Patents

Literature

67results about How to "Convenient loading and unloading operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Loading and unloading system and loading and unloading method

ActiveCN107720292AReduce lossHigh degree of automationControl devices for conveyorsStacking articlesReciprocating motionProcess region

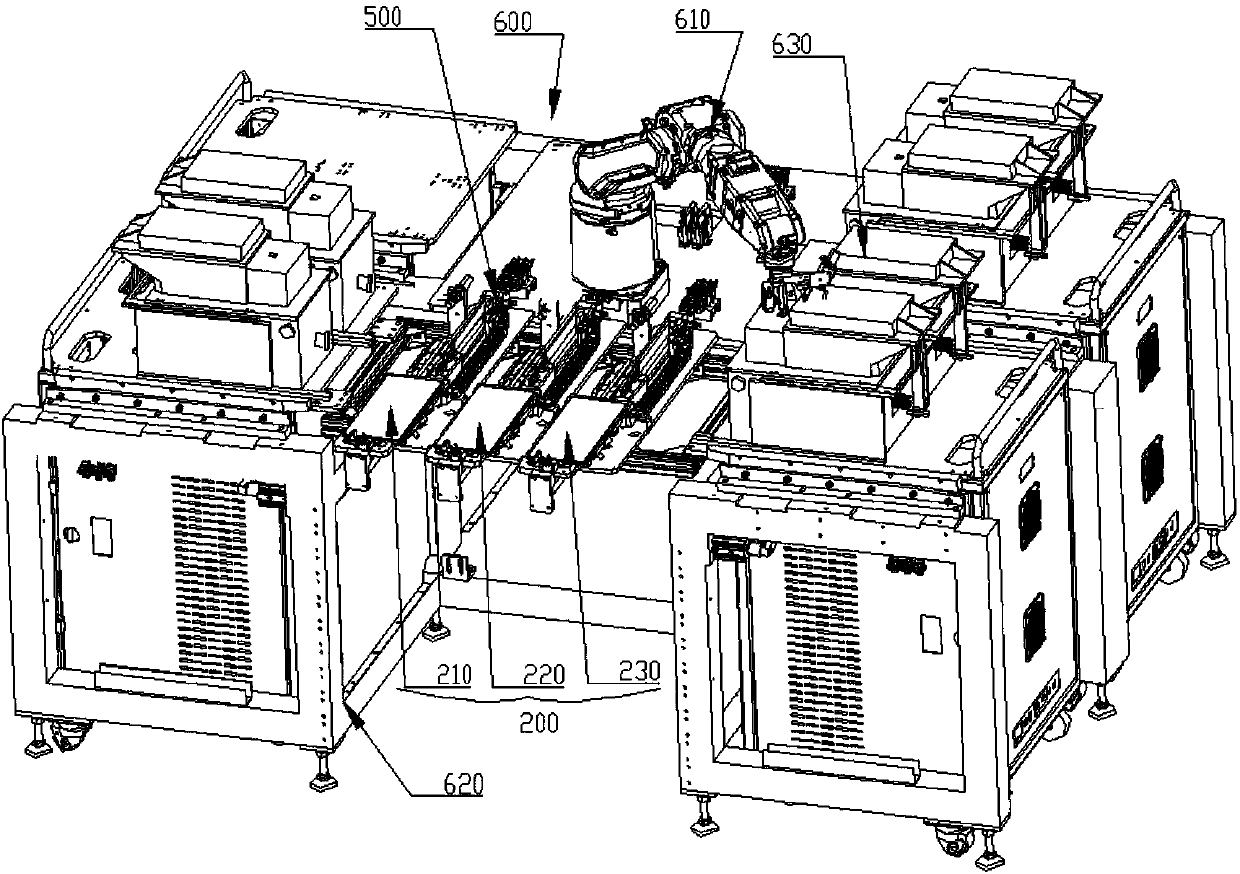

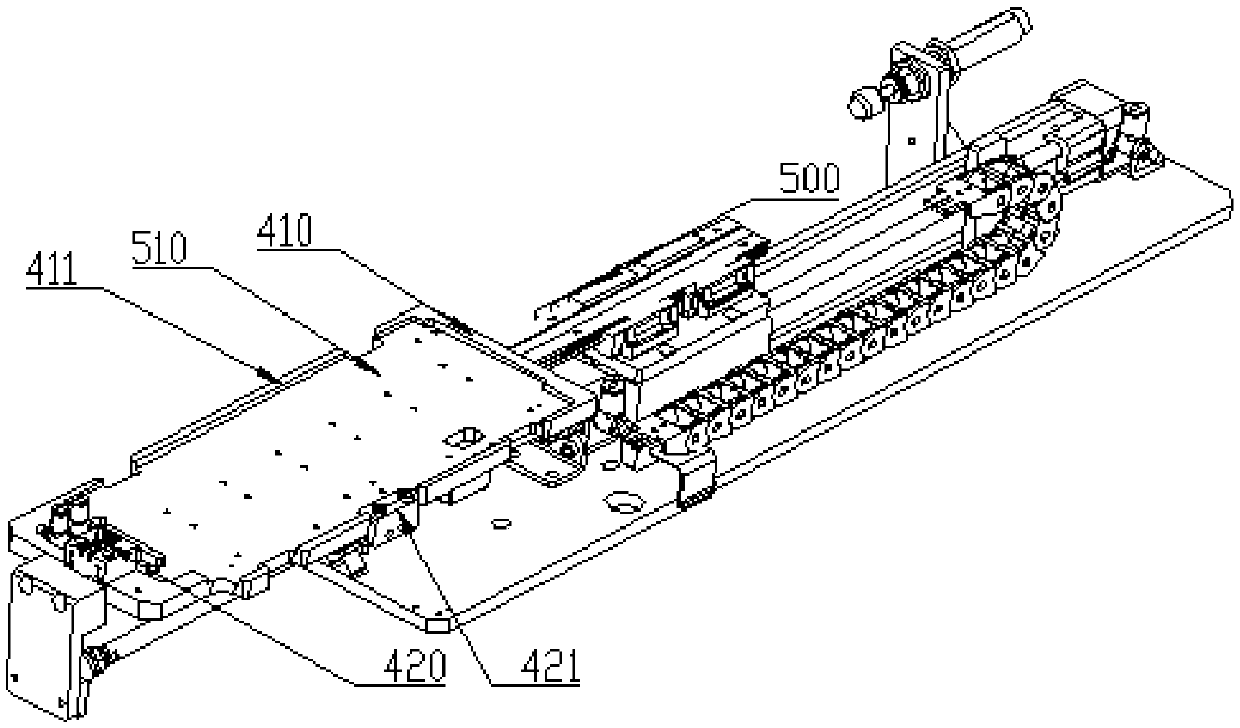

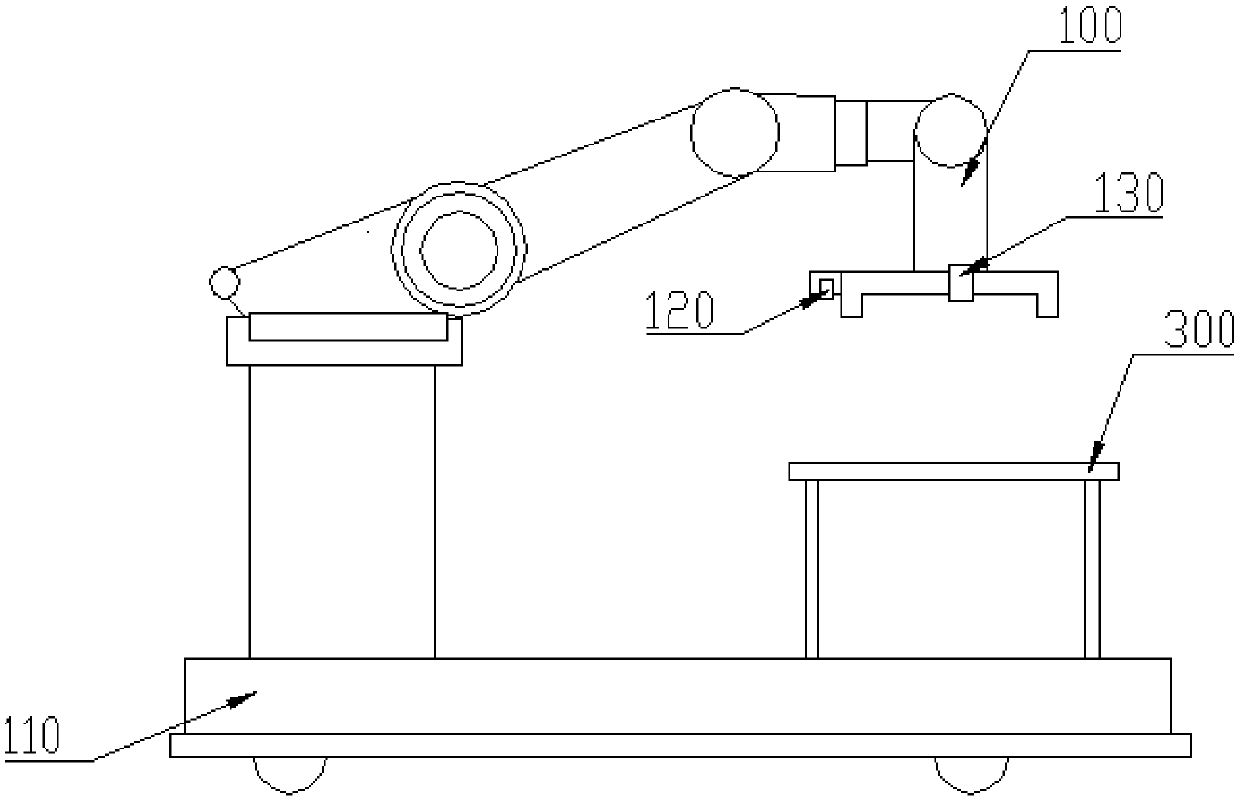

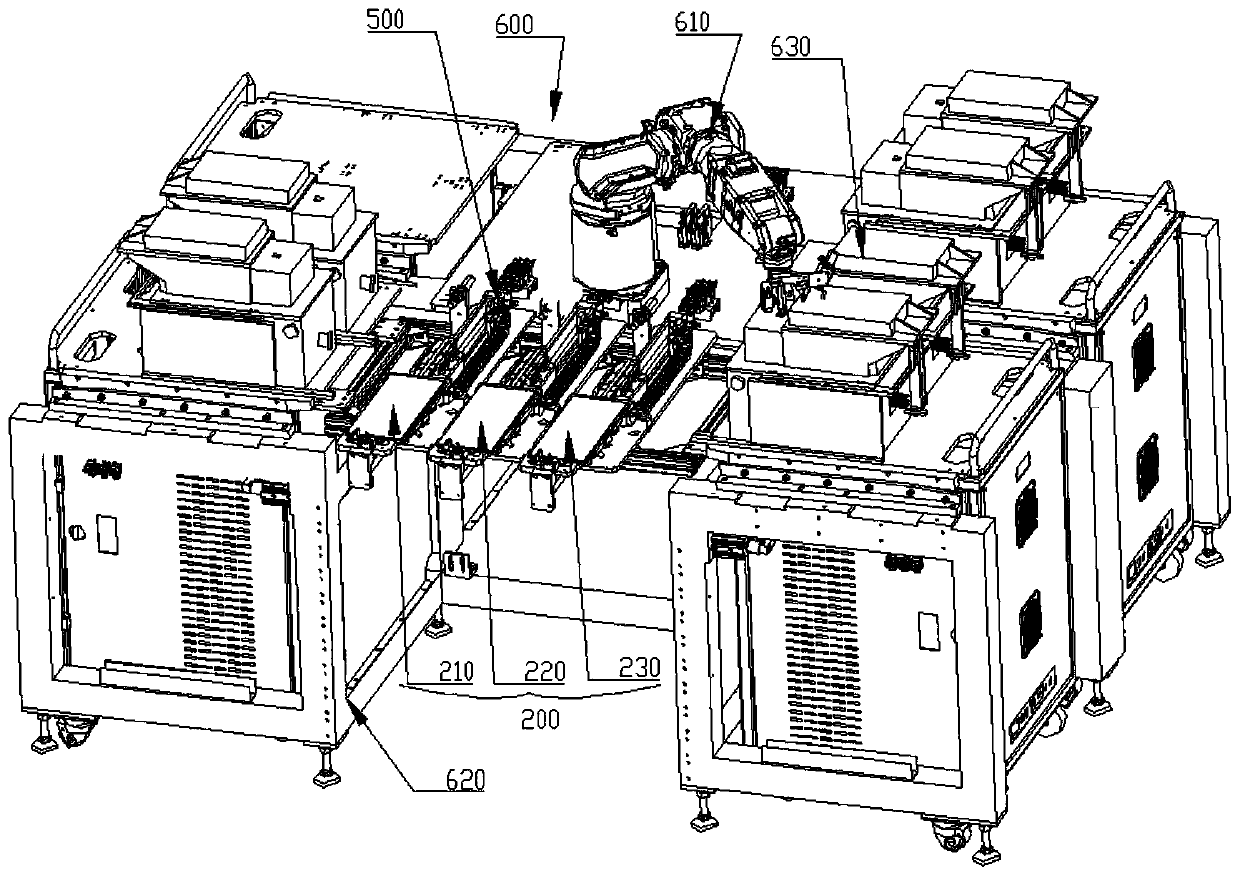

The invention discloses a loading and unloading system and a loading and unloading method. The loading and unloading system and the loading and unloading method are used for loading and unloading of afunctional device. The loading and unloading system comprises material trays, a loading and unloading area, a storage area, a height sensor, a mechanical arm device and a material tray pushing-out mechanism. The material trays are used for bearing materials, the functional device takes and places the material trays in the loading and unloading area, the storage area is used for storing the traysin a stacking mode, the height sensor senses the stacking height of the material trays in the storage area, the mechanical arm device can grab the material trays to rotate mutually between the loadingand unloading area and the storage area, the height sensor is in communication connection with the mechanical arm device, and the mechanical arm device adjusts the grabbing height according to the material tray stacking height measured by the height sensor. The material tray pushing-out mechanism moves between the function device and the loading and unloading area in a reciprocating mode. The mechanical arm device is used for transferring materials between the loading and unloading area and the storage area, and the material tray pushing-out mechanism is arranged to connect the material loading and unloading area with the processing area of the function device in series, so that the automation degree of the system is increased and the loss of manpower is reduced.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

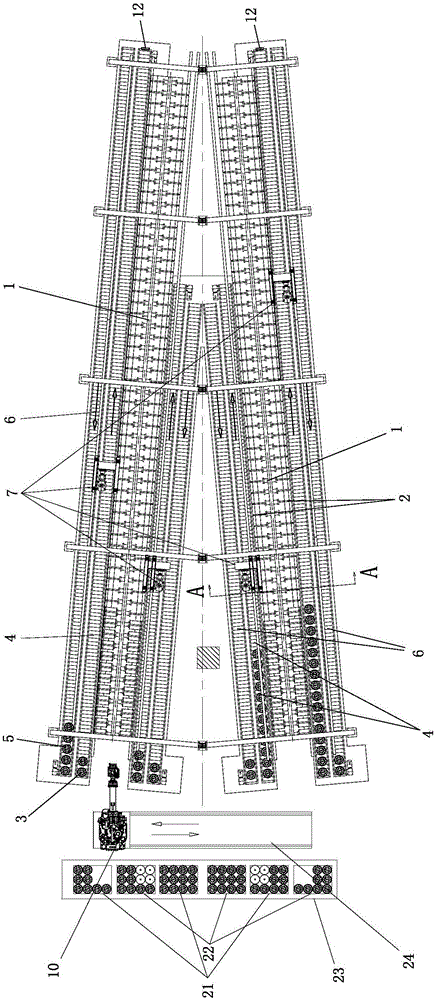

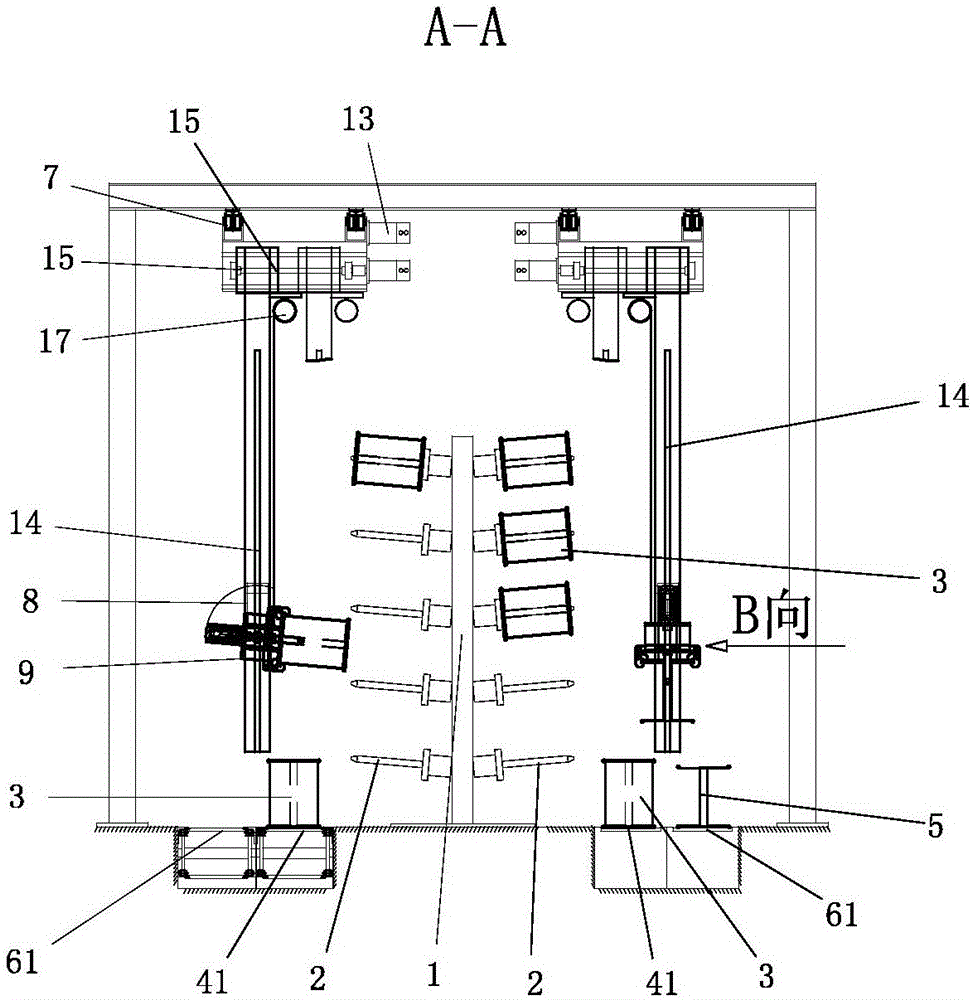

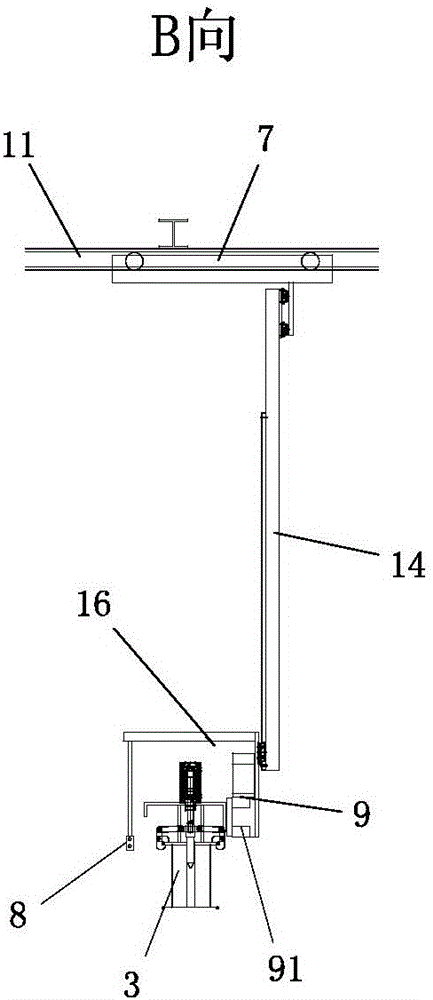

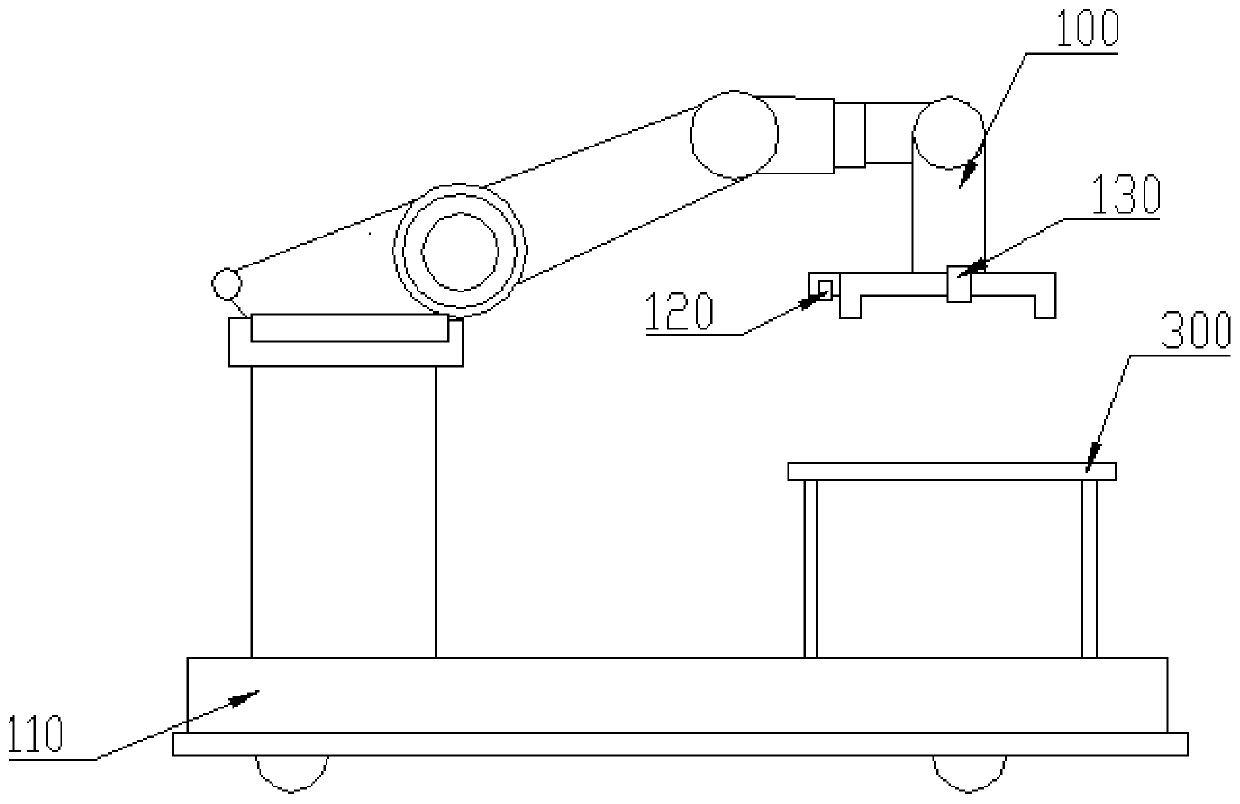

Automatic ingot loading and unloading system

ActiveCN106144774AReduce manual labor intensityImprove work efficiencyFilament handlingCar drivingControl system

The invention discloses an automatic ingot loading and unloading system. The system comprises an ingot frame; ingot mounting shafts are fixed on two sides of the ingot frame; full ingot conveying devices, empty ingot conveying devices and walking car devices are arranged at two side parts of the ingot frame; ingot unloading devices and ingot loading devices are arranged on the walking car devices; and actions of all the devices are controlled by a control system. The system further comprises a position sensor and a first image identifying sensor; the walking car devices are hung and mounted on suspension guide rails, and are driven by a car driving device to move on the suspension guide rails; vertical guide rails and guide rail driving devices are arranged on the walking car devices; mounting bases are arranged on the vertical guide rails; the ingot loading devices and the ingot unloading devices are mounted on a mounting base side by side; and a gap therebetween is adapted to a gap of two adjacent ingot mounting shafts. The automatic ingot loading and unloading system can realize automatic disassembly of empty ingots and installation of full ingots, reduces the labor intensity, and can improve the working efficiency.

