MoO3-x nanobelt material regulated and controlled by one-dimensional plasma resonance absorption and application thereof

A plasma resonance and plasma technology, applied in water/sewage treatment, general water supply saving, molybdenum oxide/molybdenum hydroxide, etc. Strong absorbing performance, good for escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

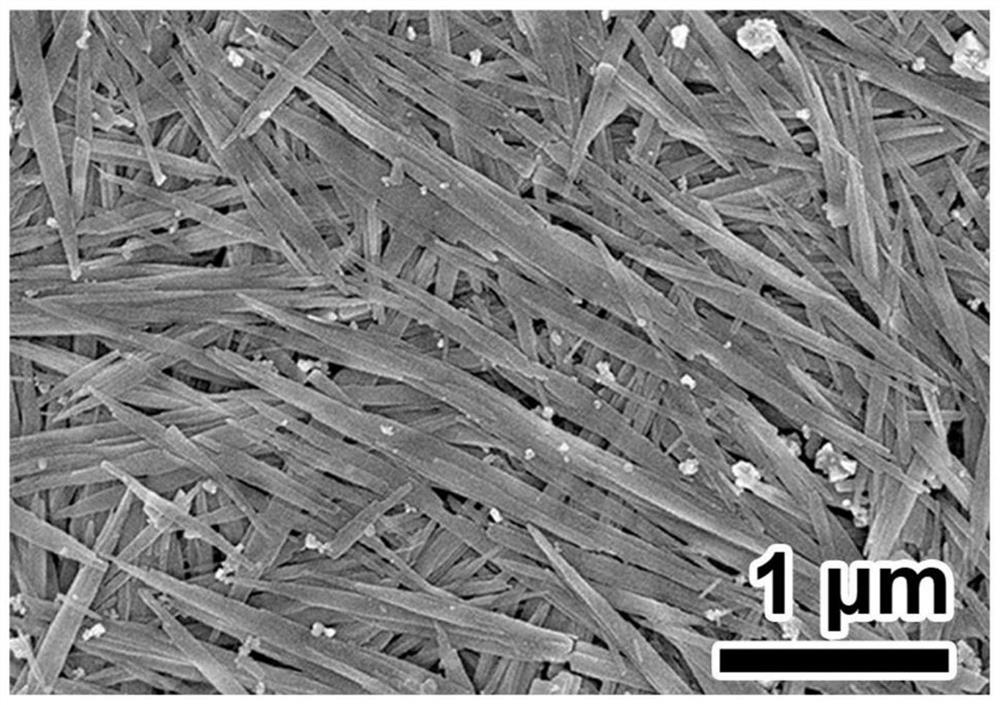

[0041] One-dimensional MoO with oxygen vacancy defects 3-x Nanobelts are prepared as follows:

[0042] (1) Get 0.6g of metal Mo powder, disperse it in 15mL of deionized water, under magnetic stirring, add 4mL of hydrogen peroxide solution (30wt%) to dissolve, and obtain molybdenum source peroxymolybdic acid colloid;

[0043] (2) Add 1000 μL of surface ligand protection and weak reducing agent polyethylene glycol (PEG) solution into a 50 mL polytetrafluoroethylene liner, stir magnetically and heat in a reactor oven at 180° C. for 12 h. The volume ratio of PEG to peroxymolybdic acid colloid is 0.01-0.05:1.

[0044] (3) Cool to room temperature after the reaction, and centrifuge wash with water and acetone to obtain one-dimensional MoO with different concentrations of oxygen vacancy defects 3-x nanobelt.

