Comprehensive painting furniture processing device capable of reducing paint consumption

A processing device and comprehensive technology, applied in the direction of injection device, liquid injection device, etc., can solve the problems of delaying processing progress, increasing processing cost, low processing efficiency, etc., and achieving the effect of convenient loading and unloading operation, preventing falling off, and reducing paint consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

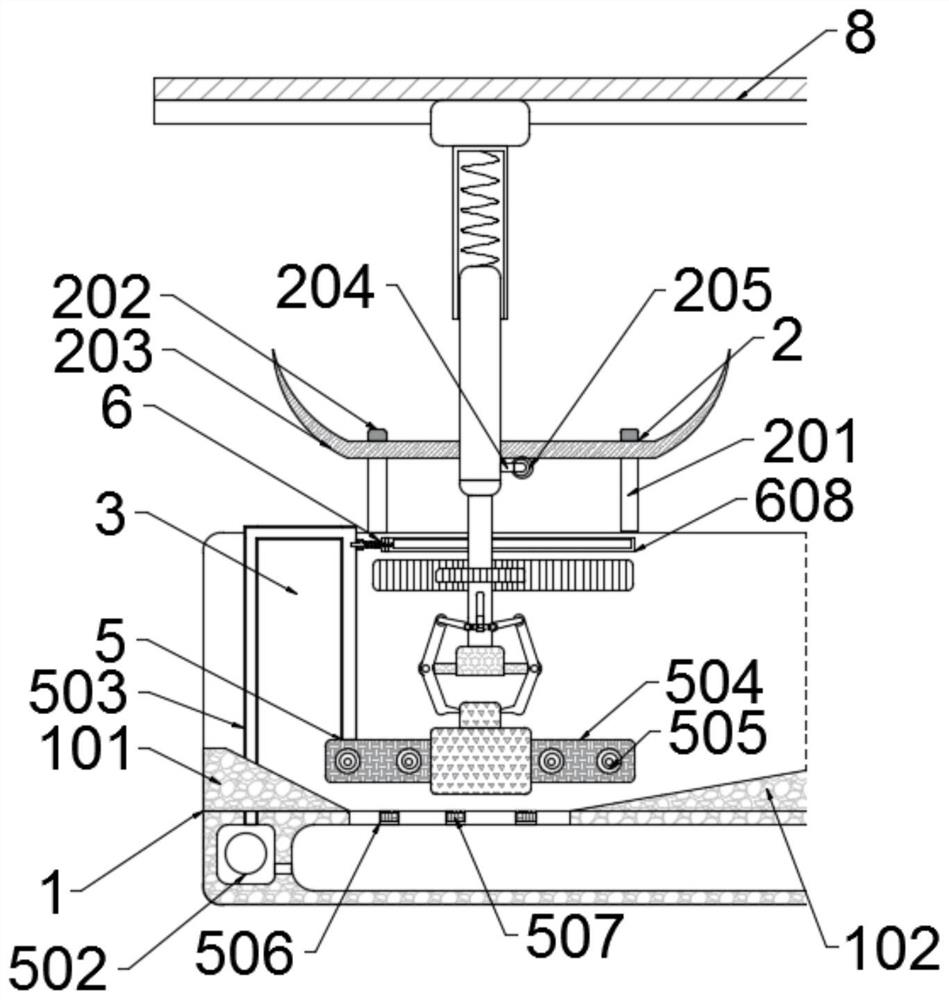

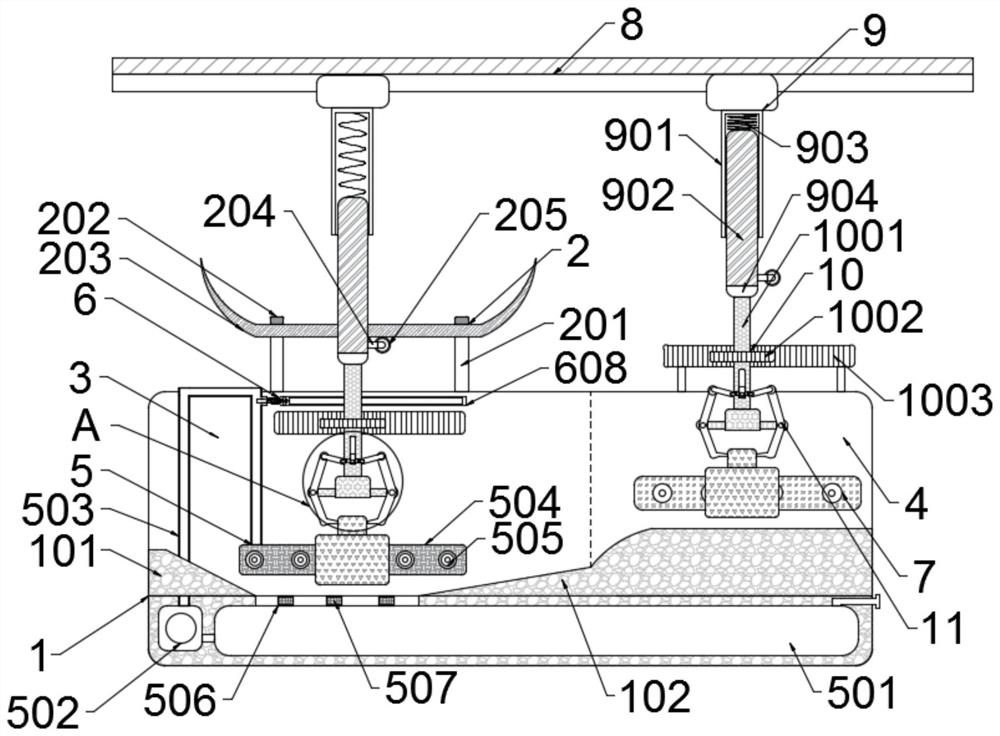

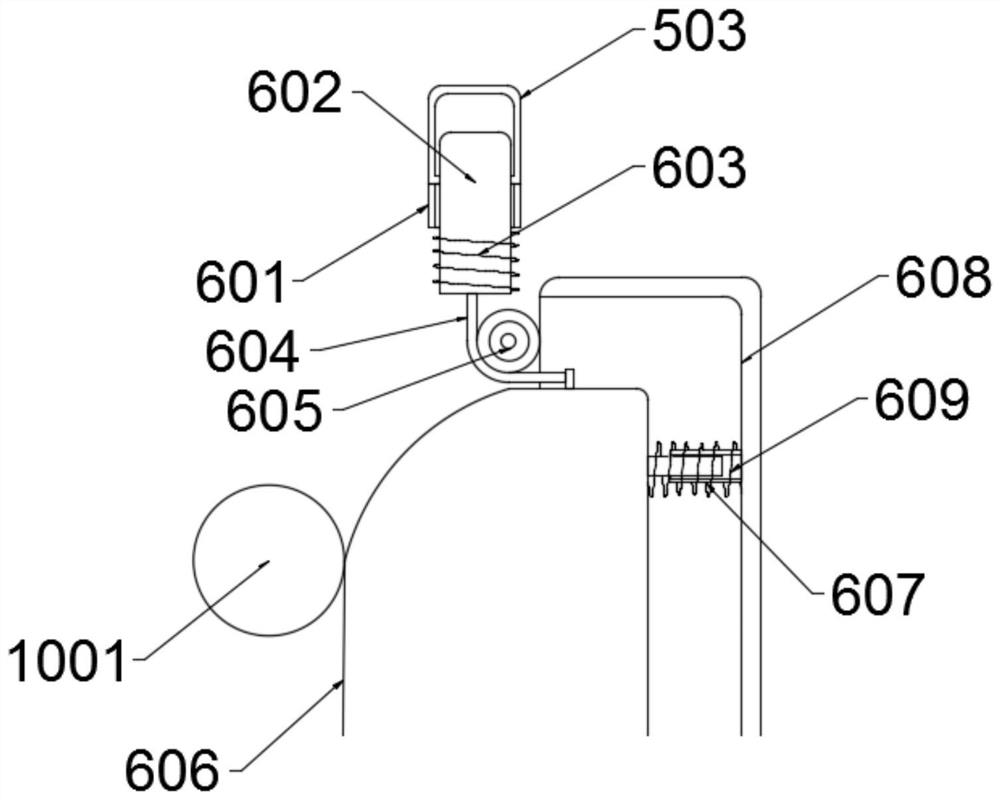

[0027] Example 1: Please refer to Figure 1-3 , a fully painted furniture processing device that reduces paint consumption, comprising a paint spraying frame 1, a lowering mechanism 2 is installed on the top left side of the paint spraying frame 1, and the left and right sides of the paint spraying frame 1 are respectively set as a paint spraying room 3 and a drying room 4, The paint spraying room 3 is provided with a paint spraying mechanism 5, the switch mechanism 6 is connected to the paint spraying mechanism 5, a drying device 7 is installed in the drying room 4, a conveyor belt device 8 is installed above the paint spraying frame 1, and clips are evenly distributed on the conveyor belt device 8. The clamping mechanism 9 includes a sleeve 901, which is evenly distributed on the conveyor belt device 8, and a sleeve rod 902 is slidably installed in the sleeve 901, and a first spring 903 is connected between the sleeve rod 902 and the sleeve 901 , the bottom end of the sleeve...

Embodiment 2

[0032] Example 2: Please refer to Figure 1-4 , a fully painted furniture processing device that reduces paint consumption, comprising a paint spraying frame 1, a lowering mechanism 2 is installed on the top left side of the paint spraying frame 1, and the left and right sides of the paint spraying frame 1 are respectively set as a paint spraying room 3 and a drying room 4, The paint spraying room 3 is provided with a paint spraying mechanism 5, the switch mechanism 6 is connected to the paint spraying mechanism 5, a drying device 7 is installed in the drying room 4, a conveyor belt device 8 is installed above the paint spraying frame 1, and clips are evenly distributed on the conveyor belt device 8. The clamping mechanism 9 includes a sleeve 901, which is evenly distributed on the conveyor belt device 8, and a sleeve rod 902 is slidably installed in the sleeve 901, and a first spring 903 is connected between the sleeve rod 902 and the sleeve 901 , the bottom end of the sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com