Owner:HAINING RUICHUANG MACHINERY TECH

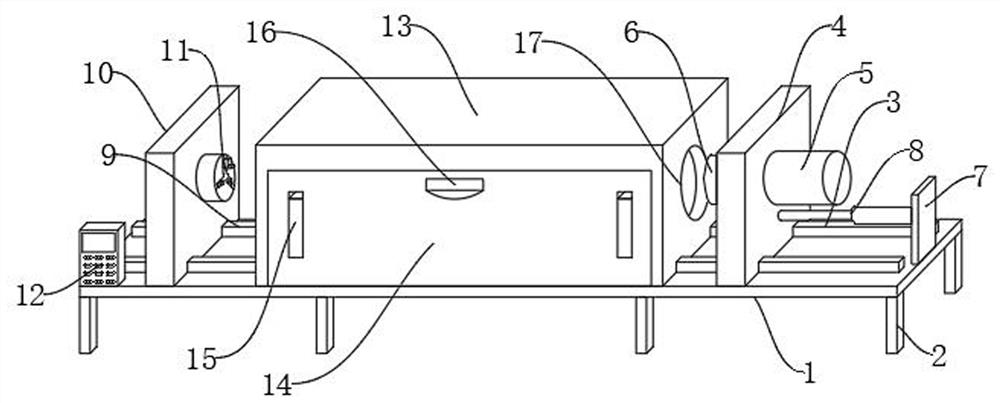

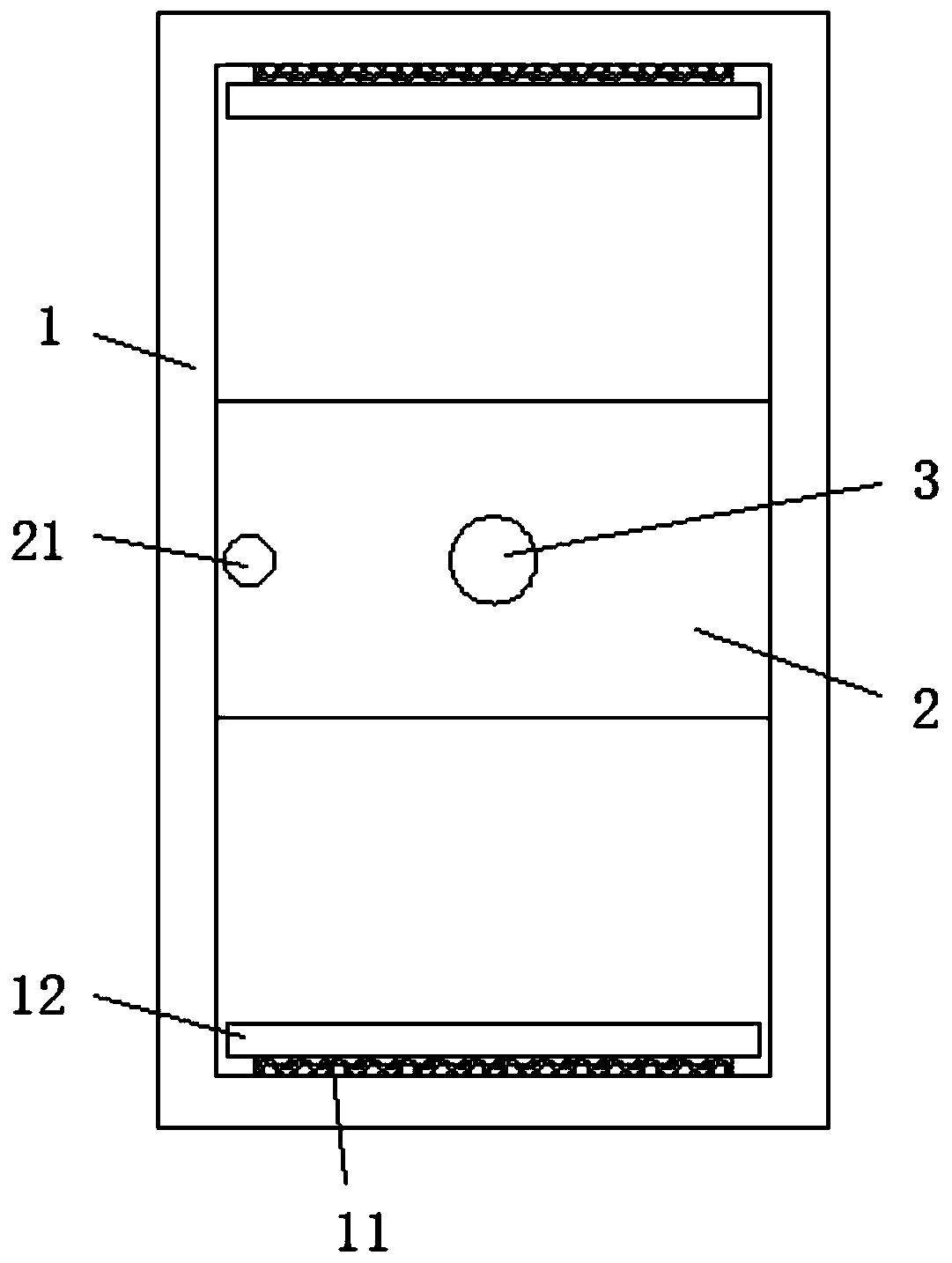

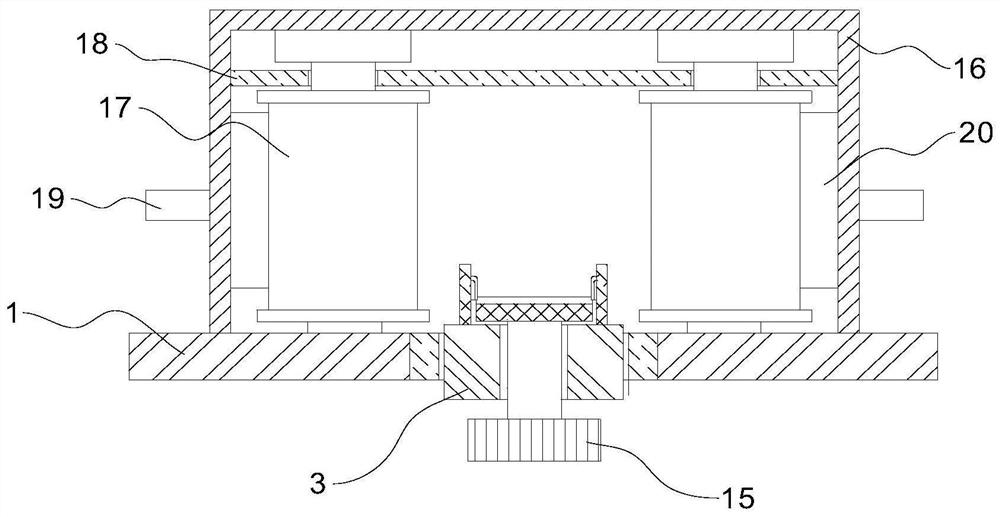

Automatic spraying device for server cabinet production

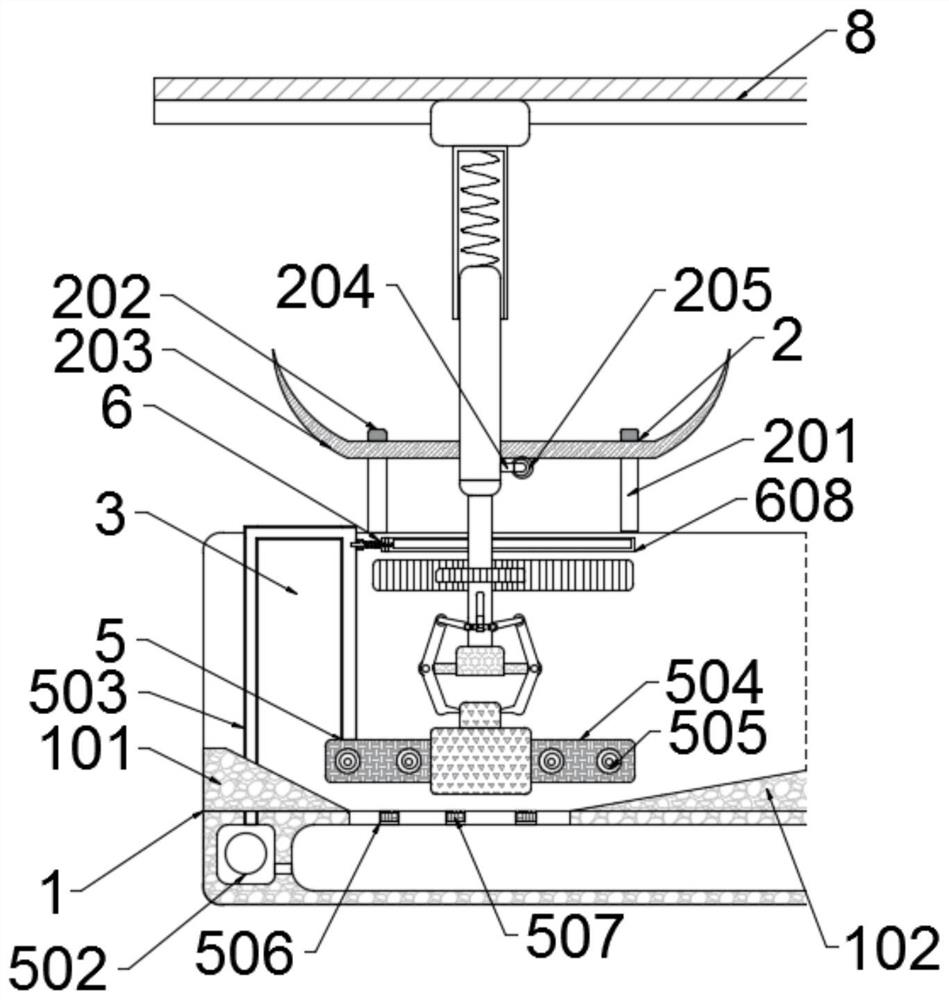

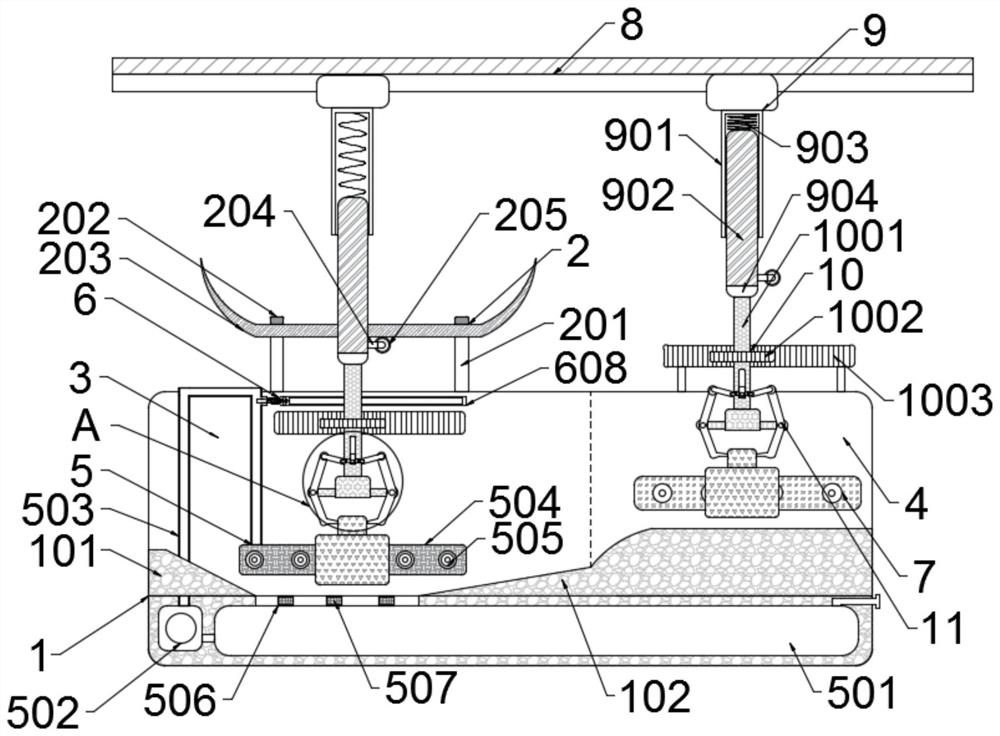

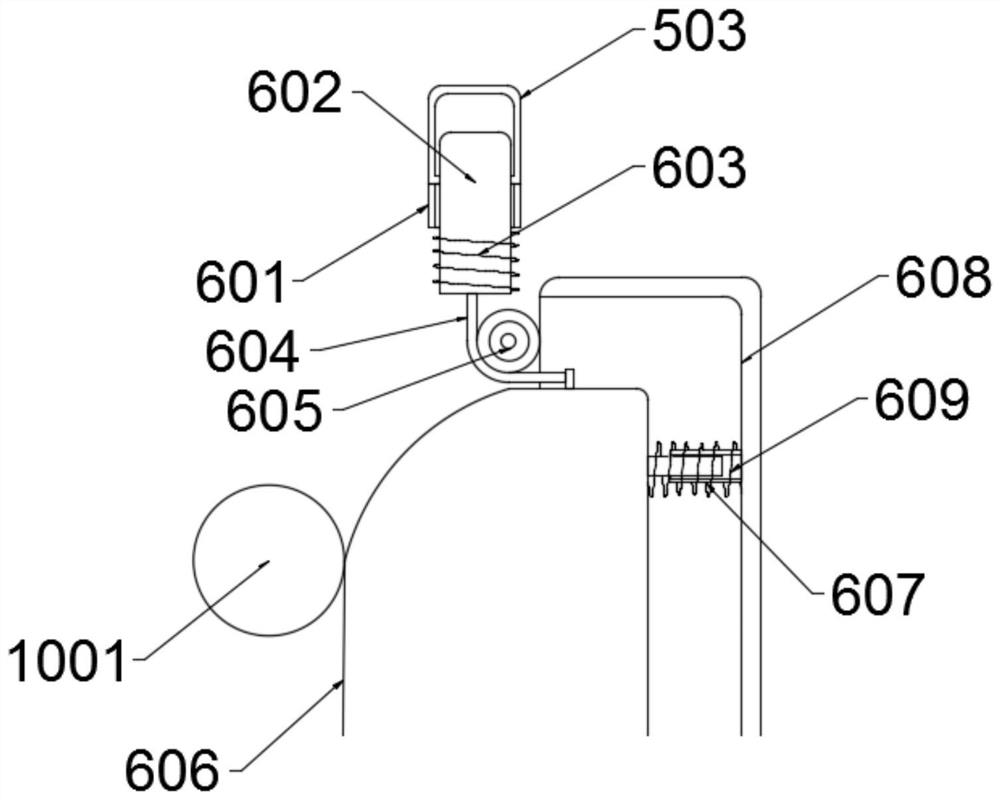

InactiveCN111299048AConvenient loading and unloading operationEasy to operatePretreated surfacesCoatingsSpray nozzleEngineering

The invention belongs to the technical field of spraying equipment, and particularly discloses an automatic spraying device for server cabinet production. The device comprises a spraying chamber, a spraying device, an adjustable nozzle, a movable spraying device, a lifting rotating device, a clamp, a movable tray, a drying device and a control panel, the movable spraying device is arranged at thetop of the spraying chamber, the adjustable nozzle is installed on the movable spraying device and connected with the spraying device, the spraying device is installed at the top end of the spraying chamber, the lifting rotating device is arranged below the adjustable nozzle, the clamp is installed on the lifting rotating device, the movable tray is arranged in the middle of the lifting rotating device, the drying devices are arranged on the two sides of the movable tray, and an inlet and an outlet are formed in the bottom end of the front side of the spraying chamber. The spray nozzle can beadjusted to adapt to cabinet plates of different sizes, meanwhile, one-time uniform and rapid spraying can be achieved, the spraying quality is improved, the automation capacity is high, and the safety of workers is protected.

Owner:SUZHOU LONGWAY ELECTRONICS MACHINERY

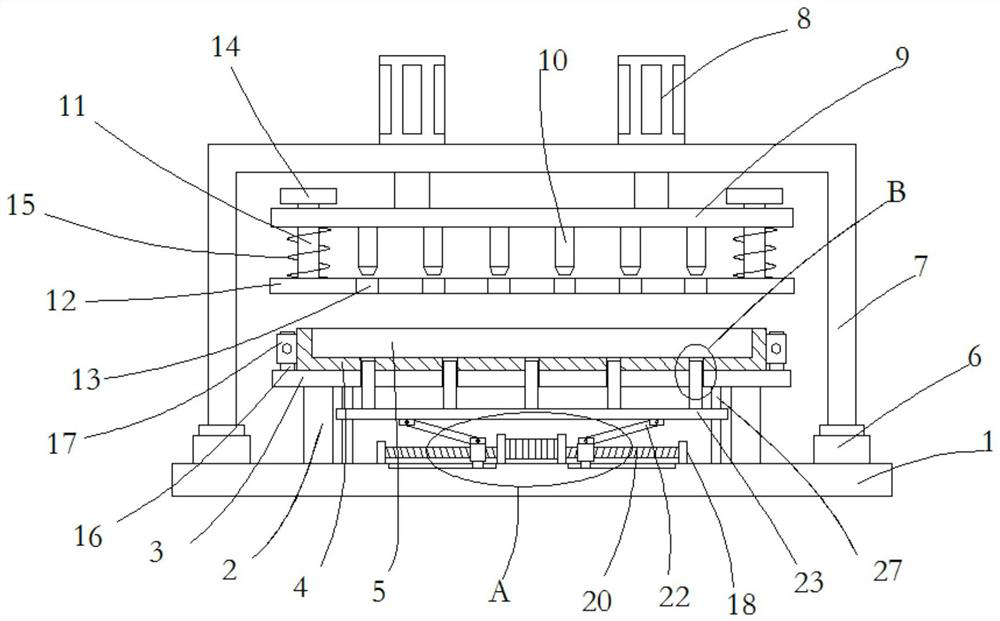

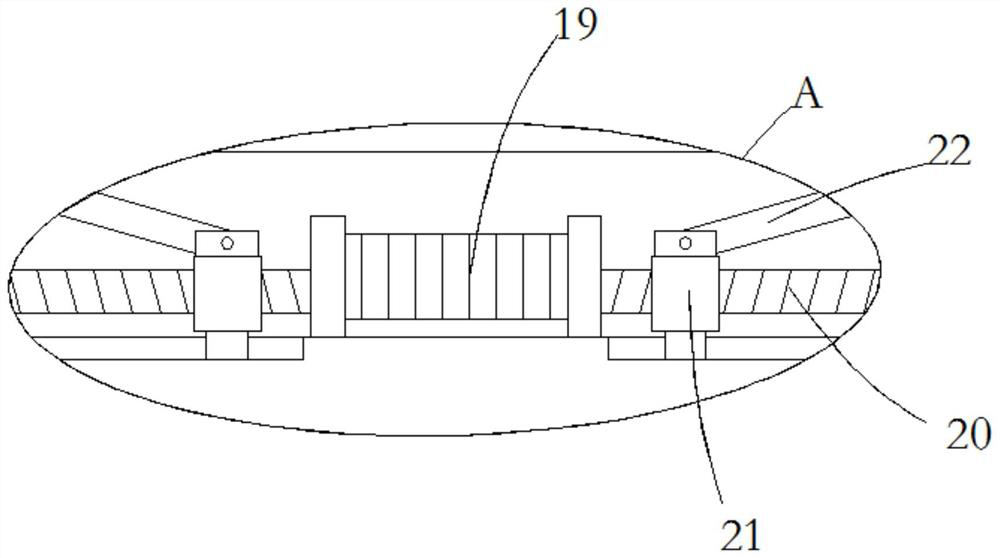

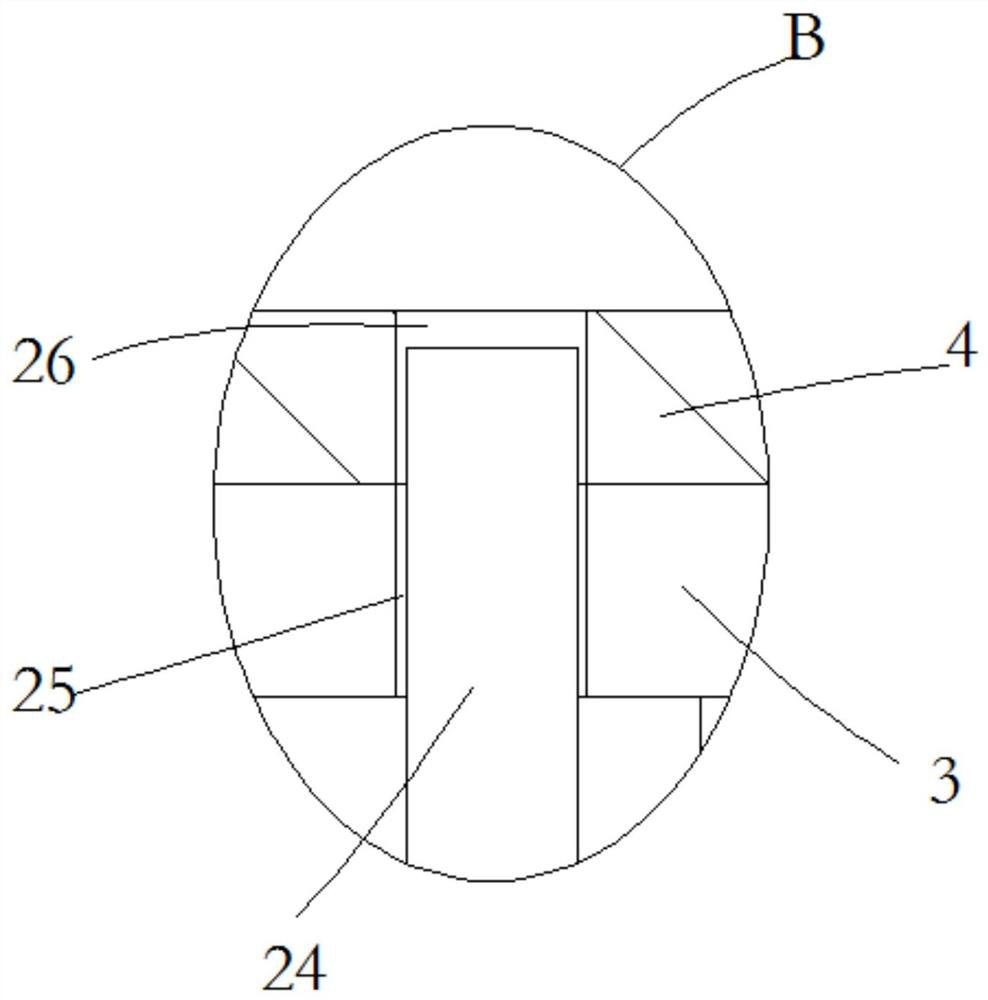

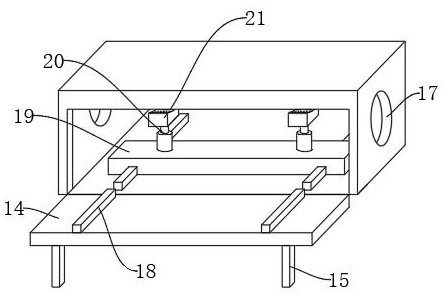

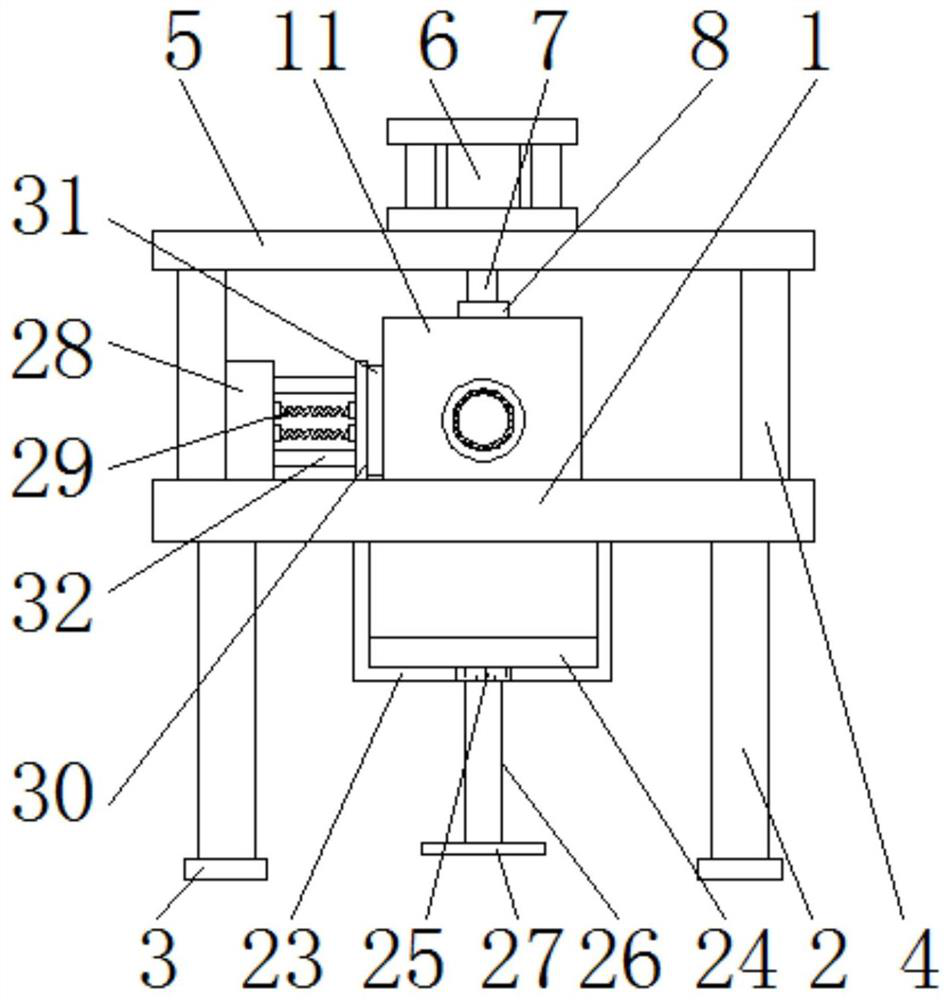

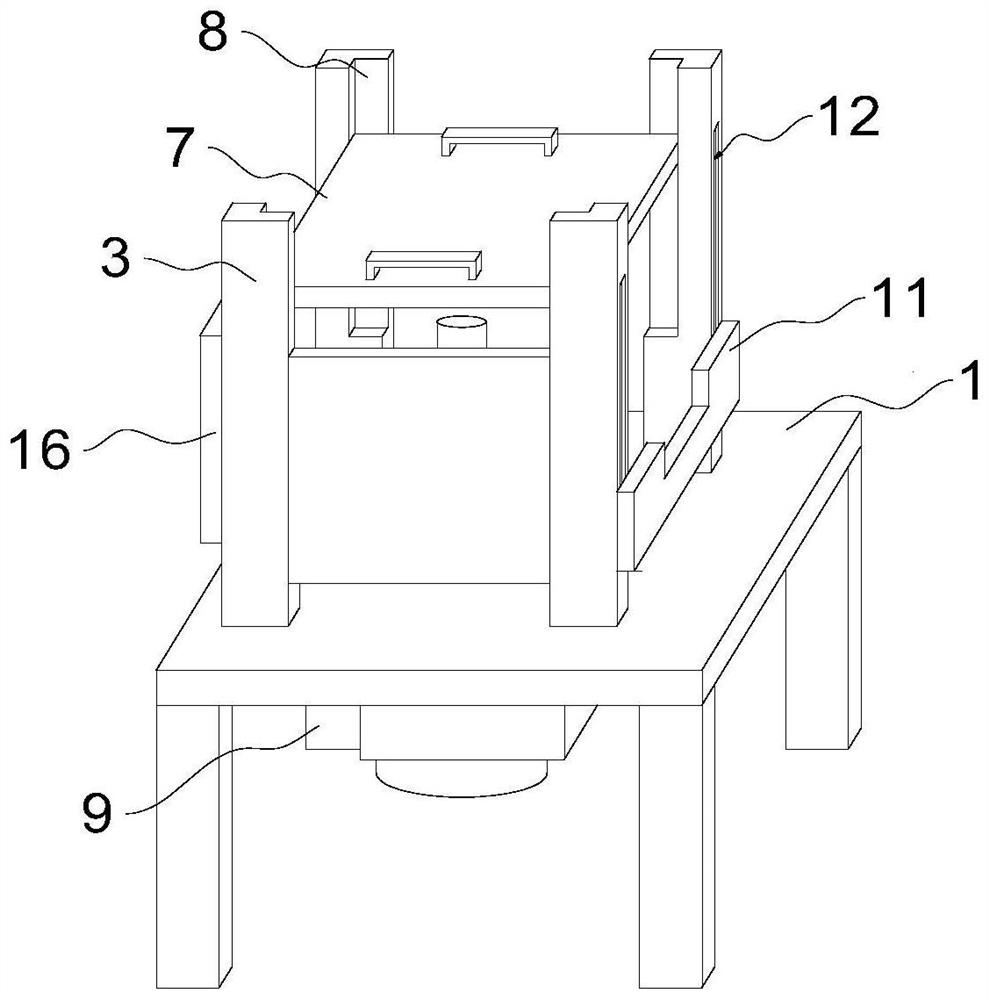

Magnesium alloy plate stamping device

PendingCN112170623AQuick placementPlace stableShaping toolsMetal-working feeding devicesStampingStructural engineering

The invention relates to the technical field of magnesium alloy plate stamping, and discloses a magnesium alloy plate stamping device. The magnesium alloy plate stamping device comprises a base, a plurality of supporting blocks are symmetrically and fixedly connected to the upper end of the base, the upper ends of the supporting blocks are fixedly connected with the same support plate, the upper end of the support plate is fixedly connected with a lower die, and two die grooves are formed in the upper end of the lower die in a front-back symmetrical mode; two electric sliding rails are fixedlyconnected to the upper end of the base in a bilateral symmetry mode, sliding blocks on the two electric sliding rails are fixedly connected with the same U-shaped supporting plate, two air cylindersare symmetrically and fixedly connected to the upper end of the horizontal portion of the U-shaped supporting plate, and output shafts at the lower ends of the two air cylinders penetrate through thelower end of the horizontal portion of the U-shaped supporting plate and are fixedly connected with the same stamping plate; and a plurality of stamping heads are uniformly and fixedly connected to the lower end of the p stamping plate. The magnesium alloy plate stamping device has the advantages that continuous stamping operation can be achieved, the production efficiency is improved, people canconduct feeding and discharging operation conveniently, and the feeding and discharging safety is guaranteed.

Owner:巢湖云海镁业有限公司

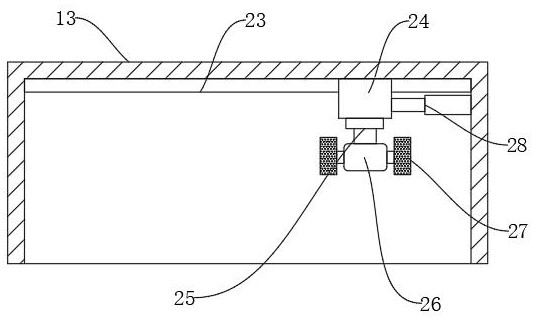

Cable peeling equipment

ActiveCN112838463AAutomate operationEasy peeling operationLine/current collector detailsApparatus for removing/armouring cablesStructural engineeringMechanical engineering

The invention discloses cable peeling equipment, and relates to the field of cable processing, and the cable peeling equipment comprises a rack, the rack is provided with a pressing device, two peeling devices and a conveying device, the two peeling devices are the first peeling device and the second peeling device respectively, the conveying device is used for enabling a cable to sequentially pass through the first peeling device and the second peeling device, and the conveying device is used for conveying the cable to the first peeling device and the second peeling device. The first stripping device is used for stripping an outer ring sheath of a cable, and the second stripping device is used for stripping a sub-wire of the cable; each peeling device comprises a sliding seat connected to the rack in a sliding manner, a peeling assembly arranged on the sliding seat and a driving part for driving the sliding seat to slide; and the sliding base slides in the direction away from the pressing device, and the peeling assembly comprises a peeling tool apron connected to the sliding base in a sliding mode and a driving air cylinder driving the peeling tool apron to slide. By arranging the pressing device, the two peeling devices and the conveying device, the cable peeling operation is more automatic, and the cable peeling operation is more convenient.

Owner:台州腾标电子有限公司

Blade edge passivating treatment device for electromechanical equipment accessory production

InactiveCN111690919AAvoid wastingAvoid pollutionMetallic material coating processesElectric machineEngineering

The invention belongs to the technical field of electromechanical equipment accessory production, and particularly relates to a blade edge passivating treatment device for electromechanical equipmentaccessory production. Aiming at the problems that an existing passivating treatment device is simple in structure, wasting occurs during passivating treatment, and the efficiency is low, the followingscheme is provided, specifically, the blade edge passivating treatment device comprises a pool body, electric push rods are fixedly installed on the two sides of the pool body, jacking plates are fixedly installed at the top ends of the electric push rods, stepping motors are fixedly installed at the top ends of the two jacking plates, and a turnover plate is fixedly installed between output shafts of the two stepping motors. According to the blade edge passivating treatment device, a rotary rod and an installation seat are driven by a driving motor to rotate in the pool body, and accordingly, a passivator solution in the pool body is stirred, the passivating treatment quality is improved; and after passivating is finished, blades are taken out of the passivator solution and are driven bythe driving motor to rotate, accordingly, the solution adhering to the surfaces of the blades is removed through rotating, the drying speed of the passivator solution is increased, and the passivating treatment efficiency is improved.

Owner:烟台福慧智能科技有限公司

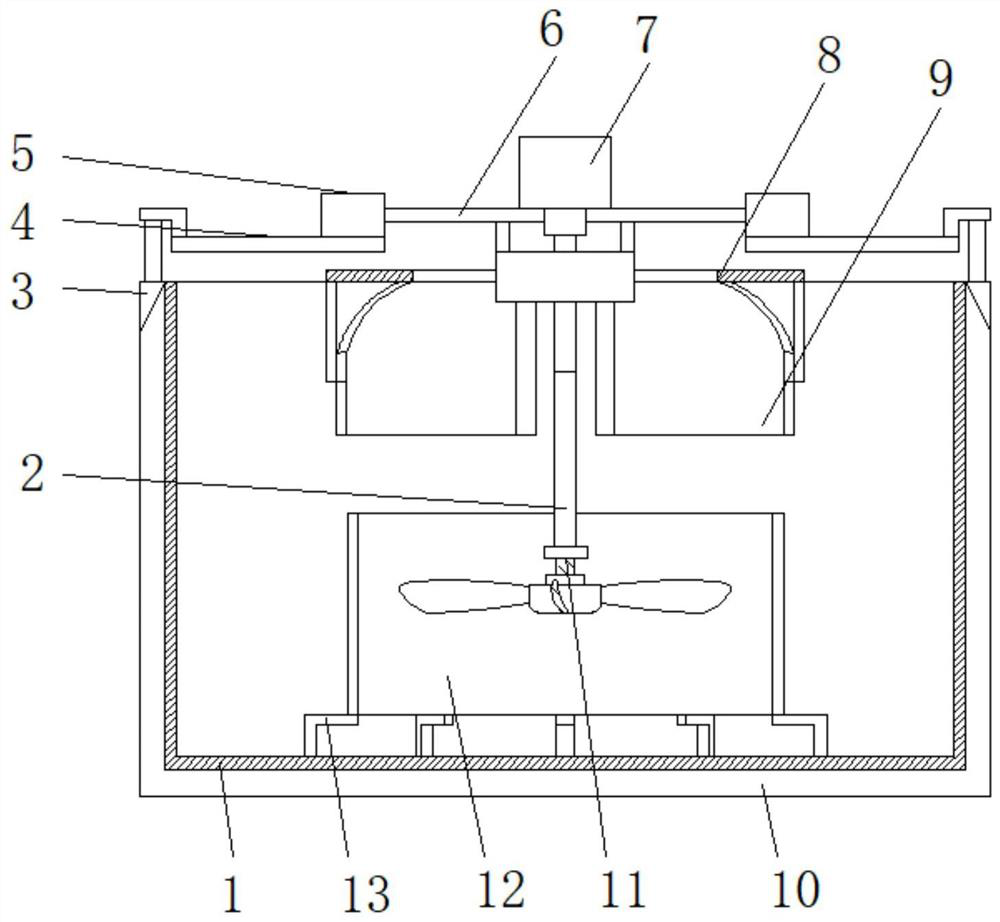

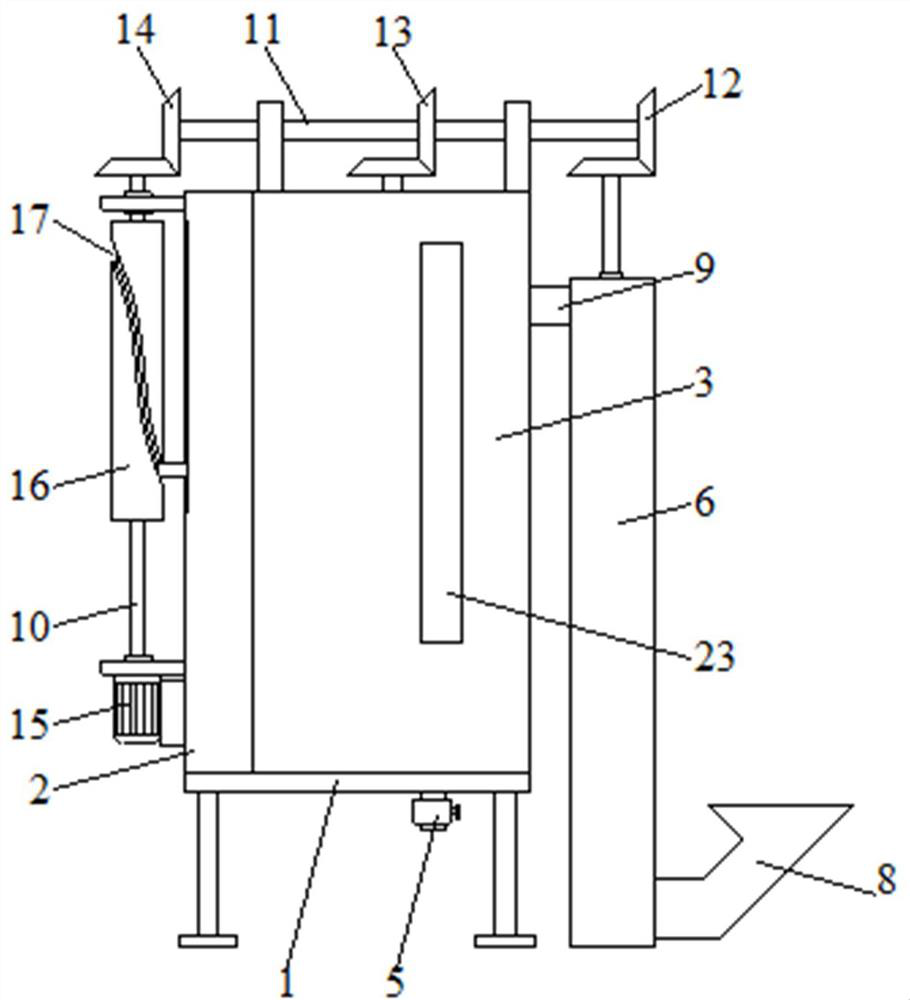

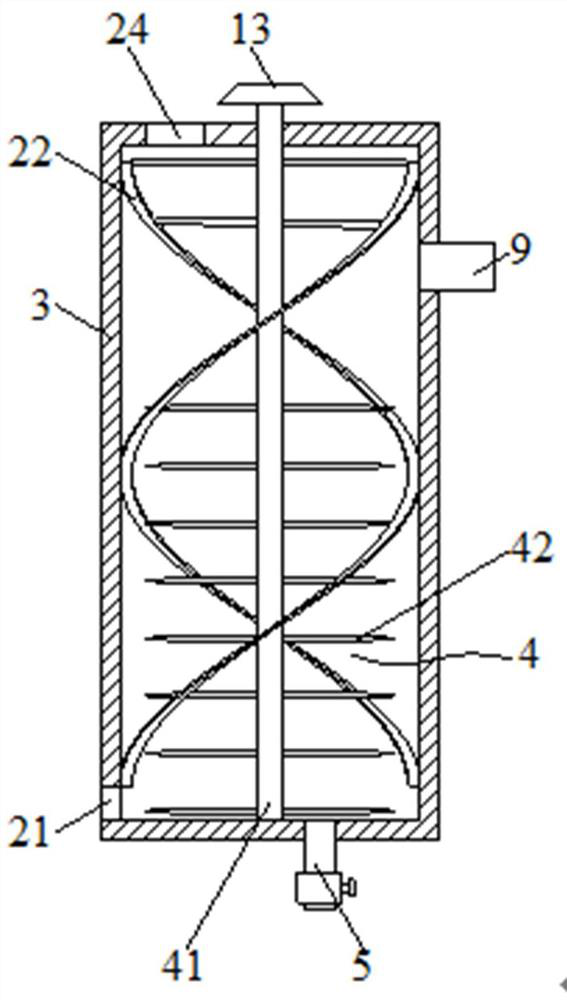

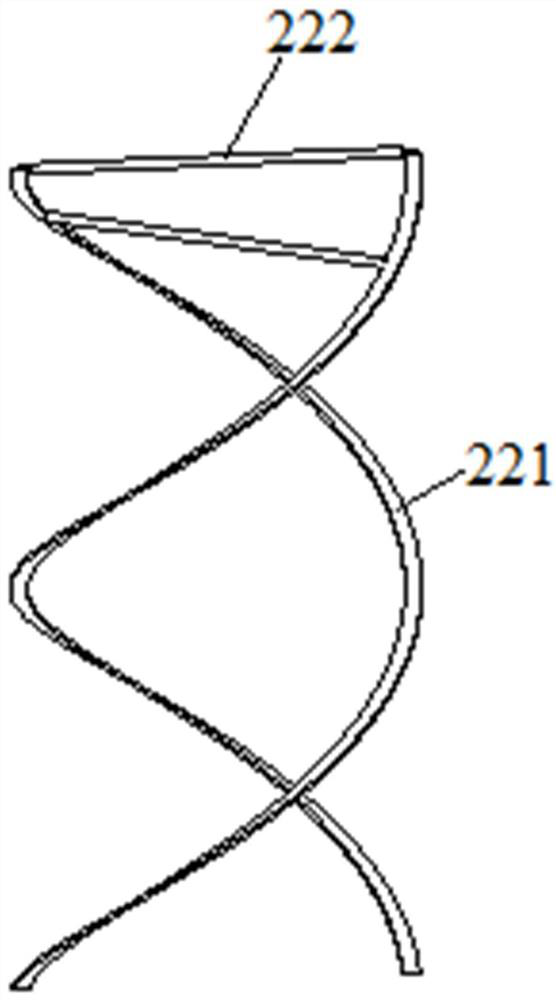

Chili smashing device for chili sauce production

InactiveCN112237978AConvenient loading and unloading operationImprove crushing effectHollow article cleaningGrain treatmentsChilli con carneEconomic benefits

The invention discloses a chili smashing device for chili sauce production in the technical field of chili processing. The chili smashing device for the chili sauce production comprises a supporting seat, wherein a cylindrical shell and a smashing box are fixedly mounted at the top of the supporting seat in sequence from left to right, a smashing assembly is rotationally connected to an inner cavity of the smashing box, a discharge pipe provided with a valve communicates with bottom of the smashing box, a feeding pipe is arranged on the right side of the supporting base, an inner cavity of thefeeding pipe is rotationally connected with a screw conveyer, a feeding hopper communicates with the bottom end of the feeding pipe, the top end of the feeding pipe communicates with the upper part of the smashing box through a first communicating pipe, a first rotating rod is rotationally connected with the left side of the cylindrical shell through a first rotating seat, and a second rotating rod is rotationally connected with the top of the smashing box through a second rotating seat. The chili smashing device for the chili sauce production is simple in structure, reasonable in design, capable of fully cutting and smashing chilies, good in chili smashing effect, high in efficiency, capable of facilitating feeding and discharging operation of a user on the chilies, high in practicability and good in economic benefit.

