Preparation method and application of high-strength oriented polyvinyl alcohol hydrogel

A technology of polyvinyl alcohol and polyvinyl alcohol powder, which is applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of single function, lack of biological function, difficulty in bearing load, etc., achieve simple preparation method and ensure biocompatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

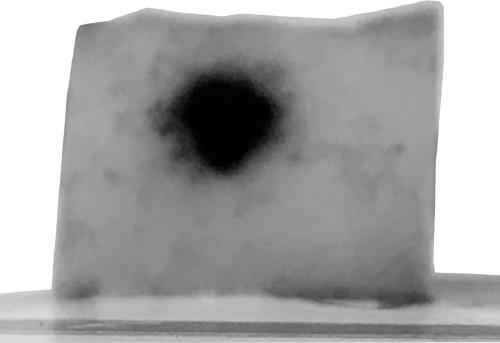

Image

Examples

Embodiment 1

[0048] Preparation of conventional polyvinyl alcohol (PVA) hydrogels.

[0049] Weigh 1 g of PVA powder and dissolve it in 9 mL of deionized water, dissolve at 90 °C for 6 h to form a uniform 10 wt% PVA solution, let it stand overnight, and quickly transfer it to the mold after deoxidizing in a vacuum box. After standing at -20 °C for 8 h, transfer to 25 °C for 4 h, and cycle 3 times continuously to obtain traditional physical cross-linked polyvinyl alcohol (PVA) hydrogel I.

[0050] The test method of gel mechanical properties is as follows:

[0051] The HZ-1003B-10Kg electronic tensile machine of Dongguan Lixian Instrument Technology Co., Ltd. was used to perform a tensile test on the obtained polymer hydrogel. The size of the tensile specimen is 50 mm × 10 mm × 1.5 mm, and the tensile strength is calculated based on the initial cross-sectional area. The stretching speed was 100 mm / min. The toughness is calculated by the integral area of the stress-strain curve, and the ...

Embodiment 2

[0057] Preparation of high-strength PVA-x-AS hydrogels.

[0058] 1) The polyvinyl alcohol (PVA) hydrogel prepared in Example 1 was pre-stretched at 0%, 25%, 50%, 75% and 100%, and freeze-dried at -20°C for 70 h to remove the contained water to obtain an orientation Type II polyvinyl alcohol (PVA) airgel.

[0059] 2) Soak the above-mentioned polyvinyl alcohol (PVA) airgel II in a 30% aluminum sulfate (AS) aqueous solution for 4 hours to obtain a series of high-strength PVA-x-AS hydrogels (where x is the pre-treatment value of PVA). stretching ratio).

[0060] According to the gel mechanical property testing method in embodiment 1, gained PVA-x-AS series hydrogel is tested, and test result is:

[0061] PVA-0-AS hydrogel: tensile strength is 22.93MPa, elongation at break is 472.85%;

[0062] PVA-25-AS hydrogel: the tensile strength is 25.79 MPa, and the elongation at break is 442.89%;

[0063] PVA-50-AS hydrogel: tensile strength is 31.67MPa, elongation at break is 310.86%; ...

Embodiment 3

[0068] Preparation of high-strength PVA-AS-y hydrogels.

[0069] 1) The polyvinyl alcohol (PVA) hydrogel prepared in Example 1 was pre-stretched to 100%, and freeze-dried at -35 °C for 48 hours to remove the contained water to prepare the oriented polyvinyl alcohol (PVA) airgel II.

[0070] 2) Soak the above polyvinyl alcohol (PVA) airgel II in 0%, 10%, 20%, 30% aluminum sulfate (AS) aqueous solution for 4 hours to obtain high-strength PVA-AS-y series water Gel (where y is the mass fraction of aluminum sulfate).

[0071] According to the gel mechanical property testing method in embodiment 1, gained PVA-AS-y series hydrogel is tested, and test result is:

[0072] PVA-AS-0 hydrogel: the tensile strength is 1.72MPa, and the elongation at break is 177.75%;

[0073] PVA-AS-10 hydrogel: tensile strength is 15.75MPa, elongation at break is 377.93%;

[0074] PVA-AS-20 hydrogel: tensile strength is 19.52MPa, elongation at break is 314.72%;

[0075] PVA-AS-30 hydrogel: tensile stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com