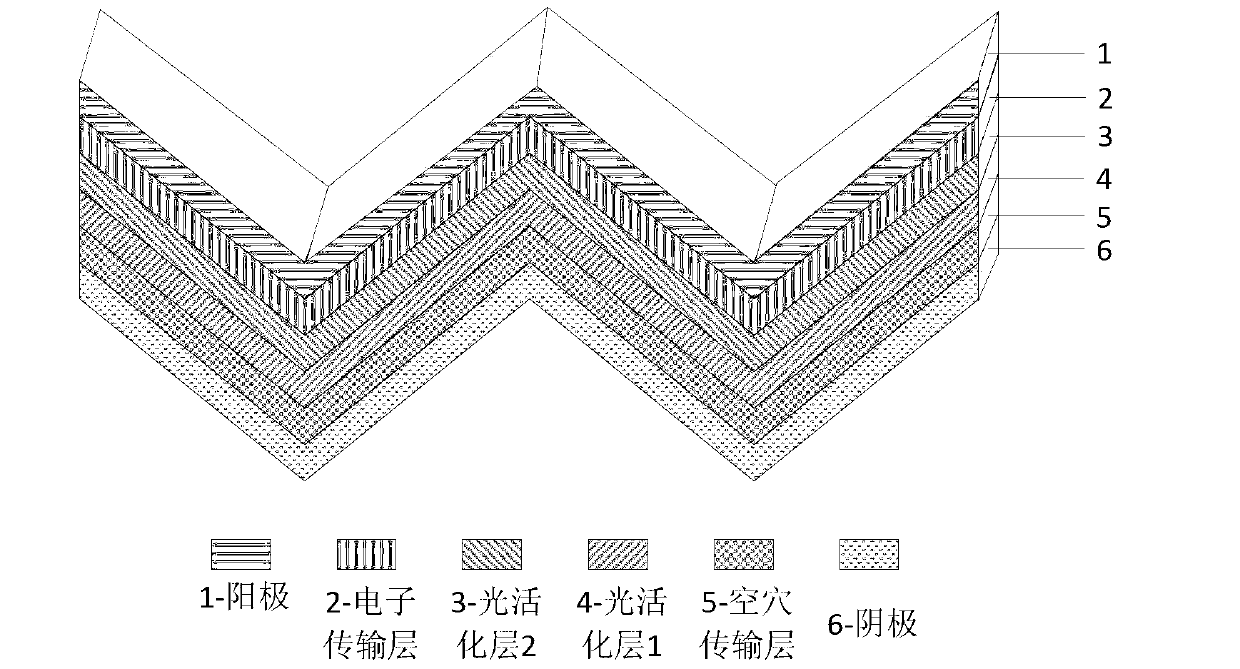

Flexible polymer solar battery with wrinkling structure and preparation method thereof

A technology of solar cells and flexible polymers, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problem that the photoelectric conversion efficiency and mechanical stability of polymer solar cells are difficult to improve at the same time, so as to facilitate large-scale production and reduce production costs. Cost, the effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of functional layer inkjet printing ink

[0043] (1) Preparation of PEDOT:PSS / graphene composite particles

[0044] Under ice bath conditions, 1.5g of graphite was added to 60ml of concentrated sulfuric acid, stirred vigorously for 30min, and further 18gKMnO 4 Add to the above mixture and stir vigorously for 30min. Transfer the above mixture to a 30°C water bath, slowly add 20g NaNO 3 , stirred for 60min; while stirring, continuously added 140ml of deionized water to the above mixture, then transferred it to an oil bath at a temperature of 90°C, stirred for 30min; then added 12ml of H 2 o 2 , continue to react for 60min to make the solution change from dark brown to bright yellow; under stirring conditions, add graphene oxide amount 10wt%PEDOT:PSS dispersing reagent in the above bright yellow graphene oxide solution, and add dropwise 30ml of hydrazine hydrate solution after dissolving , react at 80°C for 1 hour, further add 20ml of acetic acid aqueous...

Embodiment 2

[0062] 1. Preparation of functional layer inkjet printing ink

[0063] (1) Preparation of PEDOT:PSS / graphene composite particles

[0064] Under ice bath conditions, 3.5g of graphite was added to 60ml of concentrated sulfuric acid, vigorously stirred for 30min, and 20g of KMnO 4 Add to the above mixture and stir vigorously for 30min. Transfer the above mixture to a 30°C water bath, slowly add 23g NaNO 3 , stirred for 60min; while stirring, continuously added 140ml of deionized water to the above mixture, then transferred it to an oil bath at a temperature of 90°C, stirred for 30min; then added 14ml of H 2 o 2 , continue to react for 60min to make the solution change from dark brown to bright yellow; under stirring conditions, add graphene oxide amount 15wt%PEDOT:PSS dispersing reagent in the above bright yellow graphene oxide solution, and add dropwise 30ml of hydrazine hydrate solution after dissolving , react at 80°C for 1 hour, further add 30ml of acetic acid aqueous sol...

Embodiment 3

[0082] 1. Preparation of functional layer inkjet printing ink

[0083] (1) Preparation of PEDOT:PSS / graphene composite particles

[0084] Under ice bath conditions, 3.5g of graphite was added to 60ml of concentrated sulfuric acid, vigorously stirred for 30min, and 20g of KMnO 4 Add to the above mixture and stir vigorously for 30min. Transfer the above mixture to a 30°C water bath, slowly add 23g NaNO 3 , stirred for 60min; while stirring, continuously added 140ml of deionized water to the above mixture, then transferred it to an oil bath at a temperature of 90°C, stirred for 30min; then added 14ml of H 2 o 2 , continue to react for 60min to make the solution change from dark brown to bright yellow; under stirring conditions, add graphene oxide amount 15wt%PEDOT:PSS dispersing reagent in the above bright yellow graphene oxide solution, and add dropwise 30ml of hydrazine hydrate solution after dissolving , react at 80°C for 1 hour, further add 30ml of acetic acid aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com