Owner:萧县火红果蔬种植农民专业合作社

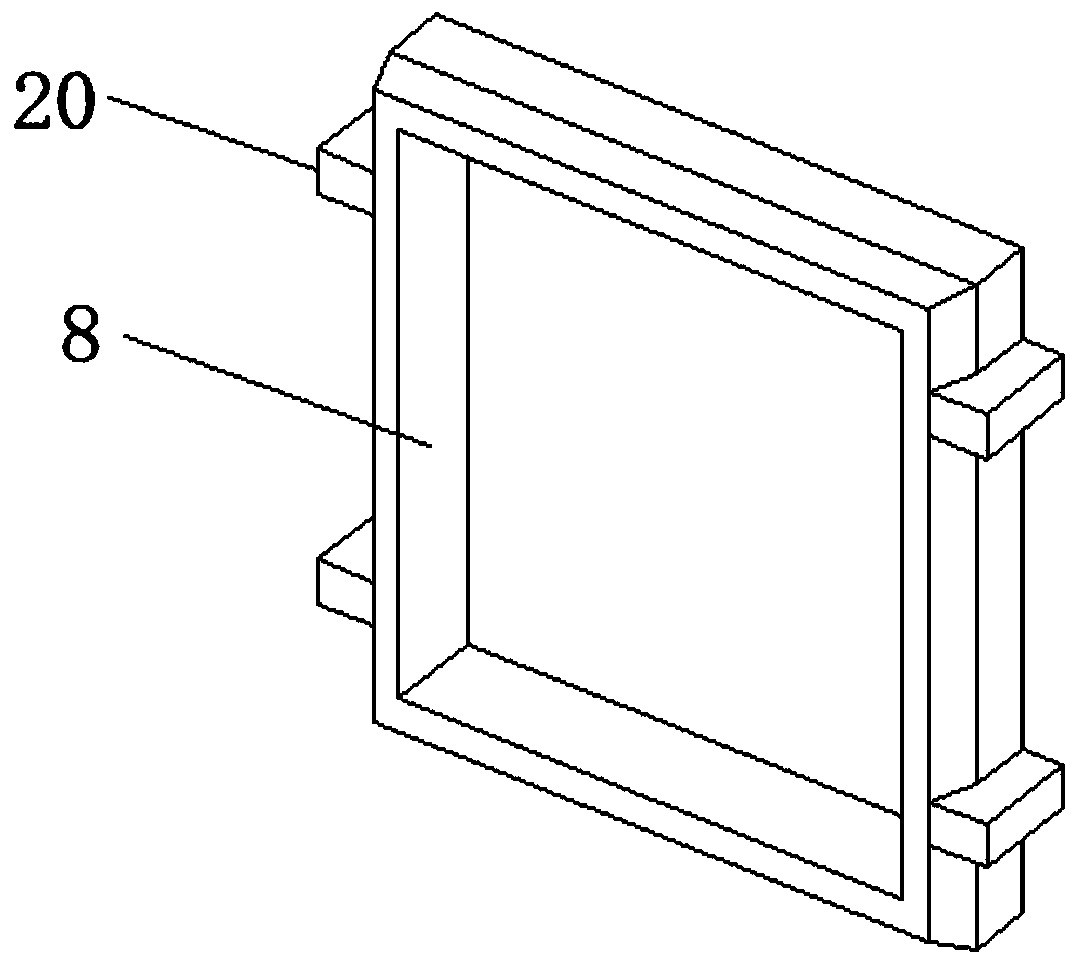

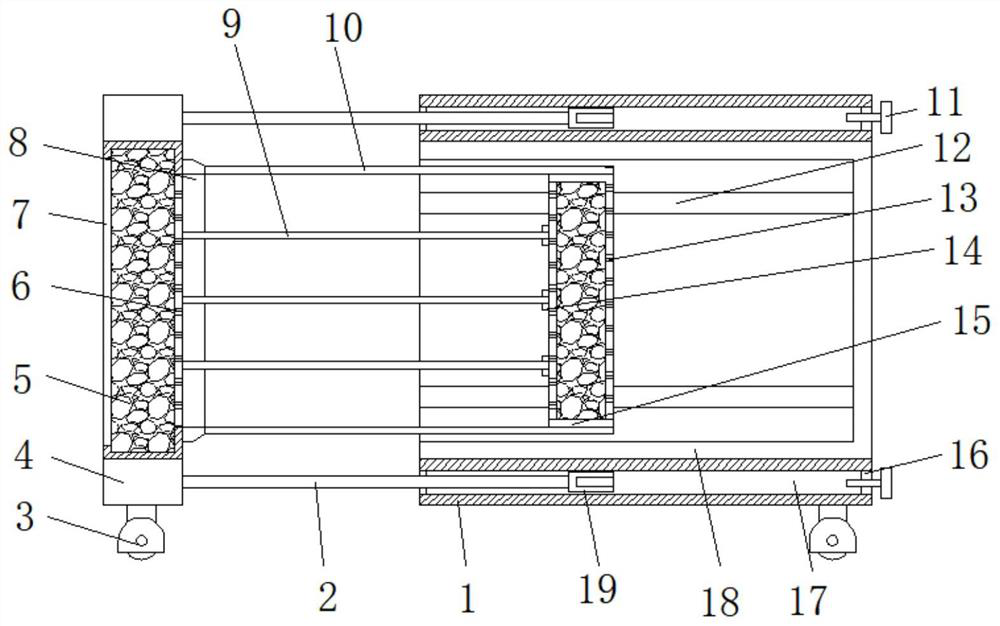

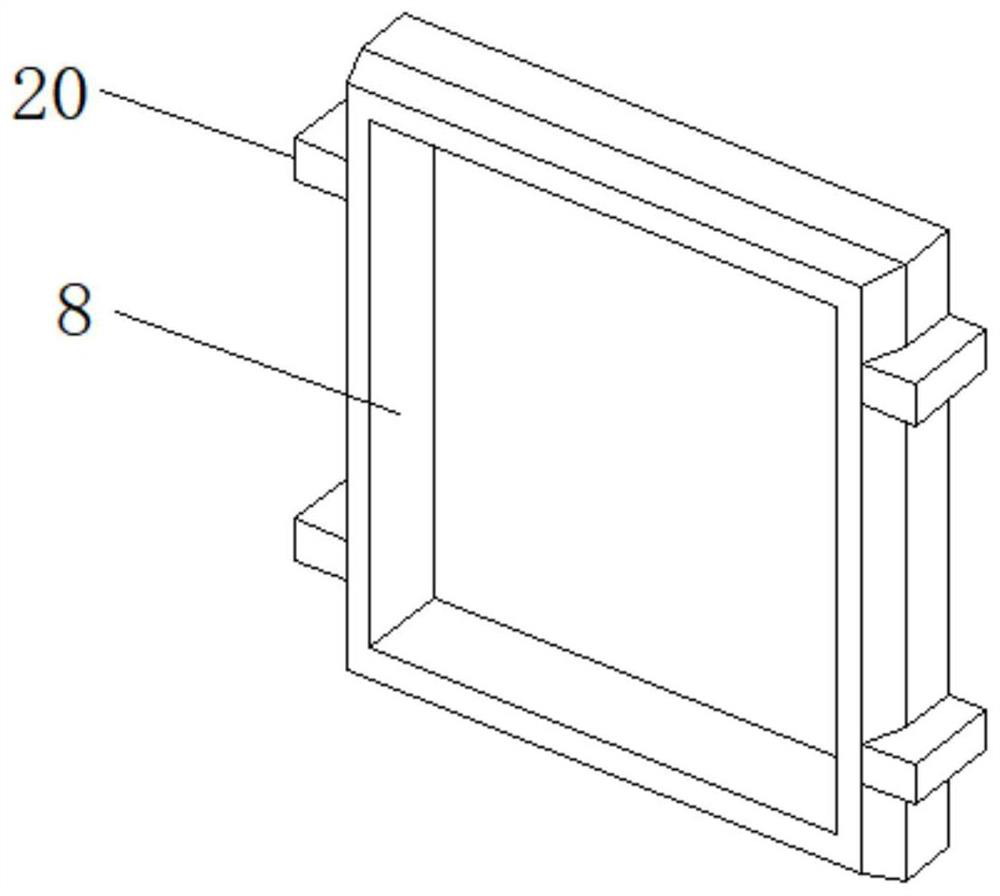

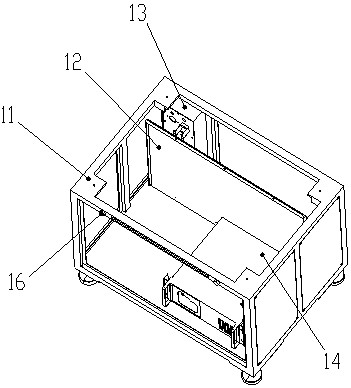

Optical fiber sensor transfer box with dampproof function

ActiveCN110844276AAffect the service lifeEasy to useSealingContainers preventing decayDesiccantEngineering

The invention belongs to the technical field of optical fiber sensor transfer, and particularly relates to an optical fiber sensor transfer box with a dampproof function. The problems that according to existing transfer boxes, in the transfer process of optical fiber sensors, the transferred optical fiber sensors are prone to being affected by external force and the natural environment are solved.According to the scheme, the optical fiber sensor transfer box comprises a box body; connecting plates are installed at the top and the bottom of the box body; and the side face of each connecting plate is provided with two round through holes. According to the transfer box, a shell body and the box body are tensioned through a fastening mechanism, a barrel body and a limiting sliding rod, the internal space of the box body is sealed, the dry environment inside the transfer box is maintained through a silica-gel discolored desiccant inside the shell body, the service life of the optical fibersensor is prevented from being affected by damp, the dampproof effect of the transfer box is improved, meanwhile, the optical fiber sensors are stacked between carrying plates and auxiliary carryingplates and can be drawn out when needed, feeding and discharging operation of cargoes in the transfer box is facilitated, and using is easy and convenient.

Owner:株洲菲斯罗克光电科技股份有限公司

Rust-removal device for outer wall of environment-friendly type pipeline for building

InactiveCN111993251AAvoid enteringFree from pollutionGrinding carriagesGrinding drivesArchitectural engineeringStructural engineering

The invention discloses a rust-removal device for an outer wall of environment-friendly type pipeline for a building. The rust-removal device comprises a base plate and a protective box body, whereinthe protective box body is arranged on the middle part above the base plate; the protective box body is connected to the base plate through a bolt; a door body is connected on one side wall of the protective box body through a hinge; a door lock fixedly connected to the protective box body through a bolt is arranged above the door body; and the two sides below the door lock are equipped with rotary supporting legs. The whole polishing rust-removal process for the pipeline is performed inside the protective box body, so that the safe protection effect can be achieved; impurities generated in apolishing process are prevented from entering outside air, so that air quality around is ensured to be not polluted; and a slide push rod acts to push a slide support base I to lock a pipeline fixed on a chuck, so that the end part of the pipeline is polished and subjected to rust-removal, and therefore, the problem that existing automatic dust-removal equipment is incomplete in rust-removal for the end part of the pipeline is solved very well.