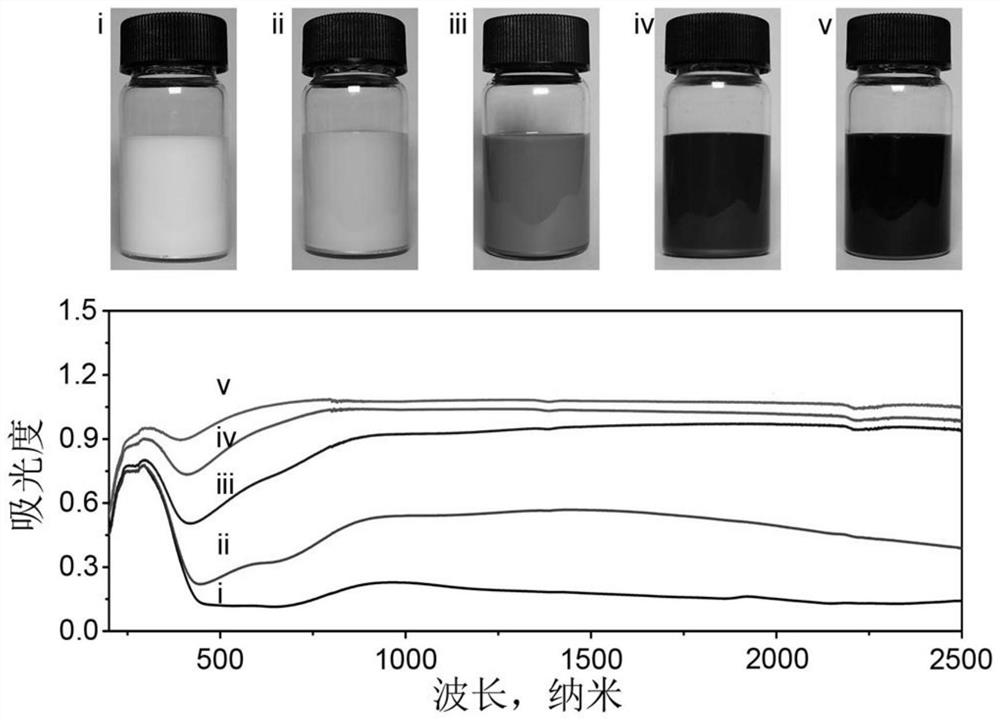

[0045] One-dimensional MoO with oxygen vacancy defects with different LSPR absorption intensities can be obtained by adjusting the reaction time, surface ligand protection a...

Embodiment 2

[0057] Embodiment 2, improve the consumption of PEG:

[0058] As described in Example 1, a MoO-based 3-x The preparation method of the solar-driven interfacial water evaporation device of the nanobelt comprises the following steps:

[0059] (1) MoO prepared under the condition that the volume ratio of PEG to peroxymolybdic acid colloid is 0.2:1 3-x Take 500 mg of nanobelts, disperse them in 100 mL of deionized water, and disperse them evenly by ultrasonic vibration to obtain MoO 3-x nanoribbon suspension;

[0060] (2) Deposit the above suspension on dust-free paper by means of sand core suction filtration, with a loading capacity of 30 mg / cm 2 , and heated and dried at 70 °C for 24 h to obtain one-dimensional plasmon resonance absorption regulated MoO 3-x nanoribbon material;

[0061] (3) MoO regulated by one-dimensional plasmon resonance absorption 3-x The nanobelt material is wrapped on the pearl cotton foam and placed on the water surface to obtain a solar-driven inte...

Embodiment 3

[0062] Embodiment 3, PEG is changed into polyvinylpyrrolidone PVP:

[0063] As described in Example 1, a MoO-based 3-x The preparation method of the interfacial water evaporation device of the nanobelt comprises the following steps:

[0064] (1) MoO prepared by using 1g polyvinylpyrrolidone PVP (Mw=130000) 3-x Take 500 mg of nanobelts, disperse them in 100 mL of deionized water, and disperse them evenly by ultrasonic vibration to obtain MoO 3-x nanoribbon suspension;

[0065] (2) Deposit the above suspension on dust-free paper by means of sand core suction filtration, with a loading capacity of 50 mg / cm 2 , and heated and dried at 70 °C for 24 h to obtain one-dimensional plasmon resonance absorption regulated MoO 3-x nanoribbon material;

[0066] (3) MoO regulated by one-dimensional plasmon resonance absorption 3-x The nanobelt material is wrapped on the pearl cotton foam and placed on the water surface to obtain a solar-driven interfacial water evaporation device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com