Preparation method and application of tungsten sulfide quantum dot and noble metal nanoparticle co-modified bismuth oxybromide composite material

A nanoparticle and composite material technology, applied in the field of preparation of bismuth oxybromide composite materials, can solve the problems of low quantum conversion efficiency, low utilization rate of sunlight, etc., achieve degradable harmful pollutants, enhance utilization rate of sunlight and photons Efficient, easy to achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation steps of BiOBr samples are as follows:

[0030] Weigh 0.004mol Bi(NO 3 ) 3 ·5H 2 O (1.94g), add in the beaker that fills 40mL ethylene glycol and stir for 30 minutes, then the molar ratio is: Bi(NO 3 ) 3 ·5H 2 O: KBr=1:1 Add 0.004mol KBr (0.476g) and continue to stir for 30 minutes. The resulting reaction solution is transferred to a stainless steel reactor lined with polytetrafluoroethylene, and kept at 140°C for 24 hours. The resulting product was washed with absolute ethanol and deionized water, and the final product was dried in an oven at 80 °C for 12 hours to obtain a BiOBr sample. The degradation efficiency of the product of this example is 63.5% for the dye rhodamine B (RhB) under visible light for 30 minutes, 76.4% for 60 minutes and 83.2% for 90 minutes.

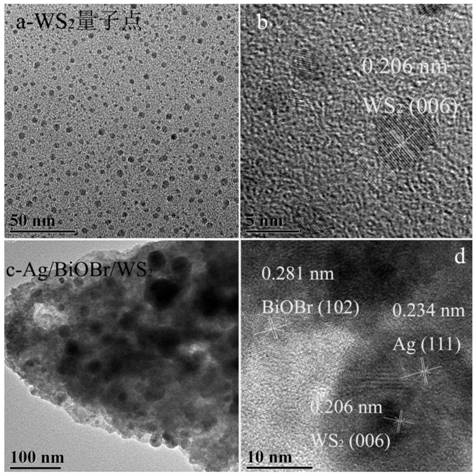

[0031] WS 2 The preparation steps of quantum dot samples are as follows:

[0032] Take 1g commercial WS 2 Add 100mL N,N-dimethylformamide (DMF) to a 250ml Erlenmeyer flask, sonicate ...

Embodiment 1

[0034] Weigh 2g BiOBr sample, add 250mL deionized water and sonicate for 1 hour, add 0.032g AgNO according to 1wt% Ag / BiOBr 3 Stir at 35°C in an oil bath for 3h, then raise the temperature to 95°C, add 0.022g NaBH 4 Cool to room temperature after half an hour. The resulting product was isolated, washed and dried to obtain a noble metal Ag nanoparticle-supported BiOBr catalyst (labeled 1% Ag / BiOBr). The degradation efficiency of the product of this example to RhB under visible light for 90 minutes is 94.2%, which is 1.13 times of the degradation efficiency of pure phase BiOBr.

Embodiment 2

[0036] Weigh 2g BiOBr sample, add 250mL deionized water and sonicate for 1 hour, add 0.04g chloroauric acid according to 1wt% Au / BiOBr, stir at 35°C for 3h in oil bath, then raise the temperature to 95°C, add 0.012g NaBH 4 Cool to room temperature after half an hour. The resulting product was isolated, washed and dried to obtain a noble metal Au nanoparticle-supported BiOBr catalyst (labeled 1% Au / BiOBr). The degradation efficiency of the product of this example to RhB under visible light for 90 minutes is 88.2%, which is 1.06 times of the degradation efficiency of pure phase BiOBr.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com