Owner:唐翠华

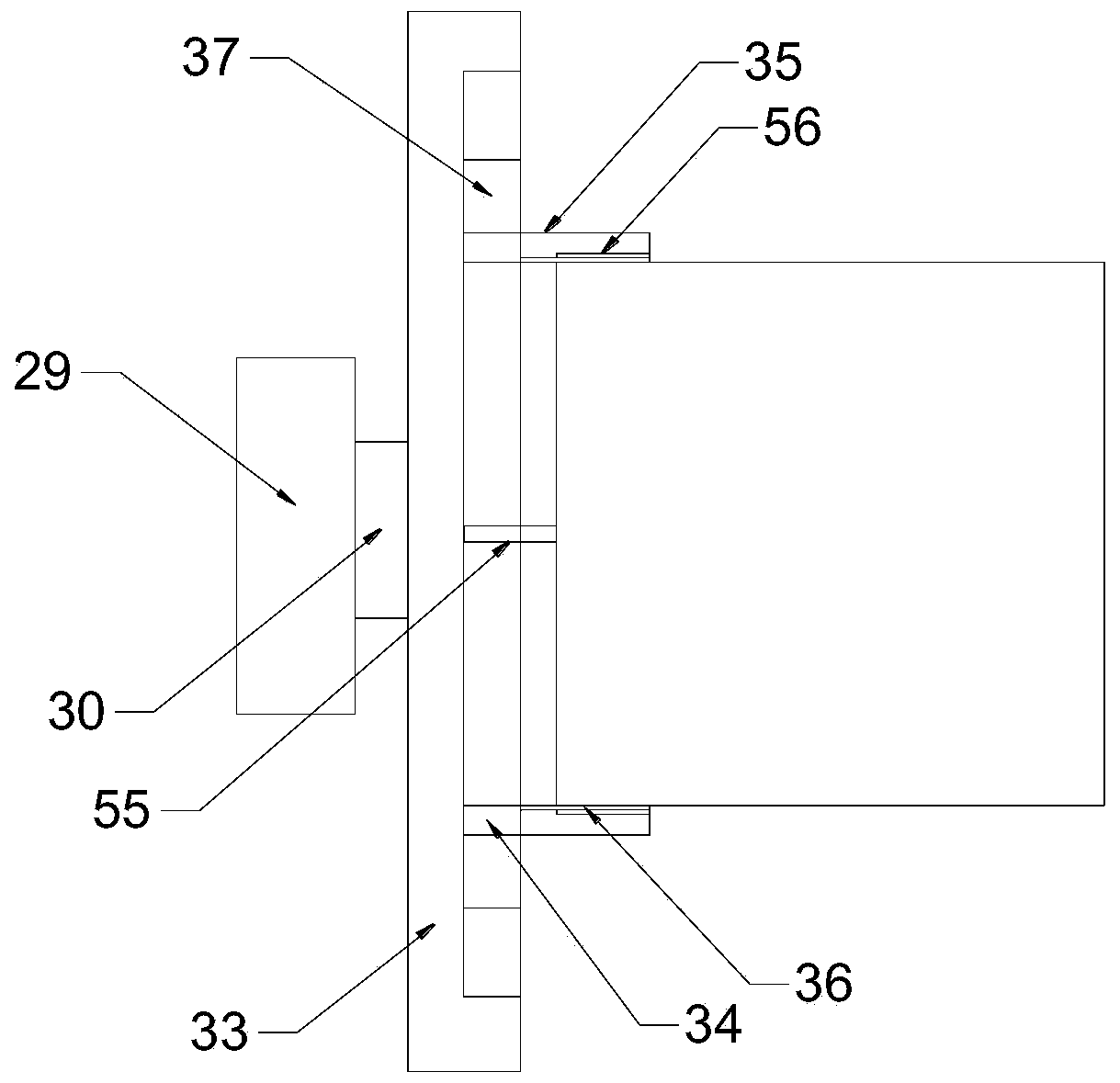

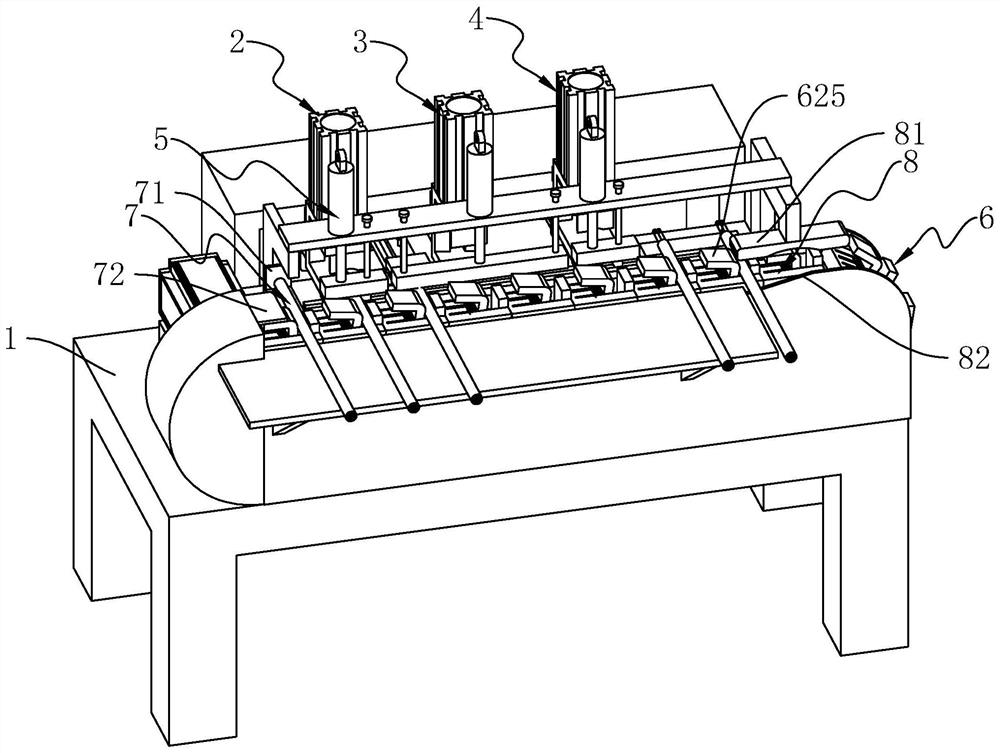

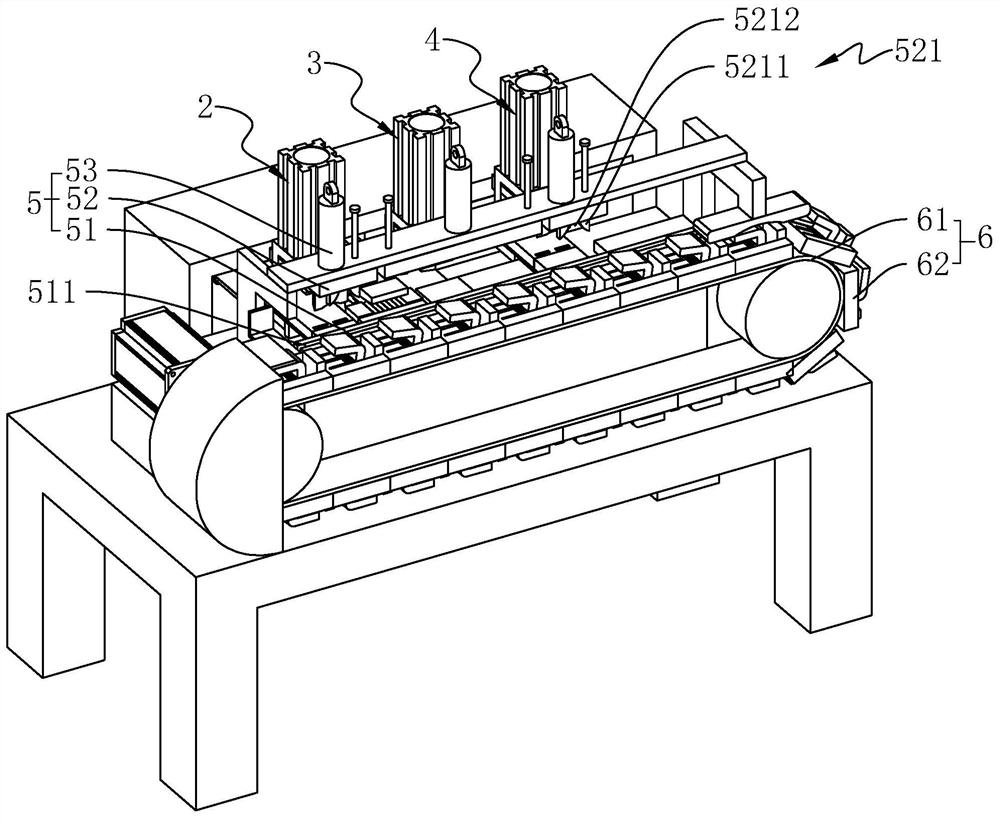

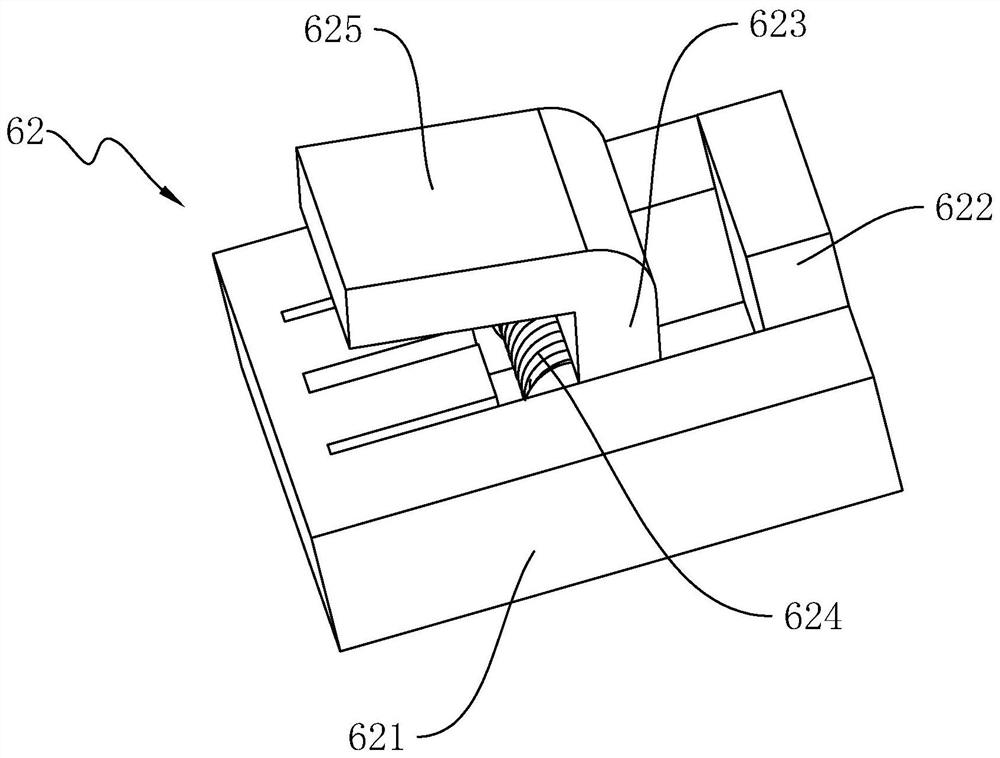

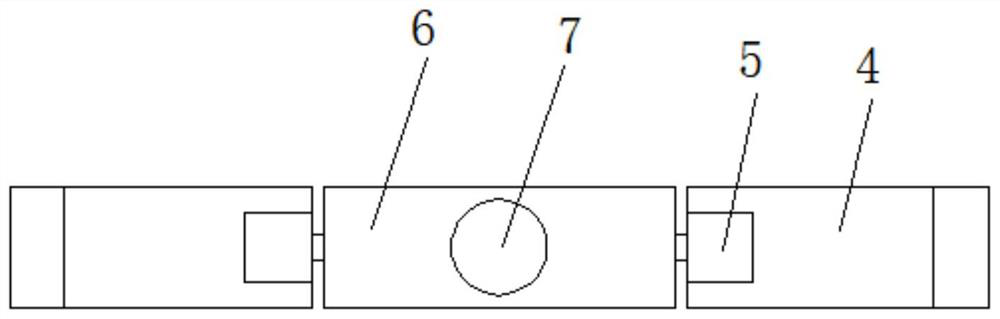

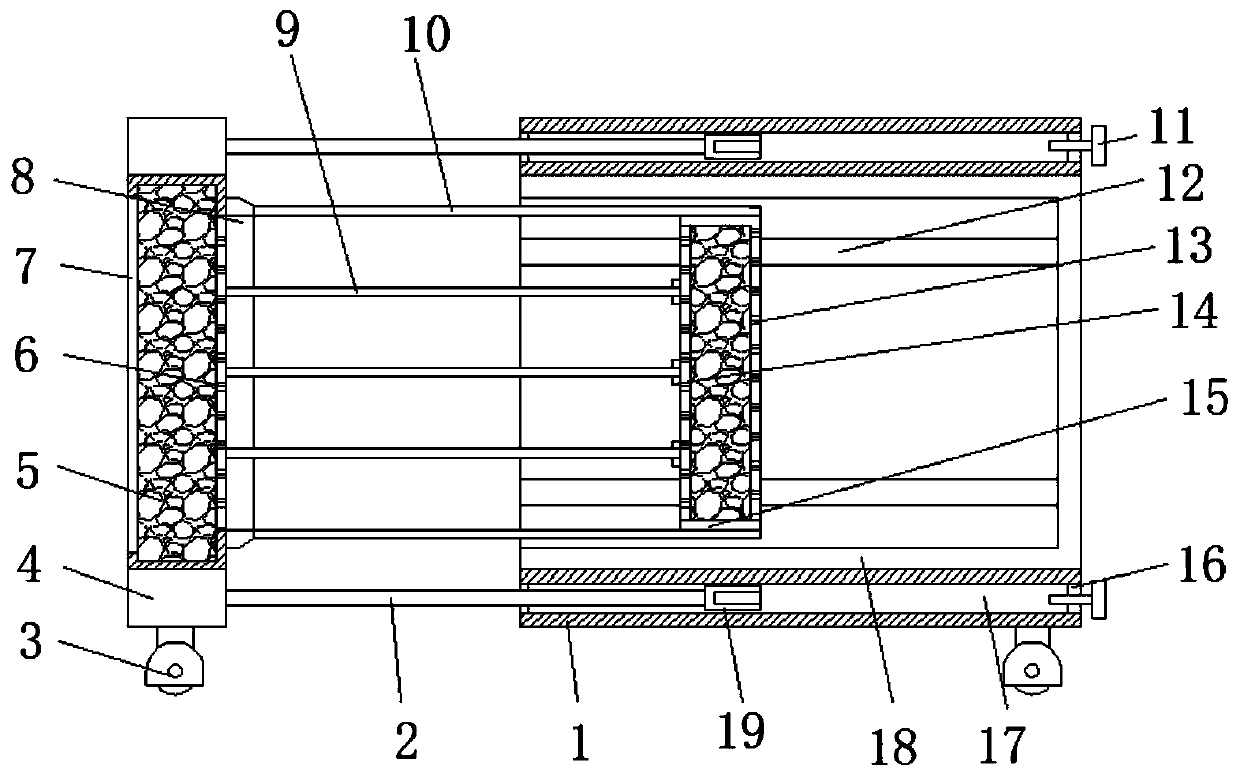

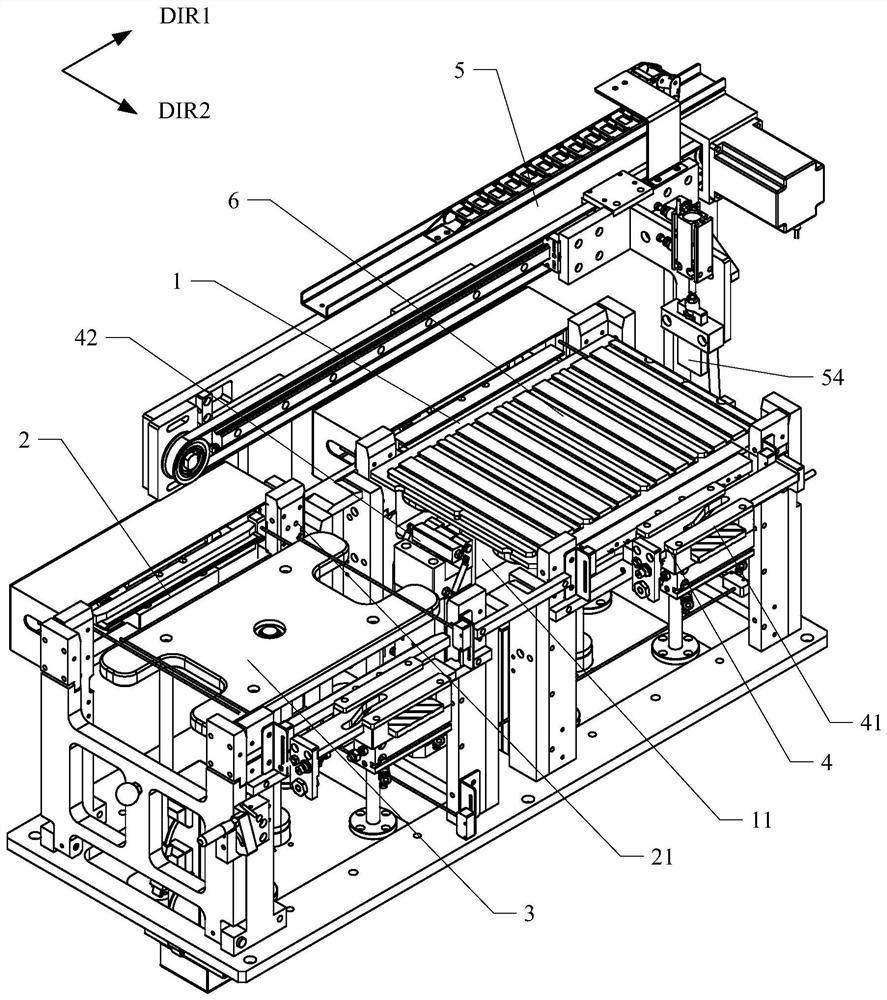

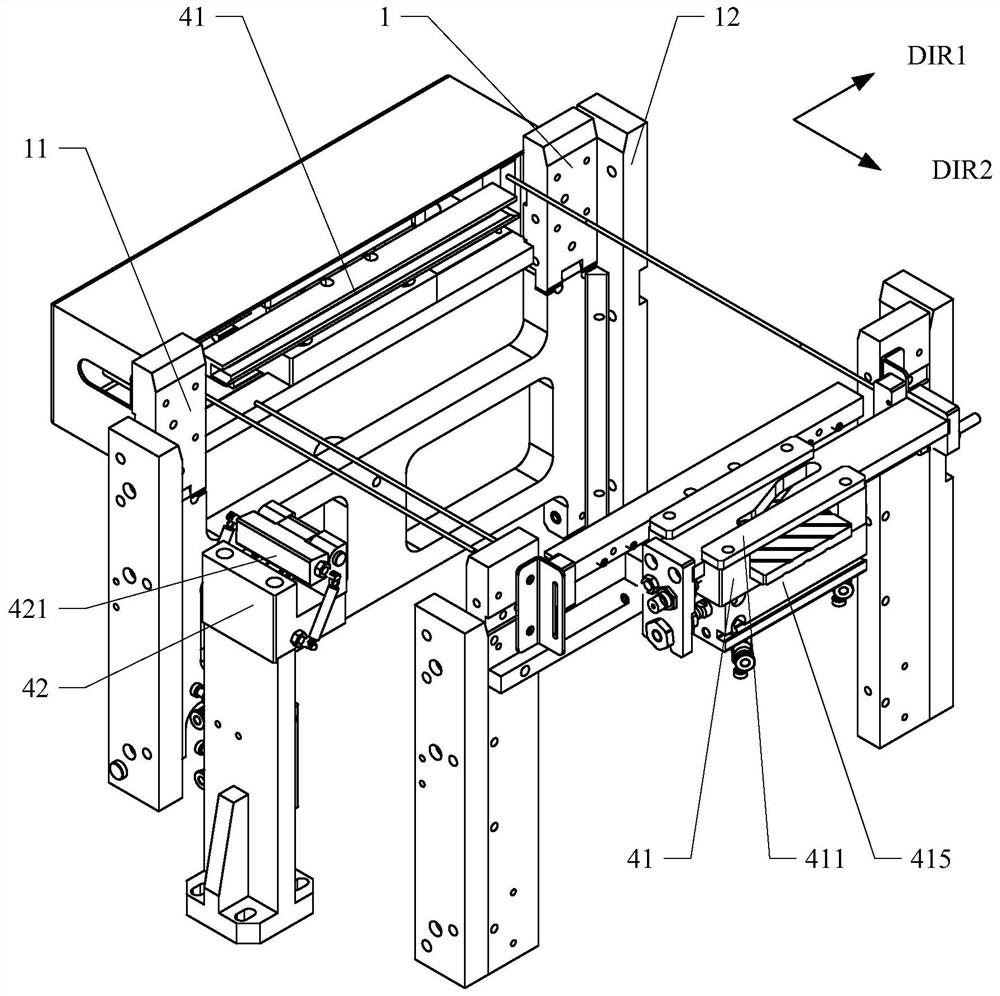

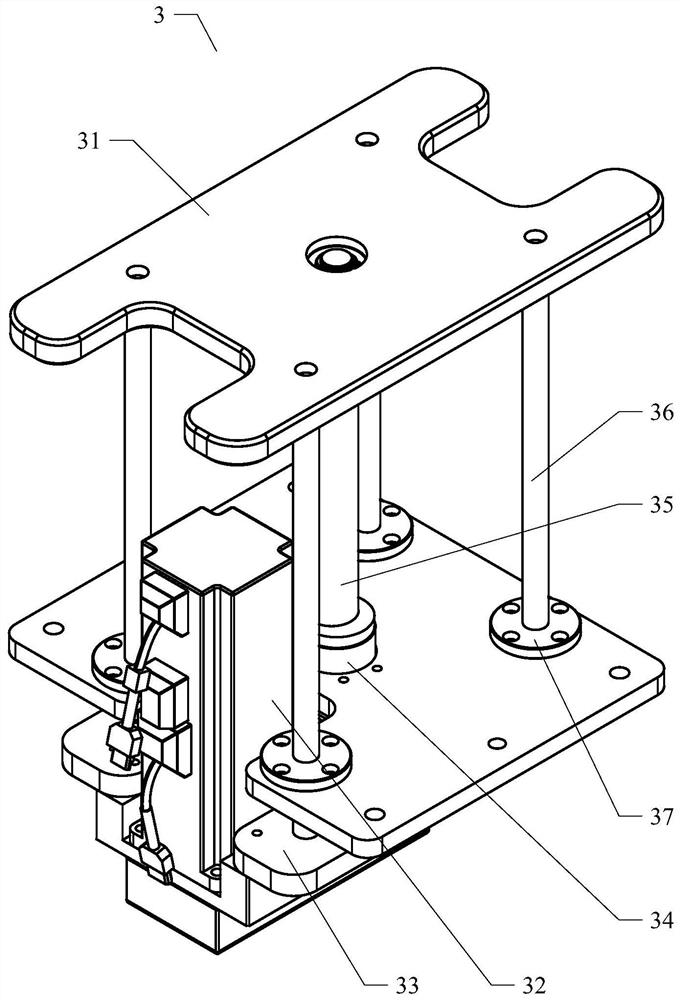

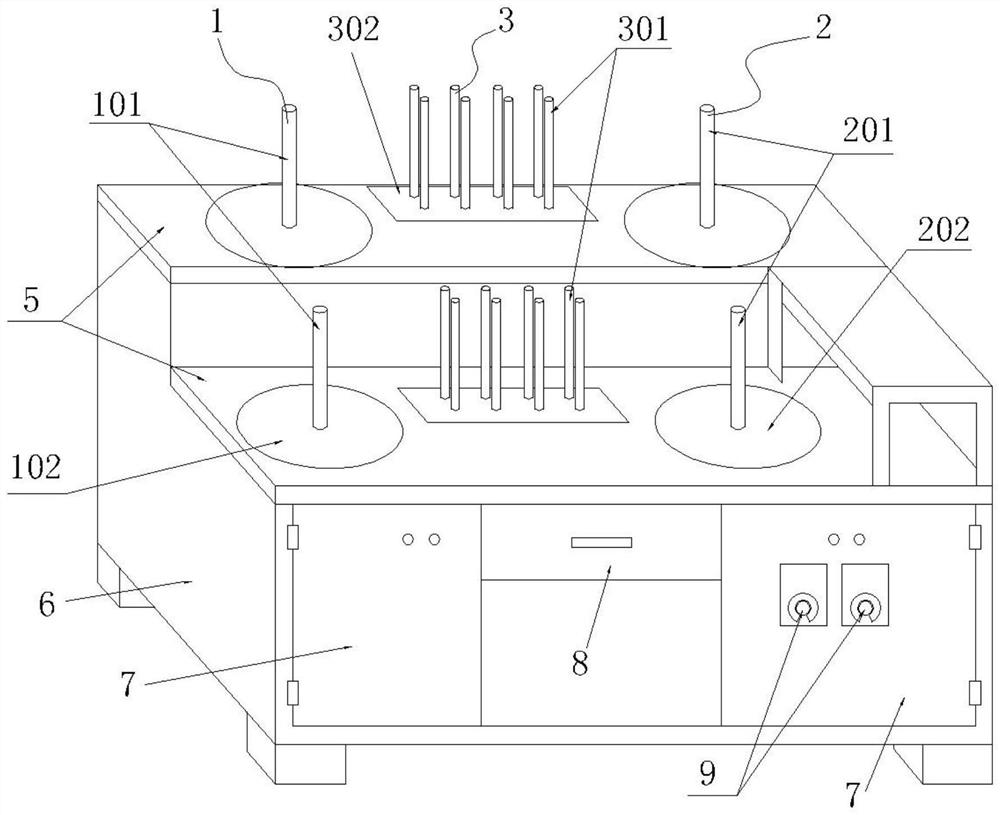

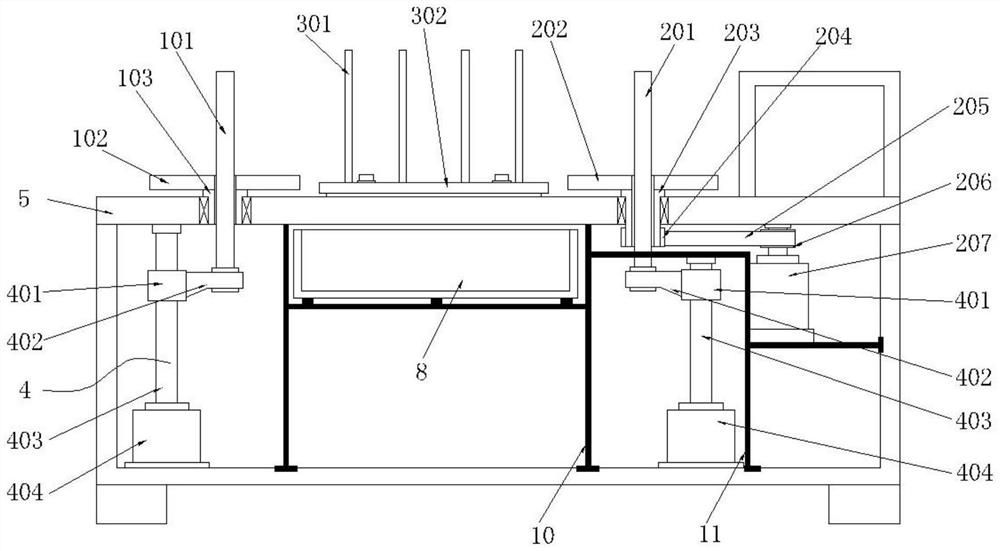

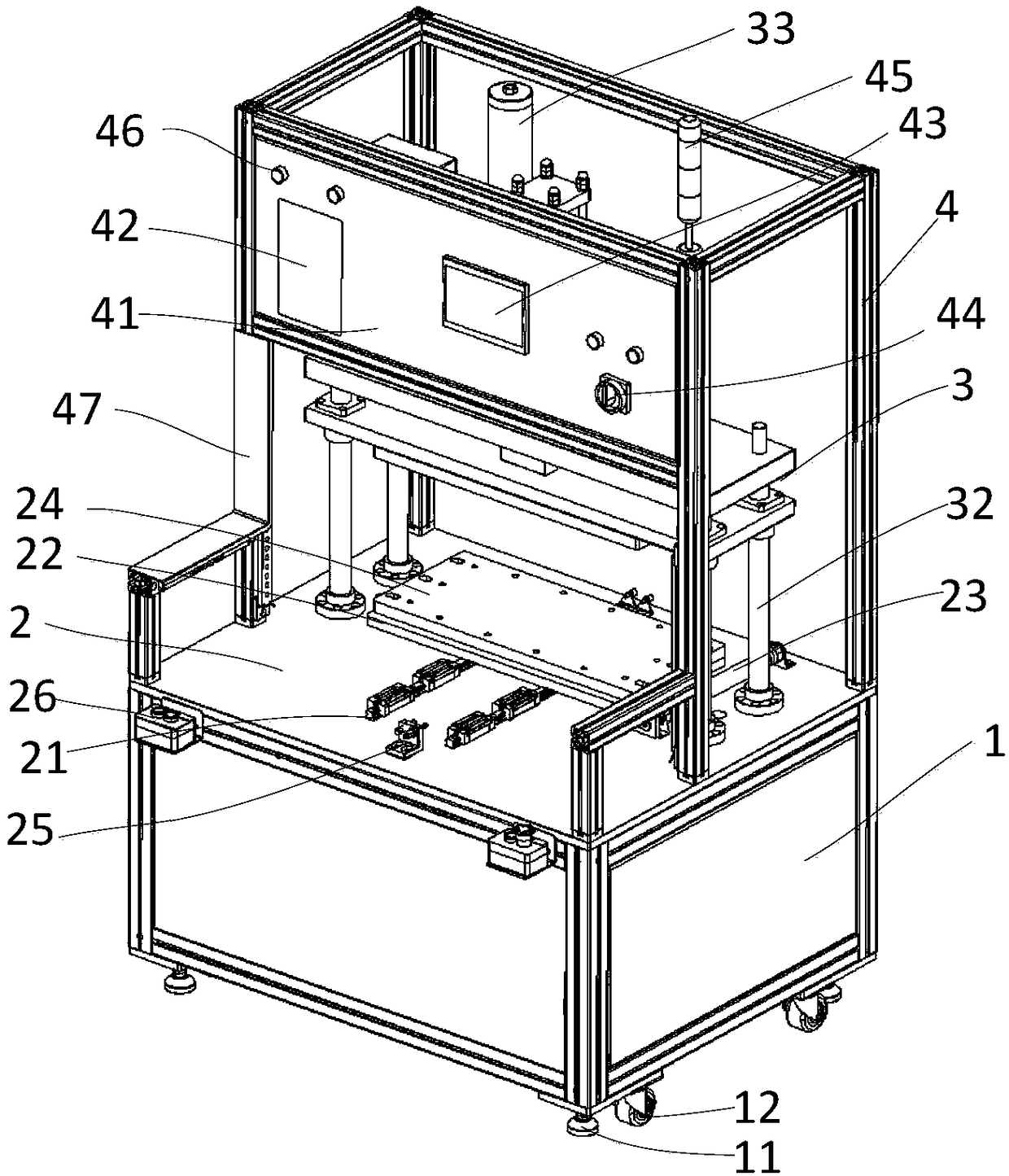

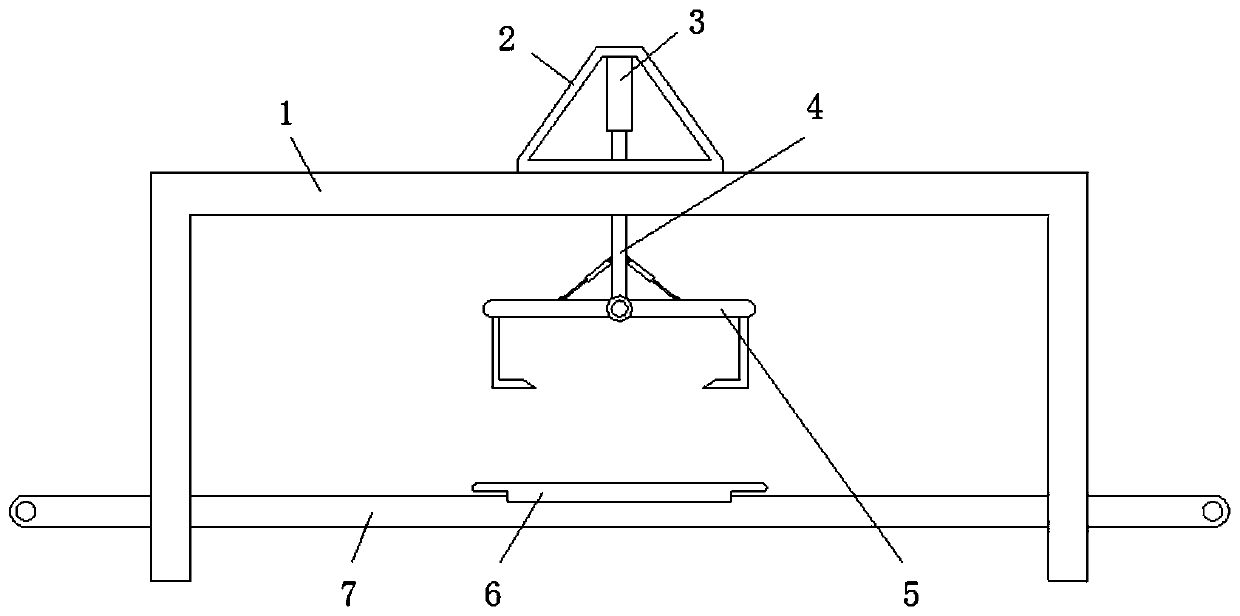

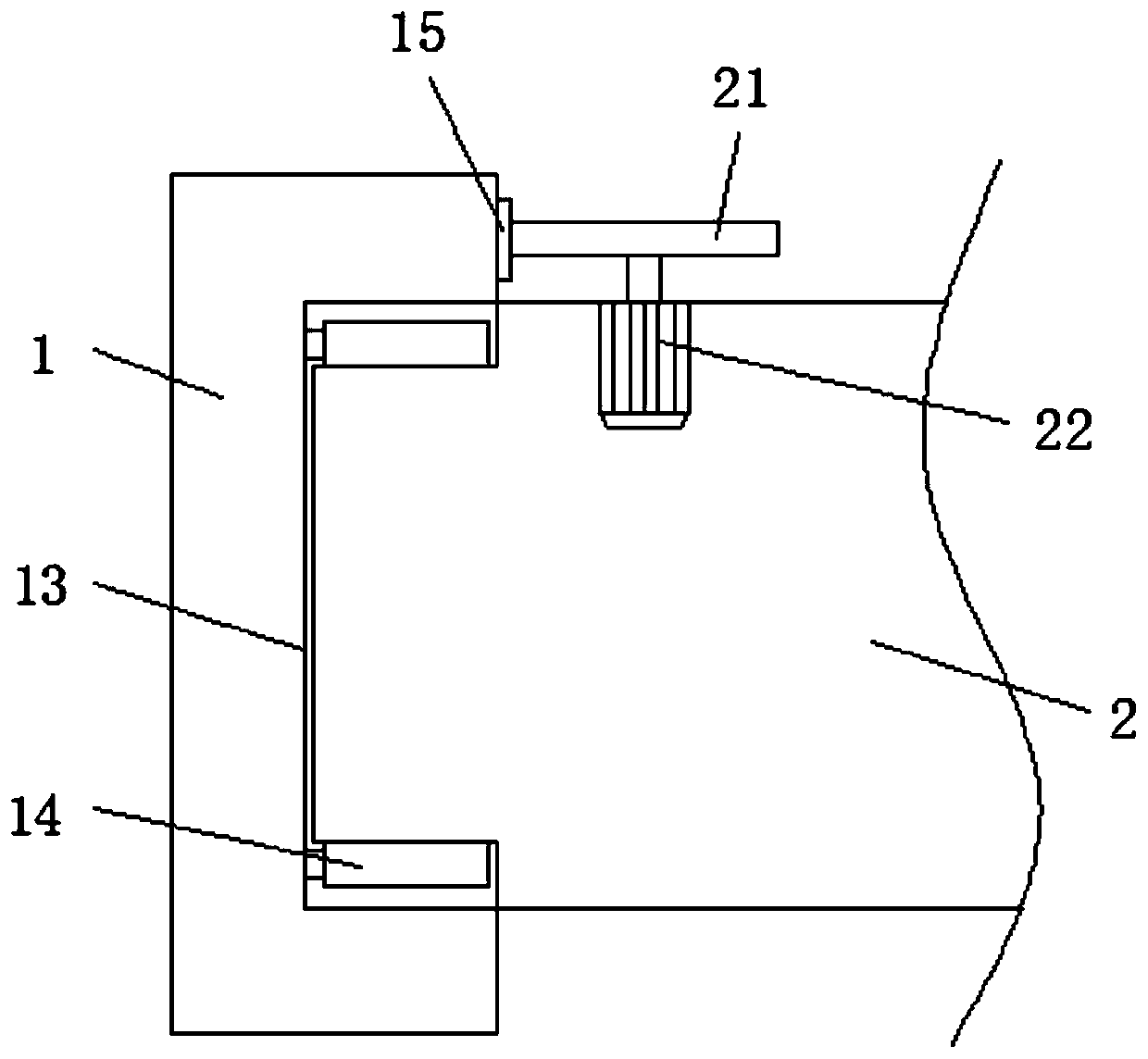

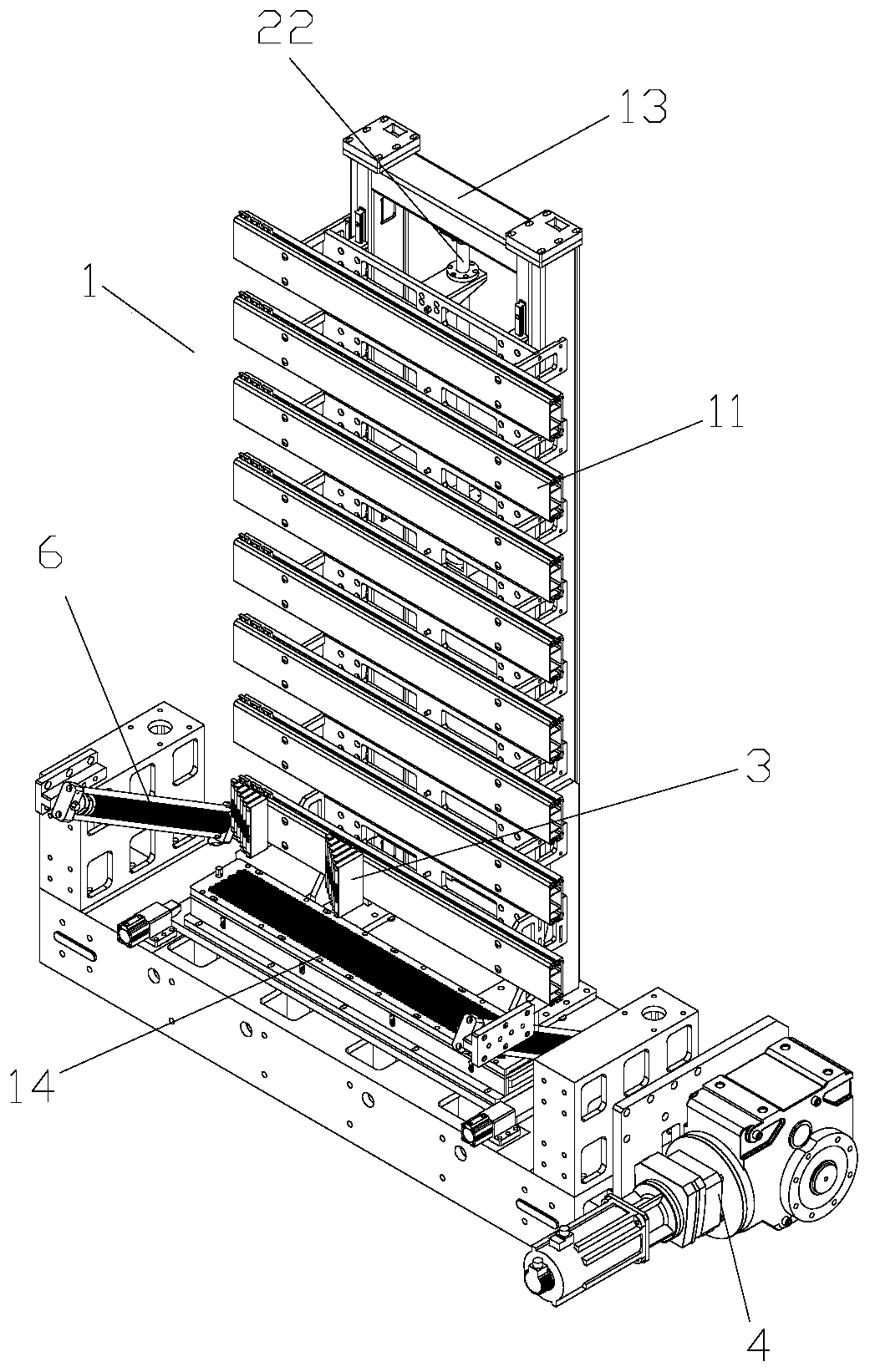

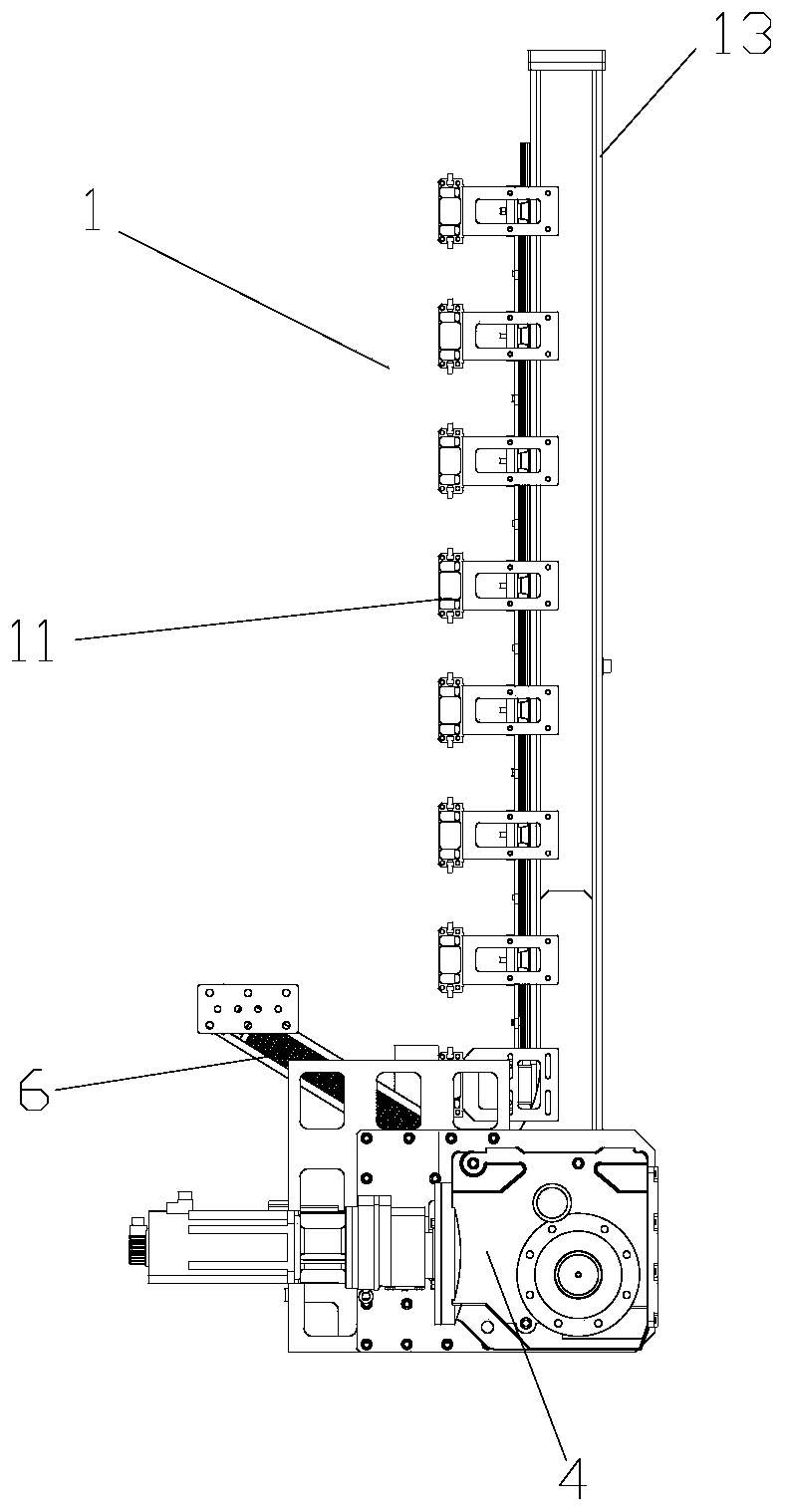

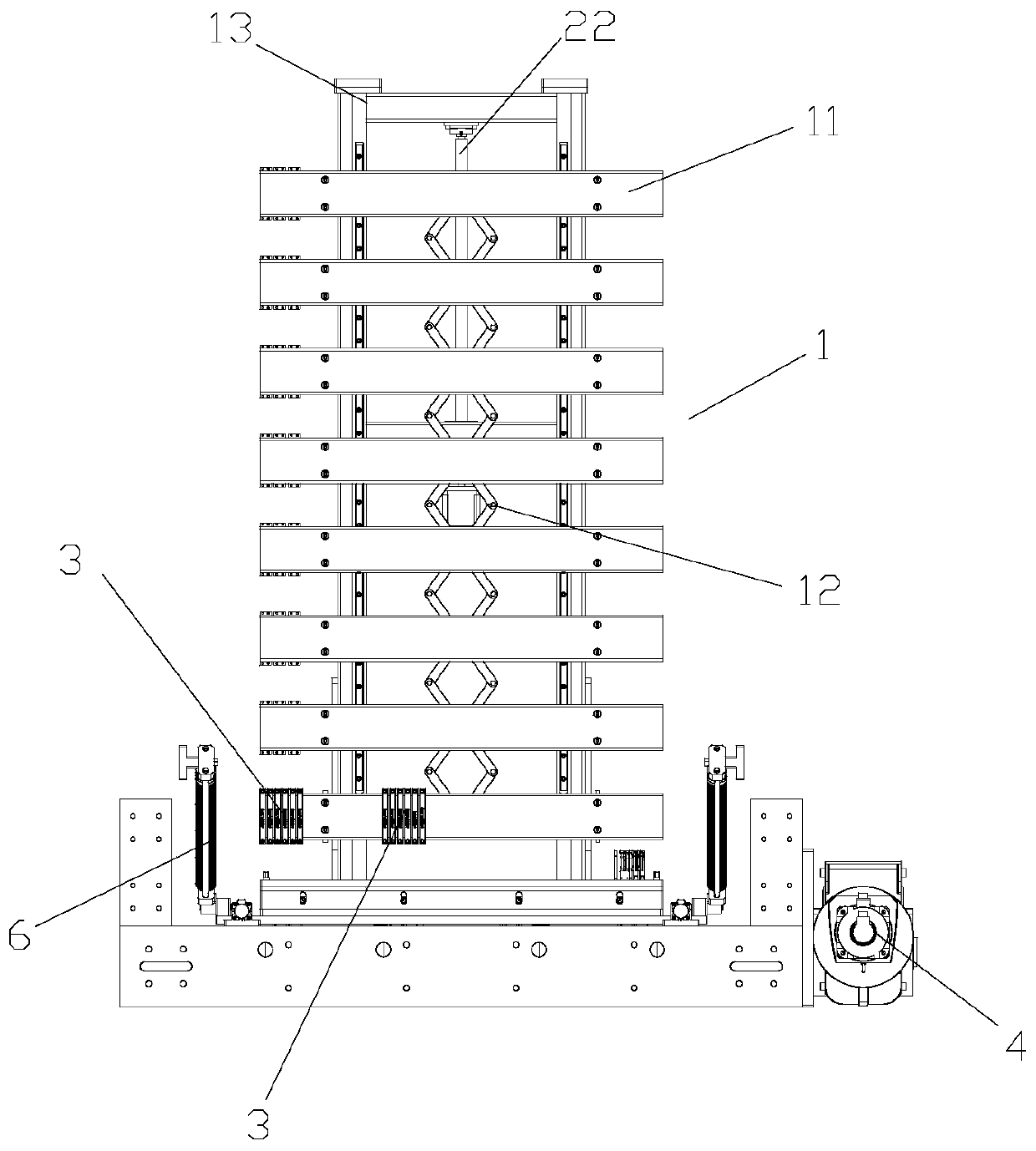

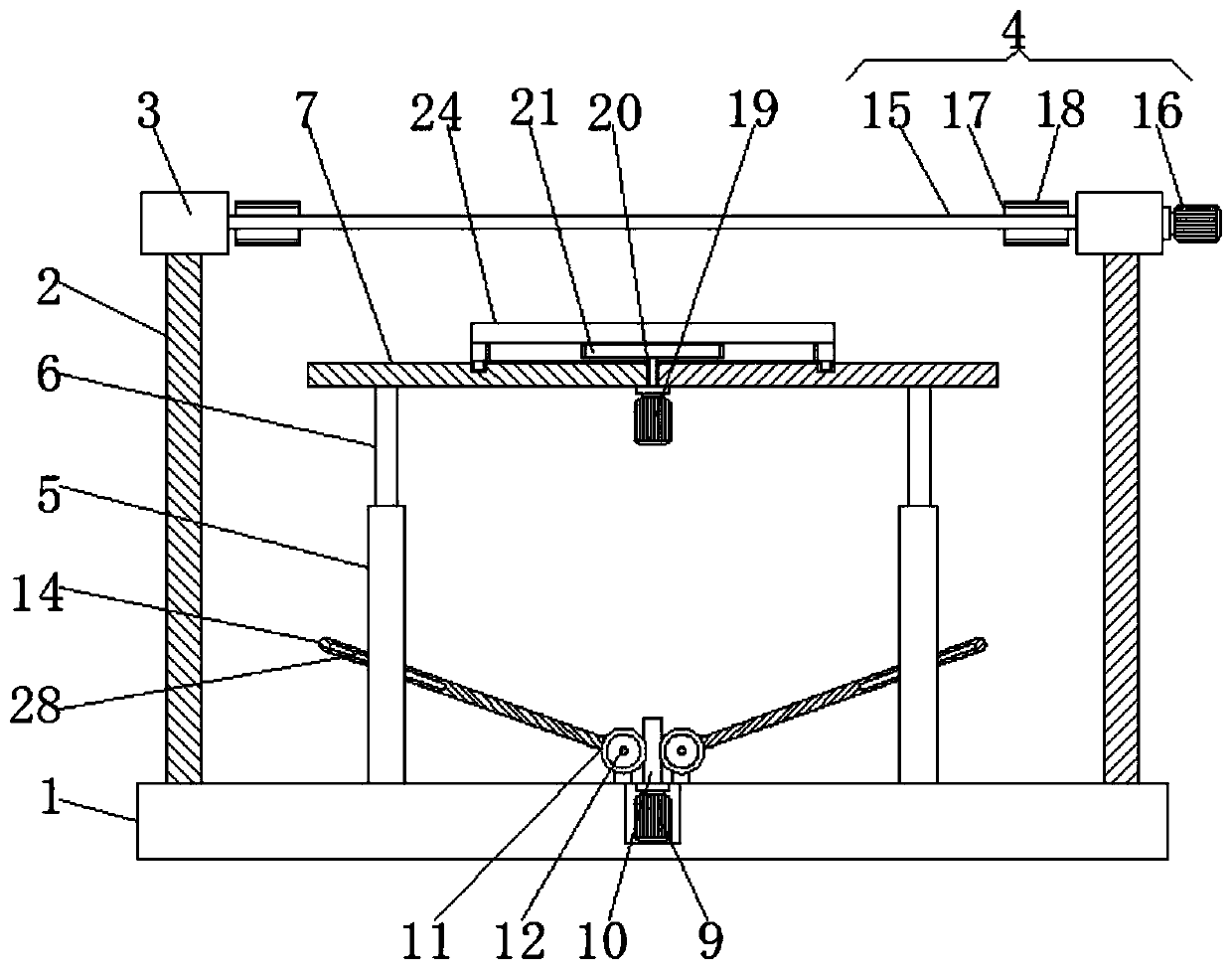

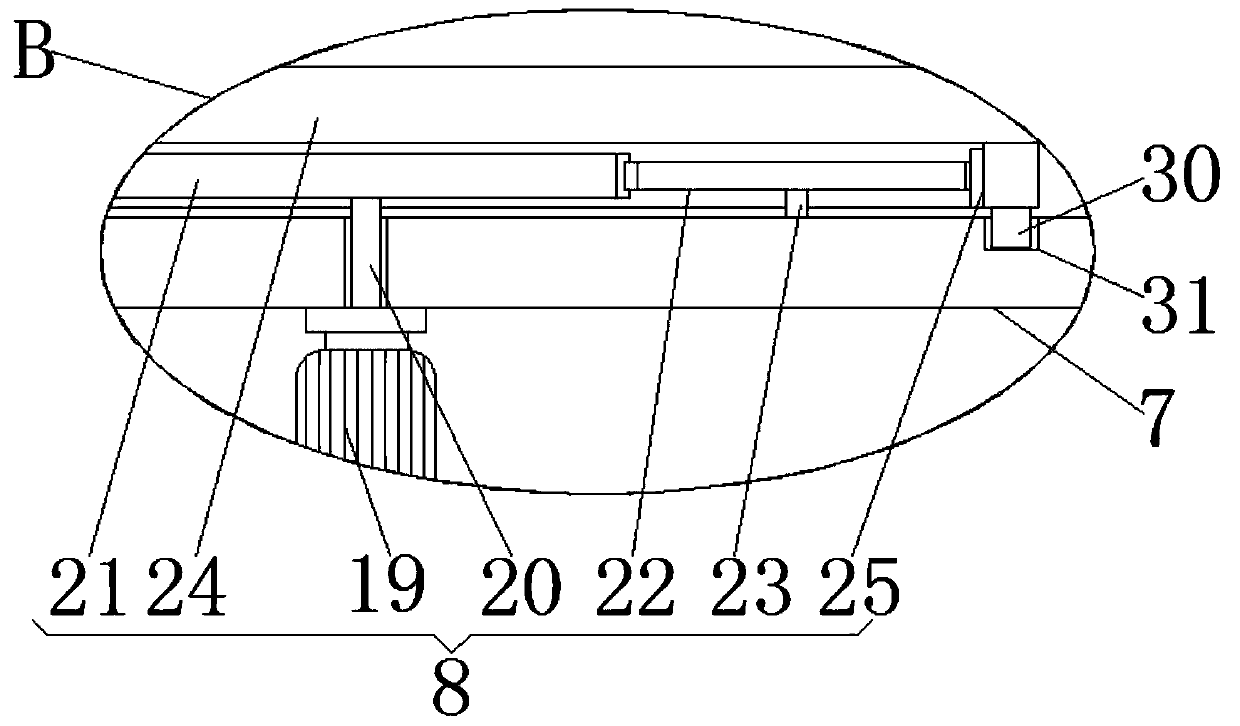

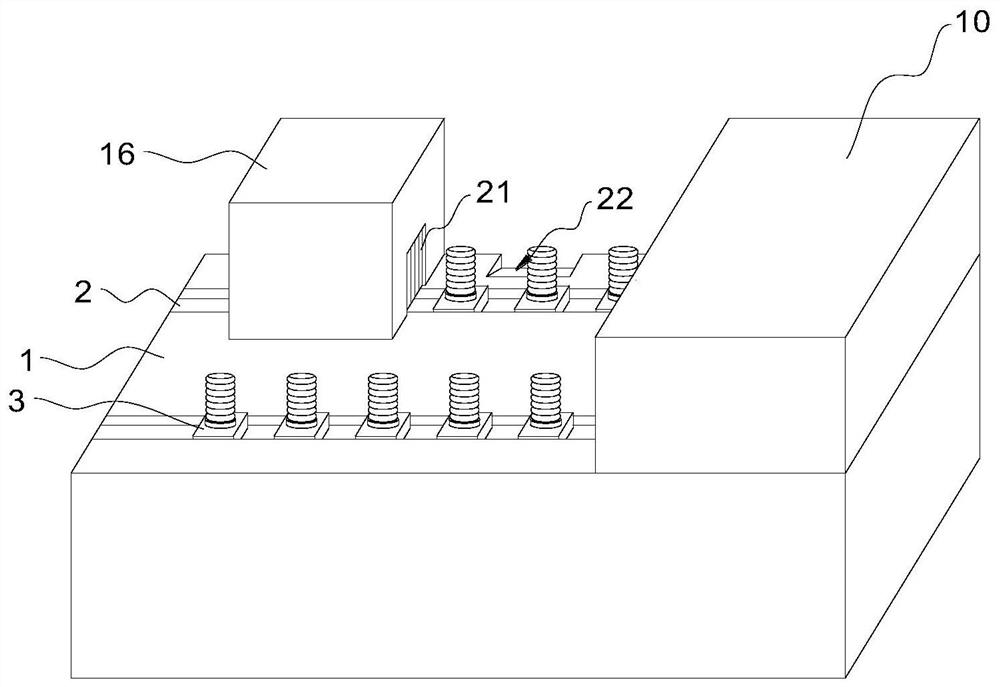

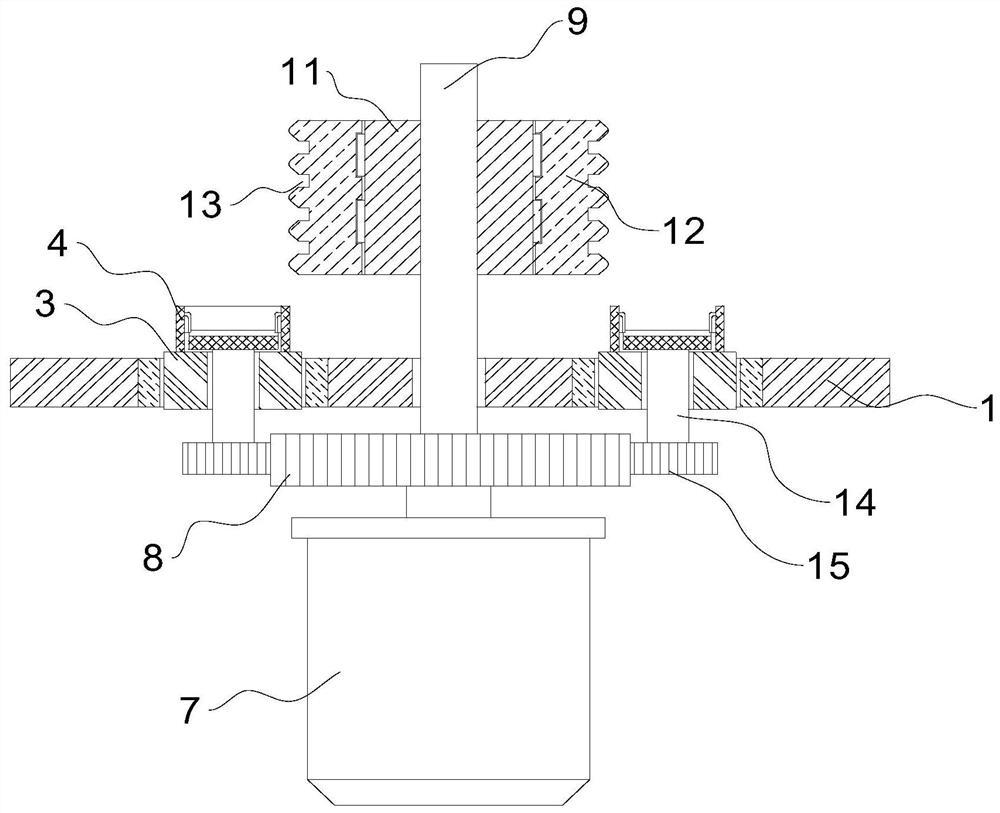

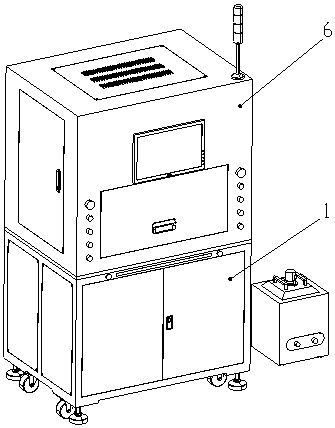

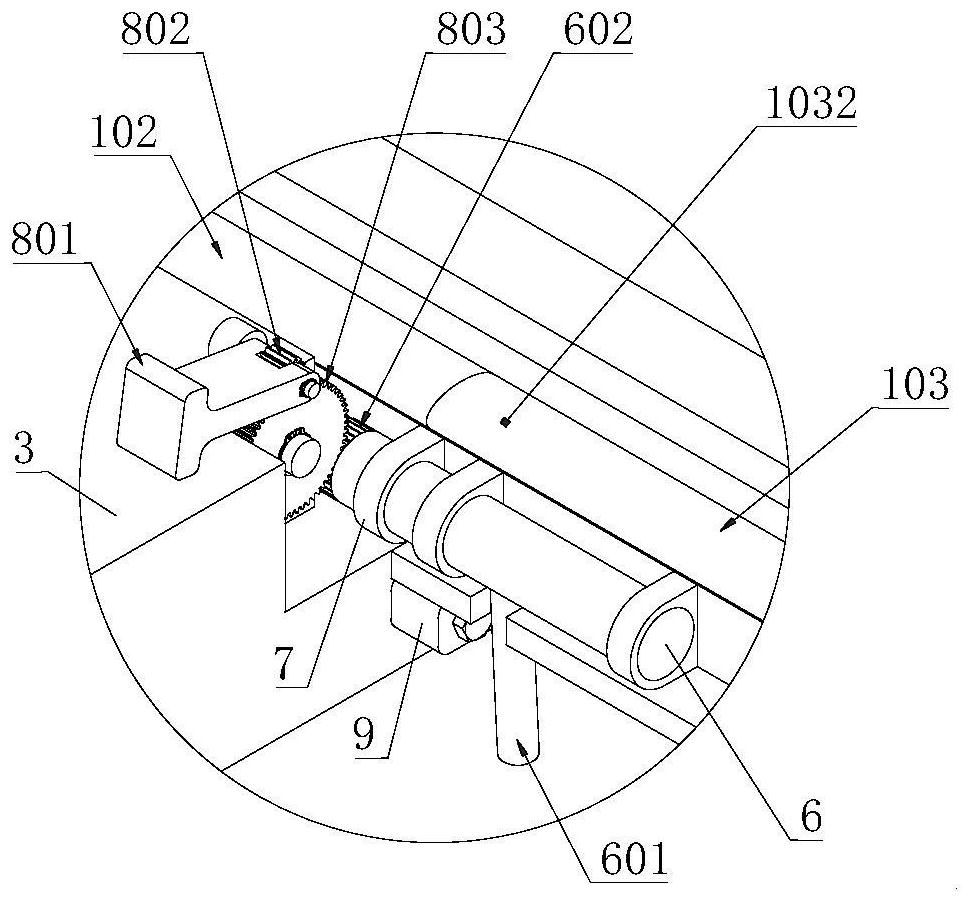

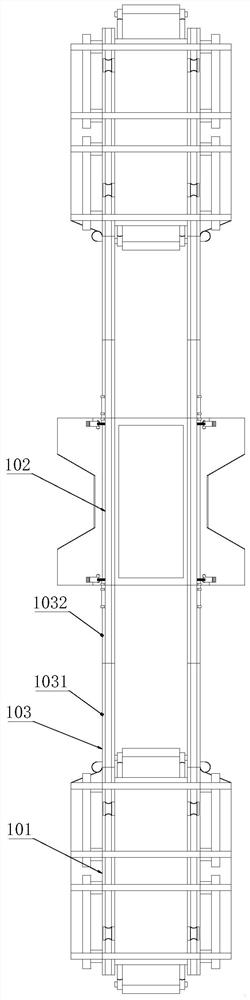

Charging tray feeding and discharging system

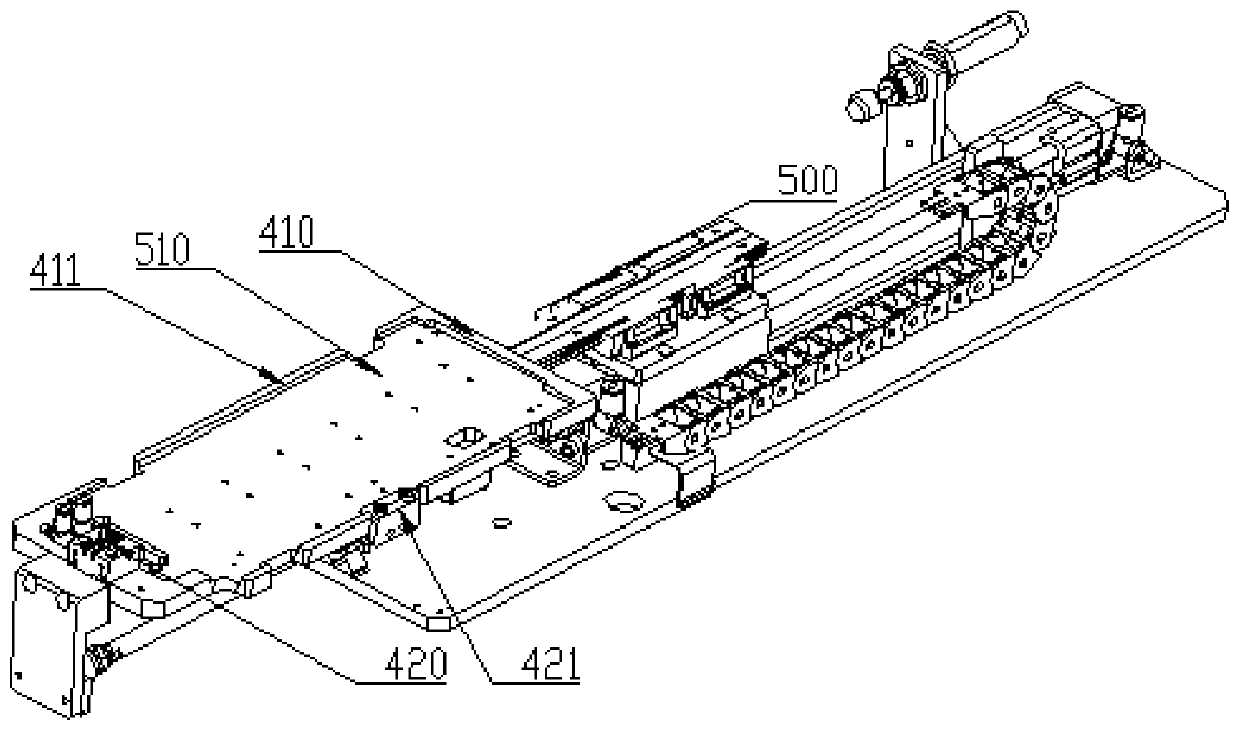

ActiveCN111674869AReduce turnaround timeSimple structureConveyorsControl devices for conveyorsProcess engineeringTransfer mechanism

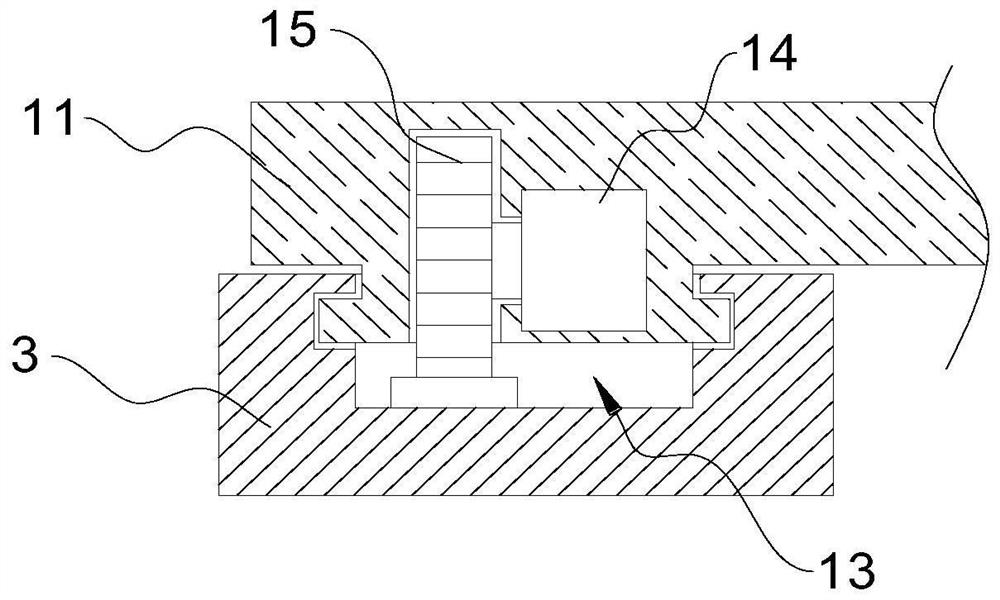

The embodiment of the invention discloses a charging tray feeding and discharging system. The charging tray feeding and discharging system comprises at least one stock bin, at least one jacking mechanism (3), at least one group of positioning mechanism (4) and a charging tray transferring mechanism (5), wherein the at least one stock bin comprises a primary stock bin (1), an outlet / outlets (11) allowing a charging tray (6) to pass is / are formed in a first direction (DIR1) of the top of the primary stock bin (1), the at least one jacking mechanism (3) bears the charging tray (6) and drives thecharging tray (6) to move up and down in the at least one stock bin, the at least one group of positioning mechanism (4) is used for positioning the charging tray (6) so that feeding and discharging operations can be carried out conveniently, and the charging tray transferring mechanism (5) drives the charging tray (6) to move in the first direction (DIR1) so that the charging tray (6) can leave the primary stock bin (1) from the outlet / outlets (11). Therefore, the charging tray feeding and discharging system provided by the embodiment of the invention is simple in structure, small in occupiedspace and capable of being matched with feeding and discharging machines to work, meanwhile, the circulation time of the charging tray can be shortened, and therefore, the production efficiency is effectively improved.

Owner:KUNSHAN XUNTAO PRECISION MACHINERY

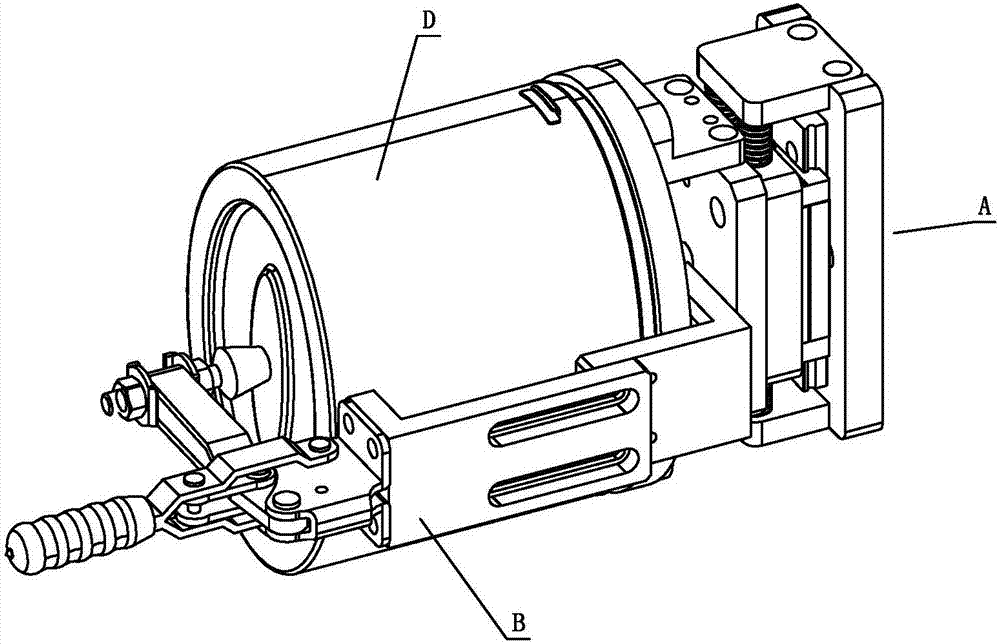

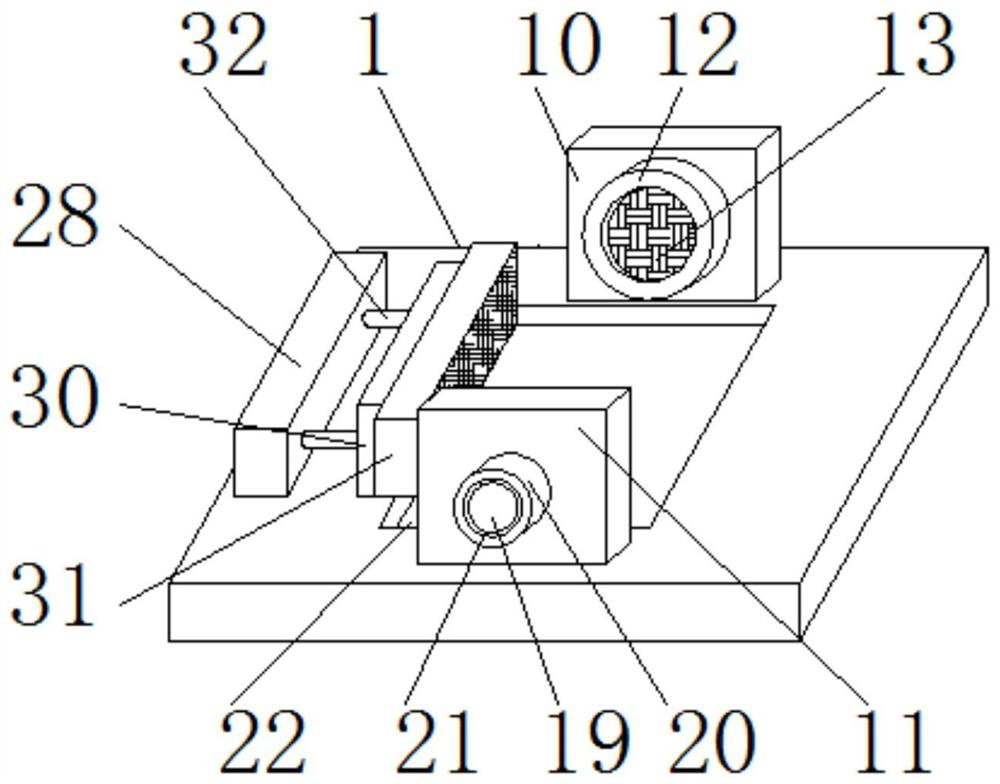

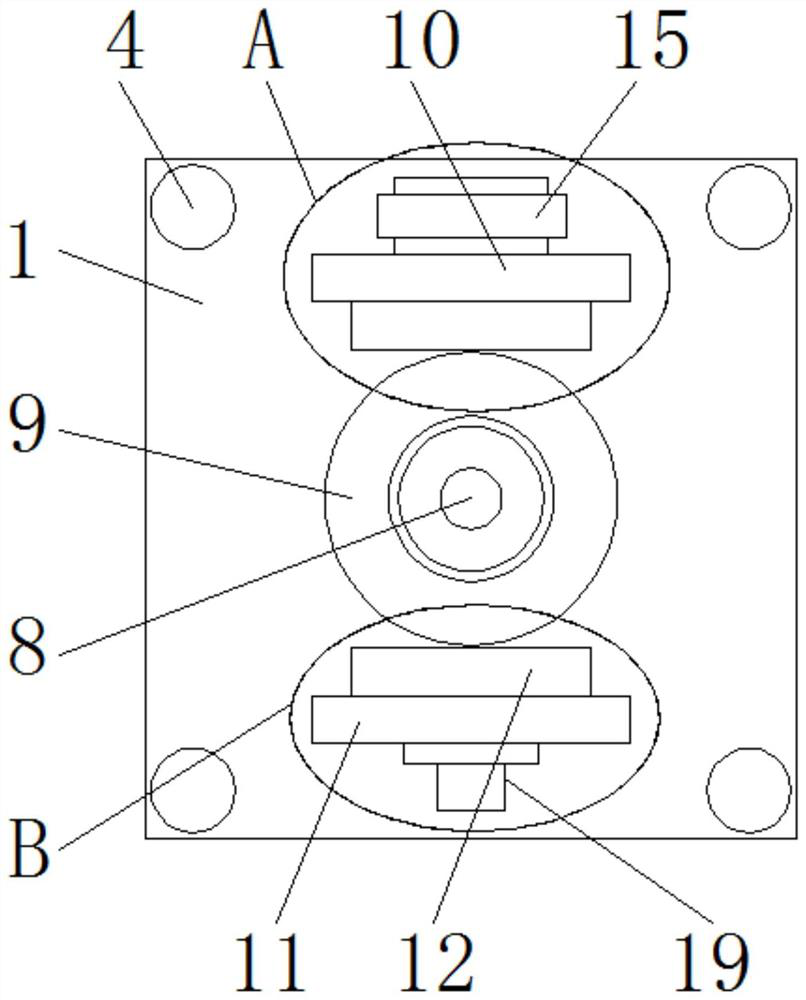

Pot body feeding, locating and floating clamp

PendingCN107570940AEliminate positional deviationAvoid subsequent processing effectsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

