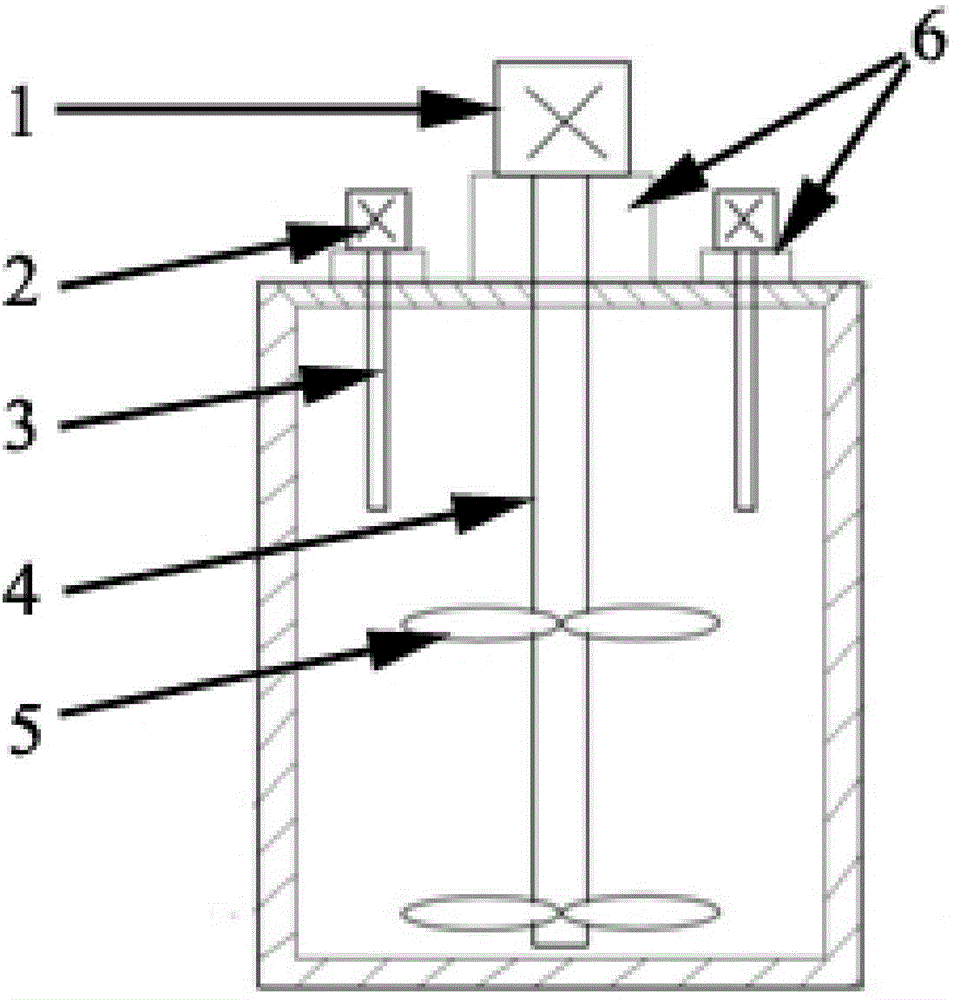

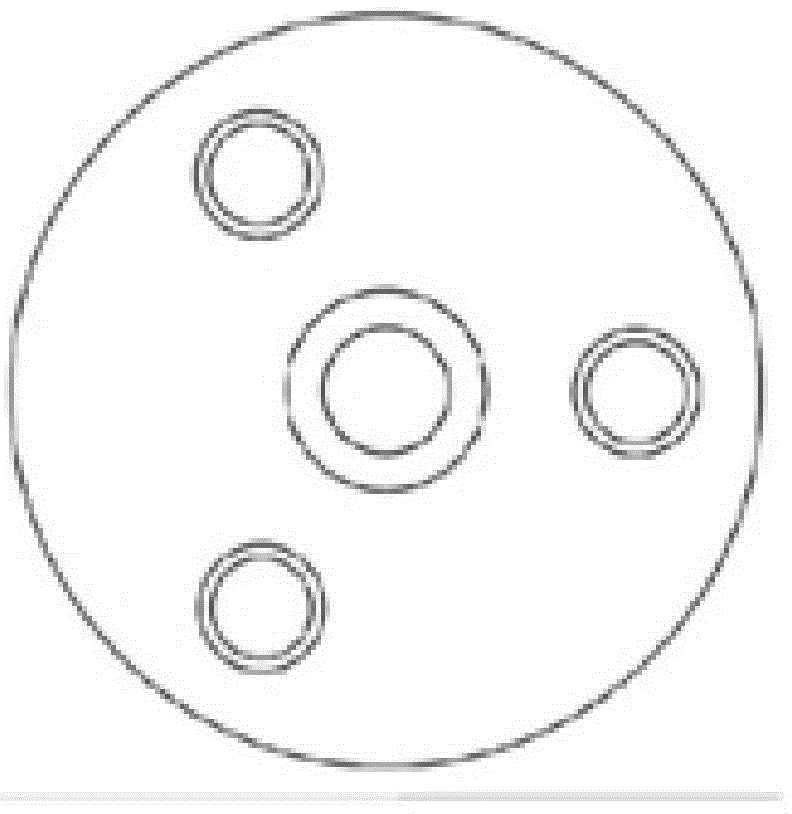

[0058] The preparation method of the rare earth deformed magnesium alloy containing a trace amount of Al of the present invention comprises the following steps:

[0059] 1 Material preparation.

[0060] There are two ways to prepare materials:

[0061] (1) new alloy

[0062] Prepare materials according to the weight percentage of the design magnesium alloy composition of the present invention; Wherein, Zr is to prepare materials with Mg-Zr master alloy, in this master alloy, the composition content of Zr is 30~40wt%, all the other are Mg; Remove master alloy Mg in Mg-Zr and Mg in other magnesium alloys are prepared as pure magnesium ingots; Gd, Y, and Nd are added in the form of pure metals.

[0063] (2) Surplus material recovery

[0064] The deformed rare earth magnesium alloy is pressed to remove the outer skin to reduce impurities. The Al content is detected online during the smelting process, and if it is less than 0.4%, it is supplemented according to the volume quali...

Embodiment 1

[0096] The melting alloy composition of this example is Mg-6.5Gd-3.0Y-2.0Zn-0.3Nd-0.3Zr-0.4Al. (RE yield is 85%, Zr yield is 25%, Al yield is 100%, Zn yield is 90%)

[0097] 1 material preparation

[0098] Zr is prepared with Mg-Zr master alloy. In the master alloy, the composition content of Zr is 30%, and the rest is Mg; except the Mg in the master alloy Mg-Zr, the Mg in the rest of the magnesium alloy is pure magnesium ingot Carry out material preparation; Gd, Y, Nd are added in the form of pure metal, and the design addition amount is:

[0099] Table 1 Alloy Design Composition Table (wt.%)

[0100]

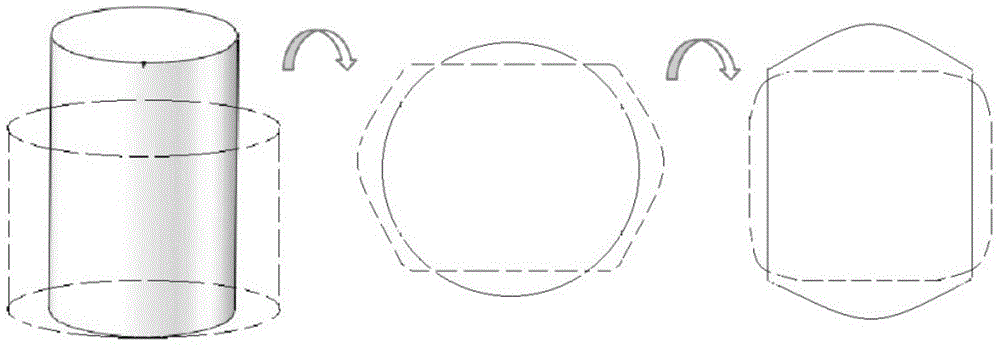

[0101] According to the amount of experimental materials and the size of the crucible, this experiment is designed to smelt 100kg. Considering the loss of alloy elements during smelting, the designed alloy composition and raw material addition are shown in Table 2. In order to ensure rapid melting, cut the raw materials into small pieces, the size of which should be put in...

Embodiment 2

[0120] The melted alloy composition of this example is Mg-7Gd-5Y-2Zn-1.5Nd-0.5Zr-0.4Al. (RE yield is 85%, Zr yield is 25%, Al yield is 100%, Zn yield is 90%)

[0121] 1 material preparation

[0122] The deformed rare earth magnesium alloy is pressed to remove the outer skin to reduce impurities. The Al content is detected online during the smelting process, and if it is less than 0.4%, it is supplemented according to the volume quality.

[0123] Raw materials are rare earth magnesium alloy Mg-7Gd-5Y-1.5Nd-0.5Zr scrap, pure Al, pure Zn; the designed dosage is:

[0124] Table 3 Alloy Design Composition Table (wt.%)

[0125]

[0126] According to the amount of experimental materials and the size of the crucible, this experiment is designed to smelt 100kg. Considering the loss of alloy elements during smelting, the design alloy composition and raw material addition are shown in Table 4. In order to ensure rapid melting, cut the raw materials into small pieces, the size of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com