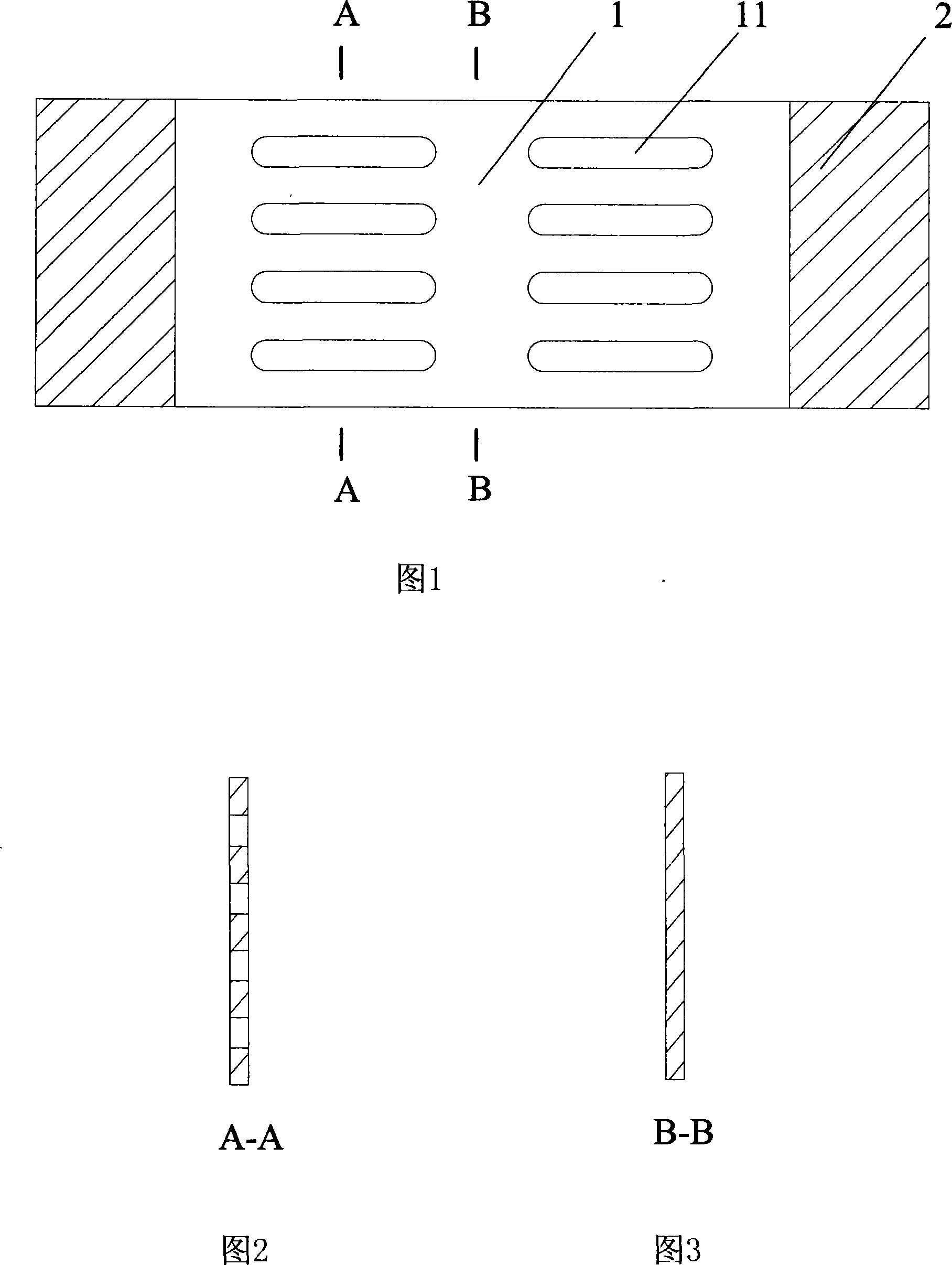

Coupled shearing force wall energy-dissipation beam-coupled steel plate damper and its using method

A damper and shear wall technology, applied in building components, building structures, earthquake-proof, etc., can solve the problem of not considering the special connection of reinforced concrete coupling beams, the reduction of lateral stiffness and energy dissipation capacity, and the insufficient development of plastic regions, etc. To achieve the effect of enhancing the energy dissipation capacity and collapse resistance of the structure, improving the seismic performance and good energy dissipation effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