A pot body feeding, locating and floating clamp comprises a jig mechanism used for clamping a pot body and further comprises a floating mechanism. The floating mechanism comprises a fixed support, a floating plate and a connecting support. An upper ejector plate and a lower ejector plate are arranged on the fixed support. The floating plate is arranged between the upper ejector plate and the lowerejector plate. Elastic parts and / or an elastic part are / is arranged between the floating plate and the upper ejector plate and / or the lower ejector plate, so that the floating plate slides back and forth relative to the fixed support to achieve the floating effect. The connecting support is fixedly connected with the floating plate, and the floating plate is connected with the jig mechanism through the connecting support. The pot body feeding, locating and floating clamp has the following beneficial effects that through the arrangement of the floating mechanism, a shell clamped on the jig mechanism can float up and down along with the floating mechanism, by means of the floating characteristic, position deviation of the pot body can be effectively eliminated, subsequent machining of the pot body is prevented from being influenced, and machining quality is ensured; through the arrangement of the jig mechanism, the pot body can be effectively and stably clamped; and the pot body feeding, locating and floating clamp can be suitable for pot bodies of different types, adaptability and universality are high, and feeding and discharging operation is convenient and fast.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Movable type loading and positioning mechanism for glass product machining

ActiveCN109531834APrecise positioningQuality improvementGlass transportation apparatusWorking accessoriesDrive shaftMovable type

The invention discloses a movable type loading and positioning mechanism for glass product machining, and relates to the technical field of machining equipment. The movable type loading and positioning mechanism comprises two supporting vertical plates which are distributed in parallel, a linear driving mechanism and a loading platform are arranged on the supporting vertical plates, and the lineardriving mechanism is composed of a stepping motor and two groups of driving assemblies which are installed on the inner sides of the supporting vertical plates in a mirroring mode; a left vertical plate and a right vertical plate are arranged between the two supporting vertical plates, and the left vertical plate and the right vertical plate are distributed in parallel, and guiding seats are arranged on the inner walls of the supporting vertical plates in a mirroring mode; and the driving mechanism comprises cylindrical cams, driving short shafts and driving rods of the driving short shafts,and a driving shaft is arranged between the two supporting vertical plates. According to the movable type loading and positioning mechanism for glass product machining, the structure is simple, the loading platform can move in walking guiding rails in a line, glass panes can be conveniently subjected to feeding and discharging operations, clamping assemblies are arranged on the loading platform, the glass panes can be stably positioned, and the machining efficiency and the machining quality of the glass panes are improved.

