Method for manufacturing flexible stretchable device based on ordered arrangement torsion structure

A technology of orderly arrangement and twisted structure, which is applied in the bundling of newly ejected filaments, textiles and papermaking, and fiber processing. , fiber morphology and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

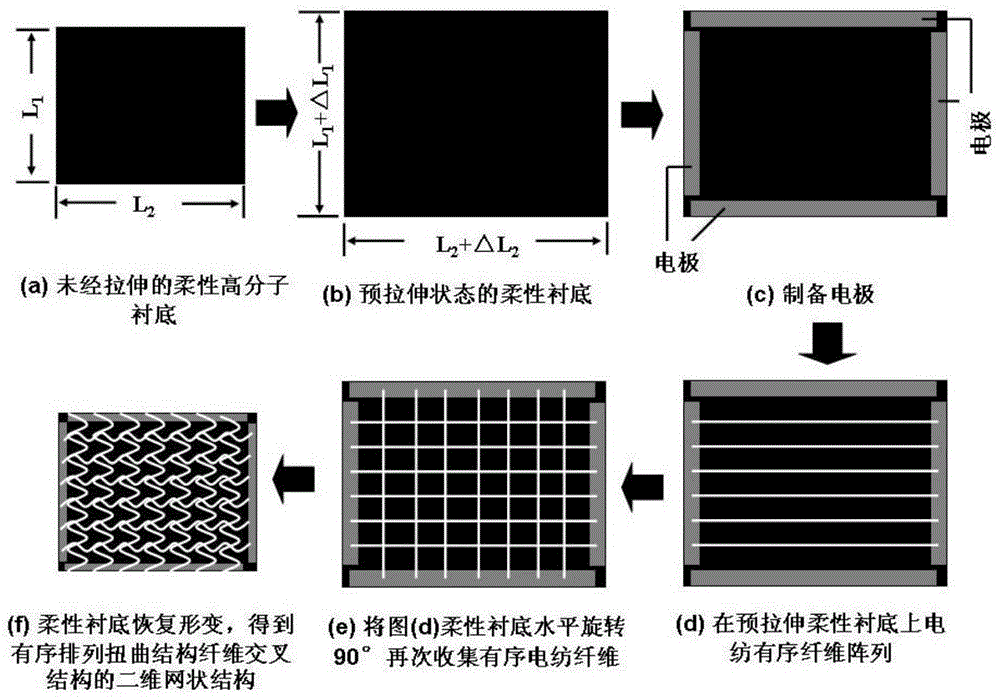

[0017] Example 1: Preparation of flexible and stretchable transparent electrodes

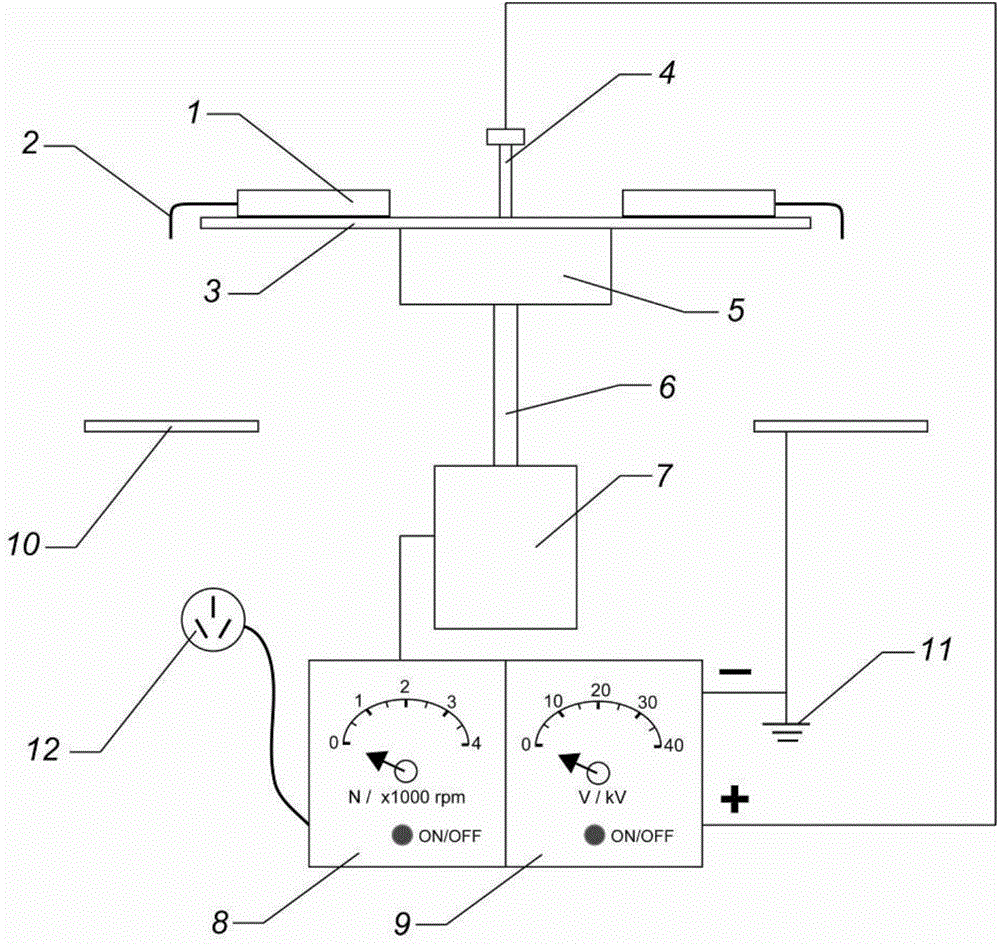

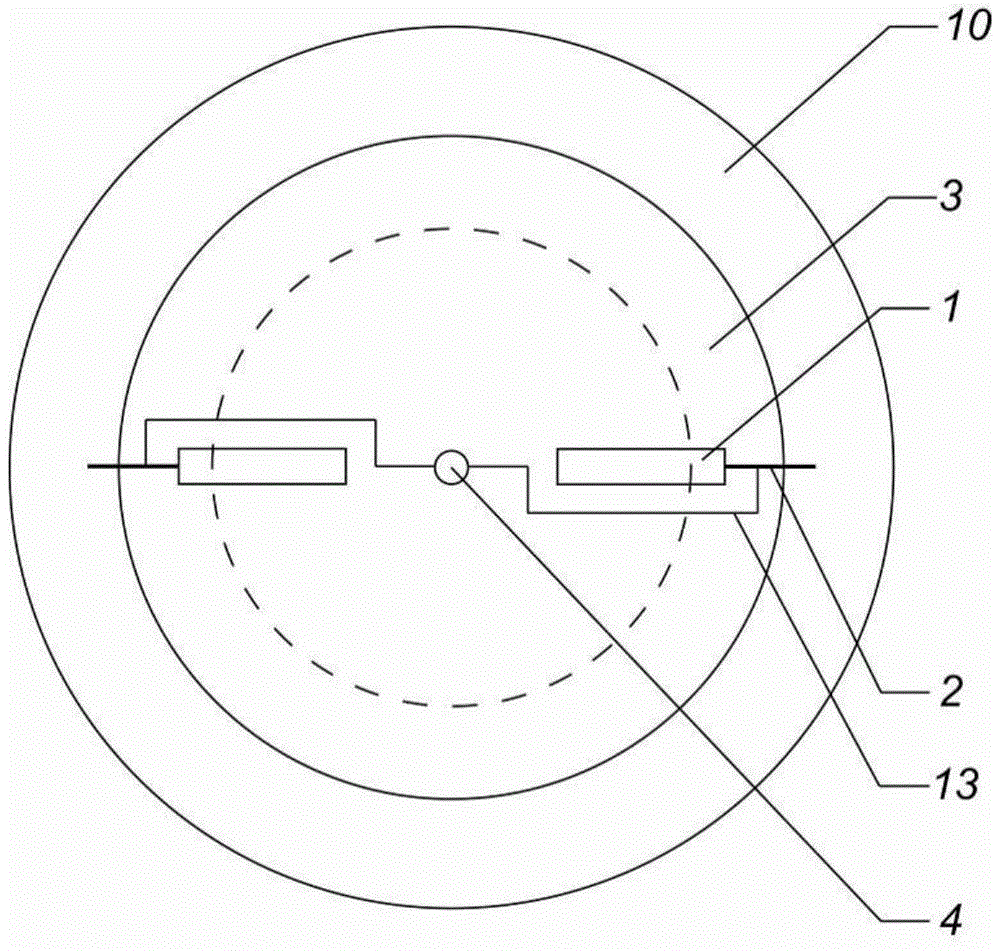

[0018] In this example, the ring-shaped aluminum foil collector is used as the collecting substrate, including the preparation of the electrospinning precursor solution, the preparation of the flexible and stretchable transparent electrode, and the performance test. The specific preparation process is as follows:

[0019] (1), preparation of electrospinning precursor solution: the selected spinning solution is a polyurethane (PU) solution doped with single-walled carbon nanotubes, first dimethylformamide (DMF) and tetrahydrofuran (THF) according to Volume ratio 1: 1 is mixed as solvent, then adding mass fraction in solvent is polyurethane (PU) of 10% to obtain polyurethane (PU) solution, in polyurethane (PU) solution, add the single-walled carbon nanotube aqueous solution prepared in advance ( Containing sodium dodecylbenzene sulfonate as surfactant), after magnetic stirring at room temperature ...

Embodiment 2

[0022] Example 2: Preparation of flexible and stretchable piezoelectric sensors

[0023] In this example, the ring-shaped aluminum foil collector is used as the collecting substrate, including the preparation of the electrospinning precursor solution, the preparation of the flexible and stretchable electric sensor and the performance test. The specific preparation process is as follows:

[0024] (1), Preparation of electrospinning precursor solution: select polyvinylidene fluoride (PVDF) precursor spinning solution, first dissolve 2 grams of PVDF in N,N dimethylformamide ( DMF, 4 grams) and acetone (4 grams) solvent, then magnetically stirred for 4 hours at 40 ° C, the solution was fully mixed, and then left to stand for 30 minutes to obtain a uniform electrospinning precursor solution;

[0025] (2) Preparation of flexible and stretchable electrical sensors: first cut out a flat PDMS film with a size of 2.5cm×2.5cm, and then apply tensile stress in the direction perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com