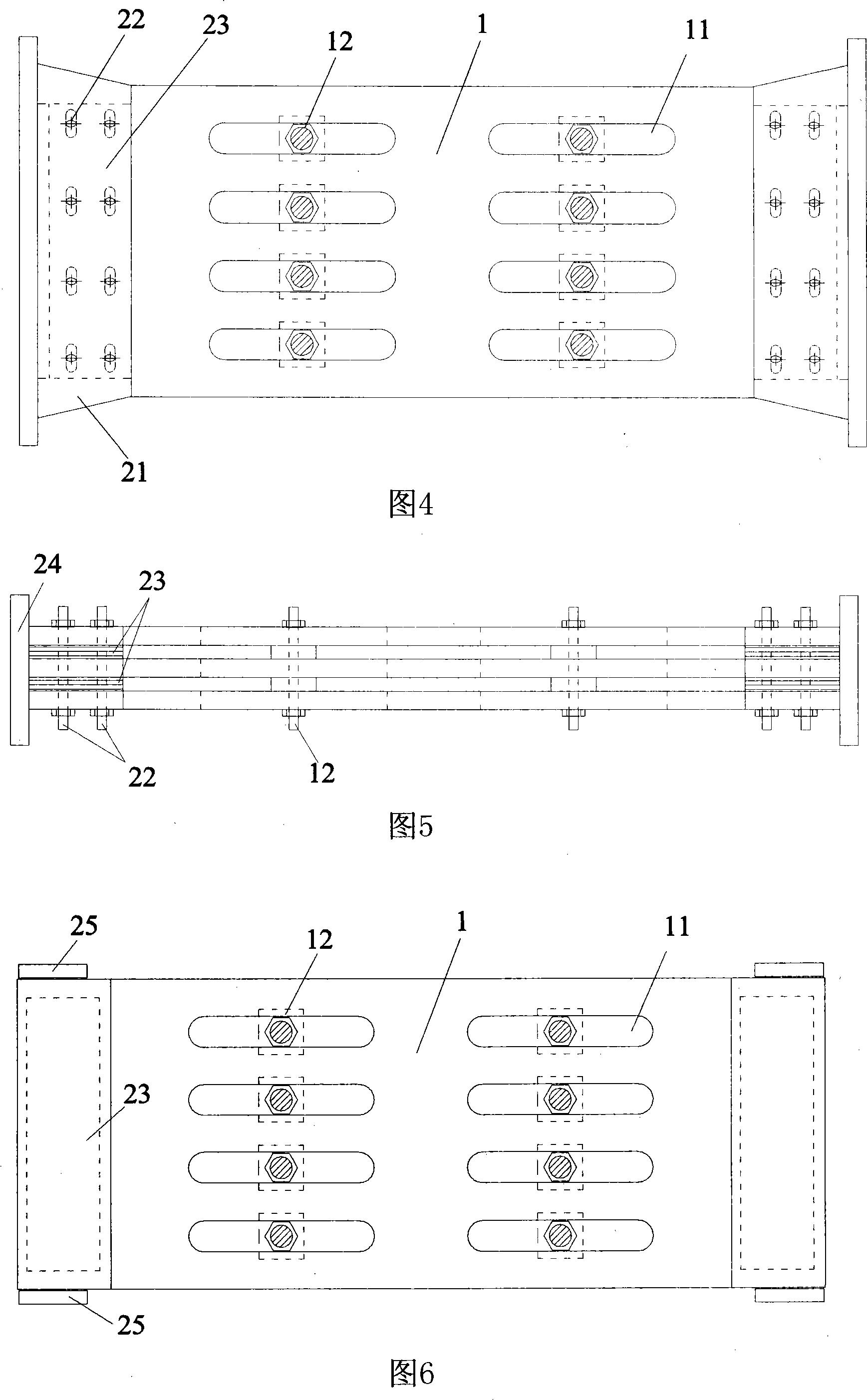

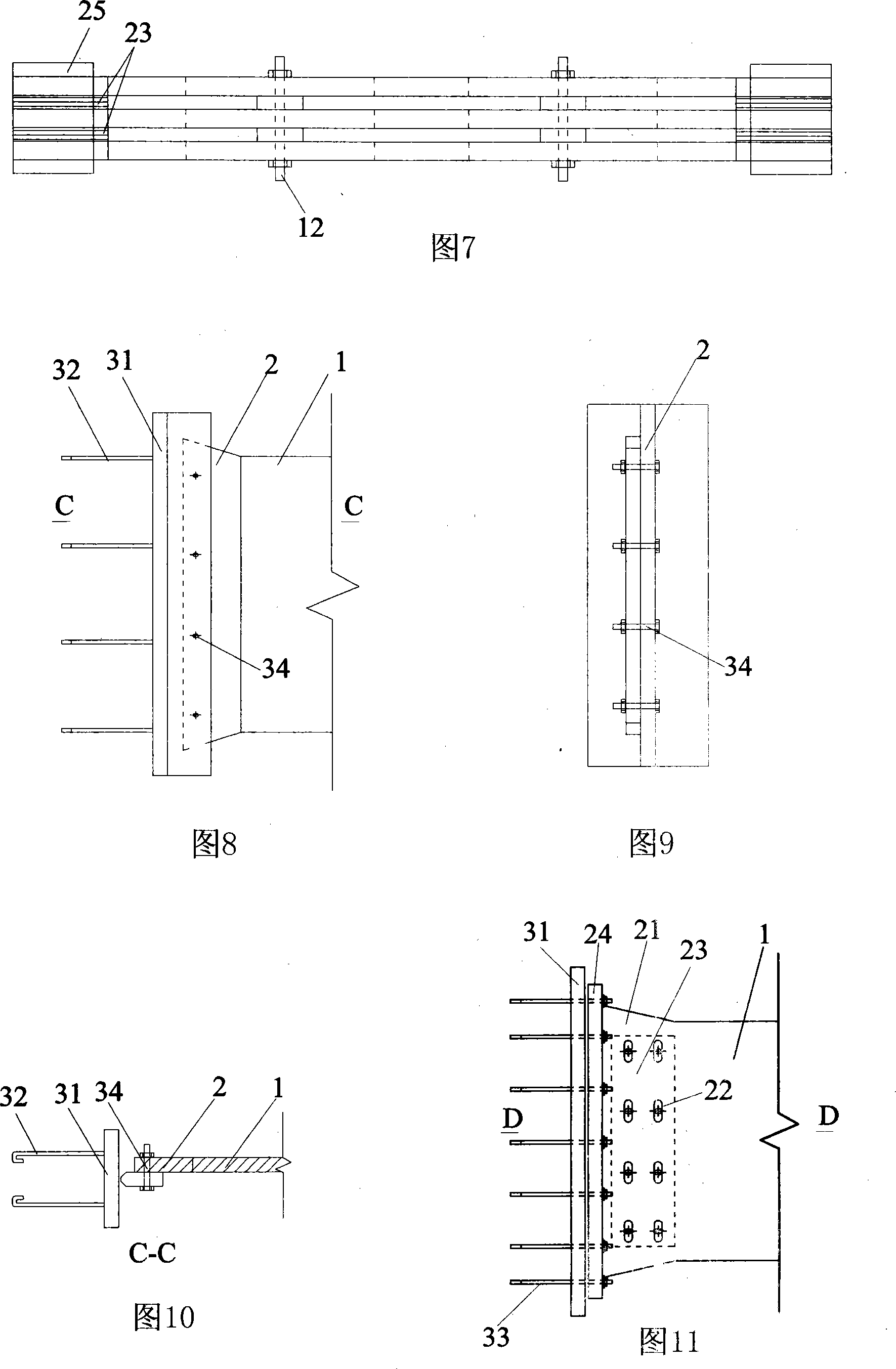

Embodiment Construction

[0052] This embodiment is a preferred embodiment of the present invention, and all other principles and basic structures or implementation methods that are the same as or similar to those of this embodiment fall within the protection scope of the present invention.

[0053] The design goal of the connecting beam shear wall structure with the damper attached or replacing the connecting beam in the present invention is: after the damper is replaced or attached to the shear wall connecting beam, the dynamic characteristics of the structure under frequent earthquakes are similar to those of the conventional connecting beam shear wall structure. Unchanging (that is, ensuring that the structural rigidity remains unchanged under normal use). The dampers can fully function under the fortification intensity or rare earthquakes, intensively absorb the structural vibration energy input by the earthquake, and protect the joint shear wall from entering plastic or Limit the plastic development ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com