Owner:芜湖中义玻璃有限公司

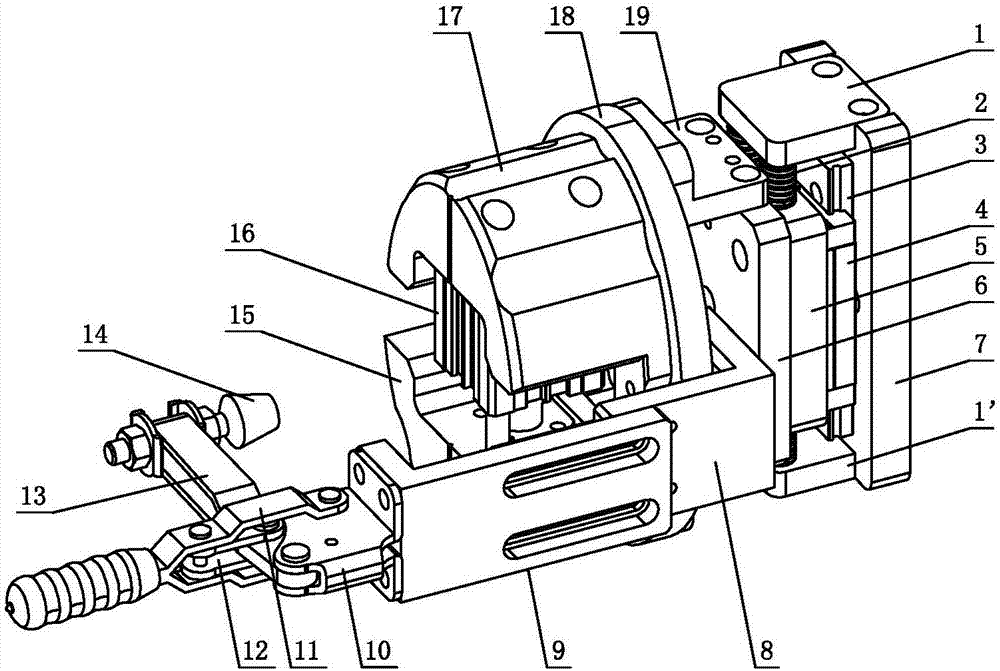

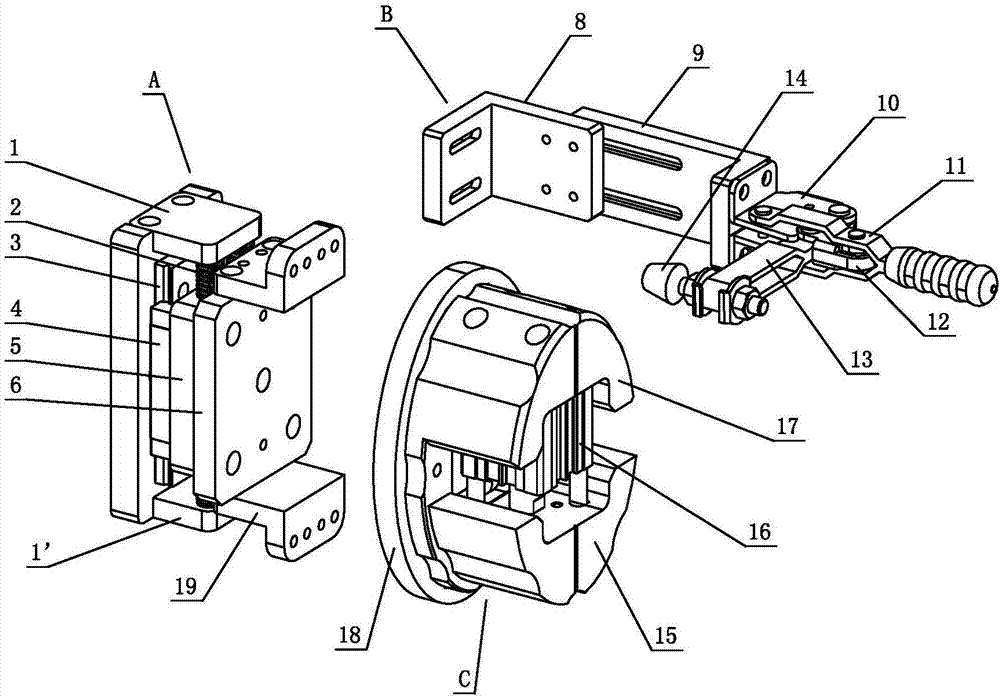

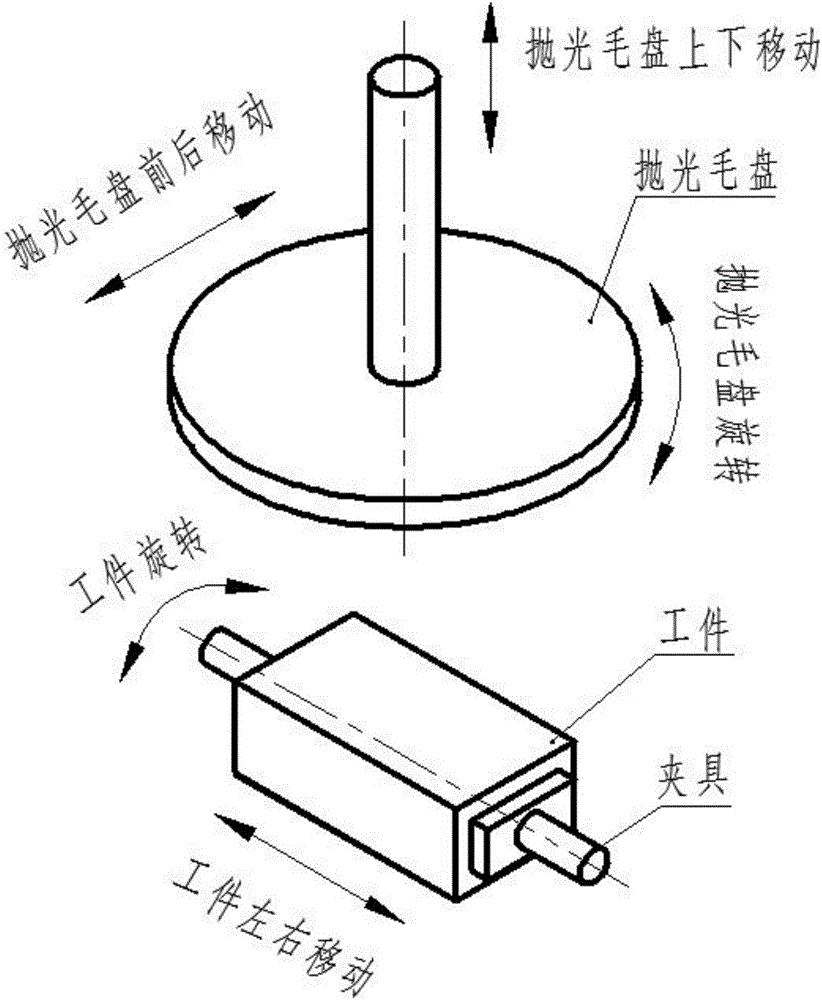

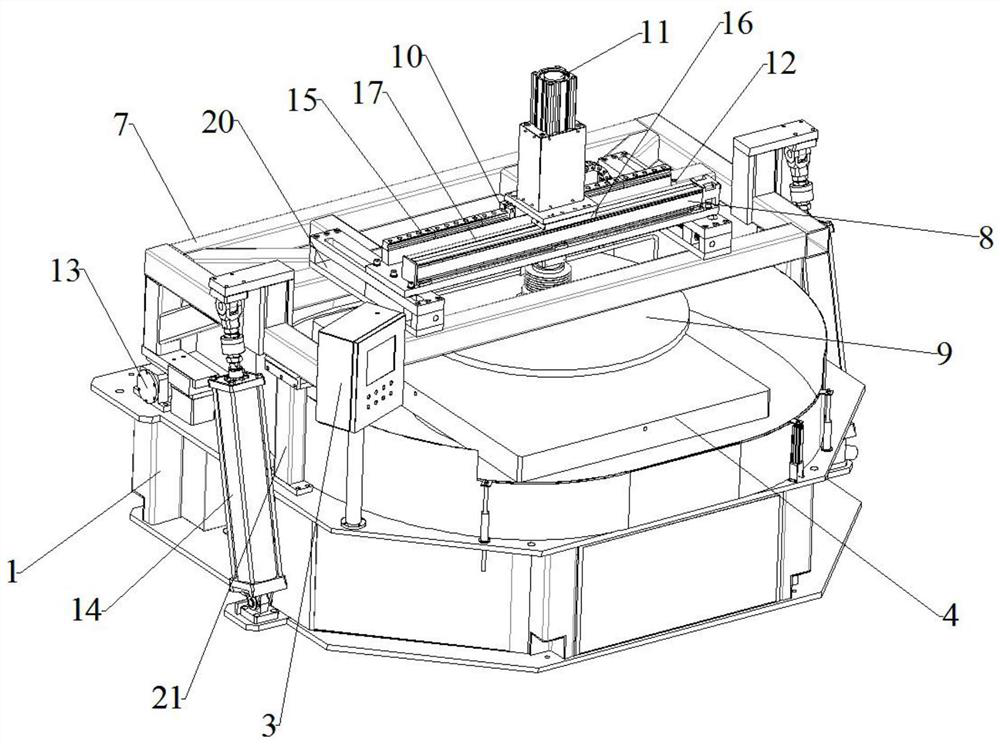

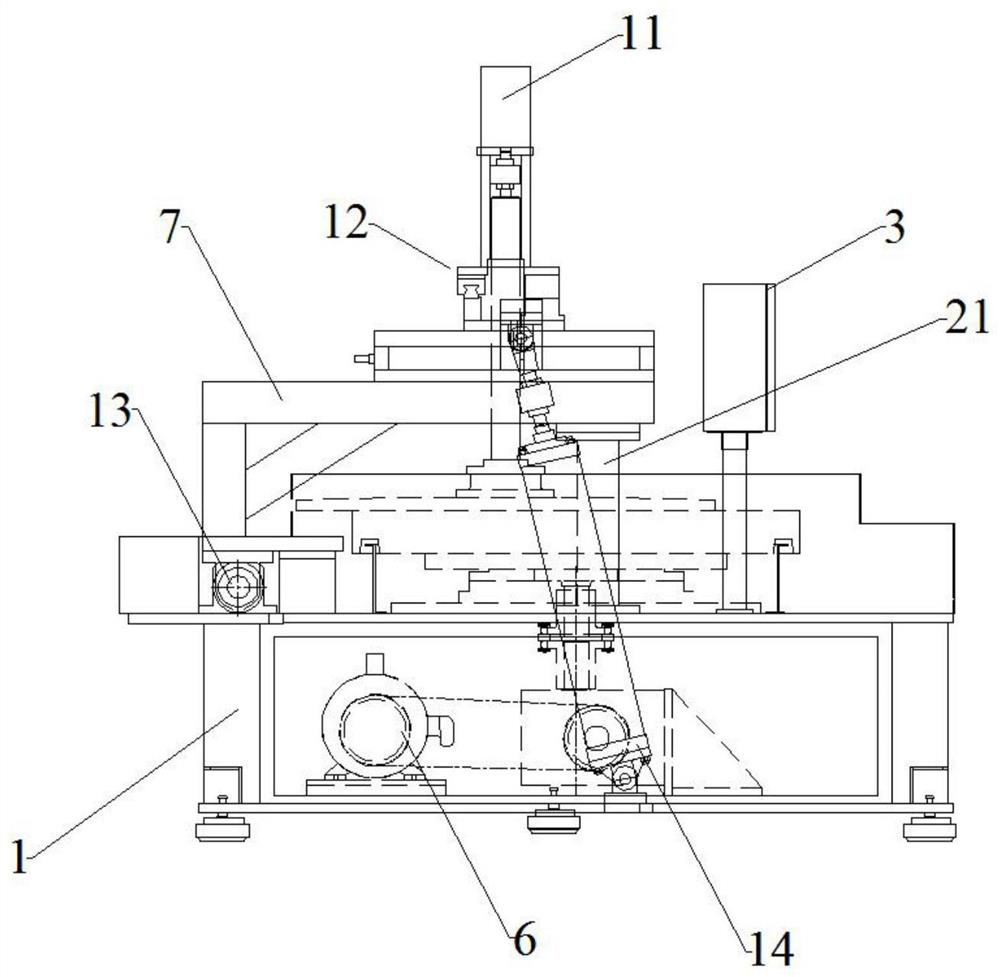

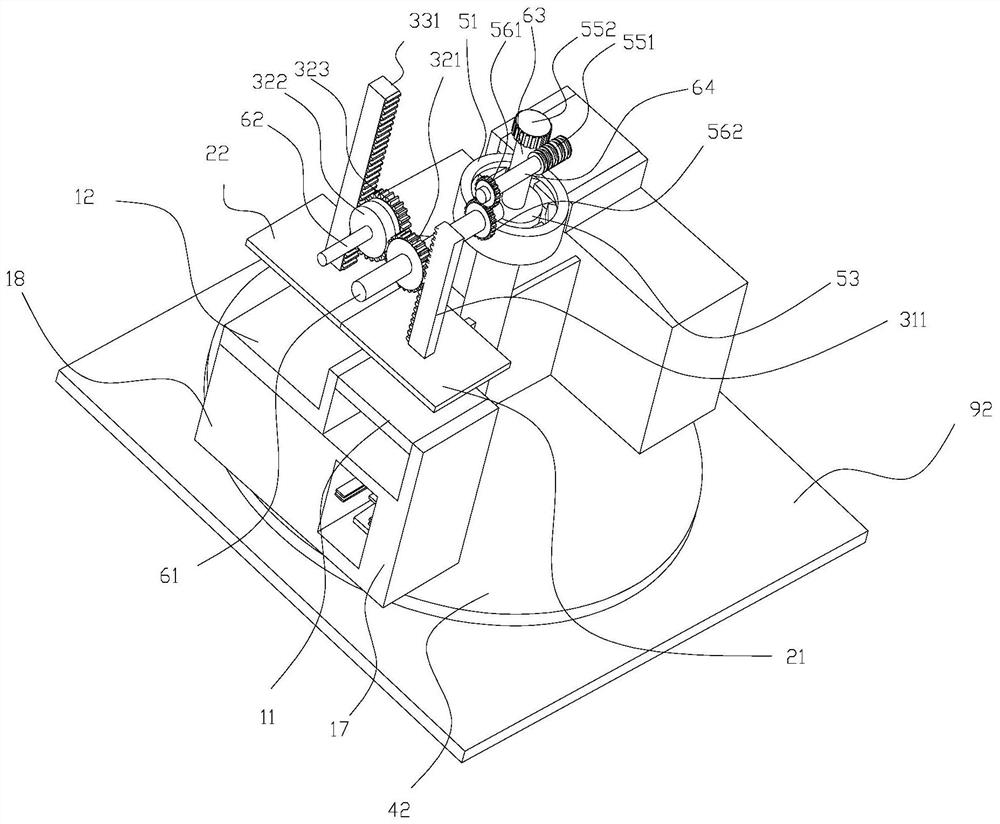

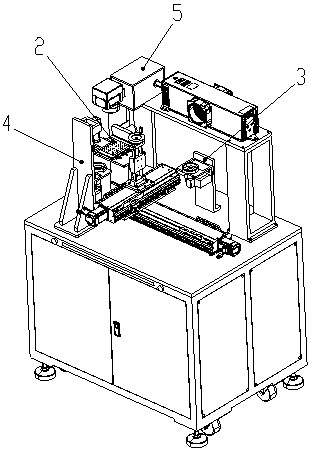

Side-sweeping polishing method

InactiveCN106584254AImproved polishing trajectoryImprove polishing efficiencyPolishing machinesGrinding drivesThree-dimensional spaceThrough transmission

Provided is a side-sweeping polishing method. A polishing wool disc drives a belt through an independent motor to achieve self rotation of a polishing wool disc. Transmission of servo motors and lead screws achieves up-and-down motion of the polishing disc. The forward-and-backward motion of the polishing disc can be achieved through transmission of the other group of servo motors and lead screws. A workpiece is clamped by a clamp and an air cylinder and driven by the servo motors to rotate its own axis. The workpiece can move leftwards and rightwards through the other group of servo motors and lead screws. Therefore, the polishing hair disc can effectively perform polishing motion within the three-dimensional space at any position. The side-sweeping polishing method has the following beneficial effects: by combining self rotation and forward-and-backward motion of the polishing hair disc, and self rotation and leftward-and-rightward motion of the workpiece, the polishing trajectory is effectively improved and polishing efficiency is increased; the polishing wool disc can be controlled to achieve profiling polishing at any position in the trajectory so that the requirement for adjusting pressuring force of the polishing air disc and the workpiece can be met.

Owner:宇晶机器(长沙)有限公司

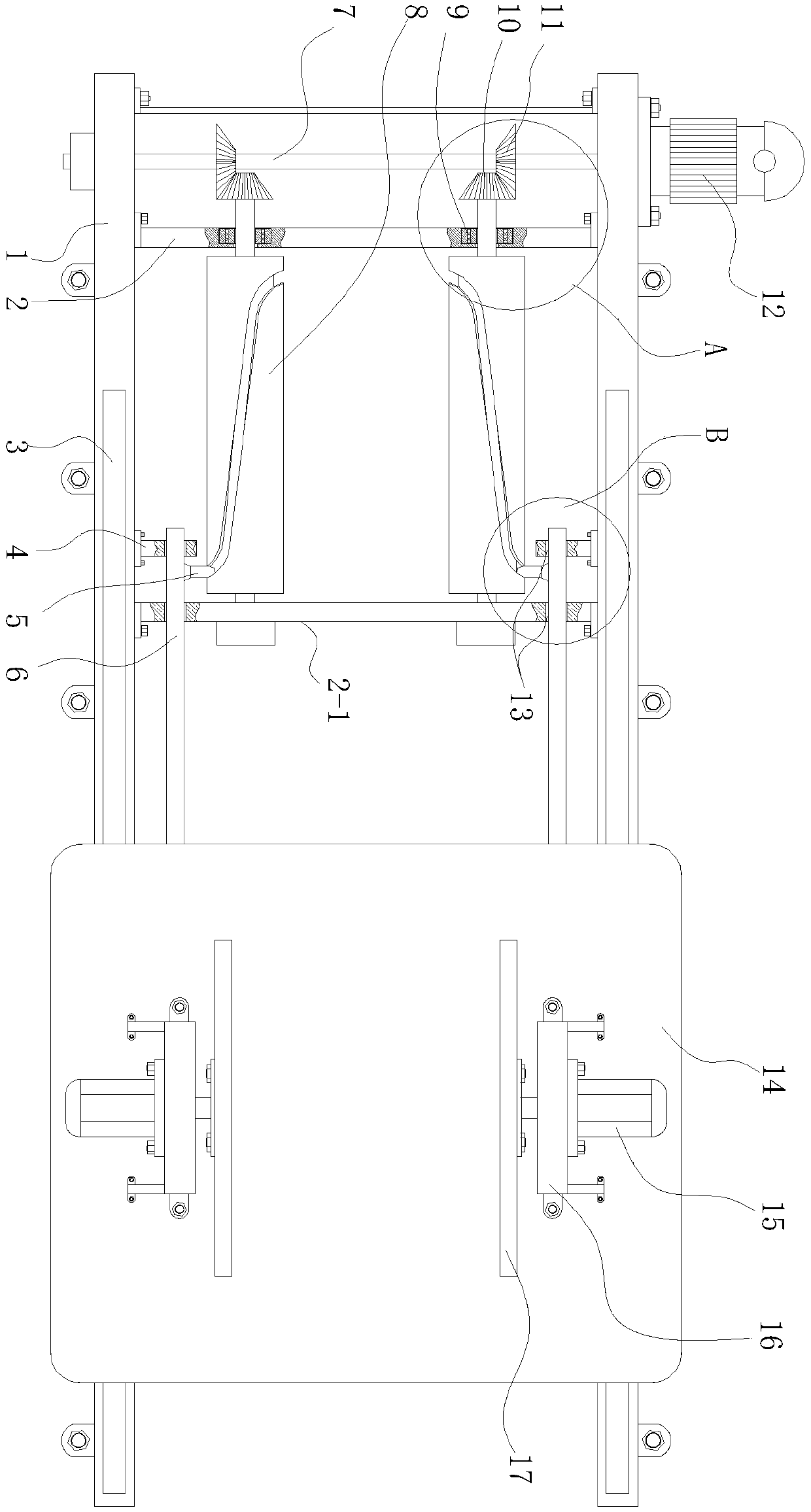

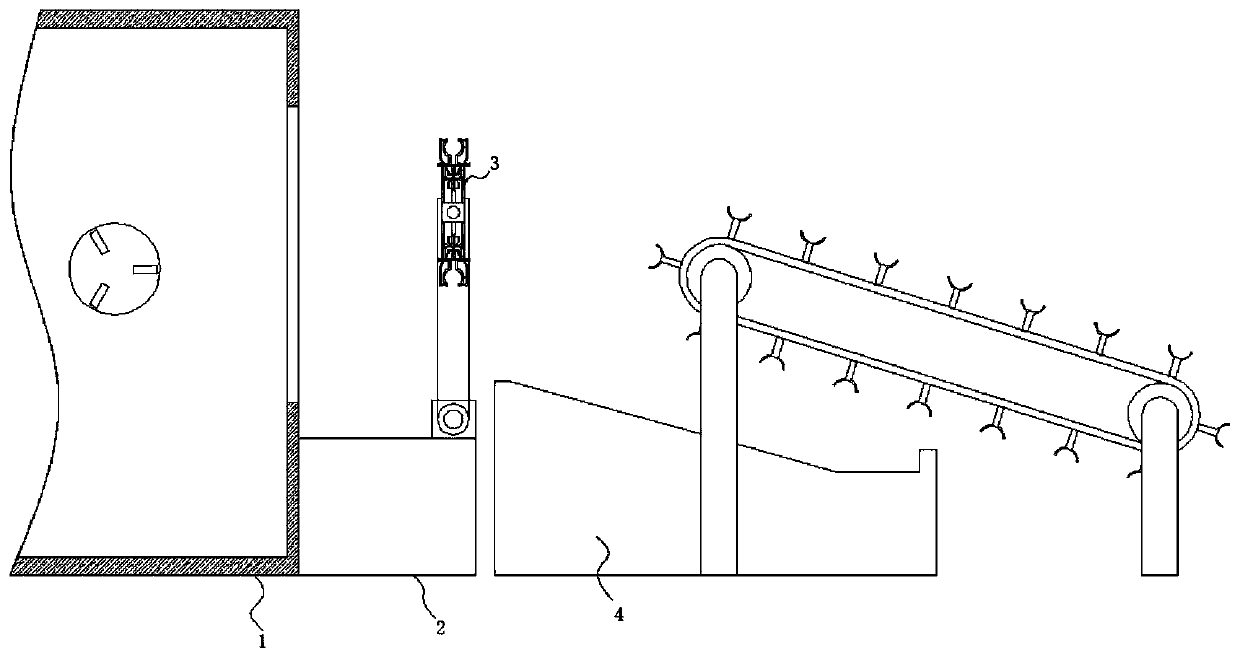

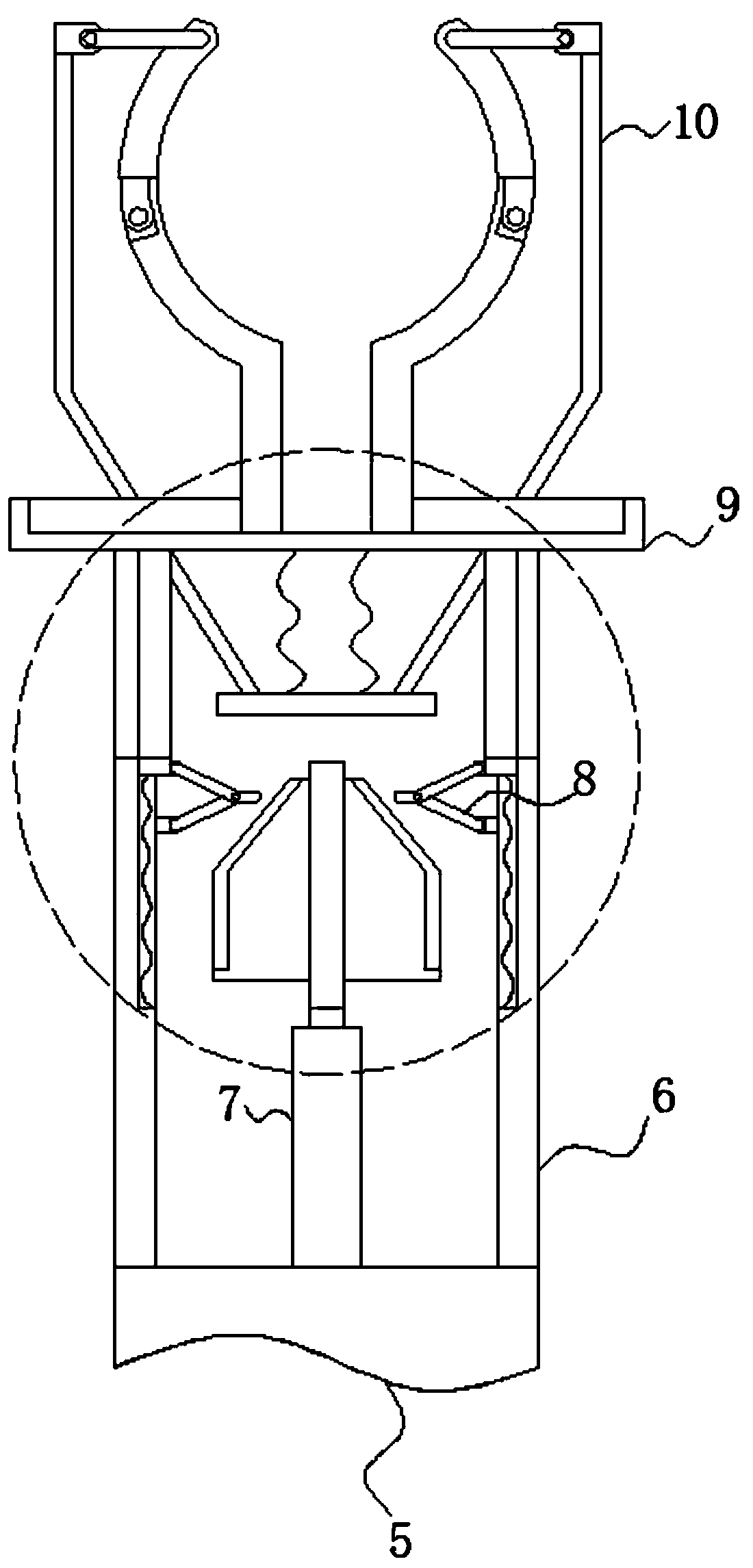

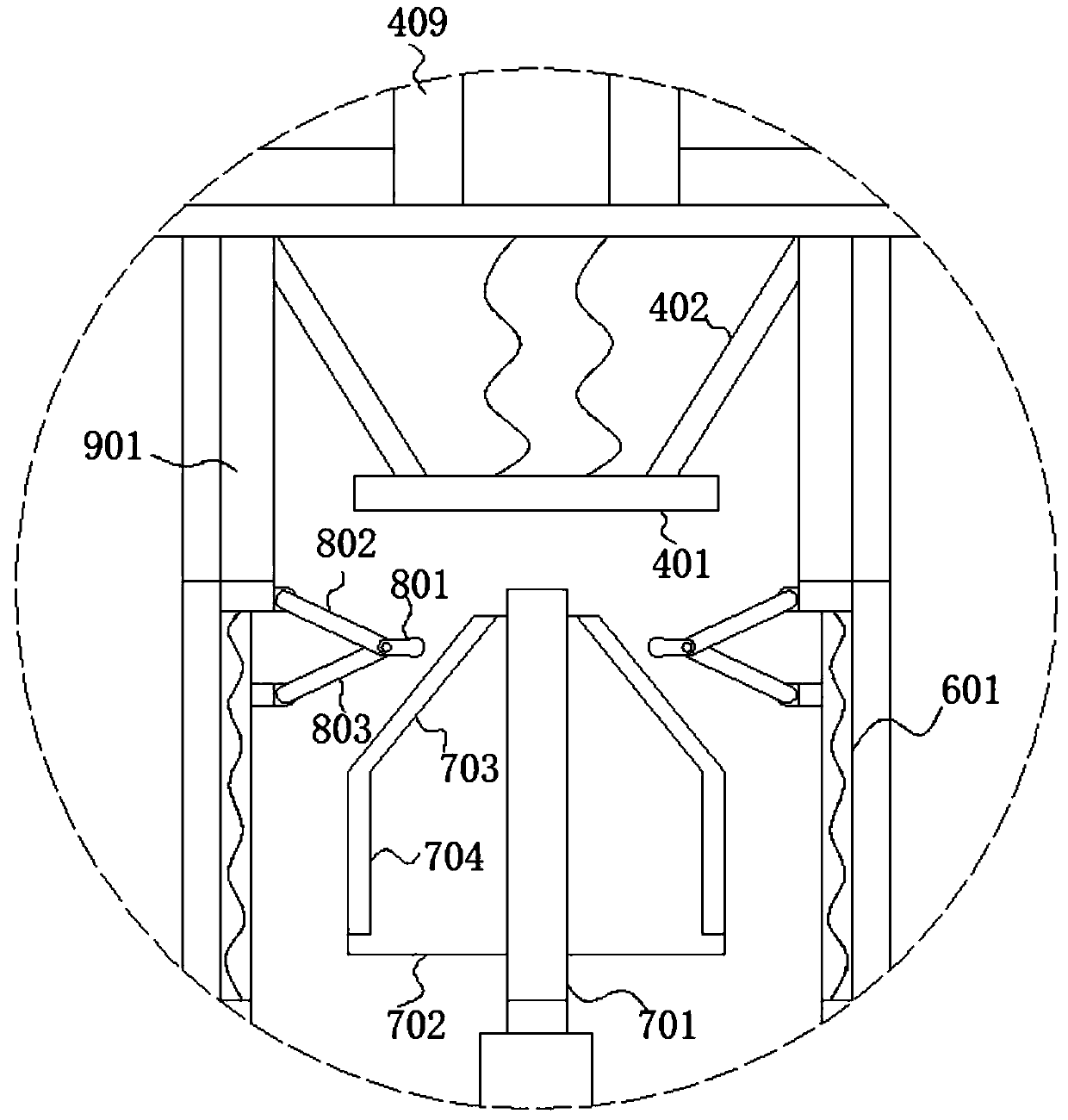

Feeding and discharging device for digital controlled lathe

ActiveCN111438376AImprove processing efficiencyConvenient loading and unloading operationMetal working apparatusDigital controlElectric cables

The invention belongs to the technical field of feeding and discharging and particularly relates to a feeding and discharging device for a digital controlled lathe. The following scheme is proposed. The feeding and discharging device comprises the digital controlled lathe and a swing mechanism arranged at an opening of the digital controlled lathe. The swing mechanism is provided with a clamping assembly for clamping a workpiece, the side, away from the digital controlled lathe, of the swing mechanism is provided with a conveying mechanism, and the clamping assembly comprises a baseplate connected with an output end of the swing mechanism. The two ends of the baseplate are provided with a housing symmetrically arranged along the baseplate, a pushing mechanism fixedly connected with the baseplate is installed in the middle in the housing, the two sides of the end, away from the baseplate, of the pushing mechanism are provided with abutting mechanisms, the opening of the housing is provided with a cover plate, and a clamping mechanism is arranged on the end, away from the housing, of the cover plate. According to the feeding and discharging device, mutual interference and collision of a clamping part and a workpiece are avoided, the safety of the equipment and the workpiece is guaranteed, the difficulty of controlling the equipment is lowered, the difficulty of laying a cable islowered, the workpiece is conveniently fed and discharged, the efficiency of machining the digital controlled lathe is improved, and the labor intensity of operators is lowered.

