A high-precision workpiece processing system and processing method thereof

A processing system and high-precision technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems that processing equipment cannot meet the requirements of automated mass production, increase production costs, reduce processing efficiency, etc., to improve support The effect of rigidity, maintaining balance, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

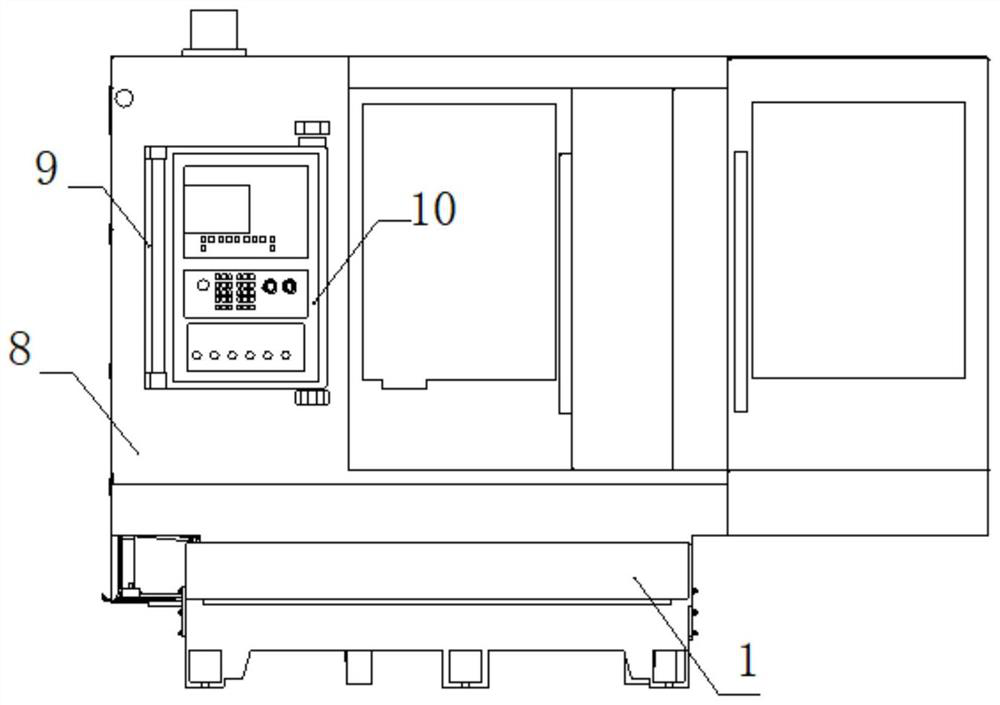

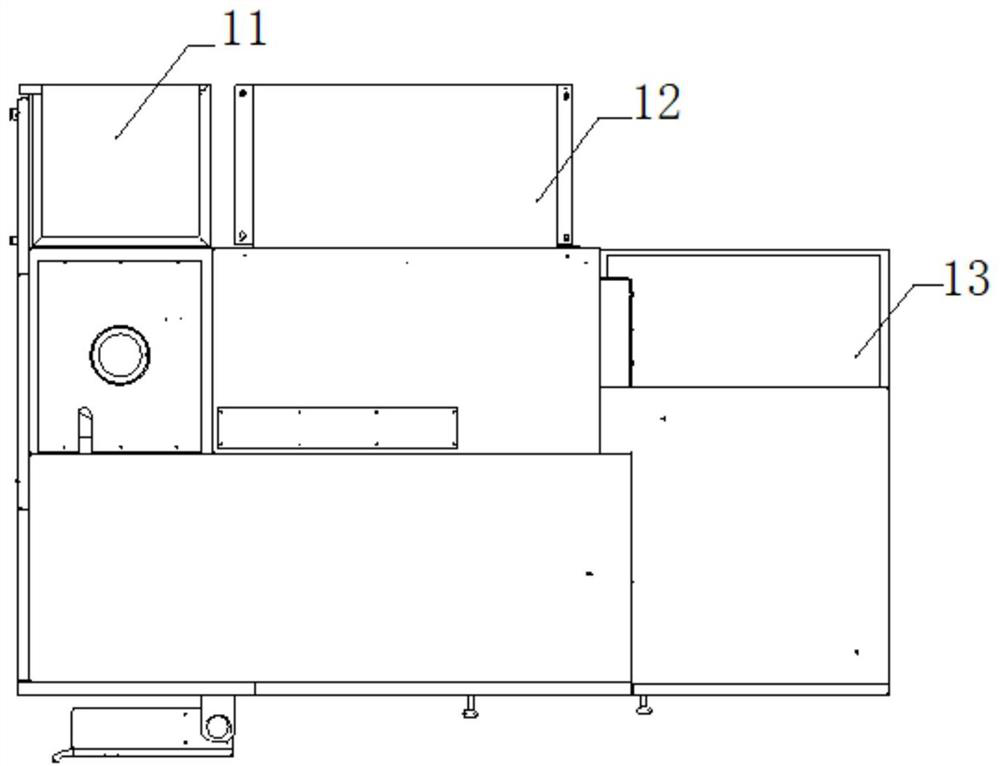

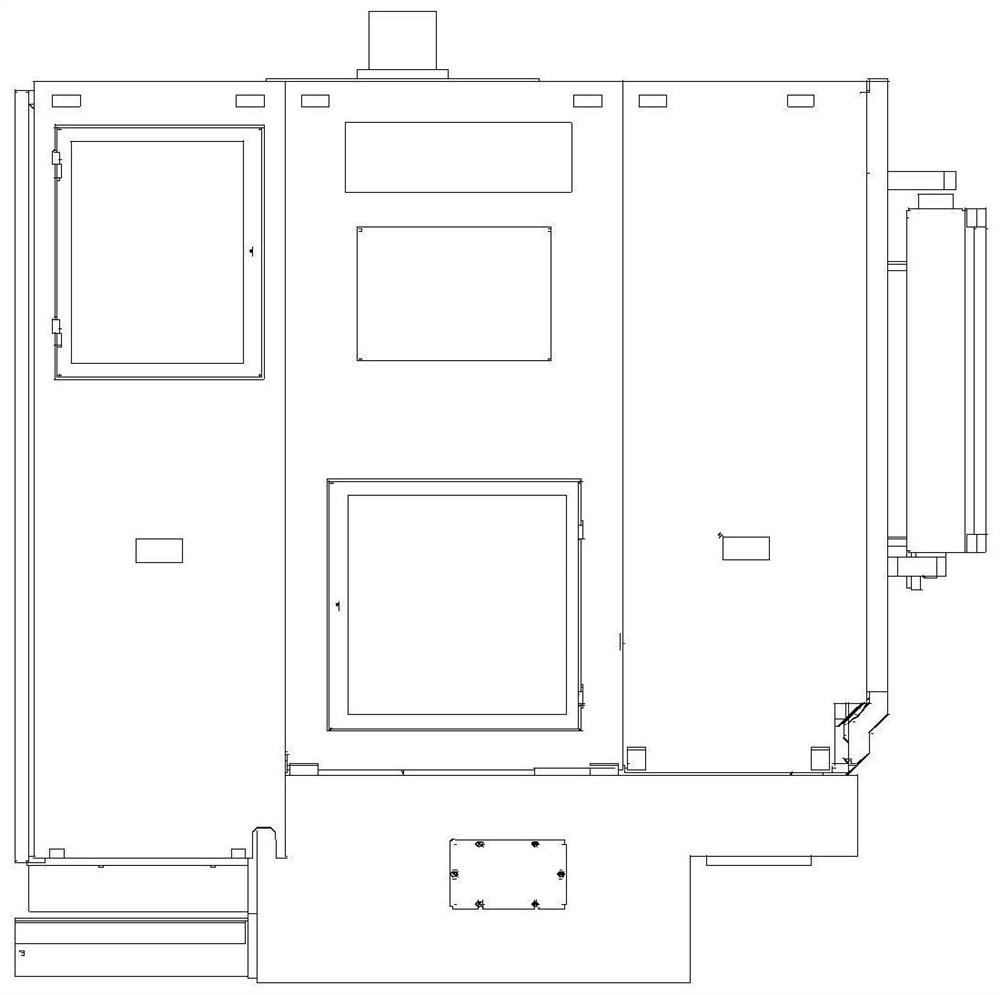

[0049] Figure 1 to Figure 17 It shows a specific embodiment of the present invention, a high-precision workpiece processing system, including a bed 1, an X-axis motion unit 2, a Y-axis compound motion unit 3, a tool rest unit 4, a workpiece headstock unit 5, and a tip unit 6 , automatic tool setting unit 7, outer casing 8, handle 9, control box 10, cooling and filtering station 11, electric control box 12, workpiece feeding unit 13 and inner casing 14, and the X-axis motion unit 2 is installed on the bed 1 On the inclined plane and the angle between the inclined plane of the bed 1 and the horizontal plane is 30°, the Y-axis compound motion unit 3 is installed on the X-axis motion unit 2, and the tool post unit 4 is installed on the Y-axis compound motion unit 3 , the workpiece headstock unit 5 is fixedly installed on the bed 1 and the workpiece headstock unit 5 is located on the left side of the tool rest unit 4, the top unit 6 is fixedly installed on the bed 1 and the top un...

Embodiment 2

[0061] A processing method for a high-precision workpiece processing system, characterized in that it includes the following steps:

[0062] a) The operator fills the circular cycle workpiece storage rack in the workpiece feeding unit 13 with material, and installs the hob on the tool rest unit 4;

[0063] b) The two-axis truss manipulator in the workpiece feeding unit 13 transports the workpiece on the circular circulation workpiece storage rack to the hydraulic chuck on the workpiece headstock unit 5, and then the top unit 6 moves to the left along the second X-axis linear guide rail pair The kinematic top is in the center hole on the right side of the workpiece;

[0064] c) Then the automatic tool setting unit 7 is started, and the automatic tool setting operation on the workpiece is realized through the first slide cylinder 702 and the second slide cylinder 703;

[0065] d) Then the X-axis motion unit 2, the Y-axis compound motion unit 3, the workpiece headstock unit 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com