Single-stage double-shaft pre-deformation method for endowing pavement joint material with shape memory function

A caulking, single-stage technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of cement pavement caulking off, poor self-healing effect, high cost, etc., to reduce road damage, prolong service life, The effect of improving the quality of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention provides a single-stage biaxial pre-deformation method for endowing cement pavement joints with shape memory function, and the specific implementation steps are as follows:

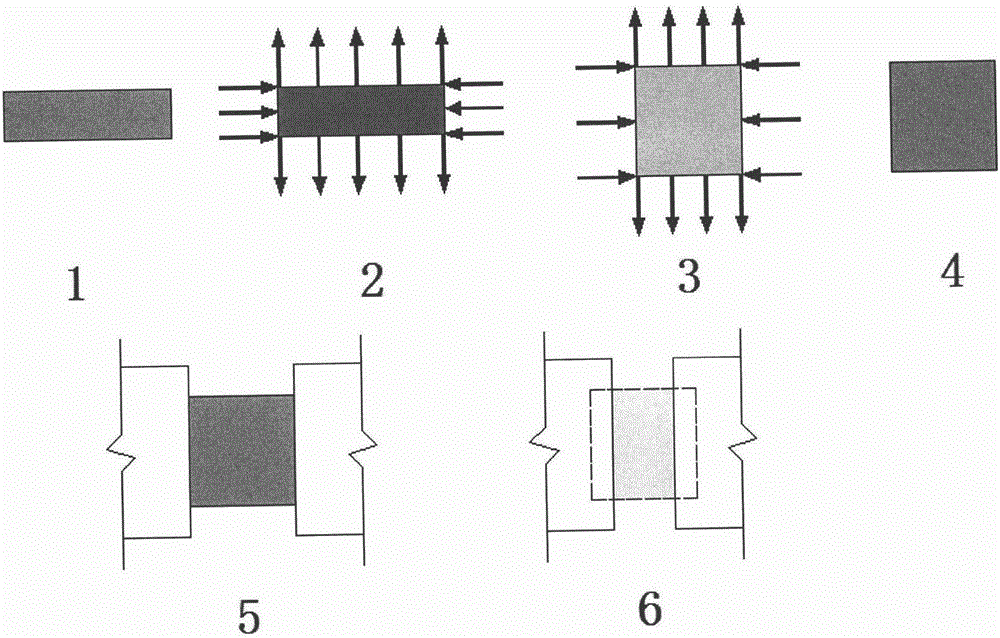

[0019] (1) Prepare shape-memory polymer-based composite materials adapted to the working conditions of cement pavement joints, and process the prepared composite materials into cross-shaped specimens;

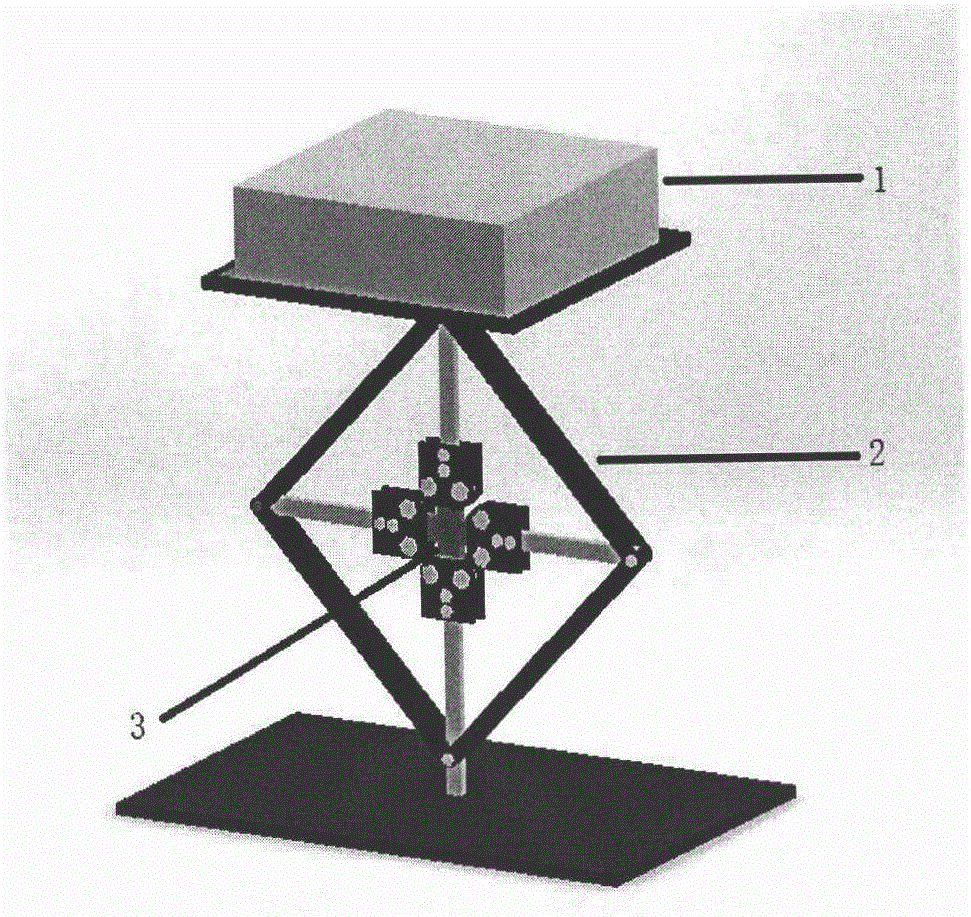

[0020] (2) Place the cross-shaped specimen in the truss-type fixture, and fix the four arms of the cross specimen with bolts, put the loading device as a whole into the environmental chamber and heat it to 5°C above the glass transition temperature at a certain heating rate, and keep the Stand at temperature for 25 minutes, and quickly retighten the bolts again due to the softening of the specimen;

[0021] (3) Put the loading device back into the environmental chamber, continue heating at 5°C above the glass transition temperature for 20 minutes, apply a certain load at this temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com