Owner:HUAINAN UNITED UNIVERSITY

Winding device for punched nickel-plated steel strip

ActiveCN113460764ANeatly coiledRealize winding operationWebs handlingDrive shaftStructural engineering

The invention discloses a winding device for a punched nickel-plated steel strip. The winding device comprises a material placement mechanism, a winding mechanism, a guiding mechanism and a lifting mechanism, the material placement mechanism is arranged on one side of the upper end of a workbench, the workbench is arranged at the upper end of a box body, a plurality of supporting legs are arranged at the bottom of the box body, the material placement mechanism is used for placing the punched nickel-plated steel strip to be wound, the winding mechanism is arranged on the other side of the upper end of the workbench and used for winding the punched nickel-plated steel strip, the guiding mechanism is arranged at the upper end of the workbench between the material placement mechanism and the winding mechanism and is used for carrying out limiting and guiding on the punched nickel-plated steel strip in the winding process, the lifting mechanism is arranged in the interior of the box body, the lifting mechanism is used for driving a driven shaft and a driving shaft to move up and down, the driven shaft is arranged in the material placement mechanism, and the driving shaft is arranged in the winding mechanism. According to the winding device for the punched nickel-plated steel strip, feeding and discharging are convenient, the working efficiency is high, and winding is neat.

Owner:赣州市中金高能电池材料股份有限公司

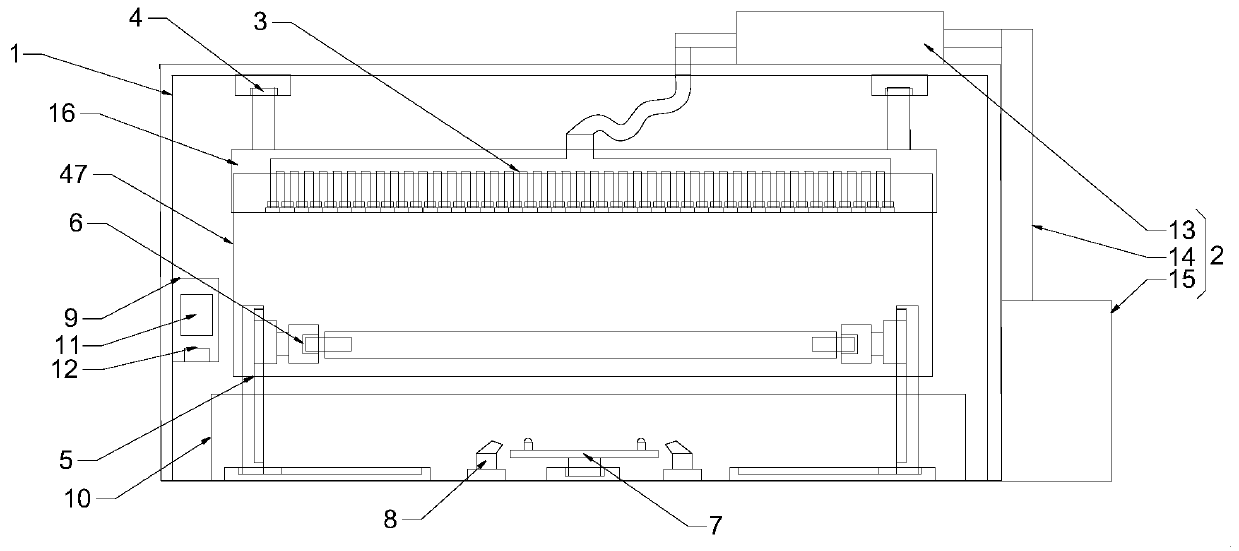

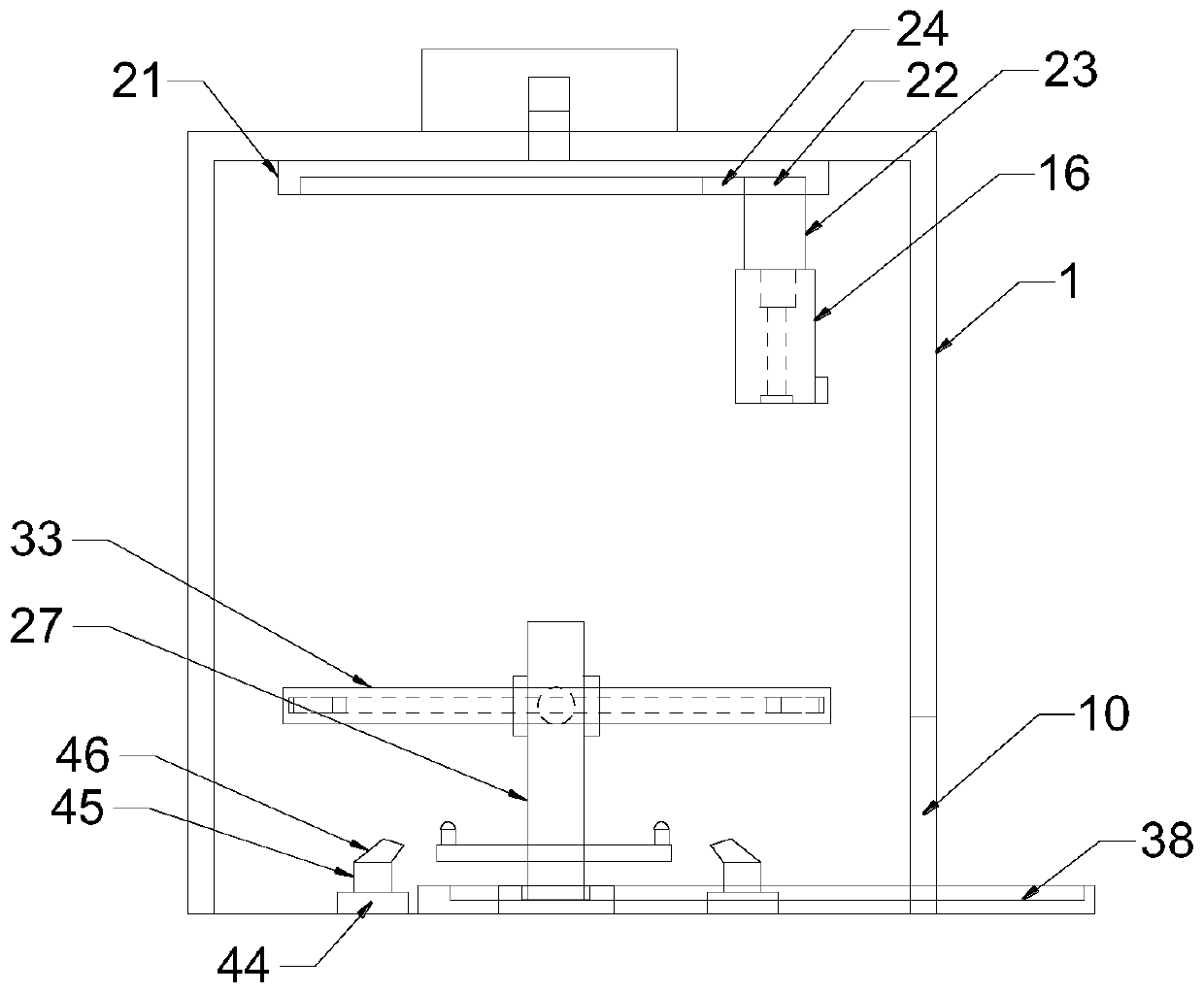

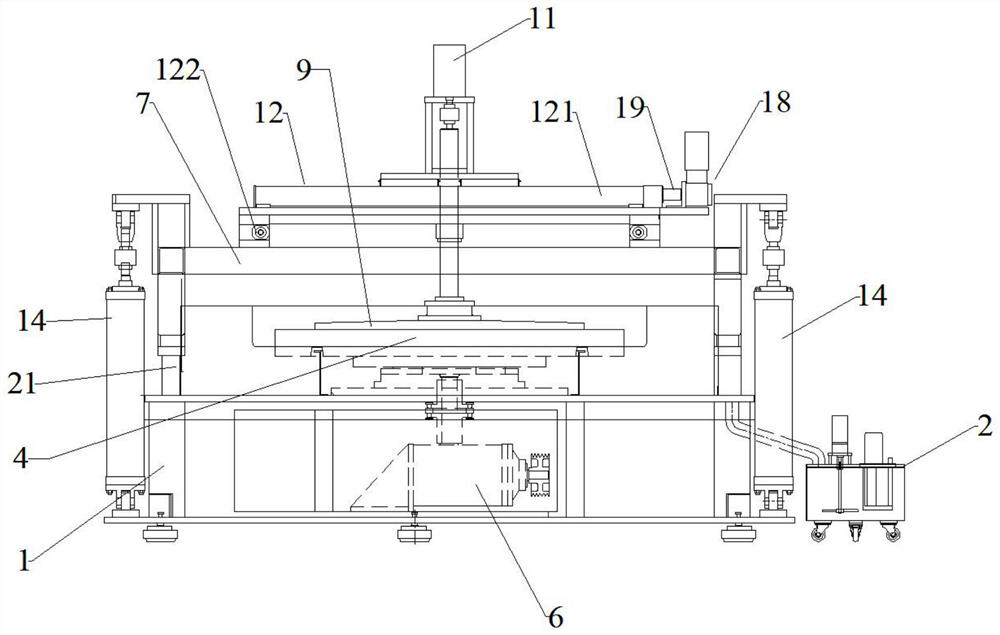

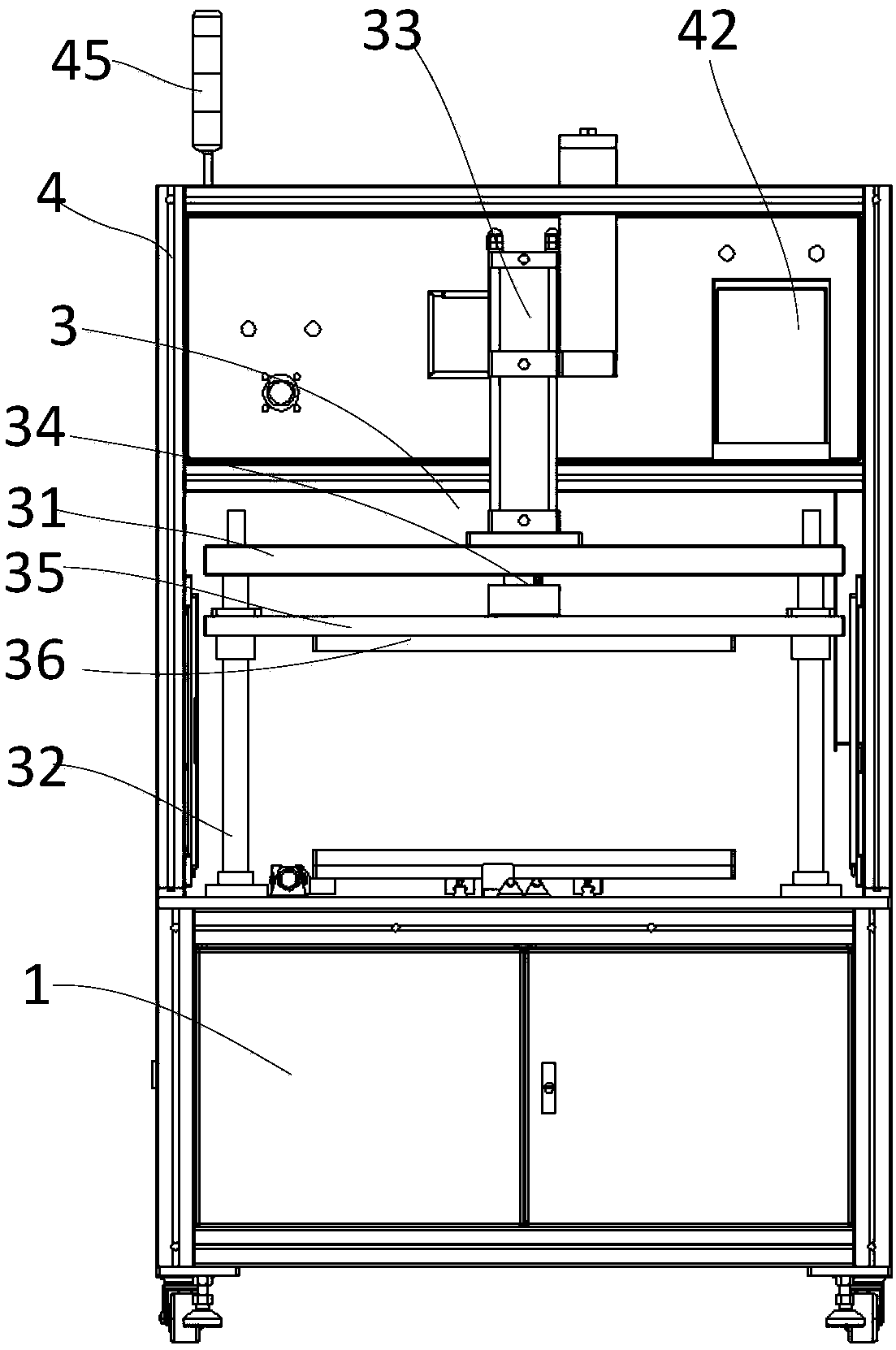

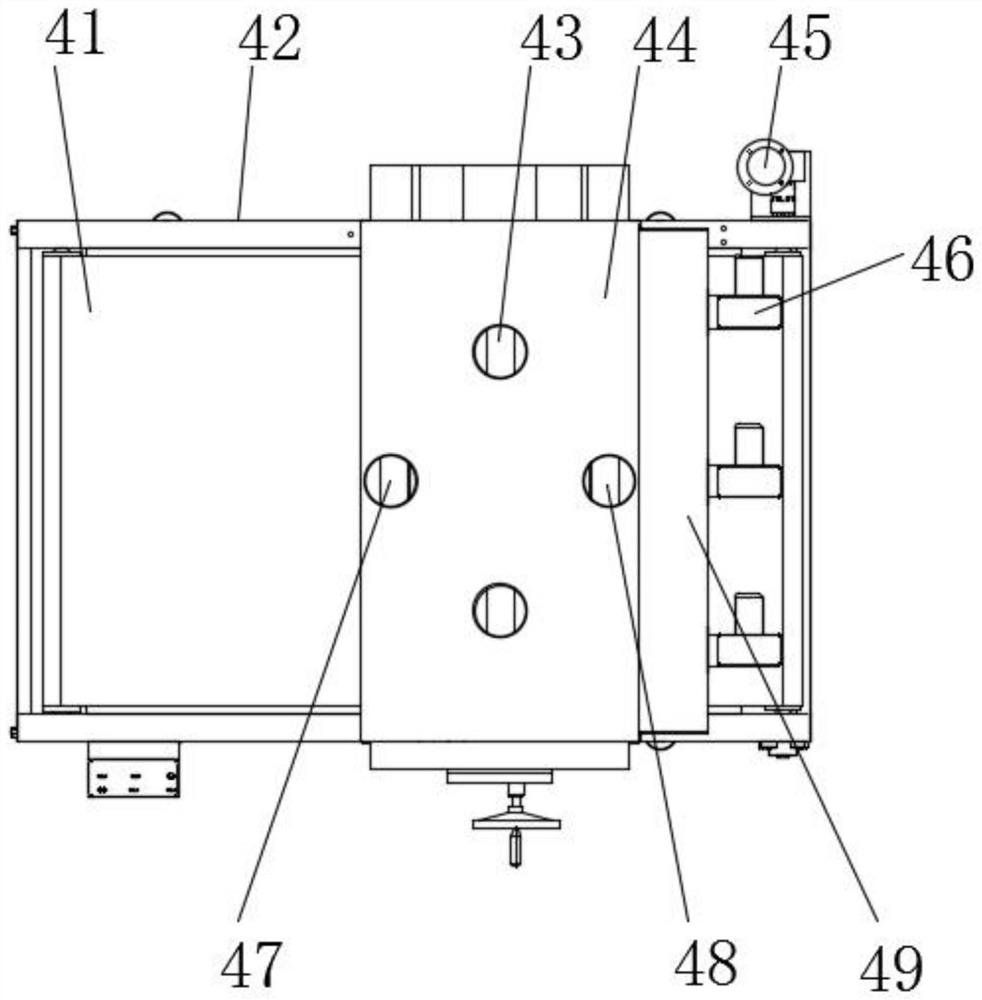

A high-generation flat panel display glass polishing machine and method for processing glass thereof

ActiveCN109015313BConvenient loading and unloading operationAutomate operationPolishing machinesAutomatic controlControl system

Owner:湖南永创机电设备有限公司

Punching device for automotive interior trim production

InactiveCN109129701AEasy to manufactureConvenient loading and unloading operationMetal working apparatusPunchingMaterial resources

A punching device for automotive interior trim production comprises a base and a work table arranged on the base, a plurality of slide rails are horizontally arranged in the middle of the work table,a slide mounting plate is arranged on the slide rails, a displacement cylinder is laterally arranged on one side of the slide mounting plate, a lower mold is arranged on the slide mounting plate, a punching mechanism is arranged above the lower mold, the punching mechanism comprises a punching mounting plate, support columns are arranged around the punching mounting plate, a pressure cylinder is arranged on the punching mounting plate, the pressure cylinder includes a push rod, the push rod passes through the punching mounting plate, a push plate is connected with the push rod, an upper film is arranged on the push plate, a bracket is arranged on the work table outside the punching mechanism, a front panel is arranged on the bracket, a controller is arranged on the front panel, and the controller is electrically connected with a touch screen and a power switch. The punching device has the advantages of reasonable structure, automation, high precision, good stability and manpower and material resource saving.

Owner:南京讯捷汽车饰件有限公司

An optical fiber sensor transfer box with moisture-proof function

ActiveCN110844276BAffect the service lifeEasy to useSealingContainers preventing decayDesiccantEngineering

The invention belongs to the technical field of optical fiber sensor transfer, and particularly relates to an optical fiber sensor transfer box with a dampproof function. The problems that according to existing transfer boxes, in the transfer process of optical fiber sensors, the transferred optical fiber sensors are prone to being affected by external force and the natural environment are solved.According to the scheme, the optical fiber sensor transfer box comprises a box body; connecting plates are installed at the top and the bottom of the box body; and the side face of each connecting plate is provided with two round through holes. According to the transfer box, a shell body and the box body are tensioned through a fastening mechanism, a barrel body and a limiting sliding rod, the internal space of the box body is sealed, the dry environment inside the transfer box is maintained through a silica-gel discolored desiccant inside the shell body, the service life of the optical fibersensor is prevented from being affected by damp, the dampproof effect of the transfer box is improved, meanwhile, the optical fiber sensors are stacked between carrying plates and auxiliary carryingplates and can be drawn out when needed, feeding and discharging operation of cargoes in the transfer box is facilitated, and using is easy and convenient.

Owner:株洲菲斯罗克光电科技股份有限公司

Palletizing robot for workshop production and using method

ActiveCN110745565AImprove palletizing safetyChange the size of the tilt angleStacking articlesDe-stacking articlesHydraulic cylinderPalletizer

The invention discloses a palletizing robot for workshop production and a using method. The palletizing robot comprises an installation rack, a sliding base and a palletizing rack, wherein the inner wall of the horizontal end of the installation rack is movably connected with the outer wall of the sliding base, the inner wall of the sliding base is provided with a lifting hydraulic cylinder, the lower side of the lifting hydraulic cylinder is connected with a driving rod, and the bottom of the driving rod is rotationally connected with the palletizing rack through a connecting shaft. A limiting groove is formed in the lower surface of the palletizing rack, the inner wall of the limiting groove is provided with a second electric push rod, the second electric push rod is connected with a clamping plate through a telescoping rod. In the palletizing robot for the workshop production, the palletizing rack of a rotation structure is adopted, the opening angle of the palletizing rack can be rotationally adjusted with the connecting shaft as the base point, and the clamping requirements of cargoes of different sizes are met; through the cooperation of the clamping plate of an L-shaped structure, a secondary supporting and lifting effect on the bottom of the cargoes can be achieved, and the phenomenon that the cargoes fall off in the palletizing movement process is prevented.

Owner:南京坤航信息科技有限公司

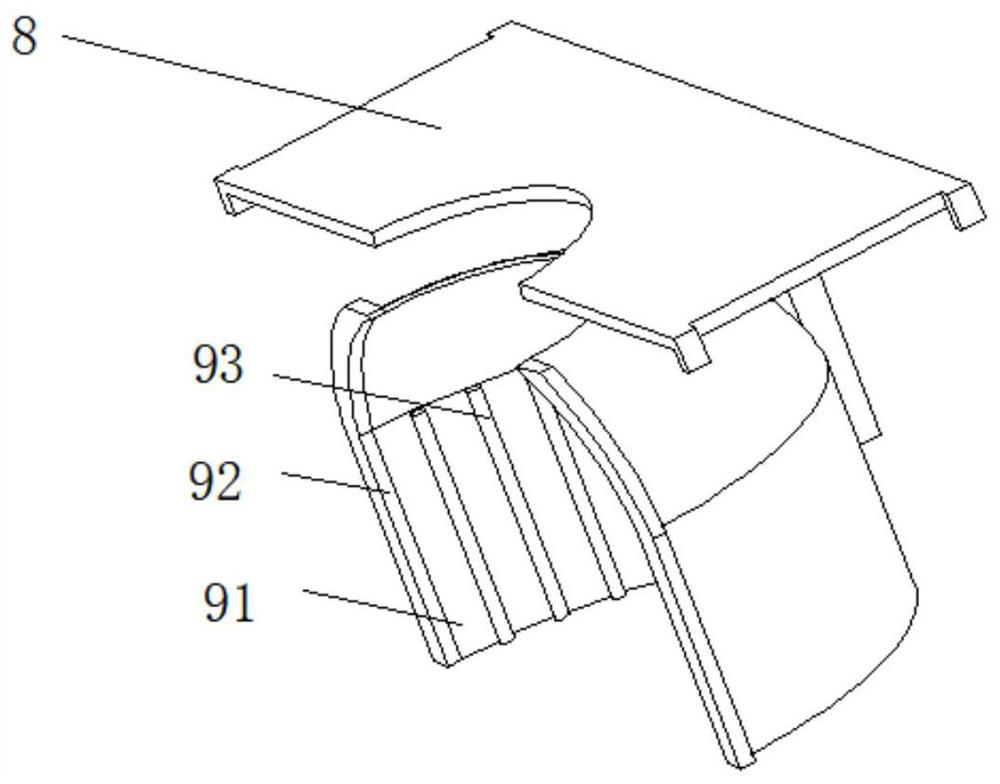

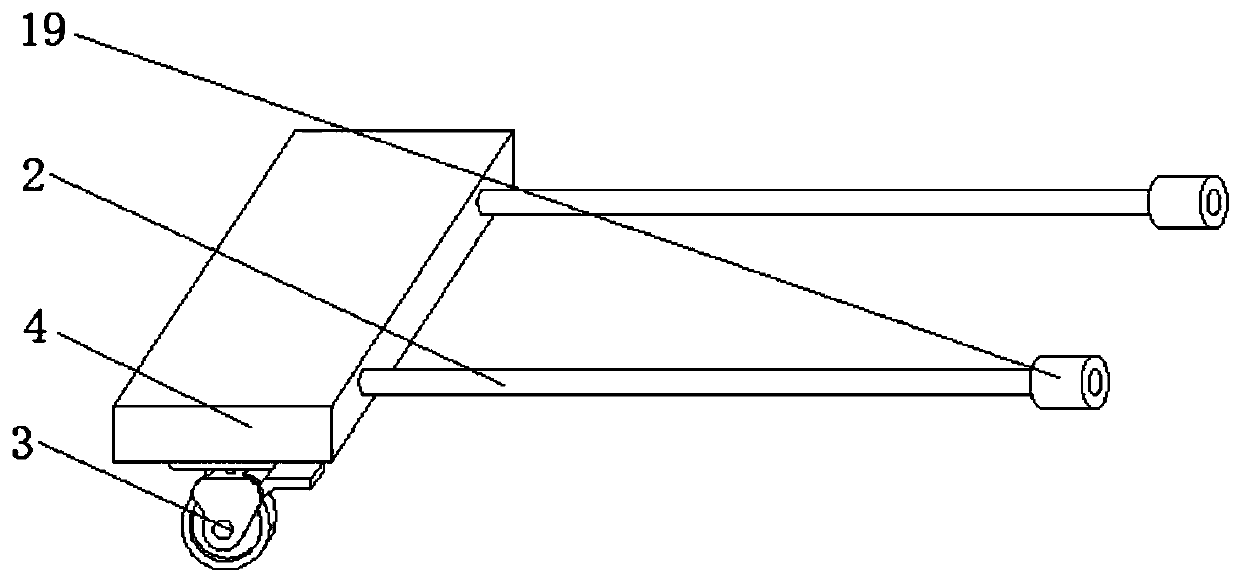

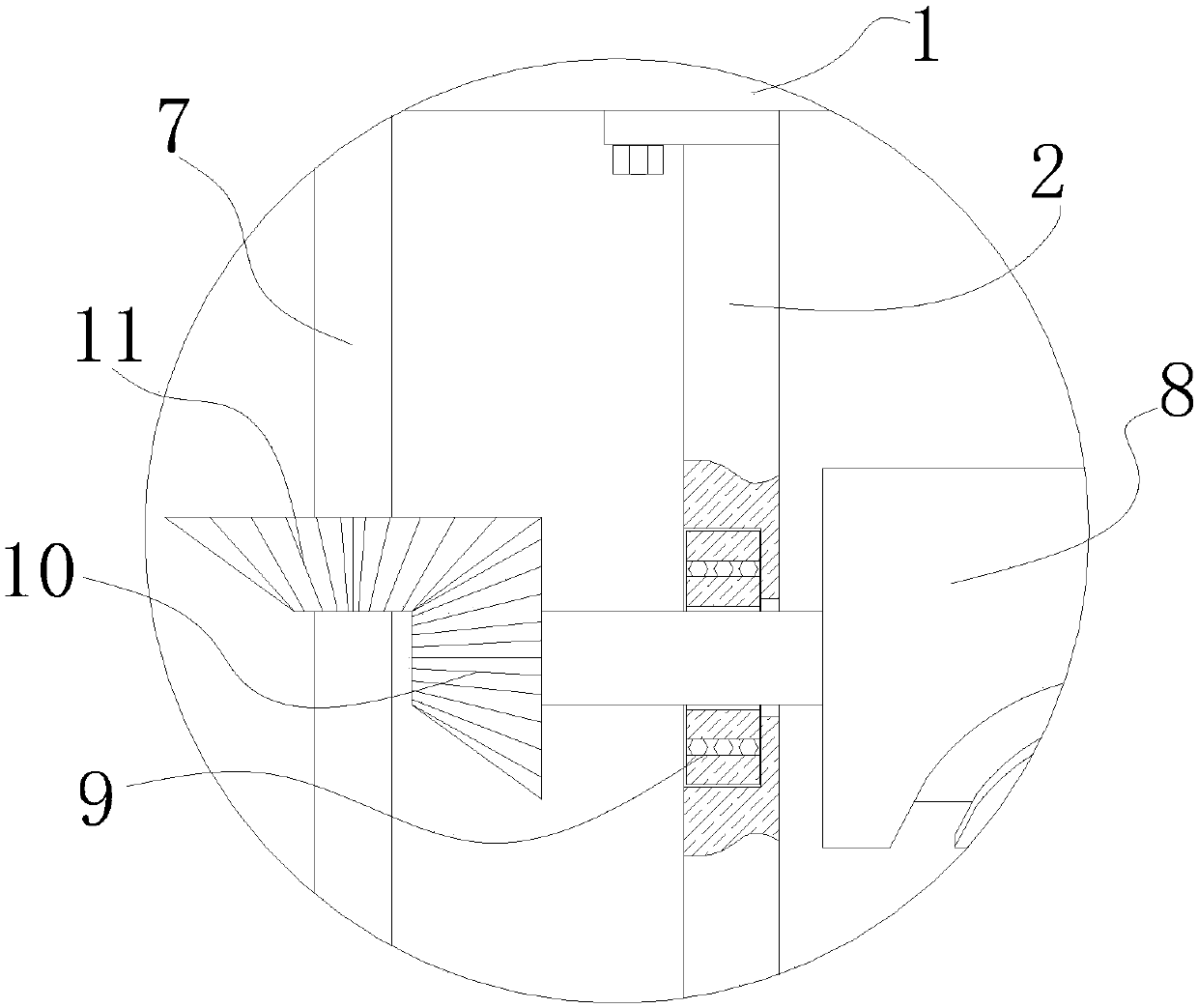

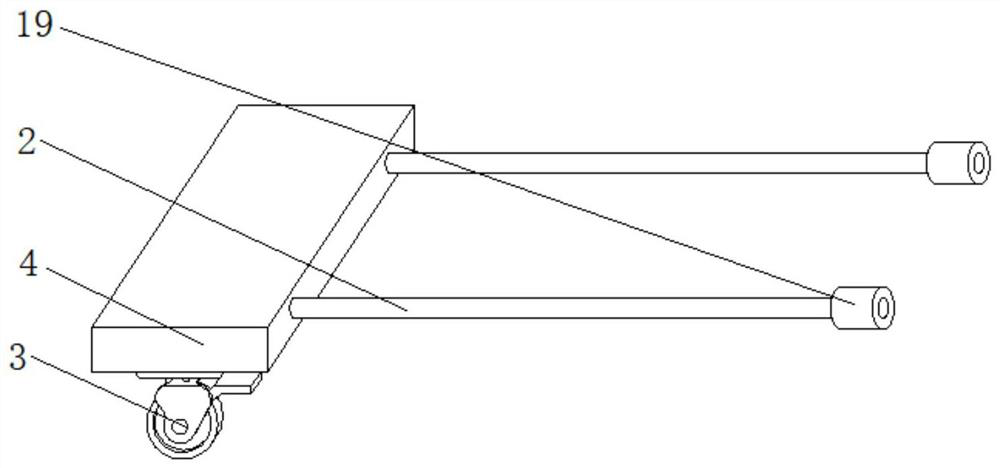

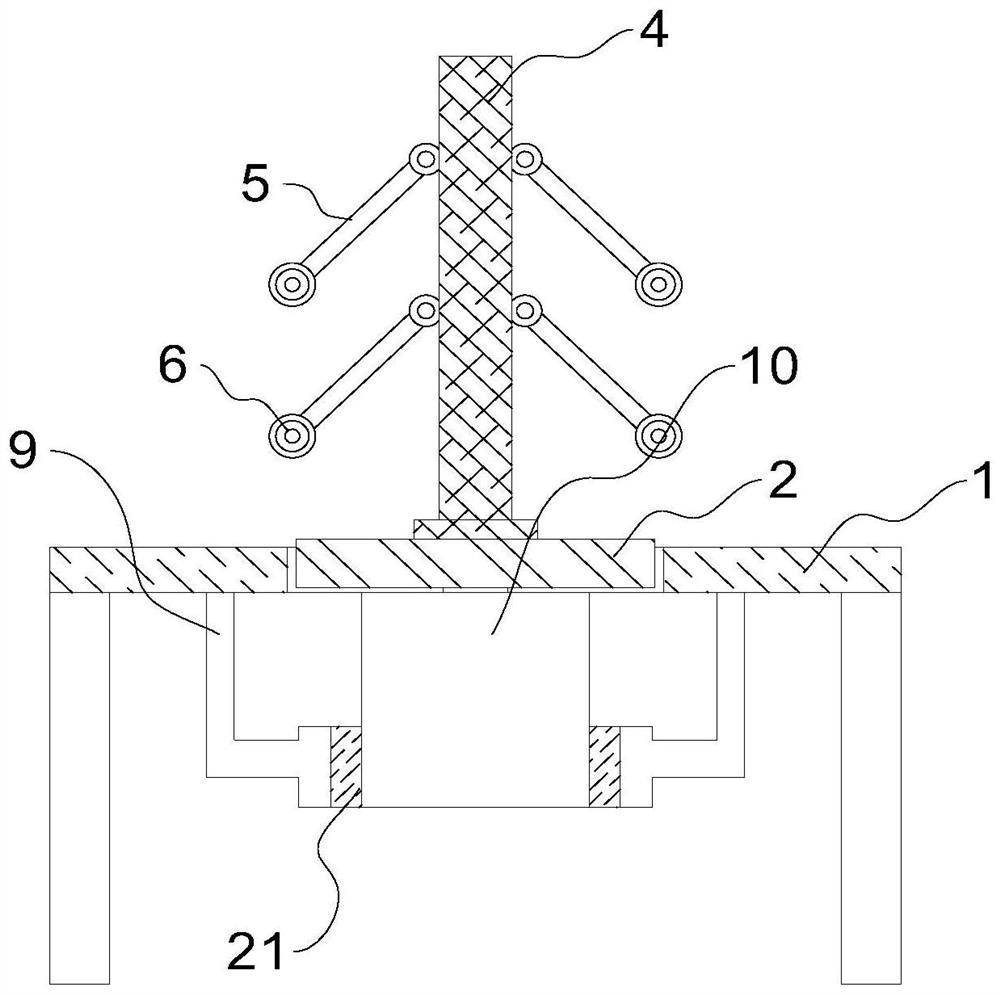

Feeding and discharging auxiliary device and pipe expander with same

InactiveCN110625019AConvenient loading and unloading operationSmall footprintMetal-working feeding devicesPositioning devicesMechanical engineeringEngineering

The invention provides a feeding and discharging auxiliary device and a pipe expander with the same. The feeding and discharging auxiliary device is used for feeding and discharging a workpiece. The feeding and discharging auxiliary device comprises a support frame, wherein the support frame is used for bearing the workpiece, is rotatably arranged around a preset axis, and has a feeding and discharging position and a working position; when the support frame is in the feeding and discharging position, the support frame is used for storing the workpiece; and in the process that the support framerotates from the feeding and discharging position to the working position, the support frame drives the workpiece to overturn by a preset angle. The workpiece can be driven to overturn by the presetangle through the rotation of the support frame, so that the feeding and discharging postures of the workpiece are changed to be convenient for the feeding and discharging operation, and the feeding and discharging auxiliary device solves the problem that the feeding and discharging postures of the workpiece are difficult to control in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

A loading and unloading system and a loading and unloading method

ActiveCN107720292BReduce lossHigh degree of automationControl devices for conveyorsStacking articlesEngineeringManipulator

The invention discloses a loading and unloading system and a loading and unloading method. The loading and unloading system and the loading and unloading method are used for loading and unloading of afunctional device. The loading and unloading system comprises material trays, a loading and unloading area, a storage area, a height sensor, a mechanical arm device and a material tray pushing-out mechanism. The material trays are used for bearing materials, the functional device takes and places the material trays in the loading and unloading area, the storage area is used for storing the traysin a stacking mode, the height sensor senses the stacking height of the material trays in the storage area, the mechanical arm device can grab the material trays to rotate mutually between the loadingand unloading area and the storage area, the height sensor is in communication connection with the mechanical arm device, and the mechanical arm device adjusts the grabbing height according to the material tray stacking height measured by the height sensor. The material tray pushing-out mechanism moves between the function device and the loading and unloading area in a reciprocating mode. The mechanical arm device is used for transferring materials between the loading and unloading area and the storage area, and the material tray pushing-out mechanism is arranged to connect the material loading and unloading area with the processing area of the function device in series, so that the automation degree of the system is increased and the loss of manpower is reduced.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

Deburring equipment for aluminum alloy castings

The invention discloses deburring equipment for aluminum alloy castings, and belongs to the technical field of deburring. The deburring equipment includes a platform body, supporting rods are vertically welded to peripheral edge positions of the upper surface of the platform body, a same set of load-bearing plates are fixedly installed among the upper end positions of the four groups of the supporting rods, a motor is fixedly installed at the middle position of the upper surface of each load-bearing plate, rotating shafts are vertically and movably connected to the bottom middle positions of the motors, the lower ends of the rotating shafts are fixedly sleeved with mounting sleeves, and a first base plate and a second base plate are vertically welded to the middle position of the upper surface of the platform body. A clamping structure of the deburring equipment can be subjected to front-back position adjustment to apply backward squeezing force to the aluminum alloy castings, the stability of the clamping installation of objects is improved, adjusting can be flexibly carried out according to the size of the objects, the feeding and discharging operations of the aluminum alloy castings are facilitated, the operations are far away from a polishing area, the safety is high, and meanwhile, a cleaning structure is arranged to clean a polishing surface, so that the cleanliness of finished products is improved.

Owner:马鞍山思哲知识产权服务有限公司

Double-heating-plates sequential hot printing rotary printing machine and textile printing method

InactiveCN112659737AAchieve integrationIncrease profitTransfer printingTransfer printing processTextile printerProcess engineering

The invention discloses a double-heating-plates sequential hot printing rotary printing machine. The machine is characterized in that two printing plates are arranged on two sides of a rotating shaft correspondingly, the rotating shaft rotates to drive the two printing plates to alternately face heating plates, a second downward pressing device performs downward pressing motion to enable a first downward pressing device to perform downward pressing motion, the first downward pressing device is static in sequence, an initial moment when the first downward pressing device is static occurs at an initial moment when the first heating plate presses downwards to textiles on the first printing plate to perform hot printing on the textiles, the second downward pressing device performs upward reset motion to enable the first downward pressing device to be static, the upward reset motion of the first downward pressing device is sequentially performed, and the rotating shaft rotates within a time period of the upward reset motion of the first downward pressing device. The invention further discloses a textile printing method. The machine and the method have the advantages that the textiles made of different materials can be subjected to hot printing in the same unit time and on the same device, the working gap during hot printing is reasonably utilized, the control steps are reduced, and the process streamline is improved.

Owner:王永进

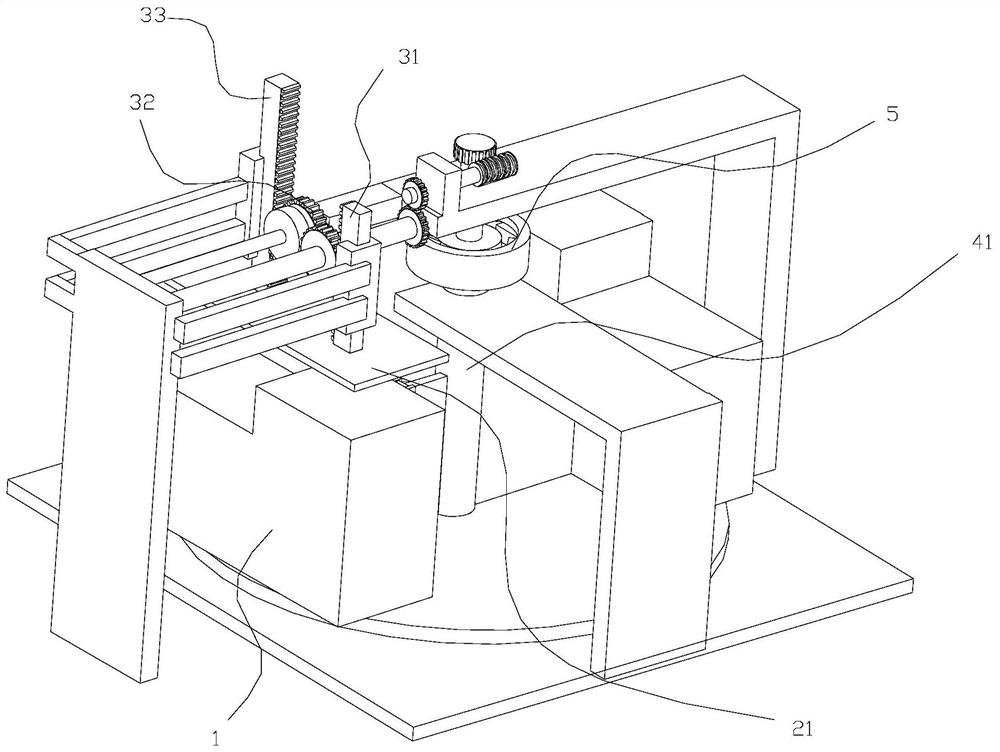

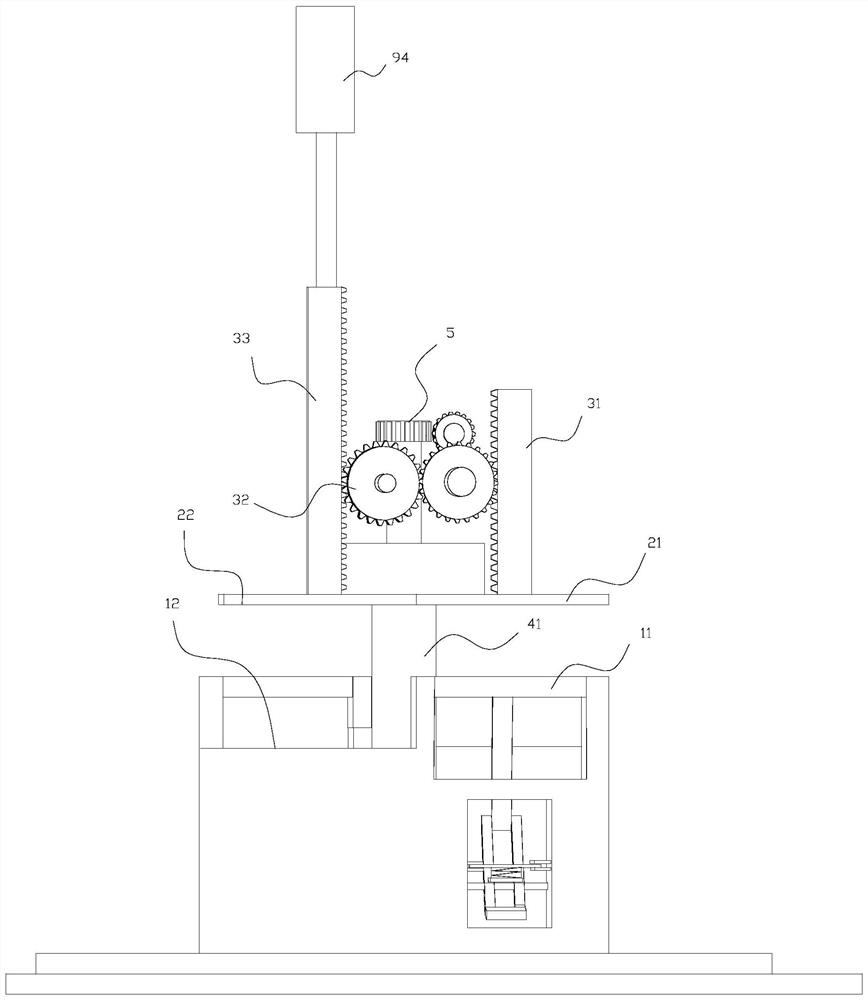

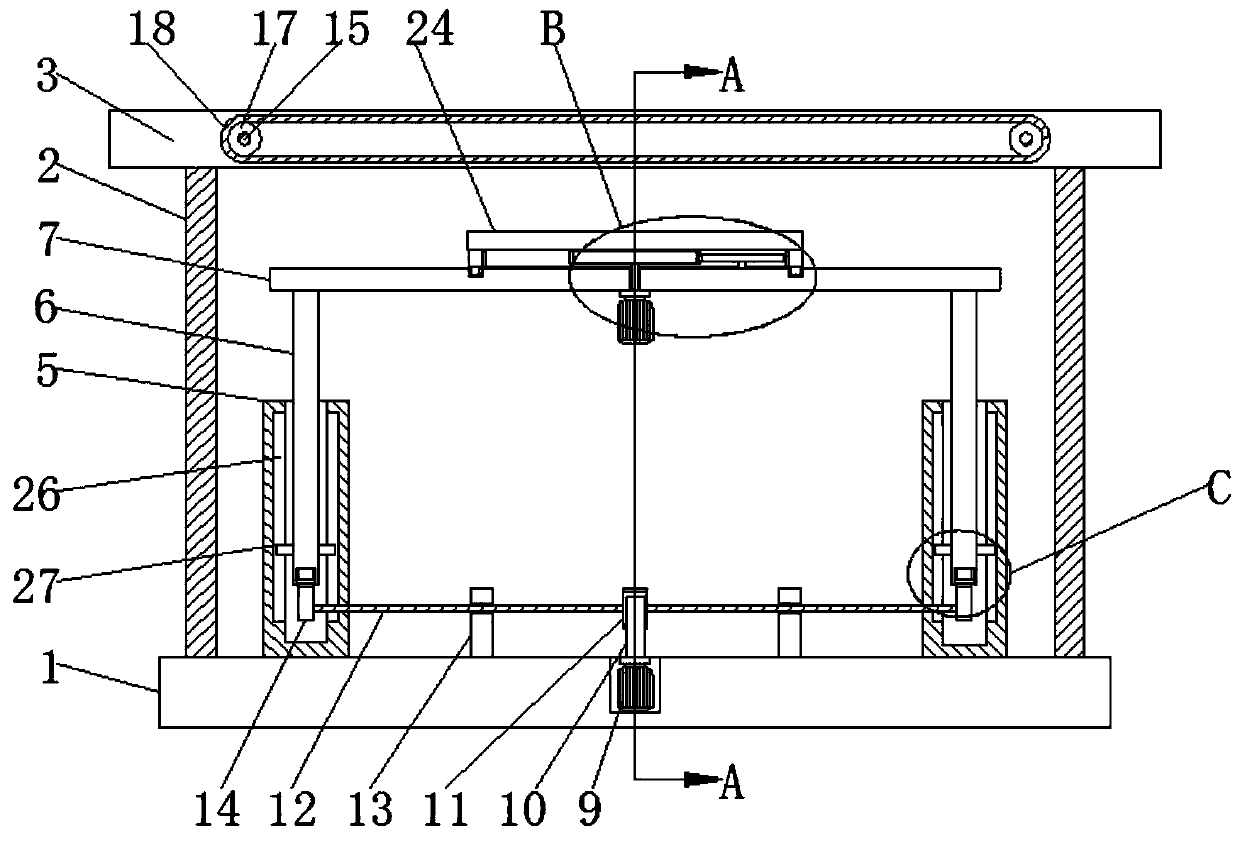

Diesel engine cover machining feeding and discharging lifting table

PendingCN111283461ARealize the delivery operationEasy to operateMetal working apparatusGear wheelTransmission belt

The invention discloses a diesel engine cover machining feeding and discharging lifting table. The table comprises a bottom plate and a top plate. According to the table, a first motor is arranged, aworm is driven to mesh with a gear to rotate through the first motor, so that a rotating shaft drives a rotating plate to jack up and lower the top plate on a movable plate, operation is convenient, and feeding and discharging operation is facilitated, through the arrangement of a rotating device, a second gear on a rolling shaft is driven by a third motor to mesh with a third gear to rotate, thethird gear meshes with a ring gear to enable a circular plate to rotate, rotation of a diesel engine cover on the circular plate is achieved, then, the diesel engine cover is placed on a conveying belt through descending of the top plate, conveying operation on the diesel engine cover is achieved, and transportation and use are facilitated. The table has the advantages of convenient operation andconvenient transportation.

Owner:宁夏巨能机器人股份有限公司

Comprehensive painting furniture processing device capable of reducing paint consumption

PendingCN113798097AEffectively fixedInhibit sheddingLiquid spraying apparatusStructural engineeringIndustrial engineering

The invention relates to the technical field of furniture processing, and discloses a comprehensive painting furniture processing device capable of reducing paint consumption. The comprehensive painting furniture processing device comprises a paint spraying frame, a descending mechanism is mounted at the top end of the left side of the paint spraying frame, a paint spraying chamber and a drying chamber are arranged on the left side and the right side of the paint spraying frame correspondingly, a paint spraying mechanism is arranged in the paint spraying chamber, a switch mechanism is connected to the paint spraying mechanism, a drying device is installed in the drying chamber, a conveying belt device is installed above the paint spraying frame, clamping mechanisms are evenly distributed on the conveying belt device and comprise sleeves, the sleeves are evenly distributed on the conveying belt device, sleeve rods are slidably installed in the sleeves, first springs are connected between the sleeve rods and the sleeves, the bottom ends of the sleeve rods are connected with a rotating mechanism through a mounting shaft, and a clamp is mounted on the rotating mechanism. According to the comprehensive painting furniture processing device, feeding and discharging are convenient, meanwhile, rotary paint spraying can be conducted on objects, the paint spraying time can be controlled, redundant paint can be recycled, paint consumption is reduced, and cost is saved.

Owner:徐州格非家居有限公司

Fettling system for electro-ceramic blank recycling

PendingCN113561297AEasy to transportAvoid the influence of trimming operationAuxillary shaping apparatusMechanical engineeringMaterials science

The invention relates to the technical field of electro-ceramic fettling, in particular to a fettling system for electro-ceramic blank recycling. The system comprises a processing table, an annular guide rail for conveying electro-ceramic blanks is fixedly mounted at the top of the processing table, and a plurality of blank bearing pieces for limiting the electro-ceramic blanks are slidably connected to the inner wall of the annular guide rail. A fettling mechanism used for carrying out fettling operation on the electro-ceramic blanks is arranged at the end of the annular guide rail. According to the fettling system, fettling operation can be conducted on the plurality of electro-ceramic blanks at the same time, continuous and automatic operation can be achieved, manpower is saved, and the working efficiency is high; and dirt adhered to the electro-ceramic blanks is cleaned through a blank cleaning mechanism, so that the influence of impurities and dirt adhered to the recycled electro-ceramic blanks on subsequent fettling operation is avoided.

Owner:醴陵华鑫电瓷科技股份有限公司

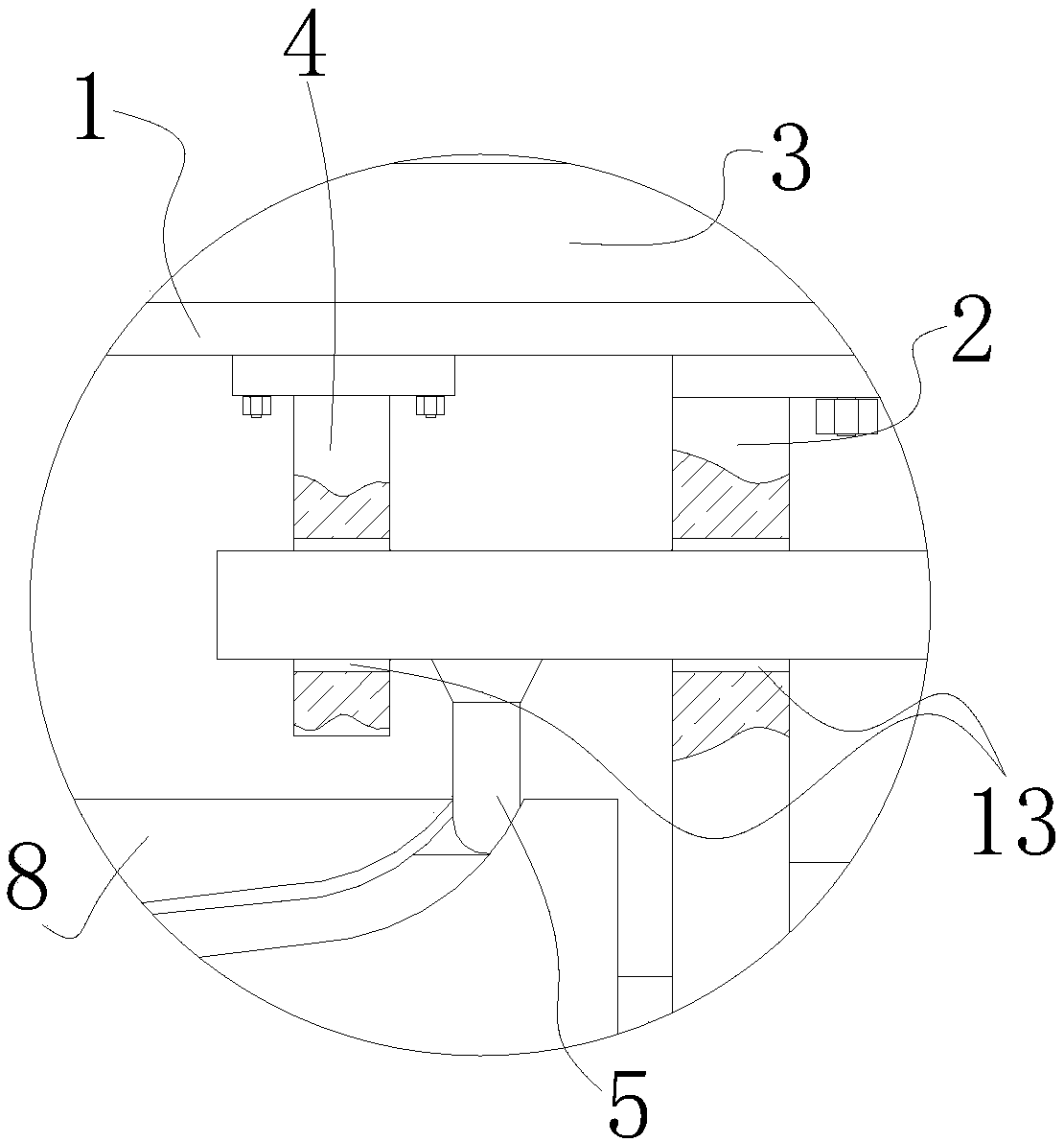

Fixed support for spraying outer surface of cylinder barrel of hydraulic cylinder

ActiveCN113695112AConvenient spraying operationConvenient loading and unloading operationSpraying apparatusPretreated surfacesHydraulic cylinderEngineering

The invention discloses a fixed support for spraying the outer surface of a cylinder barrel of a hydraulic cylinder. The fixed support comprises a working table plate; the middle of the working table plate is slidably connected with a bearing table; the top of the bearing table is fixedly connected with a limiting piece used for supporting and fixing the cylinder barrel; a limiting plate is fixedly connected to the edge of the working table plate; and one side of the limiting plate is slidably connected with a flattening piece used for flattening the top face of the cylinder barrel. The cylinder barrel is limited and supported from the interior of the cylinder barrel through an elastic clamping unit, shielding interference on the outer surface of the cylinder barrel is avoided, spraying operation of the outer surface is facilitated, the inner wall of the cylinder barrel is supported through guide rolling wheels at the ends of a clamping rod, fixing and limiting of the cylinder barrel are achieved, the cylinder barrel can freely move in the vertical direction, and feeding and discharging operations of the cylinder barrel are facilitated; meanwhile, the cylinder barrel is pushed to ascend or descend from the inner side through rotation of the guide rolling wheels, and damage to the outer wall of the cylinder barrel in the feeding and discharging process is also avoided.

Owner:马鞍山德友机械制造有限公司

Rock wool composite production line for thermal insulation and decoration integrated board

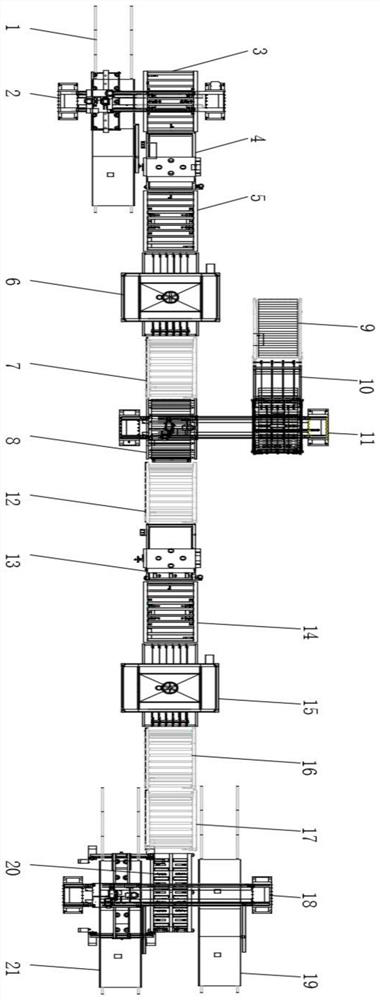

ActiveCN110694815BIncrease productivityHigh precisionCleaning using toolsLiquid spraying apparatusSprayerAdhesive glue

The invention discloses a rock wool composite production line for thermal insulation and decoration integrated panels, which includes a first centering conveyor, and a gantry upper plate is arranged above and across the first centering conveyor machine, the bottom of the gantry loading machine is provided with a first trolley close to the front of the first centering conveyor, and one end of the first centering conveyor is fixedly connected with a first dust remover, and the first dust remover The end away from the first centering conveyor is fixedly connected with the second centering conveyor, and the end of the second centering conveyor away from the first dust remover is fixedly connected with the first glue spraying machine. In the present invention, the production efficiency of rock wool composite can be improved by means of transmission, the strength of artificial composite rock wool board can be reduced, the deviation of rock wool in the process of transportation can be avoided, the accuracy of rock wool composite can be improved, and the glue can also be Evenly spray on the surface of rock wool to avoid waste of materials, and the process is easy to operate.

Owner:安徽纪兴源科技股份有限公司

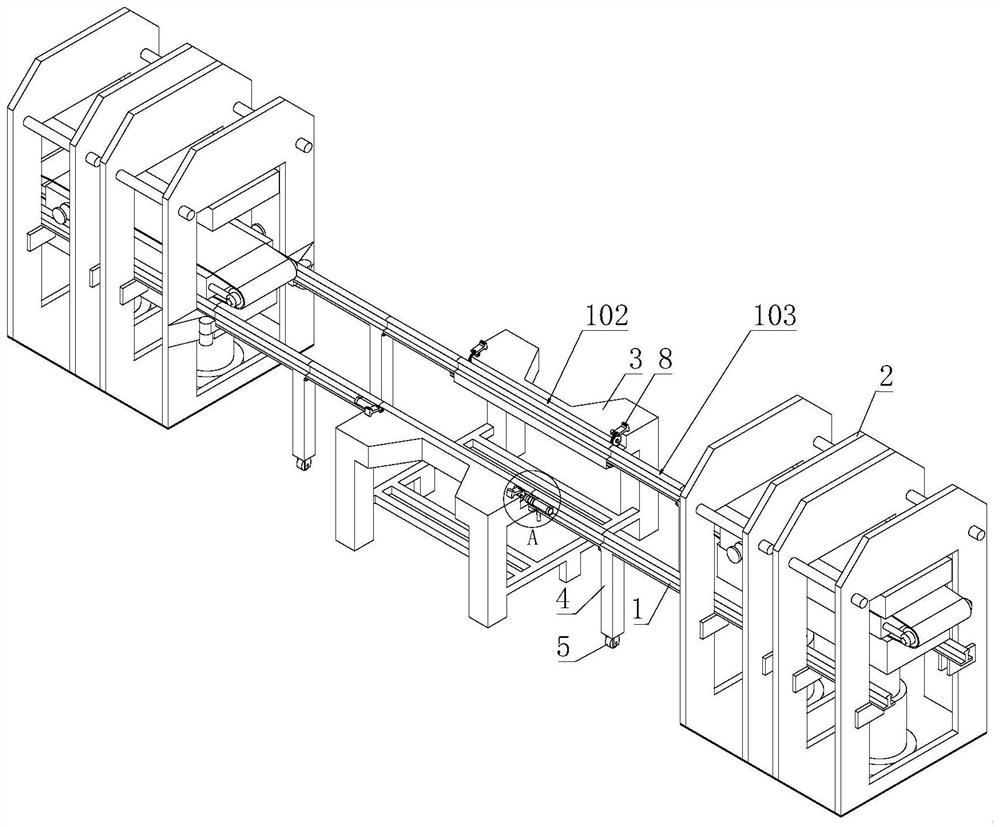

Laser cutting machine for water gaps of battery cover plates

PendingCN113146070ASave time for loading and unloadingConvenient loading and unloading operationLaser beam welding apparatusEngineeringStructural engineering

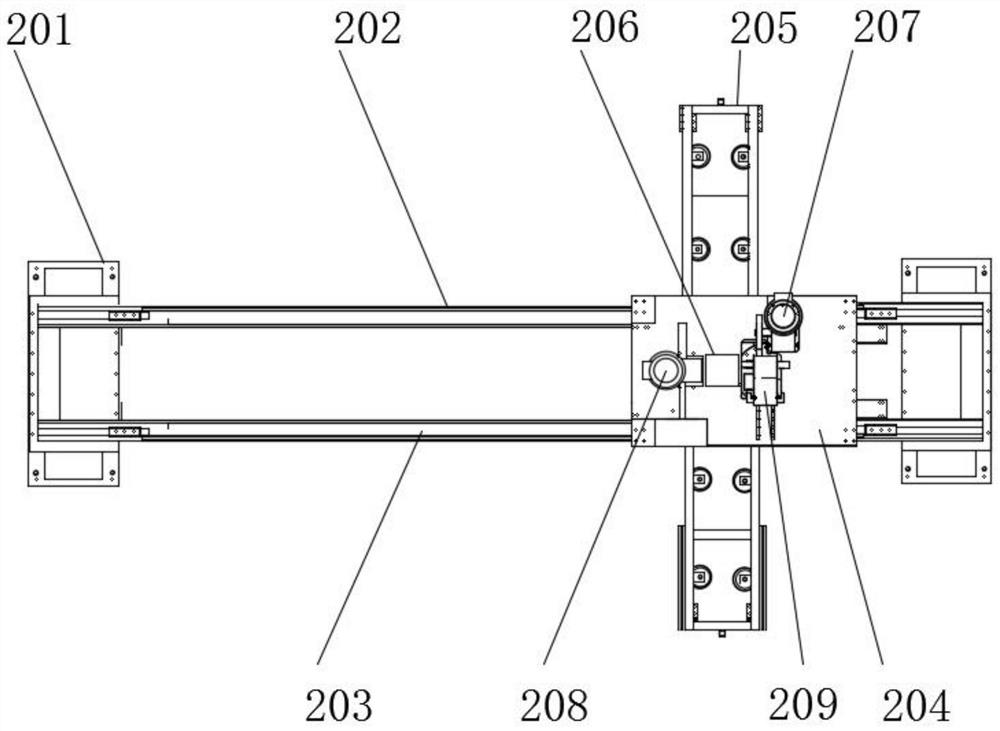

The invention discloses a laser cutting machine for water gaps of battery cover plates. The laser cutting machine comprises a lower frame assembly, a clamp movement assembly, a CCD good product detection assembly, a CCD positioning assembly and a light path assembly, wherein the clamp movement assembly, the CCD good product detection assembly, the CCD positioning assembly and the light path assembly are arranged on the lower frame assembly. The clamp movement assembly comprises a vacuum adsorption clamp, an X-axis movement module, a Y-axis movement module and a Z-axis movement module, the Y-axis movement module is arranged on the lower frame assembly along the Y axis, the X-axis movement module is movably arranged on the Y-axis movement module along the X axis, the Z-axis movement module is movably arranged on the X-axis movement module along the Z axis, the vacuum adsorption clamp is movably arranged on the Z-axis movement module, the CCD good product detection assembly and the CCD positioning assembly are arranged at the two ends of the X-axis movement module front and back along the Y axis correspondingly, and the light path assembly is arranged above the clamp movement assembly through a supporting frame. The laser cutting machine is high in automation degree and high in cutting speed, injection molded part water gap cutting of 64 positions of a whole plate can be completed at a time, meanwhile, multiple sets of CCDs are used for photographing detection, and the machining quality is improved.

Owner:广东镭泰激光智能装备有限公司

Middle stop guide rail system for rubber track vulcanization processing technology and vulcanization processing system

A middle-gear guide rail system for a rubber crawler belt vulcanization processing technology comprises a pair of guide rails arranged in parallel, and each guide rail is composed of a built-in guide rail section, an operation table guide rail section, a middle-gear guide rail section, a middle-gear guide rail section, a middle-gear guide rail section, a middle-gear guide rail section and a middle-gear guide rail section, the movable guide rail section is used for connecting the built-in guide rail section and the operating platform guide rail section; the movable guide rail section comprises a movable sub-section A and a movable sub-section B; the inner end of the movable sub-section A is hinged to the built-in guide rail section, and a hinged shaft is distributed in the vertical direction; a supporting beam is arranged on the lower side of the movable sub-section A, and trundles are arranged at the lower end of the supporting beam; the outer end of the movable sub-section A is hinged to the inner end of the movable sub-section B, and a hinged shaft is distributed in the horizontal direction; the outer end of the B movable sub-section can be connected with the middle gear operation table through a lock, so that the B movable sub-section is connected with the operation table guide rail section. The middle-gear guide rail system has the advantages of being convenient to operate and good in safety. Correspondingly, the invention further provides a rubber track vulcanization processing system.

Owner:ZHEJIANG YUAN CHUANG RUBBER TRACK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com